STARKE ARVID Vakuflex 280 User manual

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 2av 25

Contents

FOREWORD...................................................................................................................................3

TECHNICAL DESCRIPTION ..........................................................................................................4

MODE OF OPERATION .................................................................................................................5

BASIC SAFETY INFORMATION....................................................................................................6

Warning instructions and symbols...................................................................................................6

Authorised use................................................................................................................................6

Organisational measures.................................................................................................................7

Personnel selection and qualification...............................................................................................8

Safety instructions on particular operating phases...........................................................................8

Normal operation.............................................................................................................................8

Special work....................................................................................................................................9

Safety instructions for special types of danger.................................................................................9

Electrics ..........................................................................................................................................9

Oils, greases, and other chemical substances.................................................................................9

COMMISSIONING ........................................................................................................................10

Charging the battery......................................................................................................................11

The manual valve (suction/release valve)......................................................................................12

Before transporting........................................................................................................................13

OPERATION.................................................................................................................................15

Switching on..................................................................................................................................16

Working cycle................................................................................................................................17

Switching off..................................................................................................................................20

Charging the battery......................................................................................................................20

TROUBLESHOOTING..................................................................................................................21

Leak check....................................................................................................................................22

Leak check for the entire system...................................................................................................22

Leak check without suckers...........................................................................................................22

MAINTENANCE............................................................................................................................23

The suckers...................................................................................................................................23

The vacuum lines..........................................................................................................................23

Leak check....................................................................................................................................24

TECHNICAL DATA.......................................................................................................................25

CIRCUIT DIAGRAM

DECLARATION OF CONFORMITY

TEST REPORT

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 3av 25

Foreword

These operating instructions are intended to help you become familiar with the suction unit

and to use it as intended.

These operating instructions contain important instructions about operating the Vakuflex

280 safely, effectively, and economically. Observing them helps to avoid repair costs and

down time and to increase the reliability and working life of the Vakuflex 280.

These operating instructions must be supplemented by additional instructions due to exist-

ing national accident prevention regulations.

These operating instructions must always be available at the site of use of the

Vakuflex 280.

These operating instructions must be read and observed by every person responsible for

doing work on the Vakuflex 280, for example:

-operation, including equipping, troubleshooting during operation,

removal of production waste, care

-maintenance (servicing, inspection, repair) and/or

-transport.

In addition to the operating instructions and binding accident prevention regulations appli-

cable for the country of use and the application case, the recognized technical rules for

safe and professional work must also be observed.

If you discover errors when reading these operating instructions, or if you have further

comments or suggestions, please contact:

Starke Arvid AB

Manufactured by:

K. Schulten

Industriestr. 3-7

48488 Emsbueren

Germany

The management appreciates your cooperation.

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 4av 25

Technical Description

Vakuflex 280 is a network-independent vacuum device, made for using with a crane or

other lifting facilities. Due to its different configuration possibilities, the Vakuflex 280 can

be used in several transport requirements.

Some examples as follows:

The transport element can be turned by 360° and swivelled by 90°.

rotating swivelling

Two closed vacuum circuits prevent a vacuum lost in case of power failure.

Each vacuum circuit is equipped with a storage tank including a non-return valve, a vacu-

um switch and a checking vacuum gauge. Two vacuum pumps will be used to generate a

vacuum (one pump per vacuum circuit). Two vacuum pumps are used to generate the

vacuum (one vacuum pump each vacuum circuit). The vacuum pumps work without oil

lubrication and are therefore maintenance-free.

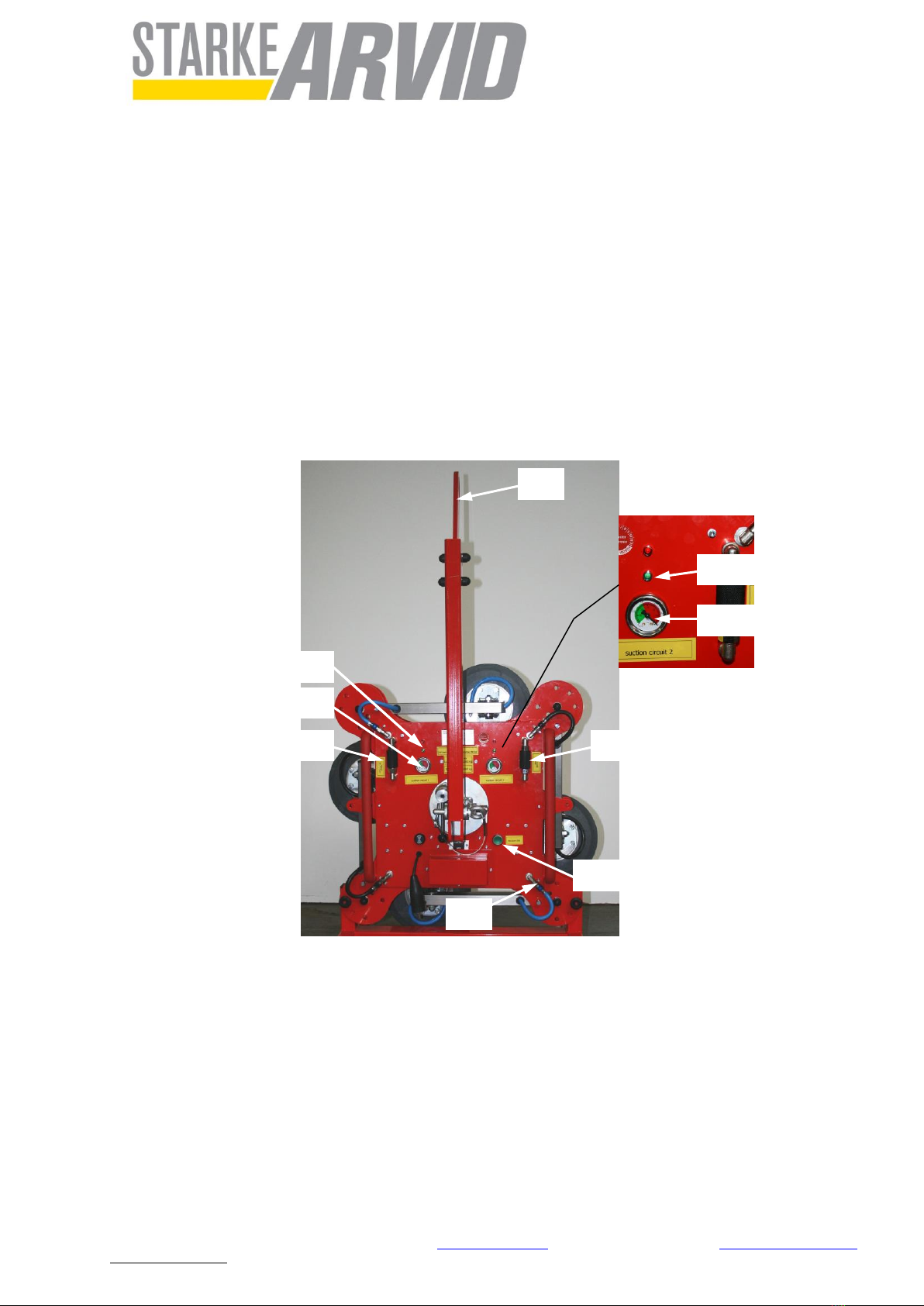

Particularly, the device consists of one main frame including four swinging rectangular

tubes and the loading arms including its suctions. The main frame exists of two vacuum

storage tanks, vacuum pumps, a battery charger and a battery. The sucker connections

are supplied with a vacuum (suction) or normal compressed air (releasing) by means of

the manual valves (suction/release valves) of the two vacuum circuits. The suckers (two

per vacuum circuit) can be blocked individually using vacuum couplings. Two inspection

90°

360°

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 5av 25

vacuum meters provide information on the exact pressure ratios in the vacuum lines to the

individual suckers. A voltage display indicates the battery charge level.

The charging circuit voltage for the charger is 220-240 volt AC (50/60 Hz).

Two vacuum pumps are used to generate the vacuum (one vacuum pump / vacuum cir-

cuit). The vacuum pumps work without oil lubrication and are therefore maintenance-free

In order to avoid draining the batteries unnecessarily, the pump switch has a two-point

controller that switches off the vacuum when the pressure reaches -0.7 bar in the vessel,

switches the pumps off and switches the pumps back on when the pressure falls below

approx. -0.68. This avoids premature draining of the batteries due to the pumps being al-

lowed to run unnecessarily.

As accessories for the machine the crane facility and conveying facility are available.

Mode of operation

Switch the machine on using the ON/OFF switch (3).

Then set the two manual valves to RELEASE.

The vacuum unit must be positioned on the load to be transported in such a way that all

suckers are flat on the smooth clean surface so that the sucker lips can seal completely.

Set both manual valves to SUCTION using the remote control and wait until the pumps of

both vacuum circuits switch off. You can check the vacuum using the vacuum meters (5.1 /

5.2) on the device. If there is a vacuum of –0.7 bar in both vacuum circuits, the load can be

transported. To release the suckers from the load, set the two manual valves to

RELEASE.

Attention!

The suction unit must NEVER be commissioned when there is only one functioning vac-

uum circuit.

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 6av 25

Basic safety information

Warning instructions and symbols

The following terms and symbols are used in the operator’s manual for especially im-

portant information:

Note!

Special information regarding the economical use of the device.

Caution!

Special information regarding requirements and prohibitions for preventing damage.

Danger!

Information or requirements, or prohibitions for protecting people or preventing extensive

damage.

Authorised use

The Vakuflex 280 has been constructed in accordance with the state of the art safety reg-

ulations. Nevertheless, its use may result in danger to life and limb of the operator or third

parties and impairment of the machine or other property may occur.

The machine may only be used when in technically perfect condition, as authorised. The

user must be conscious of safety and risks and act in accordance with the instructions.

Failures which can interfere with safety must be eliminated immediately.

The Vakuflex 280 is exclusively for transporting gas-tight, dry materials with firm, flat sur-

faces. Other use or use going beyond this, for example transporting gas-permeable mate-

rials, film-covered materials, wet materials, or rotating or swivelling large or heavy trans-

ported goods is not authorised. The manufacturer/supplier is not liable for the damages

resulting from this. The user bears the risk alone.

Use as authorised use also includes complying with the operating instructions and the in-

spection and maintenance conditions.

i

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 7av 25

Organisational measures

Always keep the operating instructions within reach at the site of use.

In addition to the operating instructions please observe and teach any other generally ap-

plicable statutory regulations concerning accident prevention.

Such obligations can also include providing and wearing personal protective equipment.

Please supplement the operating instructions with instructions including supervision and

reporting obligations taking into consideration operational corporate circumstances, e.g.

relating to work organisation, work processes, personnel used.

The personnel authorised to operate the device must read the operating instructions, par-

ticularly the chapter about safety instructions before starting work. It is too late to read the

instruction if work has already been started. This applies in particular to personnel who

only work on the machine occasionally, e.g. for equipping it and carrying out maintenance

work. Occasional checks should be carried out to ensure that the members of personnel

follow the instructions and work in a safety-conscious manner and are aware of risks.

If necessary or if required by regulations, personal protective equipment should be used.

Glass should only be transported with the appropriate protective equipment (safety shoes,

protective gloves, wrist protectors, helmet etc.) A helmet should be worn at all times when

transporting goods above head height.

All safety and danger instructions on the device should be complied with.

All safety and danger instructions on the device should be kept complete and in legible

condition.

If there are any safety-related changes to the device or its operation, the device should be

stopped immediately and the malfunction should be reported to the relevant office or per-

son.

No changes, attachments or upgrading work that could possibly impair safety should be

carried out on the machine without the consent of the supplier. This also applies to the in-

stallation and setting of safety equipment and valves as well as to welding on load-bearing

parts.

Spare parts must fulfil the technical requirements specified by the manufacturer. This is

always guaranteed with original replacement parts.

Vacuum hose lines should be replaced at the specified intervals or at appropriate intervals,

even if there are no recognisable safety defects.

Compulsory deadlines or those specified in the instructions for recurring tests / inspections

should be complied with

Appropriate workshop equipment is absolutely necessary for performing the maintenance

measures.

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 8av 25

Personnel selection and qualification

Work on/with the machine may only be performed by reliable personnel. The legal mini-

mum working age should be observed.

Use only trained or instructed personnel; responsibilities among personnel should be

clearly established for operation, equipping, maintenance, and repair.

Ensure that only authorized personnel work on the machine.

Specify a person who is responsible for operating the machine and give him/her the oppor-

tunity to refuse to comply with the safety instructions of third parties.

Personnel being trained or instructed, or who are taking part in a general training pro-

grammed, may only work on the machine when under the constant supervision of an expe-

rienced person who is familiar with this situation.

Work on the electrical equipment of the machine may only be performed by an electrician

or by trained personnel under the direction and supervision of an electrician in accordance

with the rules of electrical engineering.

Safety instructions on particular operating phases

Normal operation

Avoid all unsafe work practices.

Before starting work, become familiar with the working environment at the site of use. The

working environment includes impediments in the work and traffic area, the load bearing

capacity of the floor, and cordoning off the worksite from public traffic areas.

Take measures to ensure that the machine is only operated when safe and functional.

Check the machine for external damages and flaws at least once per shift. Report any

changes that occur (including those to the operating behavior) immediately to the respon-

sible office/person. If necessary, stop the machine immediately and secure it!

During malfunctions, the machine should be stopped immediately and secured. Malfunc-

tions should be corrected immediately.

The switching on and off procedures should be complied with, and the inspection displays

should correspond to the operating instructions.

Always stop work if it becomes dark or if visibility is poor!

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 9av 25

Special work

The setting, maintenance, inspection activities and deadlines, including information on re-

placement of parts and modules stipulated in these operating instructions must be ob-

served. These activities may only be performed by authorised specialists.

Only perform maintenance and repair work when the machine is positioned on flat ground

with sufficient bearing capacity and is secured so that it cannot roll away or collapse.

Clean machines, particularly connections and screw connections at the beginning of

maintenance/repair work. Do not use aggressive cleaning agents! Use lint-free cloths for

cleaning.

Never clean the machine with water or steam jet (high-pressure cleaner).

After cleaning, inspect all vacuum lines for leaks, loosened connections, abrasion and

damage. Repair any flaws immediately!

Always tighten screw connections loosened during maintenance and repair work.

Safety instructions for special types of danger

Electrics

Use only original fuses with the specified current strengths.

Switch off the machine immediately during malfunctions to the electrical energy supply.

Work on electrical equipment or operating materials may only be performed by an electri-

cian or by trained personnel under the direction and supervision of an electrician in ac-

cordance with the rules and regulations of electrical engineering.

Machine and system parts on which inspection, maintenance, or repair work must be per-

formed, must be switched free of current if required. First check the switched off parts to

ensure that they are free of voltage, then ground and short-circuit them, and insulate

neighboring live parts.

The electrical equipment of the machine must be checked regularly. Flaws such as loose

connections and melted cables must be repaired immediately.

Oils, greases, and other chemical substances

Observe the safety regulations applicable for the product when using oils, greases, and

other chemical substances!

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 10 av 25

Commissioning

Note!

-Do not store the suction unit in a damp or very cold (frost) environment. Otherwise

there is no guarantee that the installed pump will function properly.

-Caution!

-Always ensure that the suckers are not placed on sharp edges because this could

damage the sucker lips. This would lead to leaks in the suction circuit, impairing

the functioning of the device.

-Never place the machine with mounted suckers with the rubber surfaces of the

suckers on sandy or similar ground. This could damage the sealing lips of the

suckers. This would lead to leaks in the suction circuit, impairing the functioning of

the device. Or the grains of sand or similar substances could be pressed into the

rubber surfaces, leading to damage to the upper surface of the transported goods.

-Danger!

-Do not allow heavy rain to fall on the device.

-Do not place the device in water.

-Do not convey loads over persons or machines. Cordon off the area under hang-

ing transported goods with wide clearance.

i

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 11 av 25

Charging the battery

Check the device for any externally recognisable damages or flaws.

Compare the connection on the power supply network and check the voltage, current and

mechanical connection (plug connection) with the necessary data for the vacuum pumps.

If they do not correspond, the machine may not be operated.

Connect the Vakuflex 280 to the supply network (9) using an extension cable.

The charging procedure can be checked in voltage display (12).

The battery is charged after a maximum of 12 hours.

Remove the extension cable from the supply network.

This completes the charging procedure.

Note!

-Once the work has been finished, switch off the device with the green button (3).

In case the battery is completely discharged, the machine cannot be used.

i

3

9

12

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 12 av 25

The manual valve (suction/release valve)

Attaching the suction pads to the KS VacuFlex

Attention!

- Blue hose line = vacuum circuit1 = vacuum coupling blue

- Black hose line = vacuum circuit2 = vacuum coupling black

Attention!

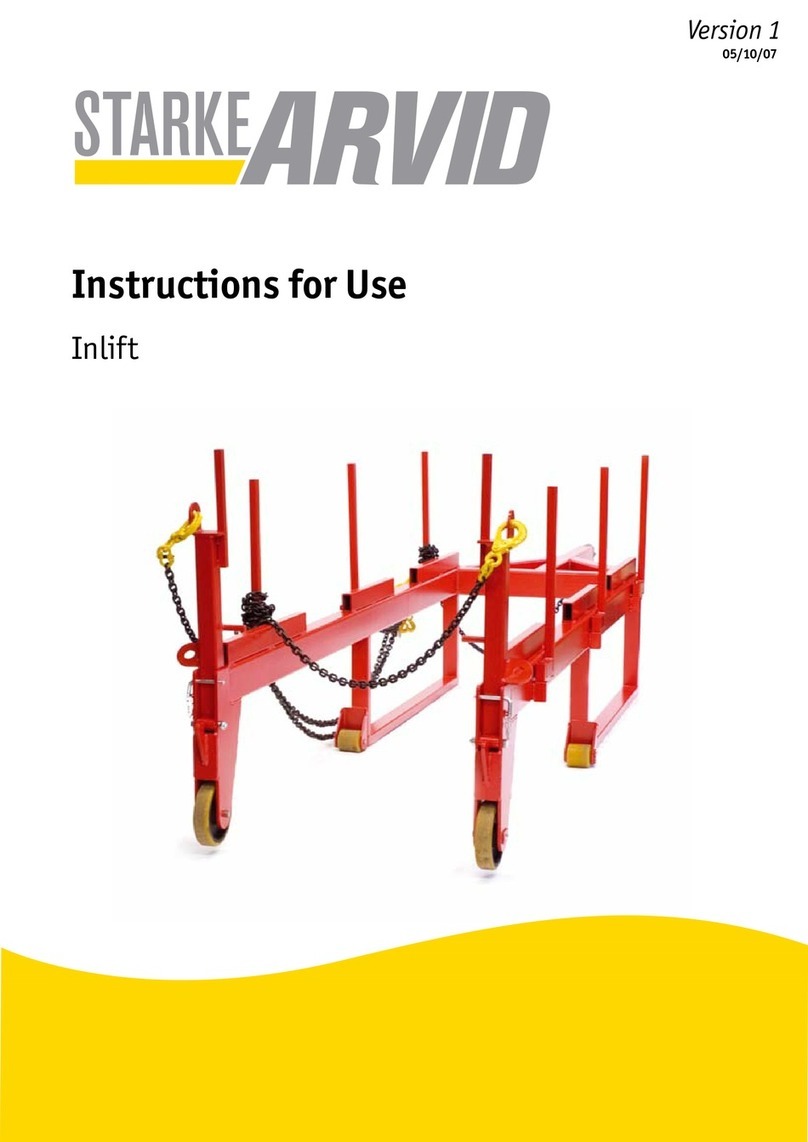

The suction pads on the device must always be attached in such a way that vacuum cir-

cuit 1 and vacuum circuit 2 are connected in every suction row see (A).

The suction pads must never be attached in such a way that only one vacuum circuit is

connected in suction row (B).

Figure A Figure B

Positon Position

Suction Release

Suction row 2

black

vacuum circuit 2

blue

vacuum circuit 1

black

vacuum circuit 2

Suction row 1

Suction row 2

blue

vacuum circuit 1

blue

vacuum circuit 1

blue

vacuum circuit 1

Suction row 1

black

vacuum circuit 2

Suction row 2

black

vacuum circuit 2

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 13 av 25

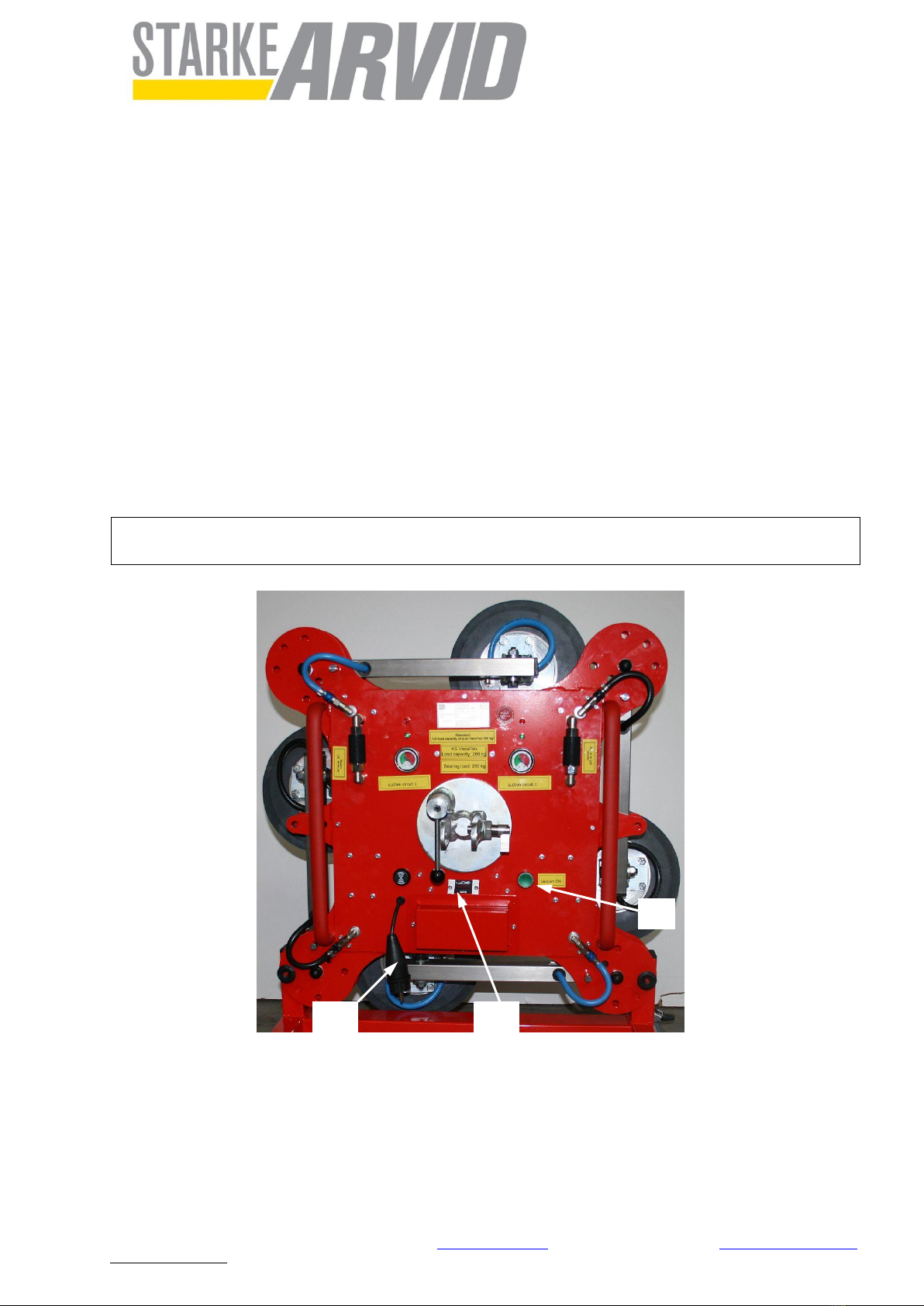

Before transporting

Before using the Vakuflex 280, check it for any externally recognisable damage or flaws.

Now, fix the Vakuflex 280 on the lifting device or on a crane hook.

Then set the two manual valves to the RELEASE position.

Turn on the device with the button "On/Off" (3). The light is green now. The pumps must

start up if the vacuum is insufficient. The Pump indicator light (4.1 / 4.2) indicates that the

pumps are active. If this is not the case, working with the Vakuflex 280 is not permitted

(see Troubleshooting).

The signal tone signalises insufficient vacuum in the lines to the suckers. The existing

vacuum in the hose system of both vacuum circuits can be checked on the two vacuum

meters (5.1 / 5.2). After a short time, a vacuum of at least -0.65 bar should have built up in

each tank. The vacuum pumps switch off when -0.7 bar vacuum is reached. This should

be the case after a short time.

In order to check the vacuum, the individual suckers (two per vacuum circuit) must be

blocked from the vacuum reserve tanks using the vacuum couplings. Then the two manual

valves (2.1 / 2.2) are set to SUCTION. The indicators of the two inspection vacuum meters

(5.1 / 5.2) must then be in the green area. Then switch the device off with the switch (3)

and wait ten minutes. During this time the indicators of the two inspection vacuum meters

may not move.

If only one indicator changes, the device is leaking and may no longer be used until the

error has been corrected. However, if this is not the case, the Vacuflex 280 is ready for

1

2.2

2.1

2.2

3

4.2

4.1

5.15.1

5.2

6

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 14 av 25

operation after the machine switch (3) has been switched on and the two manual valves

(2.1 / 2.2) have been reset to RELEASE.

The individual suckers must be connected to the vacuum reserve tanks by the vacuum

couplings (6).

In order to check the tightness of the hose lines and the individual suckers, either a larger

plate or several smaller plates of a gas-impermeable material must be present. These

plates are held onto the individual suckers and then sucked on. To do so, the manual

valves (2.1 / 2.2) must be set to SUCTION using the remote control. A vacuum of at least -

0.65 bar should build up immediately in each vacuum circuit. If this happens, the machine

switch (3) must be switched off. Read the achieved vacuum from the two inspection vacu-

um meters (5.1 / 5.2) and compare it with a reading taken about 15 minutes later. If there

is no discrepancy, the Vakuflex 280 is leak-tight and safe to operate. If a discrepancy of

more than 5% occurs, the Vakuflex 280 must be checked to find the leak (see Trouble-

shooting).

Commissioning is complete once the machine switch (3) has been switched back on.

Attention!

The device must NEVER be commissioned when there is only one functioning

vacuum circuit.

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 15 av 25

Operation

Note!

-Do not store the suction unit in a damp or very cold (frost) environment. Otherwise

there is no guarantee that the installed pump will function properly.

-Caution!

-Always ensure that the suckers are not placed on sharp edges because this could

damage the sucker lips. This would lead to leaks in the suction circuit, impairing

the functioning of the device.

-Never place the machine with mounted suckers with the rubber surfaces of the

suckers on sandy or similar ground. This could damage the sealing lips of the

suckers. This would lead to leaks in the suction circuit, impairing the functioning of

the device. Or the grains of sand or similar substances could be pressed into the

rubber surfaces, leading to damage to the upper surface of the transported goods.

-Caution!

-Do not allow heavy rain to fall on the device.

-Do not place the device in water.

-Do not convey loads over persons or machines. Cordon off the area under hang-

ing transported goods with wide clearance.

i

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 16 av 25

Switching on

Set the two manual valves (2.1 / 2.2) to RELEASE.

Switch on the device with the switch (3). The pumps must start up if the vacuum is insuffi-

cient. The pump indicator light (4.1 / 4.2) indicates that the pumps are active. If this is not

the case, working with the KS Vacu Power is not permitted (see Troubleshooting) the sig-

nal tone indicates insufficient vacuum.

After a short period, a vacuum of at least -0.65 bar should have built up. The vacuum

pumps switch off when approx. –0.7 bar is reached. This should be the case after a short

time.

As long as no transported goods are sucked on or the suction pads, it is not possible to

check the vacuum from the two inspection vacuum meters (5.1 / 5.2).

1

2.2

2.1

2.2

3

4.2

4.1

5.15.1

5.2

6

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 17 av 25

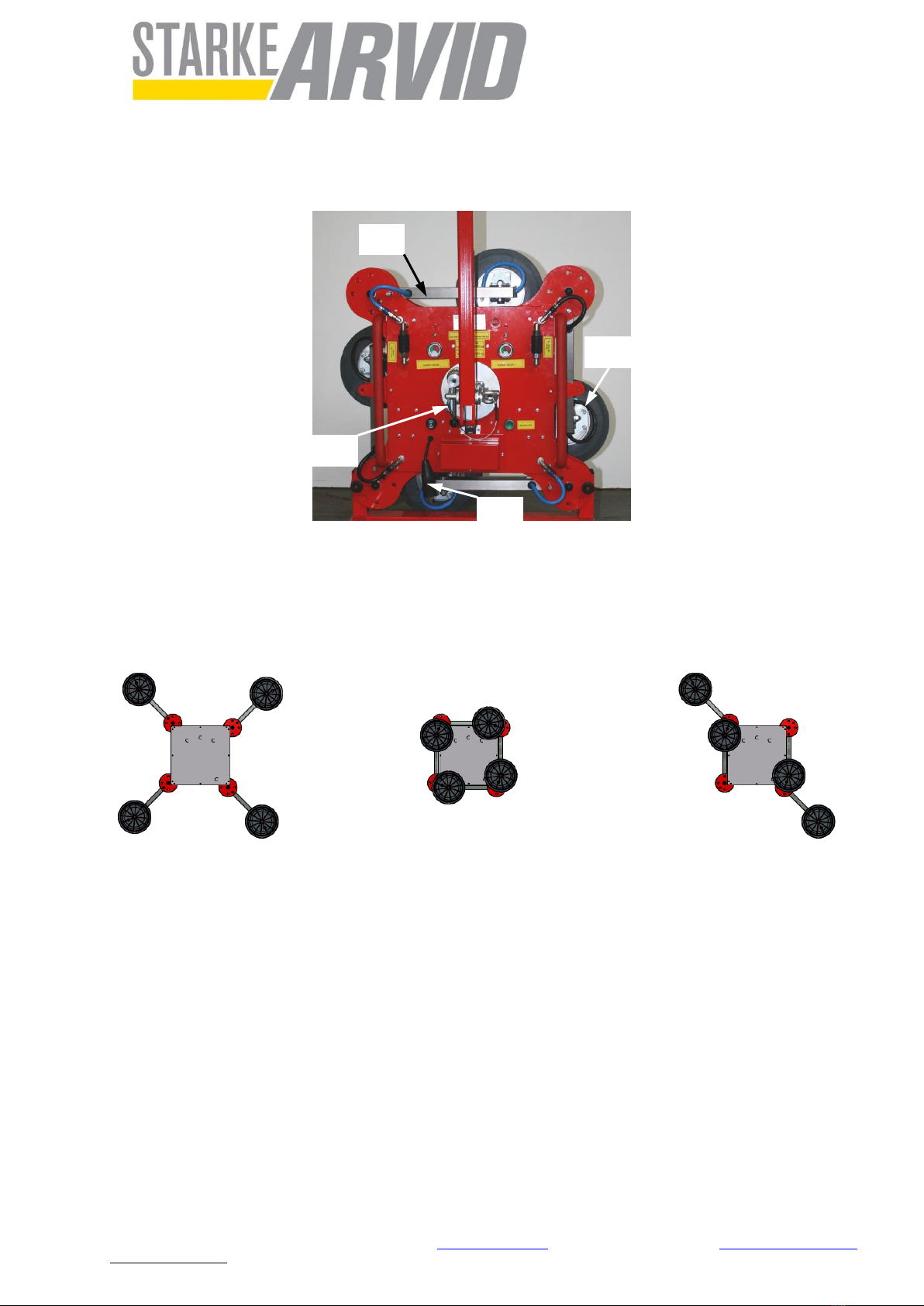

Working cycle

Determine the position of the carrier frame (7) using the rotating or swivelling device (8), in

which the transported goods are to be sucked on. Always order the suctions symmetrically

in order to hold the device in balance.

Some examples as follows:

Position the KS Vakuflex 280 on the goods to be transported.

7

8

9

10

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 18 av 25

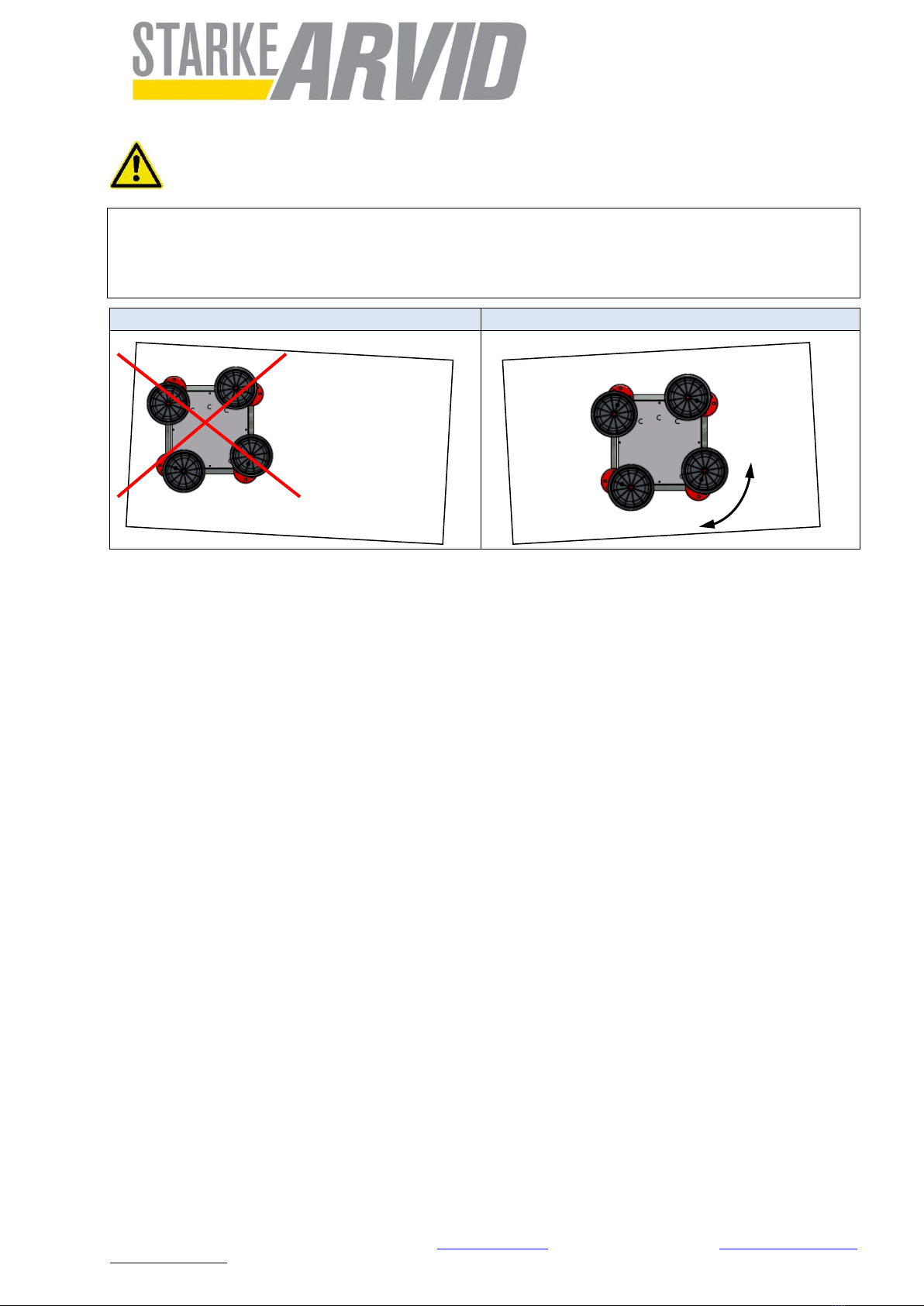

Danger!

-An uneven (A) load distribution is not permitted during rotation!

-Ensure an even (B) load distribution during rotation.

-The surface must be absolutely free of dust, rust particles, water and similar

substances.

A

B

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 19 av 25

Check that all suckers on the surface are clean and have full contact and, if necessary,

press on or align a sucker that is not making contact until it is in the correct position. If this

is not done, a vacuum cannot build up and the Vakuflex 280 can therefore not lift the mate-

rial. Set both manual valves successively to the suction.

Check the vacuum achieved using the two inspection vacuum meters (5.1 / 5.2).

The signal tone indicates insufficient vacuum. The transport procedure can take place with

the pumps switched off as soon as there is -0.7 bar vacuum in each of the two vacuum

circuits, i.e. the control lamps vacuum (4.1 / 4.2, green) light up and the signal tone is off.

-Danger!

-Do not convey loads over persons or machines.

-If the vacuum sinks below -0.65 bar in both or only one of the vacuum circuits dur-

ing transport work, a signal tone sound. In this case, try to set down the load as

soon as possible so that it does not fall down.

The transported goods are guided from the side, which means that the operator stands as

far as possible from the transported goods in order to guide them.

To rotate or swivel (8) the transported goods, use the appropriate locking mechanism. The

transported goods must always be positioned according to the drawing (B). It must also be

ensured that the rotation or swivelling motion can be performed without danger and that no

damage occurs to the transported goods. For larger plate materials, the transported goods

must be supported or held additionally.

To release the transported goods, set both manual valves to RELEASE.

The vacuum decreases and the cross arm is released from the transported goods. If the

two inspection vacuum meters (5.1 / 5.2) indicate 0, the procedure is complete and the

cross arm is released from the transported goods. It can occur that the device remains

stuck to the transported goods only to then release them, which can lead to a small shock

that shakes the transported goods. Therefor hold on tightly to the transported goods during

the release procedure.

Hint!

-If the battery is flat, the device cannot be used in network operation.

i

Starke Arvid AB Tel: +46 522 - 22 000 Fax: +46 522 - 22 344

Lyckåsvägen 3 www.starkearvid.se office@starkearvid.seSe

SE-459 30 Ljungskile

Sida 20 av 25

Switching off

After completing transport work, switch the machine off using the switch (3) to conserve

the battery power.

Charging the battery

Check the device for any external damages or flaws.

Compare the connection on the power supply network with regard to voltage, current, and

mechanical connection (plug connection) with the necessary data for the vacuum pumps If

they do not correspond, the machine may not be operated.

Connect the device to the mains power supply at the plug (9).

The charging procedure can be checked in voltage display.

After the charging procedure is completed, a value of 100% must be visible in the voltage

display when Test button is pushed.

The battery is charged after a maximum of 12 hours.

Remove the extension cable from the mains power supply.

This completes the charging.

Table of contents

Other STARKE ARVID Lifting System manuals

Popular Lifting System manuals by other brands

Hofmann

Hofmann ME1500 Installation and operation manual

Bend-Pak

Bend-Pak HD-14T Installation and operation manual

Garage Smart

Garage Smart MY LIFTER BASIC LIFTER manual

Jacka Industries

Jacka Industries JackaJay user guide

AMGO Hydraulics

AMGO Hydraulics PRO-12SX Installation and service manual

Wahlberg

Wahlberg Winch 10 user manual