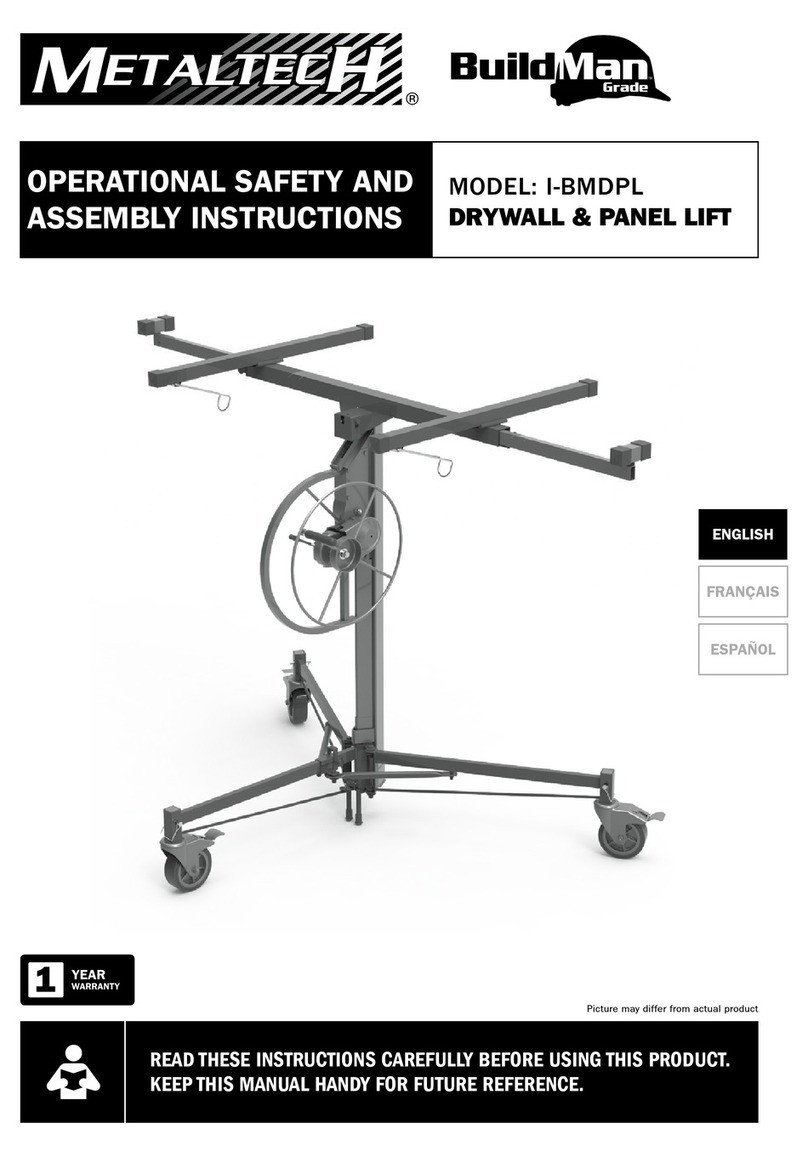

MetalTech PJ-PJST User manual

B

A

E

ENGLISH

OPERATIONAL SAFETY

AND ASSEMBLY

INSTRUCTIONS

READ THESE INSTRUCTIONS CAREFULLY

BEFORE USING THIS PRODUCT. KEEP THIS

MANUAL HANDY FOR FUTURE REFERENCE.

Pictures may differ from actual product

PUMP JACK SYSTEM

1YEAR

WARRANTY

OSHA

MEETS 1926.451

& 1926.452(J)

ANSI

MEETS 10.8-2019

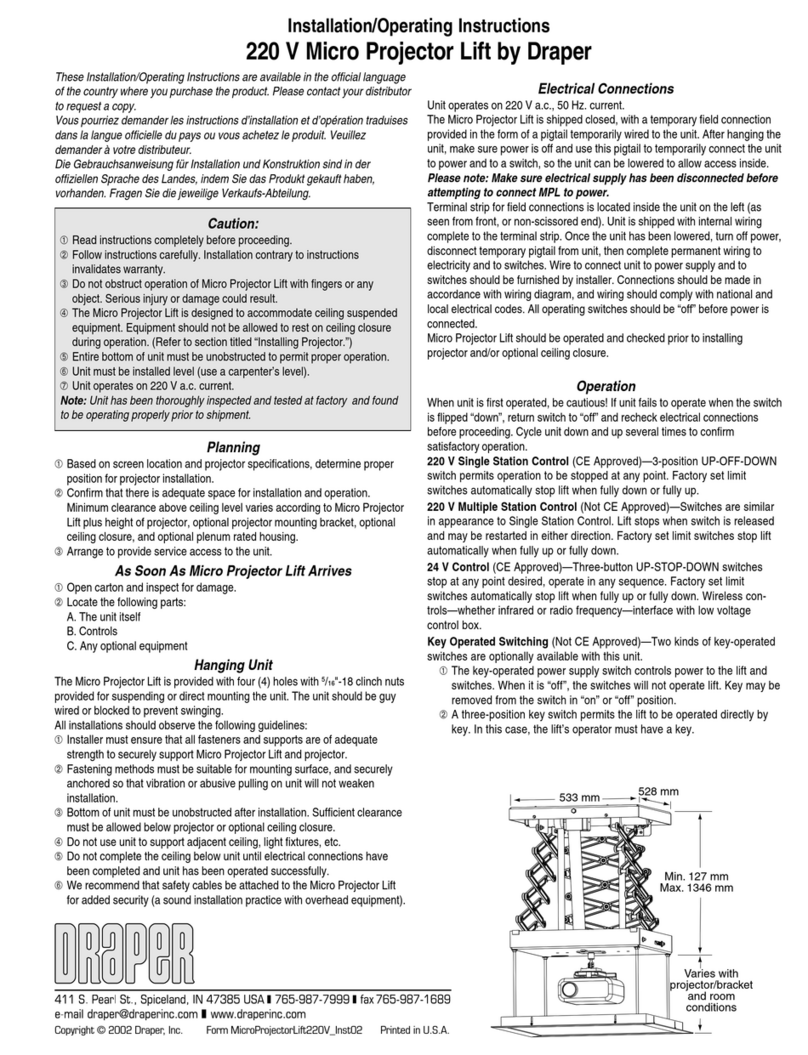

Be sure stirrup (A) is in the “Up”

position. Unlock Crank (B) by sliding

handle to the right or left until it turns

freely. (If crank seems jammed, depress

stirrup about 3” and return to “Up”

position. This will free crank for easy

unlocking.) Place left foot on the square

key (C) of lower lock. Press foot down

and hold lock open. Turn Crank (B) in

a clockwise direction to lower staging

approximately 1 foot and lock crank.

Repeat this procedure on the other

Pump Jack.

An extra Pole Brace is to be installed

approximately 4 feet above the Pole

Brace to be passed. Remove nails

from clamp of Pump Pole Brace.

Remove the wing nut and carriage

bolt. Separate plates and let the

brace swing down against the work

wall. Do not remove Pump Jack

Brace from wall. After the Pole Brace

has been passed, reconnect it to

the Pole and remove the extra Pole

Brace.

Stand on walk plank with the jack and pole in front of you. Lock the

crank (A) by sliding the crank handle to the right or left until square

rod is in square hole. Place right foot in stirrup (B) and pump slowly

until platform is raised approximately 1 foot. Repeat this procedure on

the other pump jack.

IMPORTANT – Raise Stirrup to “Up” Position (C) when desired

height is reached.

TO RAISE PUMP JACK

TO LOWER PUMP JACK

TO PASS A PUMP POLE BRACE

A

C

B

TO OPERATE

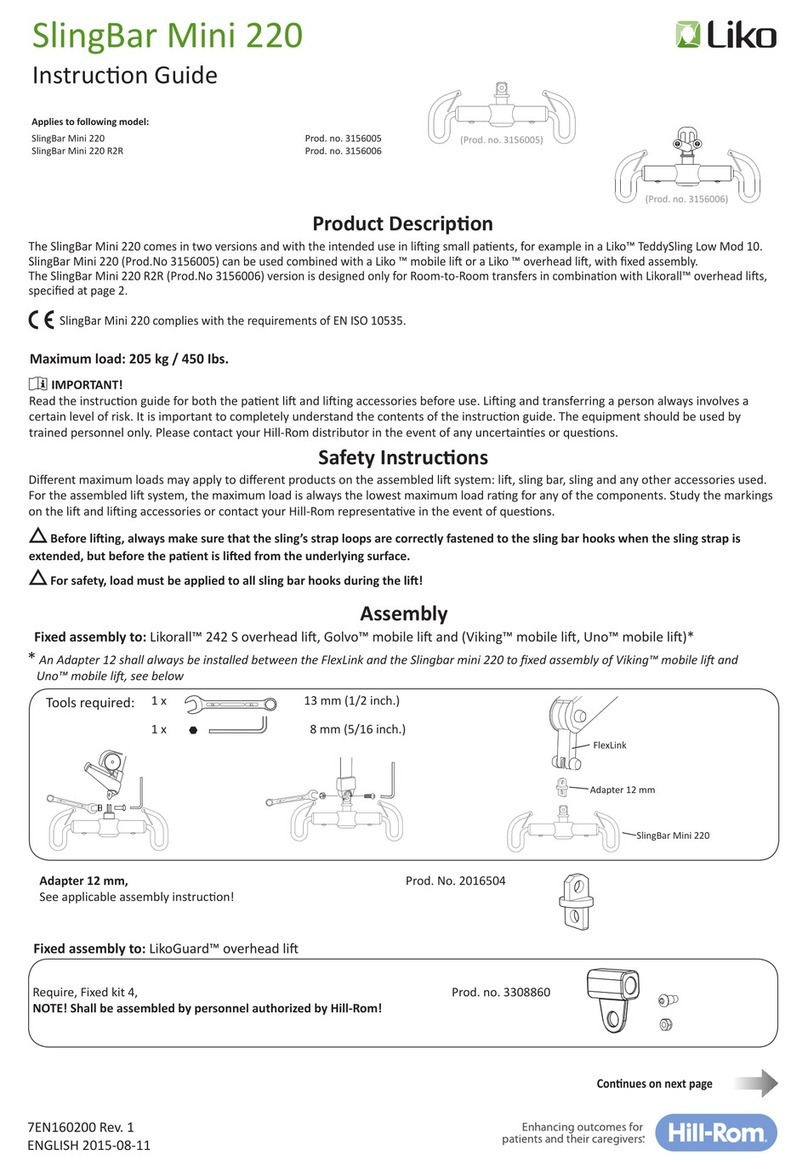

Attach the pump jack to the pole with the bed facing

the work wall, by removing pin and roller (D) crank

(E) square rod (F). Place the pump jack over the

pole and reconnect parts.

Open pump jack bed to full extended length and place

planks on bed, thus completing staging. Be sure that the

platform is fully decked and the planking secured against

movement. Install guard rails in accordance with OSHA

regulations. The Guard Rail Holder should be used to assist

in this installation.

D

SET UP

3

E

F

METAL CONDUCTS ELECTRICITY:

Do not use this equipment where contact may be

made with power lines or other live electrical circuits.

OPERATIONAL SAFETY CHOOSING A WALK PLANK

SYSTEM COMPONENTS

CAPACITY: No more that 500 lb between any two Pump

Jack Poles. This capacity considers a 4:1 safety factor as

required by OSHA Standards when installed according to

instructions.

GENERAL REQUIREMENTS: Pump Jack System products

are intended for use by qualified professional contractors.

Prior to installation, the user should review all instructions for the

installation, use and care of these products. All scaolding and

accessories must be used in strict compliance with local, national or

OSHA legislation which applies.

Pump Jack Poles must be securely braced to the work wall at the

top, bottom and at least every 10’ between with a Pump Jack Pole

Brace.

The Pump Jack System can be adjusted to any height up to a

maximum of 30 feet.

Guard rails and end rails must be used at all times. Guard rails

consist of a top rail placed 42” above the work platform and a mid-

rail placed mid-way between the work platform and the top rail.

End rails are required to close o both ends of the platform.

Toe boards shall be installed on all open sides and ends of

platforms when used above 10 feet from the ground.

A ladder, in accordance with OSHA regulations shall be provided

for access to the work platform during use.

The work bench was designed for use as a work surface and is not

to be used as a scaold platform.

Federal regulations require the user to have knowledge of all

regulations that apply to the use and care of this product and that

the employer provide training.

FAILURE TO UNDERSTAND AND FOLLOW ALL

SAFETY RULES AND ASSEMBLY INSTRUCTIONS

COULD RESULT IN SERIOUS INJURY OR DEATH.

1. Wood walk planks shall be made of Scaold Grade or

equivalent lumber. When fabricated from 2 inch full thickness

undressed lumber, the maximum span between supports

shall not exceed 9 feet. When fabricated from 2 inch nominal

thickness lumber, the maximum span between supports shall

not exceed 7 feet.

2. Aluminum walk planks must be manufactured for that

purpose and shall not exceed 24 feet in length. The maximum

span between supports should not exceed 11 feet. Aluminum

walk planks longer than 12 feet and less than 24 feet must

always be supported in the middle of the platform with a

pump jack in addition to both ends.

3. All walk planks shall be overlapped a minimum of 12 inches

and secured from movement.

4. All walk planks must extend no less than 6 inches and no

more than 12 inches over the support arms.

5. Scaolding planks should fully deck the pump jack platform

arms.

6. There should be no more than two people on a pump jack

platform between any two pump jacks.

PUMP JACK

MODEL: PJPJST

PUMP JACK WORKBENCH

AND GUARD RAIL

MODEL: PJWBST

PUMP JACK POLE

ANCHOR

MODEL: PJPAST

PUMP JACK BRACE

MODEL: PJBST

1

2

1

2

3

4

3

4

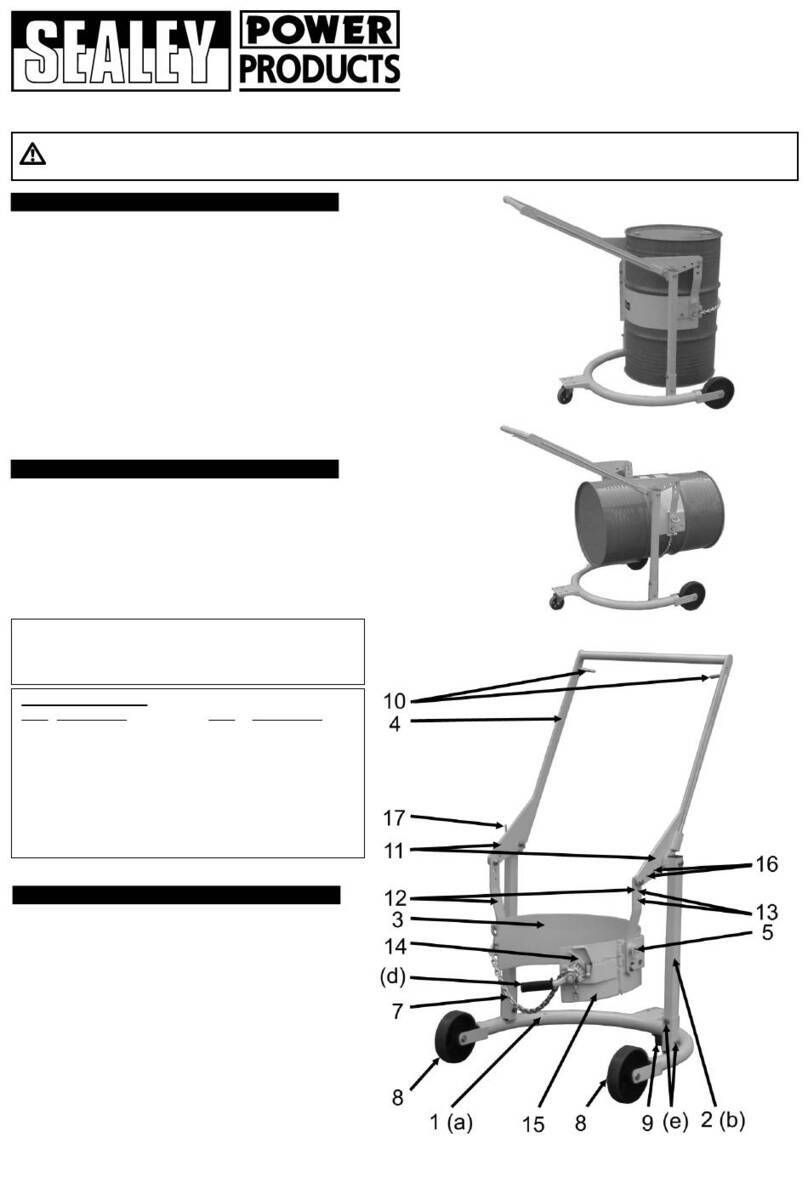

Select two clear, straight-grained

fir wood 2x4’s (1-1/2” x 3-1/2”)

free from all knots or defects.

Nail together with 10d common nails 12”

center to center, staggered uniformly from

opposite edges. Splices may be used to

extend the pole to a maximum of 30 feet.

The 2x4’s must overlap a minimum of 3 feet

and nails should be spaced a minimum

of 6” center to center for a distance of 18

inches on each side of the splice. Mending

plates shall be installed at all splices so as

to develop the full strength of the member.

Countersink all nails. Loosen wing nut (A)

on Pump Jack Brace. Slide clamps over

wood pole so that seam faces the carriage

bolt and tighten at desired height. Nail

clamps to Pump Pole.

SET UP

Stand pump pole up vertically, imbed base in dirt about

3”-4”. Be sure pole is bearing on a firm foundation (mud

sill), or use Pump Jack Pole Anchor. (Pump Jack pole must

be braced at top, bottom and every A 10’). Attach pump pole brace

to work wall with nails or screws. Round Rod (B) attaches at right

angle to wall and angle iron

brace (C) attaches 32” to right

or left, enabling installation on

studs 16” apart. Poles should be

secured to wall a maximum of

every 10 feet in height.

To determine appropriate

spacing between poles see

section on

“CHOOSING A WALK PLANK”

C

A

B

1

Customer Service: 1 800 363-7587

Our customer service sta is available to help you. For help with product assembly,

to report damaged or missing parts, or for any other information about this product,

please call our toll-free number.

KEEP THIS MANUAL FOR FUTURE REFERENCE

Keep this manual and the original sales invoice in a safe, dry place for future reference.

Metaltech is a registered trademark of Metaltech-Omega inc.

WWW.METALTECH.CO

LAVAL, QUEBEC, CANADA H7L 3N6

INPJSTNAEN

One Year Limited Warranty

Metaltech-Omega Inc. guarantees this product against any material defect.

Please return this product, freight prepaid, to Metaltech-Omega Inc. At its own

discretion, Metaltech-Omega Inc. will replace or repair this product and return it

within a reasonable time. This warranty does not cover any damage(s) caused

by any incorrect or inappropriate use, care or maintenance. Proof of purchase

must accompany the return.

2

Other MetalTech Lifting System manuals