Metal Samples Company MS3500E User manual

MS3500E/3510E

Remote ER Data Logger

MetalSamplesCompany

A Division of Alabama Specialty Products, Inc.

152 Metal Samples Rd., Munford, AL 36268 Phone: (256) 358-4202 Fax: (256) 358-4515

E-mail: [email protected] Internet: www.metalsamples.com

.

Table of Contents

I. Introduction ......................................................................................................................1

A. InstrumentFunctionOverview .................................................................................1

B. InstrumentPartsList................................................................................................ 2

II. Installation ........................................................................................................................3

A. EnclosureandMountingDetails...............................................................................3

B. BatteryInstallation................................................................................................... 4

C.4-20mALoopInstallation ........................................................................................5

D. Probe-InstrumentConnection.................................................................................. 6

E. DataDownloadConnection(s)................................................................................. 7

III. SetupandOperation .........................................................................................................8

A. Main Menu Overview ............................................................................................. 8

B. Program Setup ...................................................................................................... 10

1. Set Time and Date ..................................................................................... 10

2. Enter Probe ID .......................................................................................... 11

3. StartDataLogging..................................................................................... 12

C. Measure ProbeFunction ....................................................................................... 13

D. ViewStored DataFunctions.................................................................................. 14

E. SetReadingIntervalFunction ................................................................................ 15

F. DownloadingData ................................................................................................. 16

1. Upload to PC ............................................................................................ 16

2. Upload to MS1500E ................................................................................. 25

G. SystemShutdownFunction.................................................................................... 26

H. TestMode Function .............................................................................................. 26

I. DataInterpretation ................................................................................................. 27

1. ProbeReading........................................................................................... 27

2. Metal Loss ................................................................................................ 28

3. Corrosion Rate .......................................................................................... 28

4. 4-20mA Output ......................................................................................... 29

IV. ERTechnique-General .................................................................................................. 30

A. Measurement Theory ............................................................................................ 30

B. ERSensingElements ............................................................................................. 32

C. ERElementPerformance ...................................................................................... 34

D. ERProbe Body Design ......................................................................................... 38

AppendixA-MS3500ESpecifications ................................................................................... 41

AppendixB-Testingthe MS3500E/MS3510E with theERMeterProver .............................. 42

Appendix C - MS1500E Select Probe ID............................................................................... 44

AppendixD-ReturninganInstrument for Repair .................................................................... 47

AppendixE-Warranty .......................................................................................................... 49

AppendixF-InstallationDrawingofMS3500EinHazardousLocation ................................... 50

1

I. Introduction

A. InstrumentFunctionOverview

TheMS3500E/3510EDataLoggerisdesignedto provide a continuous record ofcorrosiveactivityin

remotelocationsthatareinfrequentlyvisited, such ascross-countrypipelines,andunmannedproduction

platforms.However,thisunitfindsequalapplicationinlocationsthatareinconvenientordifficultto

accessona regular basis, suchasrefineryoverheads,andflue-gasstacks.

TheMS3500E/3510Eiscompletelyself-containedwiththeonboardbatterysystemsupplyingthetotal

powerrequirementfor operation. It canbeusedwithanyof Metal Samples’ ERprobes,orthoseofall

othermajormanufacturers.Onceinplace,itwillautomaticallyreadtheprobeatcustomer-selected

intervalsandstoretheresultingdataintheunit’sonboardmemory.Theonboardmemorywillcollectup

to3,100datapointsbeforedata download is required. The datacollectionintervalisprogrammablein

hourlyincrements.Evenattheminimumdatacollectioninterval(1hour),datadownloadingneedonlybe

performedeveryninetydays.Withmore practical data collection intervals (8 - 12 hours), the unit may

beunattendedfor as longas6-8months between downloading operations.

Anoptical,infrared,RS232communicationlink is provided for datadownloadtoeitheraPCorMetal

Samples'MS1500E portable ERdatalogger.Downloadeddata may beanalyzed,reviewed,or re-

portedbyconventionalspreadsheet,database, or mathematical software packages.

Theinfraredcommunicationlink isanintegralpartoftheintrinsicallysafedesignoftheMS3500E/

3510E.Opticalinsteadofelectrical,thisuniquefeaturepermitsdatadownloadingwithoutremovingthe

instrumentor“memorymodule” fromthehazardousarea.

AnotheruniquefeatureoftheMS3500E/3510Eis the highlevelofonboardintelligence.Thetwo-line,

20-characterLCDallowsvisualreviewofallhistoricaldatainmemoryandreads directly as “total metal

loss”and/or“averagecorrosionrate”. Thisisincontrasttoothercommerciallyavailableunits that store

anddisplayonlytheraw “resistanceratio”thatrequiresadditionalmanipulationtoprovideusefuland

intelligibledata.

TheLCDscreen,togetherwiththe2-keymembranekeypad,provides a user-friendly,interactive,

promptingsystemthatis used for bothsystemsetupanddatareview.ThismakestheMS3500Ethe

mostadvancedunitofits type on the market.

Byaddinga4-20mAcommunication facility, the MS3500E becomes an MS3510E.Thisallows

continuoustransmissionofdata, via a 4-20mAloop,to a plant computer orcentraldatalogger, for

integrationwithotherreal-timeprocessparameters.This data transmissioncanbeaccomplishedwithout

disruptionoftheunit’s basic logginganddatastorageoperations.The 4-20mAloopextends the capa-

bilitiesoftheunittoincludeconventional,in-plant,real-timedatacommunication.

TheMS3500E/3510Eunitusesastainlesssteel NEMA 4X (IP 66) enclosure, makingitsuitableforuse

inthemostextremeofoutdoorconditions.

2

B.InstrumentPartsList

TheMS3500E/MS3510Eissuppliedwiththefollowingaccessories.

Partno. Qty. Description

ET0133 6 1.5V,AADryCells(Installed)

ET0612 1 4-20maLoop Connector (MS3510EOnly)

IN3500-2 1 OptilinkCable

IN3500-4 1 10 Ft. Probe Cable

IN3500-5 1 MeterProver

IN3500-6 1 SerialPortAdapter

IN3500-7 1 OperationsManual

Uponreceiptoftheinstrument,theusershouldverifythattheabovelistedaccessoriesareincluded.

Anyshortageshouldbereportedimmediately to:

Metal Samples

Phone:(256) 358-4202

Fax:(256) 358-4515

E-mail:[email protected]

3

II. Installation

A.Enclosure&MountingDetails

TheMS3500E/3510Eenclosureisfabricatedin carbon steel with a baked-on,high-buildepoxy

coating.Theunithasahinged door that is secured,whenshut,byscrew-downclampsthatdiscourage

unauthorizedtampering.TheenclosureisconstructedtoNEMA4X(IP66)weatherproofstandards,

makingitsuitableforthe mostrigorousofoutdoorenvironments.

Theoveralldimensionsoftheunitare12-1/4"(height),9"(width),4-3/8"(depth),makingitaconve-

nientsizetomounteveninthemostconfinedoflocations.Forthebestresults, the instrument should be

mountedwithintenfeetoftheprobelocation.Tofacilitatethis,theunit hasaversatilemountingflange

withfour.31"diameter,mountingholes.Overalldimensionsandmountingholecentersareshownin

Figure1.

Figure 1. MS3500E Dimensions

4

B.BatteryInstallation

TheMS3500E/3510Einstrument uses six 1.5V,AAsize batteries,connectedinseries,asaprimary

powersource. While anyAAsize battery canbeused,Duracell or ProcellTypeMN1500 or PC1500

batteriesarerequiredtomeettheintrinsicsafetycertificationrequirements.SincetheMS3500E/3510E

operatesinalowpowerconsumptionmodebetweenreadings,batterylifewillbeafunctionofthe

readingintervalandmeasurementtimecyclesetbytheuser.Atthemostfrequentreadinginterval(1per

hour),aminimumbatterylifeoffourmonthsistobeexpected.Morepracticalintervals,suchasevery

12or24hours,willyieldabatterylifeinexcessoftwelvemonths.Generally, to avoid unexpected

powerdrains,batteriesshouldbe replaced once everysixmonths.Intheinstanceofalowreading

interval(1per4hoursorless),threemonthlybatteryreplacementsisadvisable.

Batteriesaremountedin the back of theMS3500E/MS3510E,behindtheinstrumentscreenand

keyboardpanel. Thebatteries are accessed bylooseningthetwothumbscrewsonthe right sideofthe

panel,thenswingingthehingedpanelopentotheleft. Careshouldbeusedwhenopeningandclosing

thepaneltoensure that the internal wiringisnotpinchedordamaged. Oncethepanelisopened,

batteriescanbeinserted or removed fromthespring-loadedretainerasshownbelow.

Figure2. MS3500E BatteryInstallation

+

-

+

-

+

-

+

-

+

-

+

-

5

C.4-20mALoopInstallation

TheMS3510Eisprovidedwitha4-20mAcommunication outletthatallowscontinuous,real-time

integrationofERcorrosiondatawithotherprocessparametersinthemainplantcomputer.The

4-20mAoutlet port isa2-pinmilitaryconnector (MIL 14S-9SF)onthe base of theunit,marked

4-20mA.Thematingconnector for this outlet (ET0612)issuppliedaspartoftheaccessoriesfor the

MS3510Eunit.Thepositiveleadofthecommunicationloopshouldbeconnectedtothe“A” terminal of

theET0612mating connector,and the negative leadtothe“B”.Theloopcanthen be connected tothe

4-20mAinstrumentoutlet:

Figure 3. MS3510ECurrentLoopTermination

Theloop should bepoweredby 10-24 VDC. Forhazardousapplications,an appropriate Zener

barriershouldbeinstalledintheloop,orpowershouldbesuppliedfromanintrinsicallysaferepeater

powersupply. Typicalhazardousinstallationisshownonpage49.

Corrosion Monitoring Systems

Metal Samples

PIN 'A' (+ CURRENT LOOP)

PIN 'B' (- CURRENT LOOP)

VIEW A-A

2-PIN MALE CONNECTOR

(VIEWED FROM SOLDER-SIDE)

AB

AA

MS3510E Connections

PROBE 4-20

mA

OPTI-LINK

DATA PORT

6

D.Probe-InstrumentConnection

TheMS3500E/3510E canbemounted directly ontoanER probe, oronto an HA700110-5 probe

adaptorinthecase of a retrievable probeusedinatwo-inch,high-pressure,accessfitting(see Figure

12,p.41).However,inmanyinstancesitiseitherinconvenientorundesirable to mount theinstrument

directlyontothe probe. Forthesecircumstancesa546810,ten-foot, extension cable isprovided.The

extensioncablehasintegralconnectors withaguidingkeywaytoensurecorrectpinalignment when

attached.Thefemaleconnector (MS3106E145-6S) mateswiththe probe, orHA700110-5probe

adaptor,andthe male connector mateswiththecentralterminalonthebase of the MS3500E/3510E

unit.

The length of the extension cable has been carefully determined so as to avoid excessive

signalnoise. Longerextension cablesshouldonly beemployed afterconsultationwith Metal

Samples.

TheextensioncableprovidedwillmatedirectlywithanyMetalSamples’ERprobeorthoseofany

othermajor manufacturer,orwithanHA700110-5 probe adaptor inthecaseofretrievable probes.

7

E.DataDownloadConnection

To downloaddatafrom the MS3500Etoa PC usetheOptilink Cable andSerialPortAdaptor.

Note:Do NOTplugthephonejack ontheend ofthe OptilinkCabledirectly intoyour PC's

modem.

Ifa serial portisunavailableonyour PC andyouwishto connect theMS3500Etoyour PC via aUSB

port,you may useaserial to USBconverter.Thisconverter is notincludedwith the instrument,butmay

bepurchasedseparatelyatmajorelectronicsretailers.

To downloaddatafromthe MS3500E to aMS1500Econnectthe Optilink Cabledirectlytothe

MS1500E.

Detailedinstructionsofdatadownloadingaregivenonp.16.

UPLOAD TO PC

(SAFE AREA ONLY)

UPLOAD

TO MS1500

MS1500 HANDHELD

DATA-LOGGER

OPTI-LINK CABLE

MS3500/MS3510

DATA-LOGGER

Ò

US

S

I

L

E

T

D

REMOTE ER DATA LOGGER/TRANSMITTER

MS3510E

MS3500 SERIAL

PORT ADAPTER

SERIAL TO USB

ADAPTER (OPTIONAL)

TO

COMPUTER

SERIAL

PORT

TO

COMPUTER

USB

PORT

Corrosion Monitoring Systems

Metal Samples

Corrosion Monitoring Systems

Metal Samples

ER Data Logger

MS1500E

123

456

789

0

Exit Enter

Figure4. Data DownloadConnections

8

III. Setup and Operation

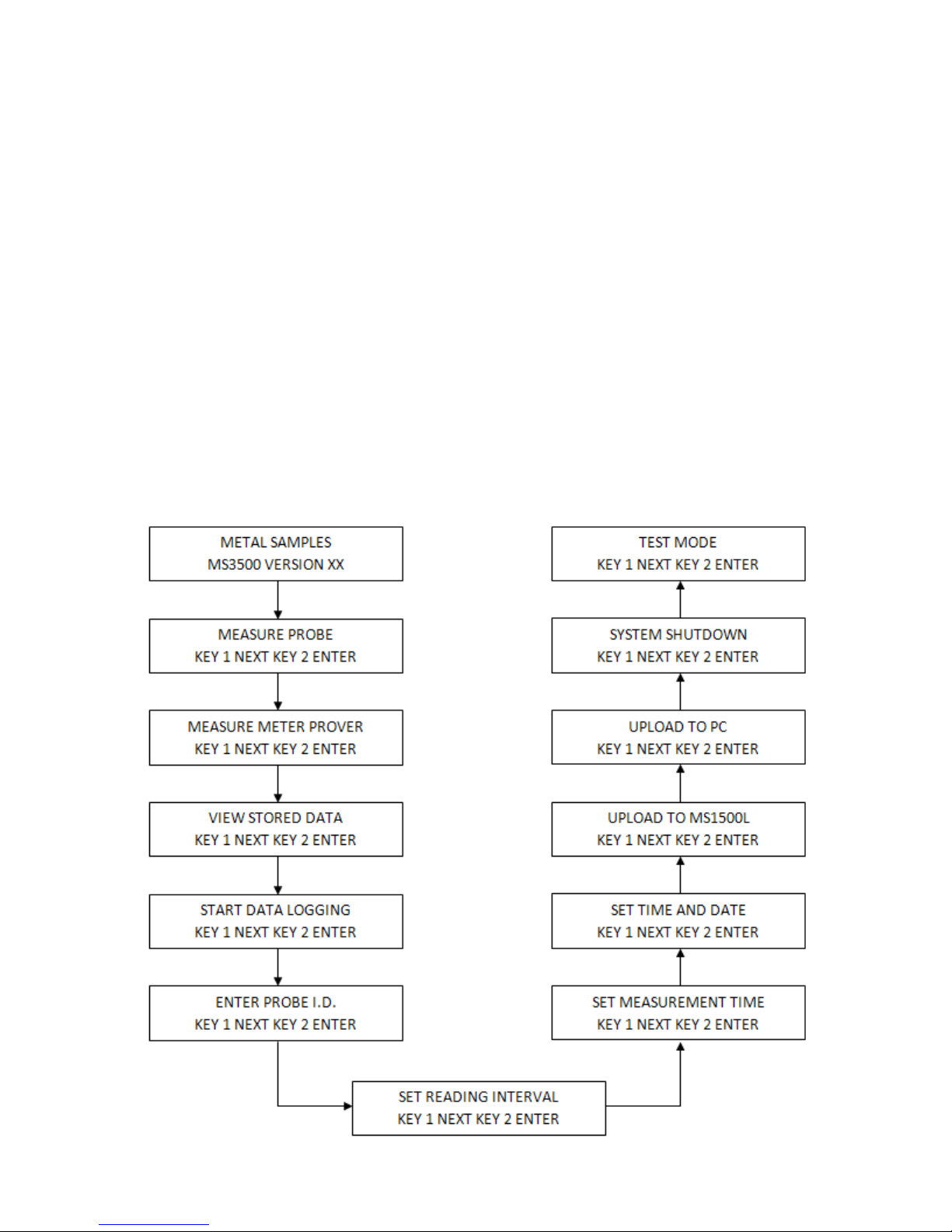

A.MainMenuOverview

Oncethebatteriesareinstalled in the MS3500E/3510E, the instrumentscreenmaybeactivatedby

pressingeitherofthekeysonthefrontpanel.Thecompanyname“METALSAMPLES”andsoftware

versionwillappear, thenafterafewsecondswillautomaticallychangetothe first ofthefunctionscreens

thatconstitutesthemainmenu.

Aseriesofninefunctionscreenscanbeaccessedsimplyby scrolling using KEY1ontheinstrument

keypad.Eachoftheninefunctionscreensallowsentryintoasubmenutoinitiateanactionsuchas

MEASUREPROBEorSTARTDATALOGGING;alternativelyitallowsinputofdatasuch as probe

identificationorreadinginterval.

Eachofthefunctionscreensandtheirsubmenusare fullyexplainedlaterinthemanual.Thefollowing

diagramshowsthesequenceofaccesstothe ten function screens:

9

Asexplained,eachfunctionscreengivesaccesstoasubmenu,thepurposeofwhichisbrieflydescribed

below:

MEASUREPROBE. Thiswilloverridethenormal intervalofloggingreadingstoallow

aspot checkreadingto be obtainedonscreen.

MEASUREMETERPROVER. Used totesttheinstrument with theMeterProver.

VIEWSTOREDDATA. Allowsvisualreviewofallreadingslogged.

STARTDATALOGGING. Initiatesthedataloggingprocessafterinputofappropriate

start-updata.

ENTERPROBEID Allowsinputof probe type and readinginterval. Togetherwith"SET

TIMEANDDATE". Thisconstitutesinitialstart-updata.

SETREADINGINTERVAL. Thisallows the initialreadingintervalthatisinputunder

"PROBEID"tobechangedwithoutdeletingstoreddata.

SETMEASUREMENTTIME. Thisallowstheinitialmeasurement (polarization) timethatis

inputunder"PROBEID"tobechangedwithoutdeletingstoreddata.

SETTIMEANDDATE. This constitutes the initialstepofstart-updata,allowingcorrect

settingofthe“realtime”clock.

UPLOADTO MS1500L. This activatesthedownload ofstoreddata to theMS1500Lor to

apersonalcomputer.

UPLOADTOPC. This activates the downloadofstoreddata to apersonalcomputer.

SYSTEMSHUTDOWN. Thiswillstoptheloggingprocess,andminimize power

consumptionwithoutdeletingstoreddata.

TESTMODE. Thisallowsacalibrationcheck of the 4-20mA loop, and supplies instrument

troubleshootingdata.

10

Thescreenoftheinstrumentisinitially activated bypressingeitherkey. The “SETTIME &DATE”

functionscreenisthenaccessedbyscrollingthroughthemainmenuusingKEY 1. KEY 2 allows entry

intothesubmenu,andthetimeanddate setup screen will be shown. Each digitofthetime,day,month,

andyearissequentially set using KEY1toselecttheappropriatedigit,and KEY 2 toenterthedigit

andmovethenextdigitof the time and date sequence.

Oncethefinaldigitoftheyearisentered,usingKEY2,thescreenwillautomaticallychangetothetime/

datedisplayscreen.Thisscreen shows the time anddateassetup.KEY2willacceptand store this time

anddate.KEY1 will reject this information.Eitherkeywillautomaticallyreturntheuserto the “MEA-

SUREPROBE”screenofthemain menu.Ifthetimeanddatehasbeenrejected, scrolltothe“SETTIME

&DATE”functionscreen,reenter the submenu and make the necessary corrections. If the time and date

arecorrect, and theuserhas used KEY2toaccept the information,scrollto the “ENTERPROBEID”

functionscreentocontinuewithprogram setup.

Pleasenote thatthetime anddate, onceset, shouldnot requirealteration exceptafter battery

replacement.Should theuser decidetochange thetimeand datewhile probedatais storedin

memory,all datawillbedisplacedin timeandhighlyinconvenient tointerpret.

B.ProgramSetup

Havinginstalledthebatteries,theMS3500Eisreadyfor start-up programming whichcompromisesthe

followingsequence: • SETTIMEAND DATE

•ENTER PROBEID

•STARTLOGGING

1.Set Time and Date

Thisoperationisillustratedbelow:

11

2. Enter Probe ID

Thisfunctionwillallow theusertoidentifytheparticular probetypeorinstallationlocationwith aunique,

4-digittagnumber.Additionally,itallowstheselectionofcorrectprobe element geometry,whichis

necessaryfortheinstrument’s calculation of metallossandcorrosionrate.Finally,itallowstheuserto

selectthedatacollectionrate.Theoperationalsequenceisasfollows:

Oncethe“ENTERPROBEID”functionscreenislocated on the main menu, KEY 2 willgiveaccessto

thesubmenu.Theinitialscreenof thesubmenuallowsdeletionofanystoreddata.Normallythere will

benodatastored,since any useful data set willhavebeenpreviouslydownloaded.Ifnousefuldatais

storedintheunit, press KEY 1 whichwilldeleteallexistingdataandgiveaccess to the ProbeID

screen. Ifuseful dataisstored, useKEY2 toreturnto themainmenu anddownloadexisting

data(p.16) priortoproceeding.

TheProbeIDscreenallowsyoutoinserta4-digitidentificationnumberfortheprobeand/ormonitoring

location.EachdigitisselectedwithKEY1,andindividually entered with KEY2.

WhenthefourthdigitoftheID numberisentered,thescreenwillautomaticallychangetotheelement

identificationscreen.

TheelementidentificationscreenshowstheProbeIDnumberanda5-6digit/lettersequencethat

identifiestheprobeelementgeometryandthickness.KEY1allowstheusertoscrollthroughthe

elementidentifications,andKEY2willentertheappropriateelementIDonceitislocated.

It should be noted that the variety of element geometries and thicknesses that is offered by

thevarious probemanufacturerstends toincrease.Consequentlyitis possible,fromtime to

time,that theusermay encounteraprobe elementstylethat isnotincludedinthe instrument

look-up table. In such a case, the user may select any of the element geometries in the table,

except wire, that has the same thickness as the element under consideration.

UponentryoftheprobeelementID,thescreenwillautomaticallychangetothedatacollectionrate

screen.Thisallowsthe user to selectthefrequencywithwhichtheprobeshouldbe read. This canbe

setinhourly increments from ashighasonceperhourtoas low as onceevery2,475hours.Thereading

frequencyisseton the screen asdays(twodigits)andhours(twodigits).The default reading is 1per

hour.Each digit is selected byaKEY1 scroll, and individually enteredwithKEY2.Oncethelasthour

digitisentered,thenextscreenwillbedisplayedwhichshowsthereadingfrequencyasentered,which

canthen beaccepted(KEY 2) orrejected (KEY 1).Ifaccepted, the screenwill revert tothe“MEA-

SUREPROBE”function screen, and theusercanproceedtothe“STARTDATALOGGING” func-

tion. Ifrejected,thescreenwill also revert to the “MEASUREPROBE”functionscreen,buttheuseris

12

3. Start Data Logging

Thisisthesetofcommandsthatstartstheloggingprocess:

Thesubmenuisenteredfromthe “STARTDATALOGGING” mainmenufunctionscreen,usingKEY

2.Thefirstsubmenuscreenisthe“SYSTEMREADY” screen, fromwhichKEY2willstartthelogging

processand shut downthescreenfor power conservation. If,foranyreason, the userdoesnotwish to

commencelogging,KEY1willallowescapetothe“MEASUREPROBE” screen of themainmenu.

Onceloggingisactivated,it willcontinueuntiltheuseractivatesthesystemshutdownroutine,orthe

batteriesdischarge.Ineitherevent,alldatacollectedtothispointwillberetained,butnoadditionaldata

willbecollected.Enteringanew probeIDwillalsostoptheloggingprocessand eliminateallexisting

probedata fromthememory; prior toenteringnewprobeID,ensurethat allusefuldata is

downloaded.

Shouldloggingcontinueinanuninterruptedfashionuntilthememorycapacityoftheunitisfull,additional

datawillsequentiallyoverwritetheinitialdatapointsstoredinmemory.

Theuser shouldalwaysset adownload scheduleofsufficient frequencysothat nomore than

3,100readings aretakenbetween downloadoperations.

Note: Evenat thehighestfrequency(1perhour),downloading canbescheduled at

intervalsasgreat as129withoutdata corruptionbyoverwriting.

nowrequiredto access the“PROBEID”functionand reset/correct the probeID,theelementID, and

thereadingfrequencypriortocommencing with thedataloggingprocess.

UponentryoftheprobeelementID,thescreenwillautomaticallychangetothedatacollectionrate

screen.Thisallowsthe user to selectthefrequencywithwhichtheprobeshouldbe read. This canbe

setinhourly increments from ashighasonceperhourtoas low as onceevery2,475hours.Thereading

frequencyisseton the screen asdays(twodigits)andhours(twodigits).The default reading is 1per

hour.Each digit is selected byaKEY1 scroll, and individually enteredwithKEY2.Oncethelasthour

digitisentered,thenextscreenwillbedisplayedwhichshowsthereadingfrequencyasentered,which

canthen beaccepted(KEY 2) orrejected (KEY 1).Ifaccepted, the screenwill revert tothe“MEA-

SUREPROBE”function screen, and theusercanproceedtothe“STARTDATALOGGING” func-

tion. Ifrejected,thescreenwill also revert to the “MEASUREPROBE”functionscreen,buttheuseris

nowrequiredto access the“PROBEID”functionand reset/correct the probeID,theelementID, and

thereadingfrequencypriortocommencing with thedataloggingprocess.

13

C. MeasureProbeFunction

The“MEASUREPROBE”functionallows the user to makeaspot-checkprobereadingatanytime,

withoutconstraintofthenormallogginginterval. Thesubmenusequenceisillustratedbelow:

Thefirstscreenofthe“MEASUREPROBE”submenudisplaystheprobeIDnumber,elementgeom-

etryandthickness.KEY1exitstothe main menu “MEASURE PROBE” function screen andKEY2

willactivateameasurement.

IfKEY2isused to activate a measurement,thesecondsubmenuscreenwillbeshownthatdisplaysthe

probeID,elementgeometryandthickness,anda“PLEASEWAIT”notation.After approximately 30

seconds,thereadingwillbecomplete and thethirdsubmenuscreenwillbeautomaticallydisplayed.This

screenwillshow the current probereadingasanintegerbetween0-1000, and will giveaKEY1EXIT

option,anda KEY 2ENTER(save)option.KEY1 will returntheusertothe“MEASURE PROBE”

functionscreen,KEY2willsave the probereadingandautomaticallydisplaythefourthsubmenu

screen.

Thefourthsubmenuscreen displays metal lossinMILSandaveragecorrosionrateasMPY. After

approximately30seconds,thisscreen willautomaticallyreverttothe“MEASUREPROBE”mainmenu

screen. Thismainmenuscreenwillautomaticallyshutdowntothepowersaving modeafterfiveminutes.

Normaldataloggingcontinuesthroughout themeasureprobesequencewithoutinterruption.

14

D. View Stored Data Functions

Thisfacilityallowsall data stored intheMS3500E/3510Etobecalledupon the screen forreview. The

submenusequenceisshownbelow:

Afterpressing either keytoaccesstheMS3500E/3510E screen, KEYlisused to scrolltothe“VIEW

STOREDDATA”functionscreen. KEY2isthenusedtoenterthesubmenu.

Thefirstsubmenuscreendisplaysthelatestreadingnumber, thedateofthereading,andthereadingin

“probeunits”.Thereadingnumberismerelythetotalnumberof readings stored upto,andincluding,the

readingdisplayed.Theprobeunitreadingis an integer from 0 to1000thatindicatesthepercentageof

effectiveprobethicknessconsumed.Previousreadingsmaybeaccessedsequentially using KEY 2.

KEYlwillexitthereviewscreenand display metal loss (MILS) and averagecorrosionrate(MPY)for

thereadingnumberdisplayedwhentheexitkeyisused.Themetalloss/corrosionratescreen will

displayforapproximately30secondsbefore automaticallyreturningtothe“MEASUREPROBE”

functionscreen.

The“VIEWSTOREDDATA”functionmaybeusedatanytimewithoutdisruptingnormallogging.

15

E.SetReadingIntervalFunction

Thisfunctionpermitsthereadingintervaltobechangedatanytimeduringloggingwithout

disruptingtheloggingprocessordeletingthestoreddata.Theoperationsequenceisasfollows:

Afterany key isusedtoactivate the screen,KEY1is used toscrolltothe “SET READINGINTER-

VAL”mainfunctionscreen. KEY2thenallowsentryintothesubmenu.

Thecurrentreadingintervalisdisplayedasdays and hours.IndividualdigitsmaybealteredusingKEY

1,andenteredusingKEY2.Afterthefinalhourdigitisentered, the screen will automatically changeto

areadingintervalconfirmationscreen.Theintervalasenteredis displayed. KEY 1willexittothe

“MEASUREPROBE”mainfunctionscreenwithoutentering(saving)thenewinterval.KEY2willenter

(save)thenewreading interval,thenautomaticallyreturntothe“MEASUREPROBE”mainfunction

screen,furtherloggingtakingplaceatthenewreadinginterval.

16

F.DownloadingData

Datastored in theMS3500E/3510Eunitmaybe downloaded, viatheOpti-Linkport, directly to aPC.

Alternatively,datamaybedownloaded to Metal Samples’MS1500E Hand-Held Data Logger, and

subsequentlytransferredtoaPC.Directdownloadingisusuallypreferredinacontrolroomor

laboratoryenvironment.WhereseveralMS3500E/3510Eunitsare distributedinafieldenvironment,

thedatais most convenientlytransferredviatheMS1500E to a PC.TheMS1500Ewillaccept data

fromasmany as onehundredMS3500E/3510Eunitsforsubsequent transfer toaPC.

1.Upload toPC

To transferdatatoaPCit is necessary toinstalltheCorrosionDataManagement Software.

ToruntheCorrosionDataManagementSoftware, you need a PCthatmeetsthefollowing

requirements:

•Pentium®classprocessor

•Windows®95 orhigheroperatingsystem

•16 MB of RAM

•10MB of available hard-diskspace

•VGAmonitorwith800 600orgreaterresolution

•Mouseorpointingdevicerecommended

•Available 9-pin serial port orUSBport

•CD-ROMdriveforsoftwareinstallation

To installtheCorrosionDataManagementSoftware:

1. Insert the setupdiskprovidedinyouraccessorykit.

2. You will bepromptedtocloseany open programs. Afteryouhavedone so, clickOK to

continue.

This manual suits for next models

1

Table of contents

Other Metal Samples Company Data Logger manuals