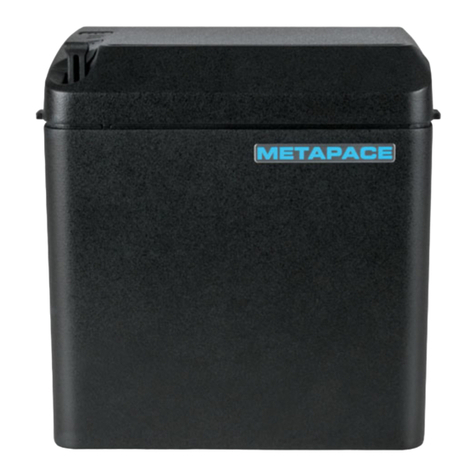

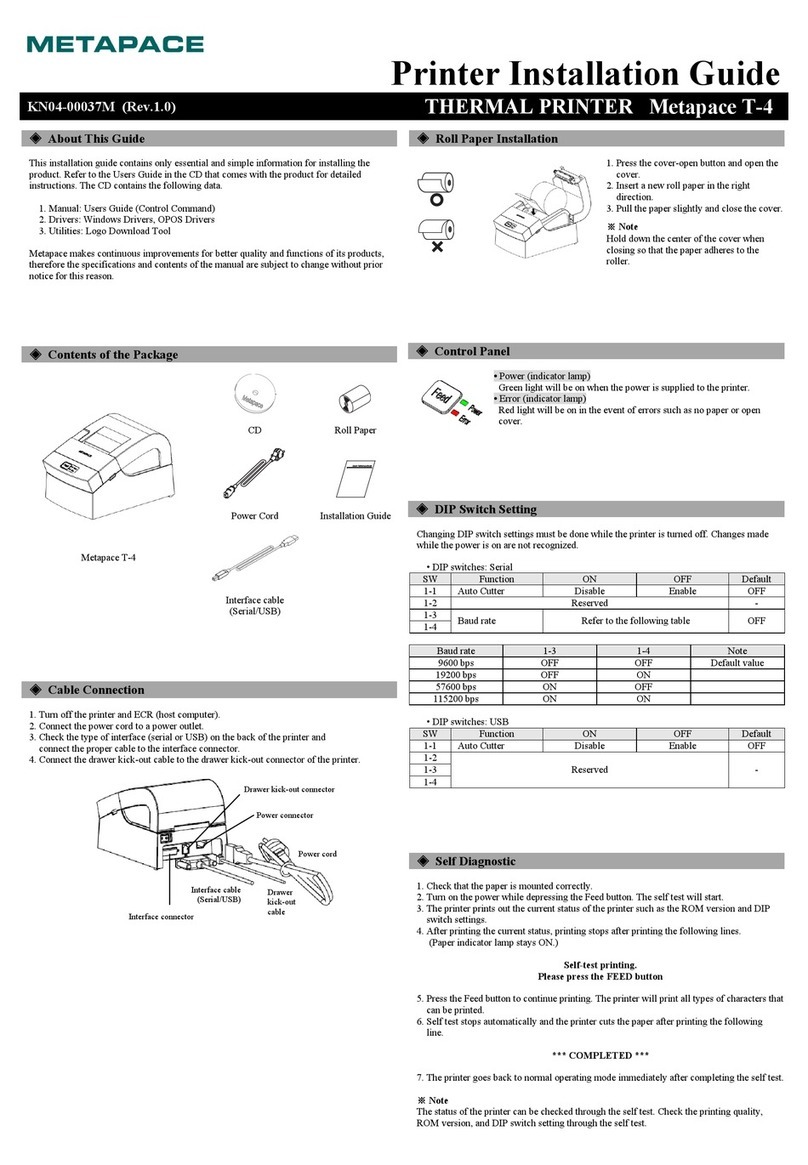

Metapace T-40 User manual

USER’S MANUAL

Thermal Receipt Printer

T-40

T-40 User’s Manual

1

Contents

1Introduction .......................................................................................................................1

1.1 Outline..........................................................................................................................1

1.2 Features .......................................................................................................................1

2Specification......................................................................................................................2

2.1 Technical specification ..................................................................................................2

2.2 Cutter parameters .........................................................................................................3

2.3 Paper specification .......................................................................................................3

2.3.1 Parameters of continuous paper................................................................................3

2.3.2 Parameters of marked paper.....................................................................................4

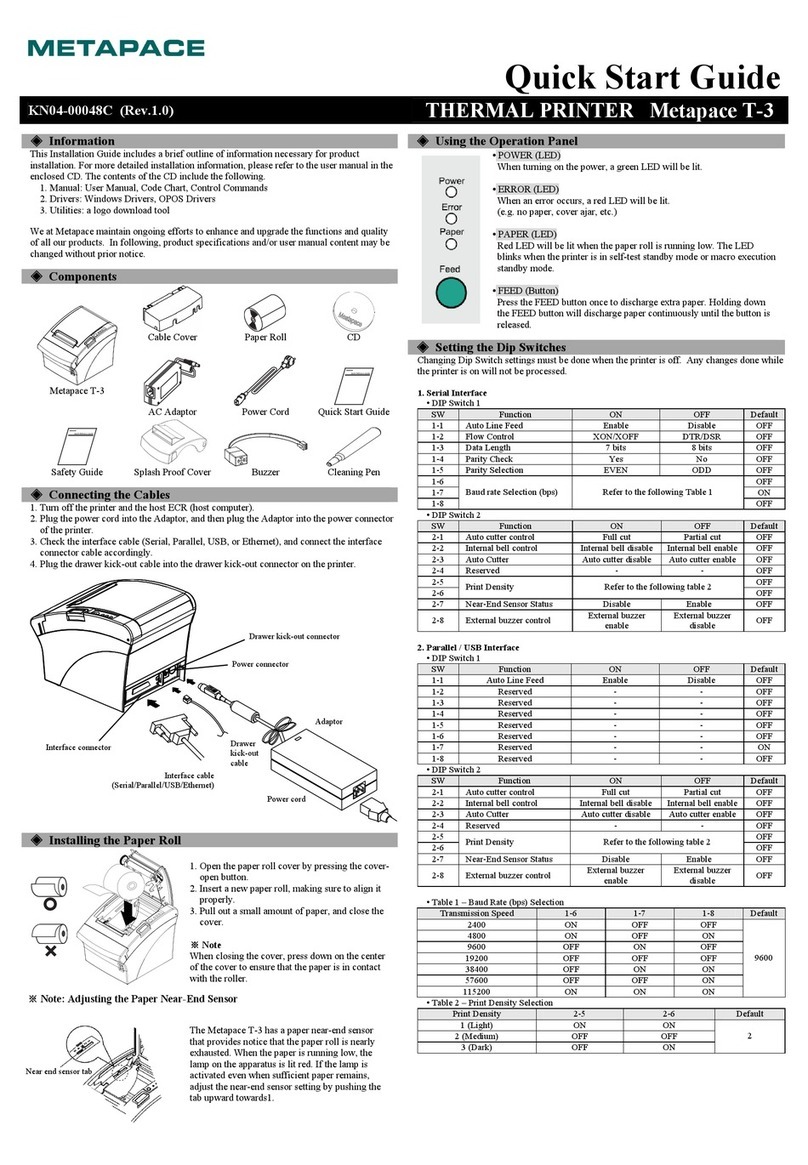

3Appearance and components............................................................................................5

3.1 Appearance and modules..............................................................................................5

3.2 LED and buzzer ............................................................................................................7

4Installation.........................................................................................................................8

4.1 Unpacking ....................................................................................................................8

4.2 Printer installation .........................................................................................................8

4.3 Power and communication interface ..............................................................................9

4.3.1 Power connection .....................................................................................................9

4.3.2 Interface connection .................................................................................................9

4.3.3 USB interface connection..........................................................................................9

4.3.4 Cash drawer connection ...........................................................................................9

4.4 Paper roll installation ..................................................................................................10

4.4.1 Paper type confirmation ..........................................................................................10

4.4.2 Install/replace paper roll .........................................................................................10

4.5 Paper near end position adjustment ............................................................................12

4.6 Power-on and self-test ................................................................................................13

4.6.1 Power-on................................................................................................................13

4.6.2 Print self-test page .................................................................................................13

4.7 Hexadecimal dumping function....................................................................................14

5Routine maintenance.......................................................................................................15

5.1 Cleaning the print head and the platen roller ...............................................................15

T-40 User’s Manual

2

5.2 Cleaning the mark sensor............................................................................................15

5.3 Clearing the jammed paper and the cutter error ...........................................................15

6Interface signal................................................................................................................16

6.1 Serial interface ...........................................................................................................16

6.2 Parallel interface.........................................................................................................16

6.3 USB interface .............................................................................................................18

6.4 Ethernet interface .......................................................................................................18

6.5 Double communication interface..................................................................................19

6.6 Power interface definition............................................................................................20

6.7 Cash drawer interface signal definition ........................................................................20

7Troubleshooting ..............................................................................................................22

7.1 Printer doesn’t work ....................................................................................................22

7.2 Error LED and buzzer alarm ........................................................................................22

7.3 Problems during printing .............................................................................................22

8Power management .........................................................................................................23

9DUMP mode .....................................................................................................................24

Appendix Button configuration ...........................................................................................25

T-40 User’s Manual

1

1 Introduction

1.1 Outline

T-40 is developed for high-end thermal receipt printing market, which is widely used.T-40 can

be connected with other devices via serial, parallel, USB, Bluetooth, Ethernet and WLAN. It

provides drivers for operation systems such as Windows 2000 / XP /Server 2003 / Vista /

Server200 / Win7 / Win8 /Win8.1 / Win10/Server 2012, POSReady2009 / POSReady7, Linux,

Mac and UPOS middleware.

Note: Windows and Linux drivers support 64-bit operation system.

1.2 Features

ØLow noise, high printing speed;

ØSupport continuous paper, marked paper;

ØSupport paper saving, water mark, upside-down, two-color printing, etc.;

ØCompact size, can output paper from the front or the top according to users’ different

demands;

ØRich interfaces: USB(fix on board), expandable serial / parallel / Ethernet / Bluetooth / WIFI /

serial + Ethernet interface;

T-40 User’s Manual

2

2 Specification

2.1 Technical specification

Item

Parameter

Printing

Print method

Direct thermal line printing

Resolution

203 ×203 DPI; 203 ×180 DPI

Paper width

57.5/80/82.5 mm

Print width

Max.80 mm

Print speed

Max.250 mm/s

Flash LOGO

Max. 1M bytes

Command buffer area

64K bytes, 4K bytes or 45 bytes

Interface

USB

USB 2.0 (full speed)

Serial interface

RS-232C

Parallel interface

IEEE1284

Ethernet interface

10/100BASE-T

Cash drawer

Can select to controlling 1~2 cash drawers

Memory

RAM: 2 MB, Flash: 4 MB

Printer status detection

Paper end sensor/ black mark sensor;

Paper near end sensor;

Cover position sensor;

Paper presence sensor

Print head temperature sensor;

Printer voltage detection

Cut mode

Full cut, partial cut

Barcode

1D

UPC-A, UPC-E, CODE 39, CODE 93, CODE 128, EAN8, EAN13,

ITF, CODABAR

2D

PDF417, QR, Maxicode

Fonts

Font A: 12 ×24

Font B: 9 ×17

Kanji font A: 24 ×24

Character set

95 Alphanumeric

14 types of international characters

128 x 68 code page

Optional: Traditional Chinese, Simplified Chinese

(GB2312/18030), Japanese, Korean, English, HK

User-defined font (95) & code page

Character enlargement

All characters can be enlarged 1-6 times horizontally and vertically

Character rotation

Rotation printing in four directions (0°, 90°, 180°, 270°)

Command

ESC/POS compatible

Paper

Paper type

Thermal continuous paper

Thermal marked paper

Paper roll OD

Max. 83 mm

T-40 User’s Manual

3

Paper thickness

0.06 mm~0.10 mm thermal paper

Power

supply

Input

100-240V AC, 50-60 Hz

Output

24V ± 5% DC, average current 2A

External or not

External power adapter

Human-machine

interface

Power switch

Support

Button

Support

LED

Support, including POWER LED and ERROR LED

Buzzer

Support, 24V buzzer

Reliability

Lifetime of print head

≥150Km (standard test sample with 12.5% duty ratio)

Lifetime of cutter

2,000,000 cuts (standard test condition)

MCBF

70,000,000 lines

MTBF

360,000 hours (main control board)

Operation temperature and humidity

5°C~45°C,20%~90% RH(40°C)

Storage temperature and humidity

-40°C~60°C,10%~90% RH(40°C)

Overall dimensions

127mm(L)*127mm(W)*134mm(H)

Functions

Saving paper

Support

Button configuration

Support (configure the printer without computer)

Right-up-side printing

Support

Water mark printing

Support

Gray scale printing

Support

Table 2.1-1 Technical specifications

2.2 Cutter parameters

Item

Parameter

Remarks

Cutting method

Sliding blade

Cutting time

500 ms

The time of one cut

Cutting interval

3 s

20 cuts/minute (Max.)

Applicable paper types

0.06 mm~0.10 mm thermal paper

Operation voltage

24V DC

Max. operation current

1.2A

Operation voltage 24V DC

Cutter lifetime

2,000,000 cuts

Standard test condition

Table 2.2-1 Technical parameters of cutter

2.3 Paper specification

2.3.1 Parameters of continuous paper

ØPaper type: thermal paper

ØPaper supply mode: paper roll

ØPaper width: 57.5/80/82.5 mm

ØPaper thickness: 0.06 mm-0.10 mm

ØThermal layer: outward

ØPaper roll specification: paper roll OD Max ф83 mm, core ID Min. ф12.8 mm

T-40 User’s Manual

4

ØPaper recommended:

Paper model

Manufacturer

600-3.1

APPLETON Papers Inc

KLS_46_e

KANZAN Spezialpapiere GmbH

FD210

OJI Paper CO., LTD.

Table 2.3-1 Recommended thermal paper model

2.3.2 Parameters of marked paper

T-40 can support marked paper printing and set the cutting and initial printing position

accurately. The marked paper not only should meet the specifications of thermal paper roll, but

also should meet the following requirements:

ØL1 mark height: 3 mm≤L1≤13 mm

ØL2 mark length: L2≥8mm

ØL3 distance between two marks: 30 mm≤L3<450 mm

ØThermal side mark sensor position: reserved the left/middle/right positions

ØNon-thermal side mark sensor position: the middle/left/right position is selectable

ØReflectivity: The reflectivity of the black mark must be no more than 15% while the reflectivity

of the paper itself should exceed 85%. There should be no image between the two marks,

such as the advertisement, etc.

Caution:

²Please use the recommended paper or its equivalents. Using the paper of low quality might

affect the print quality and shorten the lifetime of print head;

²Do not stick paper onto the core shaft;

²If the paper is contaminated by chemical or oil, it may discolor or lose heat sensitivity at the

polluted spot, which will affect the print affect;

²Do not rub the paper surface with hard objects, otherwise it may affect the print affect;

²When the environment temperature goes up to 70℃, paper will discolor. Thus don not use or

store paper under high temperature, high humidity and strong light conditions.

²The mark is measured during printing and paper feeding. If the mark height value detected

by the sensor is bigger than the default value (default setting is 13mm), the printer will alarm

paper end.

T-40 User’s Manual

5

3 Appearance and components

3.1 Appearance and modules

Fig. 3.1-1 Schematic drawing of appearance and modules

1—Top cover

2—Cutter

3—Platen roller

4—Paper end sensor

5—Paper guide

6—Micro switch

7—Cutter cover

8—Middle cover

9—Cover open spanner

10—Paper cabinet

11—Paper near end sensor

12—FEED button

13—ERROR LED

14—POWER LED

15—POWER button

16—USB

17—Power interface

18—Communication interface

19—Cash drawer interface

Button and component function:

a FEED button (12)

ØFeed paper:

Printer will feed paper when the feed button is pressed down under normal condition. To

feed paper continuously, keep pressing the button.

ØPrint configuration sample:

Pressing down the feed button while turning on the power, the printer will print out the

configuration sample, which includes print width, print speed, etc.

ØEnter button configuration mode:

Press down the feed button while turning on the power, the printer will print out the

configuration sample, and enter pause status (error LED flashes) after cutting paper.

Keep pressing the feed button at this time, the printer will enter button configuration mode.

ØPress the button to clear the cutter error:

Press the button for a short time when a cutter error occurs, the printer will try to clear the

cutter error automatically.

b Error LED (13)

Indicate printer status. Under normal status, the error LED is off. Under error status (e.g.

paper end, etc.), the error LED flashes.

c Power LED (14)

Indicate printer power status (ON/OFF).

d Power button (15)

T-40 User’s Manual

6

Press the button to connect power; press the button for a long time to disconnect the power.

e Top cover status detection sensor (14)

Detect the printer cover status (open/closed).

f Paper presence sensor (12)

Detect the paper presence / absence status when continuous paper is used; detect the

paper marks when marked paper is used.

g Spanner for adjusting paper near end sensor(7)

Detect the paper roll status. Fast flashing of error LED indicates that the paper will be used

out soon and the user should replace the paper roll in time. Printer will work normally until

paper is used out.

h Paper guide (5)

Adjust the position of paper guide in the cabinet to adapt to different paper widths between

58/80mm. When the paper guide is removed, the printer can adapt to 82.5mm paper width.

T-40 User’s Manual

7

3.2 LED and buzzer

1) Functions of LED

LED name

Status

Description

Power LED

(green)

Always on

Printer power is on.

Off

Printer power is off.

Error LED

(red)

Off

Printer is in normal status.

Flash

Printer is in error status or paper near end status.

Buzzer

Beep

Printer is in error status.

Table 3.2-1 Functions of LED

2) Error type indicated by LED & buzzer

Error Type

Error LED

Buzzer

Print head is overheating

Cycle flash 6 times

Cycle beep 6 times

Printer voltage is abnormal

Cycle flash 5 times

Cycle beep 5 times

Cutter error

Cycle flash 4 times

Cycle beep 4 times

Print head lift-up

Cycle flash 3 times

Cycle beep 3 times

Paper end

Cycle flash 2 times

Cycle beep 2 times

Paper near end

Cycle flash slowly

No beep

Cannot find mark or mark calibration error

Cycle flash slowly

No beep

Table 3.2-2 LED and indication information

Caution:

²The temperature of the print head is detected by a thermal resistor. If the print head is

overheating, the protective circuit will shut off the power automatically and force the printer

to stop printing; the temperature of print head when printing is stopped is 65℃.

T-40 User’s Manual

8

4 Installation

4.1 Unpacking

Check whether all items, which are listed on the packing list, are present and in a good

condition. If any item is damaged or missing, please contact your dealer or the manufacturer.

4.2 Printer installation

1) T-40 supports two working methods: out put the paper from the front or the top when place

the printer horizontally on the table. When the printer is placed horizontally on the table,

the incline installation angle should not exceed 5°, otherwise the paper near end sensor

will not work normally.

Fig. 4.2-1 Horizontally on the table (paper output from the front)

Fig. 4.2-2Horizontally on the table (paper output from the top)

2) Keep the printer far away from water source;

3) Do not place the printer in the place exposed to vibration and impact;

4) The printer power must be safely grounded;

5) It is recommended to keep proper space in order to guarantee the reliability and

operational convenience of the printer during operation and maintenance.

Fig.4.2-3 Printer maintenance and operation space

T-40 User’s Manual

9

4.3 Power and communication interface

4.3.1 Power connection

1) Ensure that the power switch is turned off;

2) Insert the power plug into the corresponding socket on the back of the printer.

Caution:

²When the printer is not in use for a long period of time, disconnect the power cord from the

printer.

4.3.2 Interface connection

1) Ensure that the power switch is turned off;

2) Plug the connector into corresponding port and fix it with screw or spring as shown in the

figure;

3) Connect the other end of cable to the host.

4.3.3 USB interface connection

1) Ensure that the power switch is turned off;

2) Plug the USB cable into corresponding interface in place as shown in the figure;

3) Connect the other end of USB cable to the host.

4.3.4 Cash drawer connection

T-40 User’s Manual

10

1) Ensure that the power switch is turned off;

2) Plug the cash drawer cable into the cash drawer interface which locates at the back of

printer.

Caution:

²The cash drawer interface is used to connect the cash drawer only (cannot connect with

phone wire, etc.).

4.4 Paper roll installation

4.4.1 Paper type confirmation

After connecting the power cord and interface cable, confirm paper type after media installation

before printing.

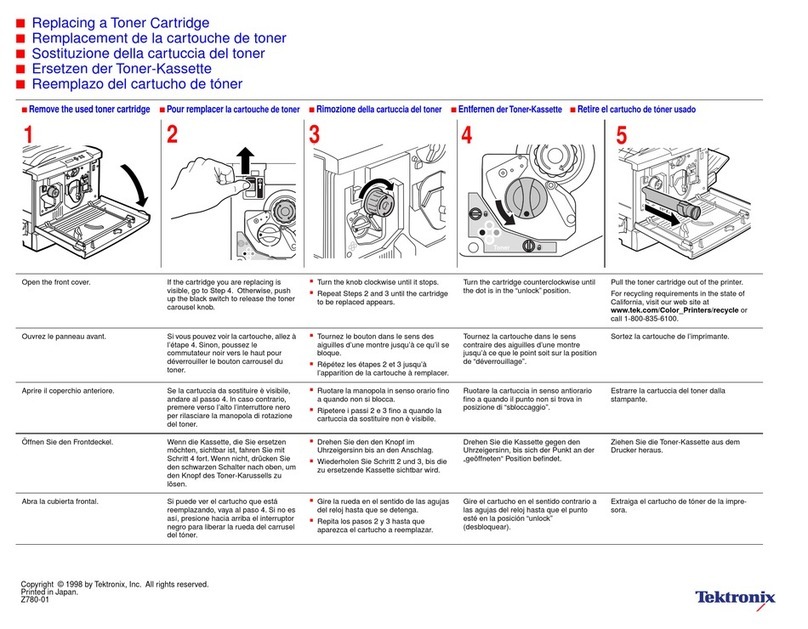

4.4.2 Install/replace paper roll

1) Turn off the printer;

2) Push the spanner in the direction shown in the Fig. to open the top cover;

3) Place the paper roll into the printer;

4) Close the top cover.

Fig. 4.4-1 Schematic drawing of paper roll installation/replacement

Fig. 4.4-2 Schematic drawing of paper roll installation/replacement

Caution:

²Adjust the paper guide according to the paper specification: install the paper guide at the

position of 57.5 for 57.5 wide paper roll; install the paper guide at the position of 80 for 80

wide paper roll; and remove the paper guide for 82.5 wide paper roll. Pay attention that the

winding direction of paper roll should meet printer requirements. Remove the end in

operation hole firstly when disassemble the paper guides, and install the end in operation

hole firstly when install the paper guides;

图7

图8

图7

T-40 User’s Manual

11

Fig. 4.4-3 Failure model

²Ensure that the paper roll is tightly wound; otherwise paper jam or other failure may occur

(eg. Fig.4-3 Failure model );

²Paper roll should be placed stably in the paper cabinet without incline, or the printing will be

affected.

Fig.4.4-4 Position of 57.5 Fig. 4.4-5 Position of 80

Fig. 4.4-5 Operation hole

T-40 User’s Manual

12

4.5 Paper near end position adjustment

Fig. 4.5-1 Schematic drawing of paper near end position adjustment (output paper from the front)

Fig. 4.5-2 Schematic drawing of paper near end position adjustment (output paper from the front)

T-40 User’s Manual

13

The following diameter of core shaft of paper roll supported by the printer are as following: OD

of 16.2mm core shaft and OD of 20.8 mm core shaft; adjust the paper near end sensor to adjust

the application method and paper near end alarm function for core shaft with different outer

diameters. There are four positions indicated by the scale marks for paper near end alarm, and

users can rotate the paper near end adjustment spanner to make the indication line locate at

different position, which change the paper near end alarm functions under different application

conditions. The position 1 and 2 are for the application that output paper from the top, position

1 is for 16.2 mm core shaft of paper roll and position 2 is for 20.8 mm core shaft of paper roll.

The position 3 and 4 are for the application that output paper from the front, position 3 is for

20.8 mm core shaft of paper roll and position 4 is for 16.2 mm core shaft of paper roll.

Fig. 4.5-3 core shaft of paper roll

4.6 Power-on and self-test

4.6.1 Power-on

1) Ensure that the printer is connected to power;

2) Turn on the power switch to power on the printer.

4.6.2 Print self-test page

1) Ensure that the printer is connected to power, and that paper roll is installed;

2) Ensure that the power LED is off and the printer is under power-off condition.

3) Press the feed button while turning on the printer power, and then release the button. The

printer will print out configuration information and prompt characters “Press and Release

FEED key to print characters” and “Press and Hold FEED key to config the printer”. Then

the printer enters pause status, and the error LED flashes;

T-40 User’s Manual

14

4) Pressing the feed button momentarily, the printer will print out a character test sample, and

the printing of self-test page is completed. Pressing the feed button for a long time, the

printer will enter button configuration mode.

4.7 Hexadecimal dumping function

After entering Hexadecimal dumping mode, the printer will print out the data transmitted from

the host computer in hexadecimal and their corresponding ASCII characters.

The sample printed under Hexadecimal dumping mode is as follows:

Fig. 4.7-1 Print sample under Hexadecimal dumping mode

Using Hexadecimal dumping mode:

1) Entering Hexadecimal dumping mode in the following ways:

a. Open the printer mechanism and turn on the printer while pressing the feed button.

Release the button after the printer alarms (LED flashes and buzzer beeps).

b. Send command “GS ( A”.

2) The printer first prints "Hexadecimal Dump To terminate …..", and then prints the data

transmitted from the host in hexadecimal and their corresponding ASCII characters.

3) Exiting from Hexadecimal dumping mode in the following ways:

a. Turn off the power, and then restart the printer.

b. Press the feed button three times.

Caution:

²If the hexadecimal data has no corresponding ASCII characters, the printer will print ".";

²Under Hexadecimal dumping mode, only commands DLE EOT, DLE ENQ, or DLE DC4 are

valid.

²The data of the last character line can be printed by pressing down the feed button.

图7

图8

图7

T-40 User’s Manual

15

5 Routine maintenance

Caution:

²Before starting routine maintenance, ensure that the printer power is turned off.

²Do not use organic solvents like gasoline or acetone.

²When cleaning sensors, do not turn on the printer power until the pure alcohol has

completely evaporated.

²It is recommended that the maintenance cycle should not be longer than one month.

5.1 Cleaning the print head and the platen roller

Follow the steps below to clean the print head and the platen roller:

1) Turn off the printer and open the top cover;

2) If the printing was just finished, please wait for the print head to cool down completely;

3) Wipe off the dust and stains on the surface of print head and platen roller with alcohol cotton

(it should be wrung out);

4) After the alcohol is completely evaporated, close the top cover.

5.2 Cleaning the mark sensor

When the printer cannot identify the mark effectively, the mark sensor should be cleaned.

The cleaning steps are as follows:

1) Turn off the printer;

2) Press the cover open lever to open the top cover;

3) Wipe off the dust and stains on the surface of the sensor with soft cotton cloth dipped with

pure alcohol (it should be wrung out);

4) Install the sensor cover after the pure alcohol is completely evaporated, then close the top

cover and finish mark sensor cleaning.

5.3 Clearing the jammed paper and the cutter error

Steps for clearing jammed paper and cutter error are as follows:

Method 1:

1) Turn off the printer power and turn the spanner to open the top cover;

2) Clear the jammed paper, and then close the top cover;

3) Turn on the printer power again, and then the cutter can be reset automatically.

Method 2:

1) Turn off the printer power, disassemble the cutter cover in the direction shown in the figure,

and turn the spanner to open the top cover;;

2) Clear the jammed paper, close the paper cabinet and turn on the printer power again, and

then the cutter can be reset automatically.

3) Install the cutter cover.

T-40 User’s Manual

16

6 Interface signal

6.1 Serial interface

The serial interface of the printer is compatible with RS-232 standard, and its interface socket

is D-SUB25 socket.

Pin

Signal

Signal definition

Function

1

FG

—

House ground

2

TXD

Output

Data output

3

RXD

Input

Data input

5

NC

—

Not connected

6

DSR

Input

Data device is ready

7

SG

—

Signal ground

8-19

NC

—

Not connected

4,20

DTR

Output

Require to send

21-25

NC

—

Not connected

Fig. 6.1-1 Serial interface definition

User can query interface setting status via printing configuration sample. The default settings of

serial interface are as follows:

Baud rate: 115200bps; Data bits: 8; Parity: none; Stop bit: 1; Handshake: DTR/DSR.

6.2 Parallel interface

The parallel interface can work in IEEE 1284 compatible mode or nibble mode. The interface is

36PIN socket.

Interface definition:

Pin No.

Signal source

Signal definition

1

H

nStrobe

2

H

Data 0 (Least Significant Bit)

3

H

Data 1

4

H

Data 2

5

H

Data 3

6

H

Data 4

7

H

Data 5

8

H

Data 6

9

H

Data 7 (Most Significant Bit)

10

P

nAck

11

P

Busy

12

P

Perror

13

P

Select

14

H

nAutoFd

15

Not defined

16

Logic Gnd

17

Chassis Gnd

18

P

Peripheral Logic High

19

Signal Ground (nStrobe)

20

Signal Ground (Data 1)

T-40 User’s Manual

17

21

Signal Ground (Data 2)

22

Signal Ground (Data 3)

23

Signal Ground (Data 4)

24

Signal Ground (Data 5)

25

Signal Ground (Data 6)

26

Signal Ground (Data 7)

27

Signal Ground (Data 8)

28

Signal Ground (PError, Select, and nAck)

29

Signal Ground (Busy and nFault)

30

Signal Ground (nAutoFd, nSelctIn, and nInit)

31

H

nInit

32

P

nFault

33

Not defined

34

Not defined

35

Not defined

36

H

nSelectIn

36

H

nSelectIn

²H stands for the host and P stands for the printer;

²The letter “n” in front of signal name indicates that the low level is effective;

²In data transmission, the host should not ignore “Busy” signal; otherwise print data may be

missing;

²If the host cannot provide all the signal lines listed in the table above, the communication

may fail;

²Parallel interface signal adopts TTL level; the rise and fall time of the signal from the host

must be controlled within 0.5s when it is used;

²For the interface, the signal line should use twisted pair with feeder line end, with the

feeder line end connected to signal ground;

²The parallel interface connecting wire should be as short as possible on condition that it

meets the use condition.

Other manuals for T-40

1

Table of contents

Other Metapace Printer manuals

Metapace

Metapace T-1 User manual

Metapace

Metapace T-2 Installation instructions

Metapace

Metapace T-1 Installation instructions

Metapace

Metapace T-1 Installation and operation manual

Metapace

Metapace T-311 User manual

Metapace

Metapace T-3 User manual

Metapace

Metapace T-3II User manual

Metapace

Metapace T-3 User manual

Metapace

Metapace T-3II Installation and operation manual

Metapace

Metapace T-4 User manual