Metal Man FWTD User manual

DELUXE FOLDING WELD TABLE

OWNER’S MANUAL

9/2018

WARNING:

Read carefully and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

Page of 14

2

WARRANTY

METAL MAN WORK GEAR CO

EFFECTIVE JANUARY 1, 2013

LIMITED WARRANTY

This warranty applies to the original purchaser and is subject to the terms and conditions listed below. This Limited Warranty is for

new equipment sold after the above date, providing coverage for defects in material and workmanship at the time it is shipped from

the factory.

Limited to the warranty periods below, Metal Man Work Gear Co will repair or replace the item under warranty that fails due to

defects in material and workmanship. Metal Man Work Gear must be notified within 30 days of the failure, so as to provide

instructions on how to proceed with the repair of your welder and warranty claim processing. Warranty period begins at the time the

welder is purchased from and Authorized Reseller of Metal Man Work Gear Co. products. Keep your receipt as proof of

purchase.

Warranty Periods

Limited Warranty is divided into three categories. No Warranty, 90 days, 1 year and 3 year.

No Warranty

Normal wear items, MIG gun parts (contact tips, nozzle, contact tip adapter, MIG gun liner), drive roll, electrode holder, ground

clamps, Plasma torch parts (nozzle, electrode, diffuser, cover) are considered consumable items and are not covered under

warranty.

90 days

Parts for Metal Man Work Gear welding carts and welding cabinets. This warranty covers the absence of or defective parts.

1 year

Parts and Labor on MIG gun parts (except those listed under normal wear items), cables, regulator, and plasma torch (except those

listed under normal wear items).Any shipping related to warranty repair is the responsibility of the customer.

1 year/3 year

Please see your product information to determine if your product has a 1 year or 3 year warranty. This warranty covers parts and

Labor on items such as: transformer, reactor, rectifier, solenoid valve, PC Board, switches, controls, gas valve, drive motor, drive

system other than drive roll and any other component that requires the removal of the sheet metal to access. Any shipping related

to warranty repair is the responsibility of the customer.

Voiding Warranty

Warranty does not apply to: Shipping Damage, Misuse and abuse of the unit, alteration of the unit in any way.

Warranty Claim

This is a parts and labor warranty. Do not return your unit to the retailer you purchased it from. Retain your receipt in the case

a warranty claim is needed. No warranty will be provided without the original receipt from an authorized reseller of Metal Man Work

Gear Products. To make a warranty claim, call our welder help line at 888-762-4045, M-F 8:00 am to 5:00 PM Central time or email

sales@metalmangear.com.

Page of 14

3

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this Flux Core 125 until they

have read this manual and have developed a thorough understanding of how the Flux Core

125 works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY CONSIDERATIONS

1.1 Your Welding Environment

-Keep the environment you will be welding in free from flammable materials.

-Always keep a fire extinguisher accessible to your welding environment.

-Always have a qualified person install and operate this equipment.

-Make sure the area is clean, dry and ventilated. Do not operate the welder in humid, wet or poorly

ventilated areas.

-Always have your welder maintained by a qualified technician in accordance with local, state and

national codes.

-Always be aware of your work environment. Be sure to keep other people, especially children,

away from you while welding.

-Keep harmful arc rays shielded from the view of others.

-Mount the welder on a secure bench or cart that will keep the welder secure and prevent it from

tipping over or falling.

1.2 Your Welder’s Condition

-Check ground cable, power cord and welding cable to be sure the insulation is not damaged.

Always replace or repair damaged components before using the welder.

-Check all components to ensure they are clean and in good operating condition before use.

1.3 Use of Your Welder

Do not operate the welder if the output cable, electrode, torch, wire or wire feed system is wet. Do

not immerse them in water. These components and the welder must be completely dry before

attempting to use them.

Page of 14

4

-Follow the instructions in this manual.

-Keep welder in the off position when not in use.

-Connect ground lead as close to the area being welded as possible to ensure a good ground.

-Do not allow any body part to come in contact with the welding wire if you are in contact with the

material being welded, ground or electrode from another welder.

-Do not weld if you are in an awkward position. Always have a secure stance while welding to

prevent accidents. Wear a safety harness if working above ground.

-Do not drape cables over or around your body.

-Wear a full coverage helmet with appropriate shade (see ANSI Z87.1 safety standard) and safety

glasses while welding.

-Wear proper gloves and protective clothing to prevent your skin from being exposed to hot metals,

UV and IR rays.

-Do not overuse or overheat your welder.Allow proper cooling time between duty cycles.

-Keep hands and fingers away from moving parts and stay away from the drive rolls.

-Do not point MIG gun at any body part of yourself or anyone else.

-Always use this welder in the rated duty cycle to prevent excessive heat and failure.

1.4 Specific Areas of Danger, Caution or Warning

Electrical Shock

Electric arc welders can produce a shock that can cause injury or death. Touching

electrically live parts can cause fatal shocks and severe burns. While welding, all metal

components connected to the wire are electrically hot. Poor ground connections are a hazard, so

secure the ground lead before welding.

-Wear dry protective apparel: coat, shirt, gloves and insulated footwear.

-Insulate yourself from the work piece. Avoid contacting the work piece or ground.

- Do not attempt to repair or maintain the welder while the power is on.

-Inspect all cables and cords for any exposed wire and replace immediately if found.

-Use only recommended replacement cables and cords.

-Always attach ground clamp to the work piece or work table as close to the weld area as possible.

-Do not touch the welding wire and the ground or grounded work piece at the same time.

-Do not use a welder to thaw frozen pipes.

Fumes and Gases

-Fumes emitted from the welding process displace clean air and can result in injury or

death.

-Do not breathe in fumes emitted by the welding process. Make sure your breathing air is clean and

safe.

-Work only in a well-ventilated area or use a ventilation device to remove welding fumes from the

environment where you will be working.

-Do not weld on coated materials (galvanized, cadmium plated or containing zinc, mercury or

barium). They will emit harmful fumes that are dangerous to breathe. If necessary use a ventilator,

respirator with air supply or remove the coating from the material in the weld area.

-The fumes emitted from some metals when heated are extremely toxic. Refer to the material safety

data sheet for the manufacturer’s instructions.

-Do not weld near materials that will emit toxic fumes when heated. Vapors from cleaners, sprays

and degreasers can be highly toxic when heated.

Page of 14

5

UV and IR Arc Rays

The welding arc produces ultraviolet (UV) and infrared (IR) rays that can cause injury to

your eyes and skin. Do not look at the welding arc without proper eye protection.

-Always use a helmet that covers your full face from the neck to top of head and to the back of each

ear.

-Use a lens that meets ANSI standards and safety glasses. For welders under 160 Amps output,

use a shade 10 lens; for above 160 Amps, use a shade 12. Refer to the ANSI standard Z87.1 for

more information.

-Cover all bare skin areas exposed to the arc with protective clothing and shoes. Flame-retardant

cloth or leather shirts, coats, pants or coveralls are available for protection.

-Use screens or other barriers to protect other people from the arc rays emitted from your welding.

-Warn people in your welding area when you are going to strike an arc so they can protect

themselves.

Fire Hazards

Do not weld on containers or pipes that contain or have had flammable, gaseous or liquid

combustibles in them. Welding creates sparks and heat that can ignite flammable and

explosive materials.

-Do not operate any electric arc welder in areas where flammable or explosive materials are

present.

-Remove all flammable materials within 35 feet of the welding arc. If removal is not possible, tightly

cover them with fireproof covers.

-Take precautions to ensure that flying sparks do not cause fires or explosions in hidden areas,

cracks or areas you cannot see.

-Keep a fire extinguisher close in the case of fire.

-Wear garments that are oil-free with no pockets or cuffs that will collect sparks.

-Do not have on your person any items that are combustible, such as lighters or matches.

-Keep work lead connected as close to the weld area as possible to prevent any unknown,

unintended paths of electrical current from causing electrical shock and fire hazards.

-To prevent any unintended arcs, cut wire back to ¼" stick out after welding.

Hot Materials

Welded materials are hot and can cause severe burns if handled improperly.

-Do not touch welded materials with bare hands.

-Do not touch MIG gun nozzle after welding until it has had time to cool down.

Sparks/Flying Debris

Welding creates hot sparks that can cause injury. Chipping slag off welds creates flying

debris.

-Wear protective apparel at all times: ANSI-approved safety glasses or shield, welder’s hat and ear

plugs to keep sparks out of ears and hair.

Page of 14

6

Electromagnetic Field

-Electromagnetic fields can interfere with various electrical and electronic devices such as

pacemakers.

-Consult your doctor before using any electric arc welder or cutting device

-Keep people with pacemakers away from your welding area when welding.

-Do not wrap cable around your body while welding.

-Wrap MIG gun and ground cable together whenever possible.

-Keep MIG gun and ground cables on the same side of your body.

Shielding Gas Cylinders Can Explode

High pressure cylinders can explode if damaged, so treat them carefully.

-Never expose cylinders to high heat, sparks, open flames, mechanical shocks or arcs.

-Do not touch cylinder with MIG gun.

-Do not weld on the cylinder

-Always secure cylinder upright to a cart or stationary object.

-Keep cylinders away from welding or electrical circuits.

-Use the proper regulators, gas hose and fittings for the specific application.

-Do not look into the valve when opening it.

-Use protective cylinder cap whenever possible

1.5 Proper Care, Maintenance and Repair

-Always have power disconnected when working on internal components.

- Do not touch or handle PC board without being properly grounded with a wrist strap. Put PC board

in static proof bag to move or ship.

-Do not put hands or fingers near moving parts such as drive rolls of fan

USE AND CARE

•Do not modify this unit in any way. Unauthorized modification may impair the function and/or

safety and could affect the life of the equipment. There are specific applications for which this

unit was designed.

•Always check of damaged or worn out parts before using this unit. Broken parts will affect

the operation. Replace or repair damaged or worn parts immediately.

•Store idle. When this unit is not in use, store it in a secure place out of the reach of children.

Inspect it for good working condition prior to storage and before re-use.

SPECIFICATIONS

Item

Description

Overall Dimensions

36 in. x 20 in. x 36 in. (In Use)

36 in. x 10 in. x 43-1/2 in. (When Folded)

Work Surface

36 in. x 20 in.

Product Weight

43 lbs.

Load Capacity

110 lbs.

Page of 14

7

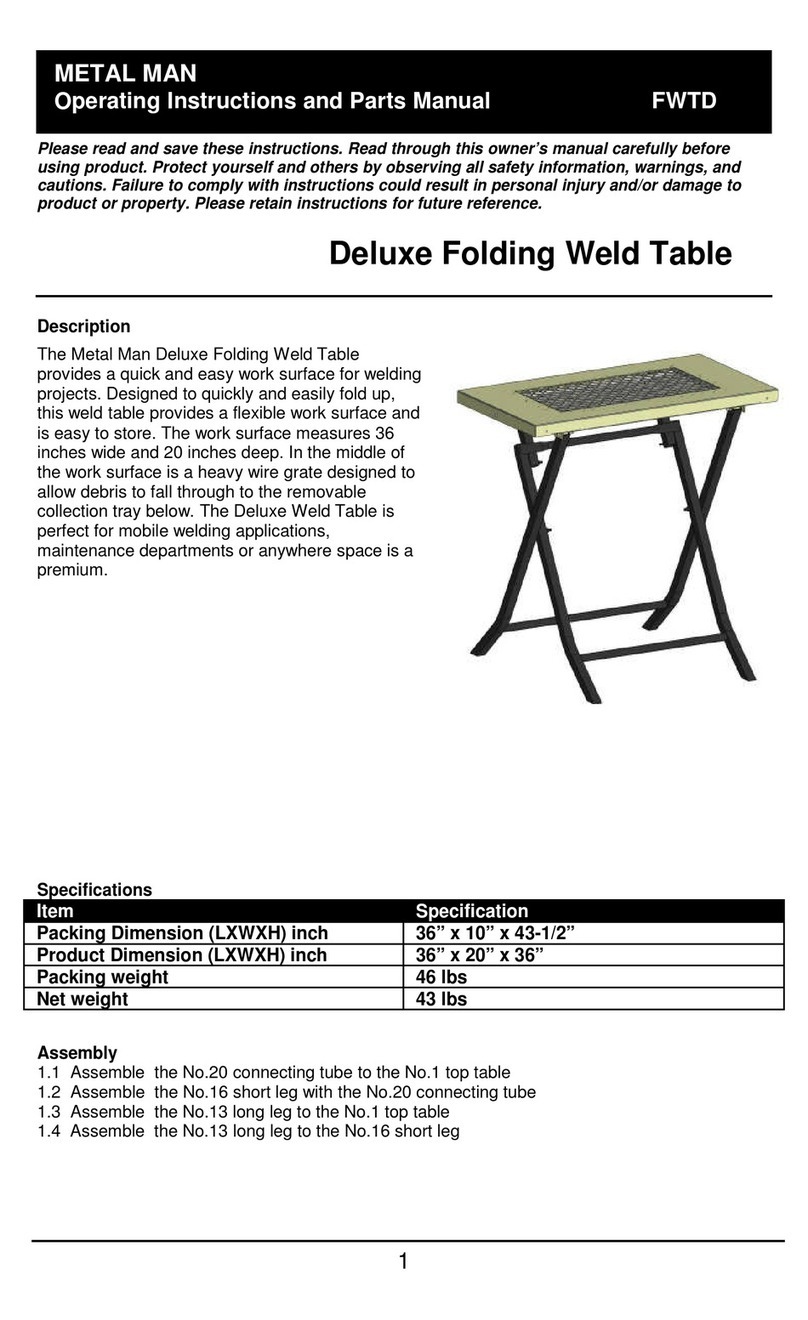

DESCRIPTION

The Metal Man Folding Weld Table provides a quick and easy work surface for welding

projects. Designed to quickly and easily fold up, this weld table provides a flexible work surface

and is easy to store. The work surface measures 36 inches wide and 20 inches deep. In the

middle of the work surface is a heavy wire grate designed to allow debris to fall through to the

removable collection tray below. The Folding Weld Table is perfect for mobile welding

applications, maintenance departments or anywhere space is a premium.

Base Stabilizing

Feet

Removable

Debris Tray

36 in. x 20 in.

Work Surface

Fold Up For

Easy Storage

Page of 14

8

ASSEMBLY

Place the table work surface

upside down on a stable

surface.

Take the longer of the two table

legs and place on top of the

table work surface to align with

the wider set of pivot clips on

the table work surface. Table leg

ends should be pointing down.

Install the hardware through the

hole in the pivot clip and the

hole through the leg.

Hand-tighten only, tighten only

after table assembly is

complete.

Hex head bolt M6x45MM

Thick Flat Washer 6

Lock Washer 6

Hex Head Lock Nut M6

Repeat for both sides.

Page of 14

9

Align short table leg extension

with the other set of pivot clips.

Install the hardware through the

hole in the pivot clip and the

hole through the leg.

Hand-tighten only, tighten only

after table assembly is

complete.

Hex head bolt M6x45MM

Thick Flat Washer 6

Lock Washer 6

Hex Head Lock Nut M6

Repeat for both sides.

Flip the attached longer table

legs over so the feet are

pointing up. Then lay in place

the short table leg under the

short table leg extension

assembly to align mounting

holes. Make certain the ends of

the short table legs are pointing

down.

Page of 14

10

Install the hardware through the

mounting hole in the short table

leg and the mounting hole

through short table leg

extension. Hand-tighten only,

tighten only after table assembly

is complete.

Hex head bolt M8x75MM

Nylon Flat Washer

Lock Washer 8

Hex Head Lock Nut M8

Repeat for both sides.

Raise both legs until the

pre-drilled holes in both legs

line up.

Page of 14

11

Install the hardware through the

hole in both legs. Hand-tighten

only, tighten only after table

assembly is complete.

Hex head bolt M8x75MM

Nylon Flat Washer

Lock Washer 8

Hex Head Lock Nut M8

Place the removable slag tray on

a sturdy surface, with the flat

side (bottom) up.

Place the slag tray handle to

align with the predrilled holes in

the slag tray. Put a flat washer 6

on the M6 x 12MM hex head bolt

and push through the holes in

the handle and the tray.

Flip the tray assembly over and

add the hardware to the bolt.

Flat Washer 6

Lock Washer 6

Hex Head Nut M6

Repeat for both sides.

Page of 14

12

Insert slag tray into the bottom

of the table work surface.

Go back through all hardware

connections and securely

tighten.

Page of 14

13

DIAGRAM & PARTS LIST

Reference #

Part#

Description

Qty.

1

105100167

TABLE WORK SURFACE

1

2

105100168

HEX HEAD BOLT M6 X 45MM

4

3

105100169

REMOVABLE SLAG DRAWER

1

4

105100031

HEX HEAD NUT M6

2

5

105100032

LOCK WASHER 6

2

6

105100033

FLAT WASHER 6

4

7

105100170

SLAG TRAY HANDLE

1

8

105100171

BOLT M6 X 12 MM

2

9

105100172

HEX HEAD LOCK NUT M6

4

10

105100011

LOCK WASHER 6

4

11

105100173

THICK FLAT WASHER 6

4

12

105100174

LONG TABLE LEG

1

13

105100050

HEX HEAD BOLT M8 X 75MM

4

14

105100175

SHORTER TABLE LEG

1

15

105100176

NYLON FLAT WASHER

4

16

105100177

FLAT WASHER 8

4

17

105100178

HEX HEAD LOCK NUT M8

4

18

105100179

SHORT TABLE LEG EXTENSION ASSEMBLY

1

For replacement parts or technical questions, please contact our

welder help line at 1-888-762-4045.

Page of 14

14

METAL MAN WORK GEAR COMPANY

1760 PROSPECT CT #120

APPLETON WI 54914

www.metalmangear.com

Made in China

Other manuals for FWTD

1

This manual suits for next models

1

Table of contents

Other Metal Man Welding Accessories manuals