Metasys H1 Installation instructions

Hygienesystem

H1

Gerätedokument

Einbau, Betrieb und Wartung

Hygiene system

H1

Equipment Logbook

Assembly, operation and maintenance

Systeme d’hygiene

H1

Livret d’appareil

Installation, fonctionnement et entretien

Sistema d’igiene

H1

Verbale d’installazione

Montaggio, funzionamento e manutenzione

H

1

1

EN

EN

2

1. Index

The header on each page defines the user group particular information is

aimed at.

Chapter Page

1. Index 2

2. Explanation of the pictograms 2

3. General information 3

4. Product description 4

5. Explanation of the type plate 4

6. Technical data 4

7. Installation requirements 5

8. Modular assembly 6

9. Functional description 7

10. Cleaning cycles 9

11. Hygiene System H1 - maintenance 10

12. Hygiene System H1 - control panel 11

13. Electronic circuit board 12

14. Inspections 14

15. Cleaning and disinfection 14

16. Re lling the H1 cartridge 15

17. Disposal 15

2. Explanation of the pictograms

iInformation

Caution!

General warning sign

Refer to instruction manual/booklet

Index Explanation of the pictograms

Practice personnel, technicians

3

EN

3. General information

The safety, reliability and performance of the appliance is

only guaranteed by METASYS if the following instructions are

observed:

Assembly, alterations or repairs may exclusively be carried out

by authorized service personnel in compliance with EN Standard

60601-1 (International Standard for Medical Electrical Apparatus, in

particular Part 1: General Rules for Safety).

The electrical installation must comply with the regulations of the IEC

(International Commission for Electrical Engineering).

The apparatus must exclusively be used in conformity with the

instructions for installation, operation and maintenance.

Only original parts may be used for repairs or replacements.

All the guidelines provided by the manufacturer on the correct use of

the Hygiene system H1 must be followed.

All inspection and service work must be entered into the device docu-

mentation at the rst pages of this manual

When requested by an authorized engineer, METASYS agrees to make

all documents available for the use of technically qualied service

personnel.

METASYSacceptsnoresponsibility for damagescaused due toexternal

factors, such as wrong installation, improper use of the apparatus or

unauthorized technical intervention.

Users must study equipment and assure themselves of its good

condition before every use.

When the apparatus is dismantled at the end of its service life, it must

be disposed of properly.

General information

Practice personnel, technicians

1

2

2.1 2.5

2.2 2.3 2.4

EN

4

Product description Explanation of the type plate Technical data

Practice personnel, technicians

4. Product description

The Hygiene System H1

1 provides automatic and continuous

cleaning, disinfection, defoaming and deodorisation of the entire suction

system during operation, with integrated selective function of the suction

hoses.

The system can be retrotted with a tube holder for two suction hoses and

two extra retainers with selectable conguration.

5. Explanation of the type plate

2 See illustration

2.1 Serial number

2.2 Address of the manufacturer

2.3 Mains supply data

2.4 Protection class II

2.5 Type BF sign

6. Technical data

Permissible water pressure 2-4 bar (working pressure: 2 bar)

Water connection PU tube, nominal width 2 mm,

external Ø 4 mm

Voltage 24 V AC

max. current consumption 450 mA

Frequency 50/60 Hz

max. power consumption 11 VA

Volume of the H1 cartridge 125 ml (pouch: 500 ml)

Suction system wet or dry vacuum pump

Permissible vacuum 100 mbar - 250 mbar

Dimensions (H x W x D)

128 x 132 x 95 mm

(excl. housing and suction tube

holder)

Space requirements (H x W x D)

180 x 260 x 110 mm

(excl. housing and suction tube

holder)

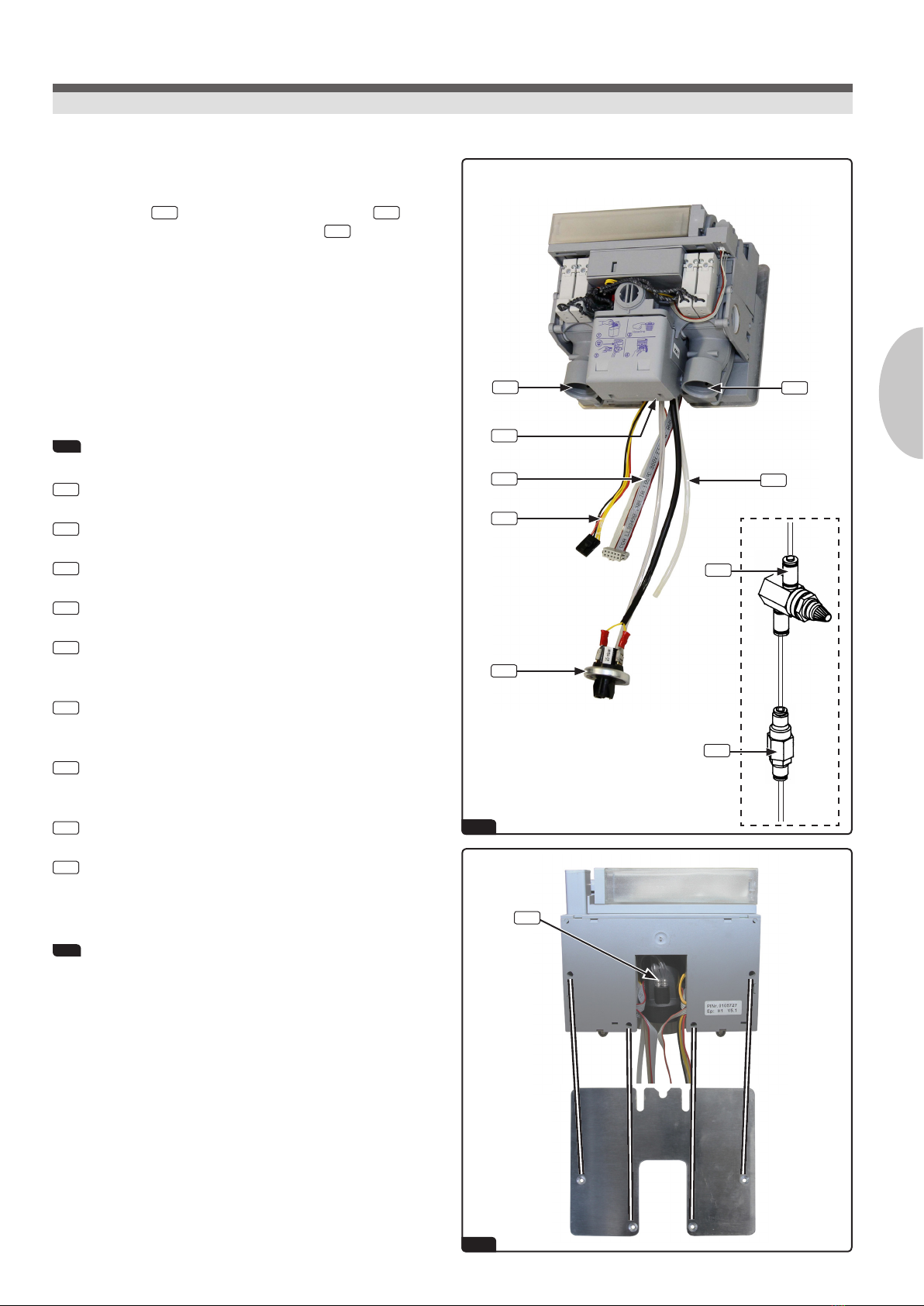

3

4

3.1

3.3

3.1

3.5

3.6

3.2

3.4

3.8

3.9

3.7

5

EN

Installation requirements

Practice personnel, technicians

7. Installation requirements

A water lter 3.9 (40 µm) and a pressure regulator 3.8 (2 bar)

must be attached to the mains water supply 3.7 (included in the

scope of delivery).

The underpressure may not exceed 250 mbar at the cannula.

Voltage to terminal X2 must be 24 V AC.

The manufacturer‘s regulations regarding the installation of particular

units must be adhered to.

3 See illustration

3.1 Suction line

3.2 Suction hose 1

3.3 Suction hose 2

3.4 Vacuum switch

3.5 Connection cable (4- and 6-pole)

(control unit, support signal)

3.6 Voltage 24 V AC (red/black)

start signal for suction system (yellow)

3.7 Mains water supply

PU tube, nominal width 2 mm, external Ø 4 mm

3.8 Pressure regulator

3.9 Water lter

4 Fastening on the rear, see illustration

5

6

7

8

9

PUSH

LRH2OGREEN&CLEAN H1

4312

EN

6

Modular assembly

Technicians

8. Modular assembly

To ensure maximum serviceability and to allow variations in assembly, the

Hygiene System H1 consists of ve modules:

5 Module 1: H1 cartridge &adapter plate or connection of pouch

The exchangeable H1 cartridge contains the disinfectant supply for an

approx. 12-15 hours of suction time and is simply slid onto the adapter

plate.

6 Module 2: H1 valve block, double membrane pump &DVGW (air gap)

container

The valve block, in combination with the double membrane pump, is

the heart of the Hygiene System H1. It determines the ratio of water to

disinfectant, dispenses the cleaning agent to the respective handpiece

and controls the elbow closure pieces.

In order to prevent any backow of process water into the drinking water

network, the fresh water is taken from a container with free outlet (per

DVGW).

7 Module 3: Filter housing, elbow closure pieces &suction tubes

The lter housing contains a removable non-drip rake.

The elbow closure pieces (one per suction tube) serve as locking devices

for the suction ow and in order to interrupt the supply of disinfectant if

vacuum pressure drops. They are rotatably hung and form the connection

of the suction tubes which are tted with a thin inner tube that supplies

the cleaning agent to the handpiece. The power of the suction ow can be

adjusted with the regulator on the lter housing.

8 Module 4: Electronic circuit board &housing

The circuit board housing serves as a protection of the electronic circuit

board. This forms the central control unit for the Hygiene System H1.

9 Module 5: Control panel

The control panel displays the main operating states and can be mounted

where desired or as part of the METASYS suction tube holder.

For a more detailed description, refer to page 11.

10

12a 12b

11

H2O

GREEN&CLEAN H1

oH2O IN Suction GREEN&CLEAN H1

Knieverschluss 2

1 2

4

3

6

5

8

9

10

11

7

A

B

C

LRH2O

7

EN

Functional description

Technicians

9. Functional description

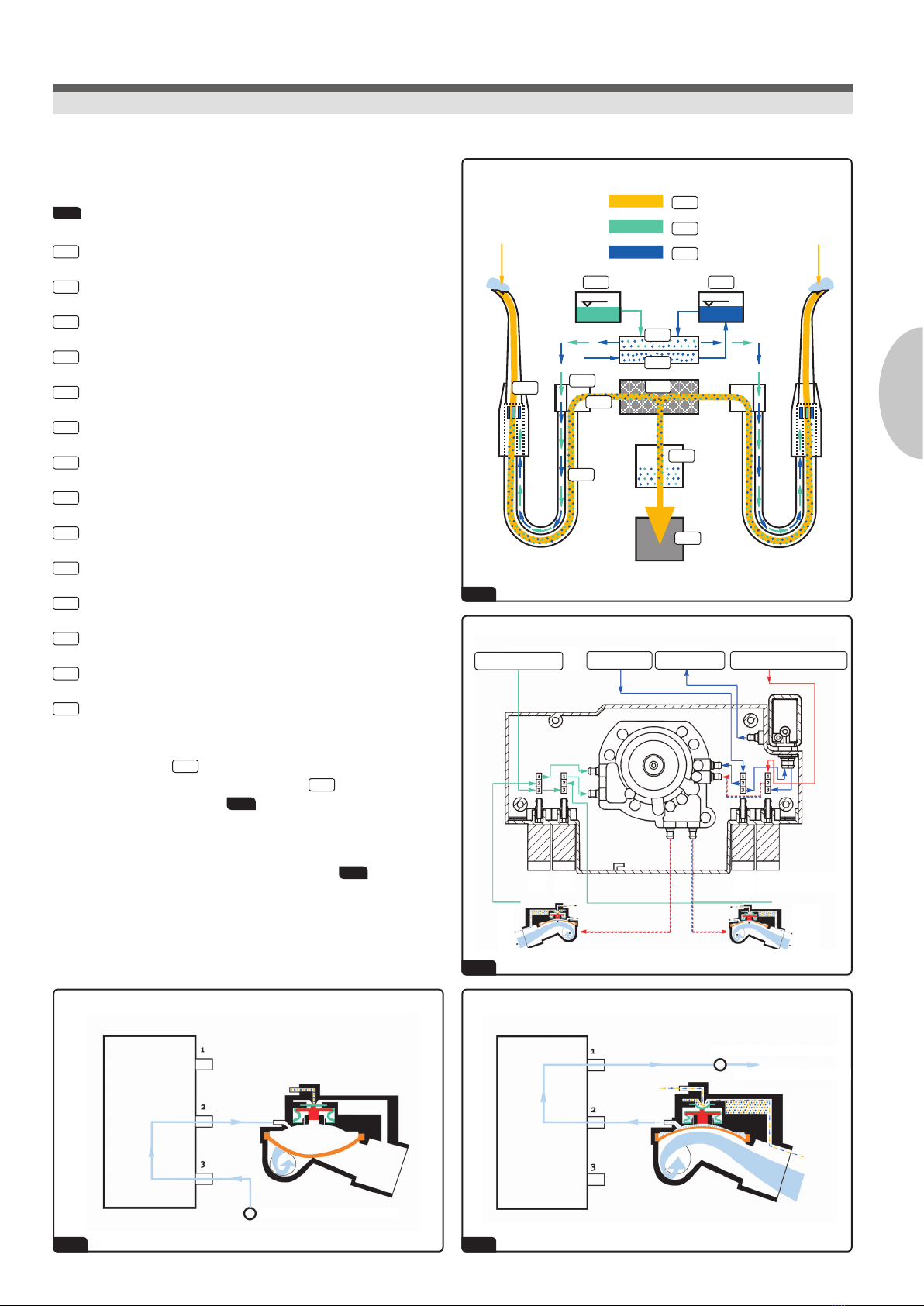

10 Function diagram, see illustration

ASuction ow

BDisinfectant GREEN&CLEAN H1

CWater

1H1 cartridge or pouch

2DVGW container (water)

3Double membrane pump

4Pump chamber

5Suction ow closure

6Chemical closure

7Filter housing

8Handpiece

9Suction tube with inner tube

10 Amalgam separator or automatic separator

11 Suction system

Lifting the handpiece 8of a suction hose results in a vacuum causing

the respective suction ow sealing membrane 5to be opened by an

associated solenoid valve (L/R) 12a .

The suction ow seal is designed as a pipe elbow and as such it is highly

streamlined and is also insensitive to contaminants 12b . The cleaning

cycles start at the same time as the suction process.

16

13

14

15

EN

8

9. Functional description

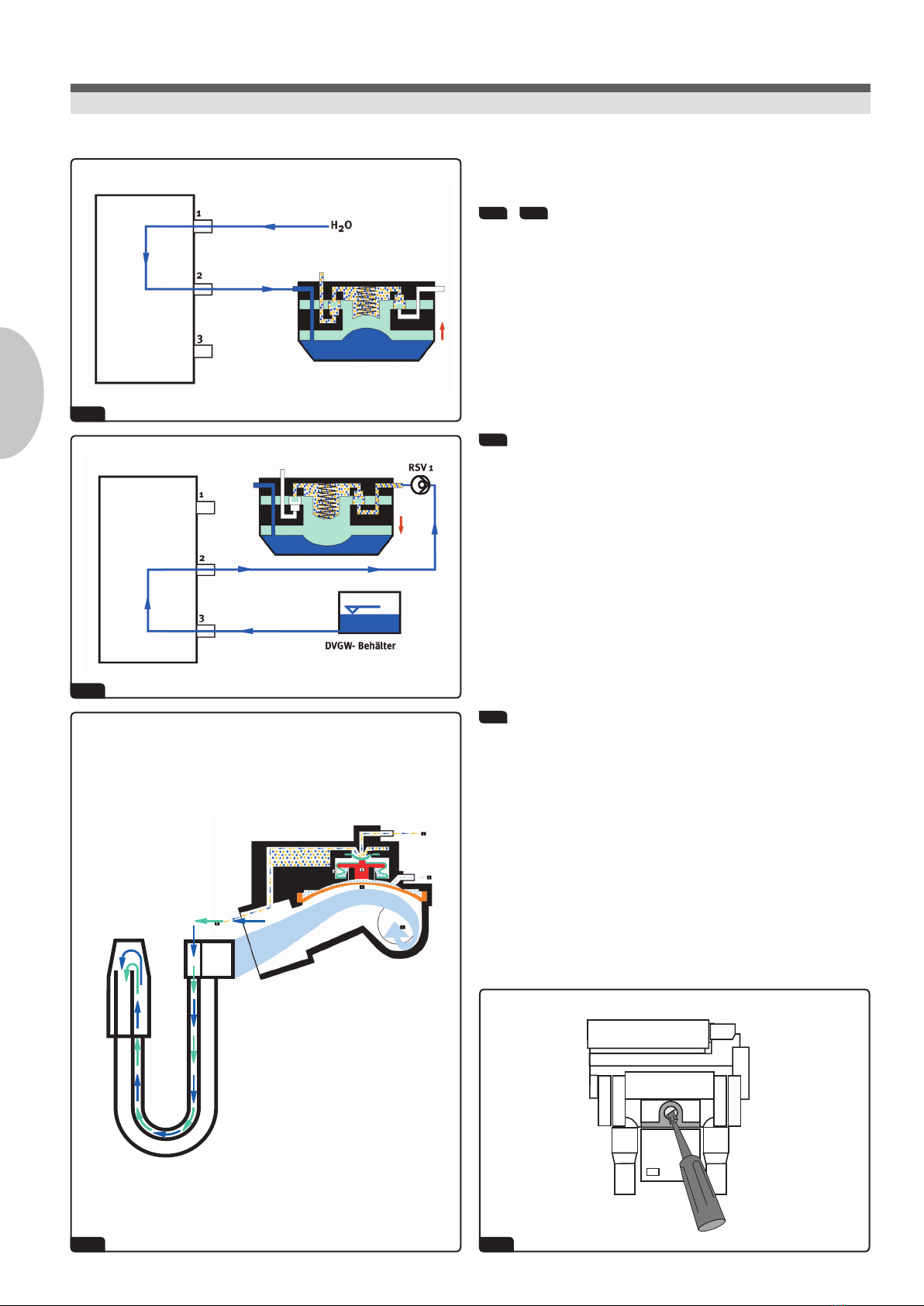

13 + 14 See illustration

Water is drawn out of the DVGW container, or GREEN&CLEAN H1 is drawn

out of the cartridge or pouch by means of a water pressure-driven

double membrane pump.

15 See illustration

Once drawn off, the disinfectant is pumped through the knee sealing

membrane and through lines in the suction hoses to the handpiece in

use.

The cleaning mixture is then distributed evenly over the inner surface of

the suction tube by the suction ow and thus ensures optimal cleaning

and disinfection of the whole suction system.

16 Adjusting the suction ow rate, see illustration

The suction ow rate can be adjusted by a regulator above the lter cup.

A screwdriver or a coin may be used to adjust the regulator.

Please observe the markings on the regulator!

Functional description

Technicians

17

PUSH

9

EN

10. Cleaning cycles

A cleaning cycle only takes place with suction. As the vacuum decreases,

the ongoing pumping of the cleaning medium is interrupted.

17 Initial cleaning, see illustration

Initial cleaning at the start of each treatment stage. This program is

activated by switching on the main device switch on the treatment

unit. The increased disinfectant dosing creates the ideal starting

prerequisites for the pending treatments with respect to defoaming

and blood solution.

The valve sequence (H1 disinfectant) with 10 x H2O or 2 x H1, 10 x H2O

per suction hose is shown ashing on the external display.

Sequence: 10 / 2 / 10 per hose

The program duration is 1 min 5 sec per suction hose.

18 Normal operation

takes place with a raised suction hose

Sequence: 1 x H1 / 413 x H2O / 1 x H1 per hose

This sequence is halted with an interruption to the suction operation

and is continued when the suction operation resumes or starts anew.

19 Special cleaning

The special cleaning program is started by pressing the respective

button on the operating interface.

This program should be used at the end of each treatment day and

after particularly intense loading of the suction system (e.g. after

lengthy surgical procedures).

Sequence: 40 x H2O / 4 x H1 / 8 x H2O per hose

The program duration is 2 min 35 sec per suction hose.

This intensive cleaning rinses any residues or deposits out of suction

system. Problems arising from periods of inactivity (such as evenings or

holidays) are avoided. A nal disinfection is guaranteed.

During these programs the Hygiene System H1 controls the suction

system, which means that the suction tubes must remain in their holders.

Cleaning cycles

Practice personnel, technicians

27

26

24 25

22 23

20 21

EN

10

11. Hygiene system H1 - maintenance

Daily cleaning of the lter cup:

Please wear protective gloves when performing this task!

20 Turn down the container clip of the Hygiene System H1.

21 Pull out the lter cup horizontally.

22 Lift out lter rake.

23 Empty the amalgam particles into the designated collection

container (METASYS ECOCEntEr).

24 Clean or replace the lter rakes and grease the sealing lip, if

necessary clean the underside of the housing.

25 Place lter cup with inserted lter rake horizontally back into the

previously cleaned housing.

26 Turn container clip upwards and lock in place.

A change of the lter rake is recommended every 2 to 3 months. The

lter rake must always be in place and the container clip closed when the

suction system is in operation. If the performance of the suction system

declines, check the lter rake for contamination.

Changing the H1 cartridge/pouch (see illustration 27 )

Please also refer to the H1 instructions on the rell package

and on page 11!

If the yellow monitor light no. 2 (empty tank warning) on the control

panel ashes and a short alarm is audible every time the suction tube is

lifted, please exchange the H1 cartridge or renew the pouch as follows:

Removing the H1 cartridge:

Turn off the main switch of the unit.

Press onto the front end of the cartridge briey to release the locking

mechanism (PUSH). The cartridge will slide into a position from which

it can pulled out on its slide rails horizontally.

Inserting the H1 cartridge:

Fit the cartridge in the guide and slide in until it latches in the locking

mechanism.

Turn on the main switch of the unit.

The initial cleaning program starts automatically (duration:

1 min 5 sec/suction hose).

Hygiene system H1 - maintenance

Practice personnel, technicians

28

PUSH

28.328.2

28.1

28.4

11

EN

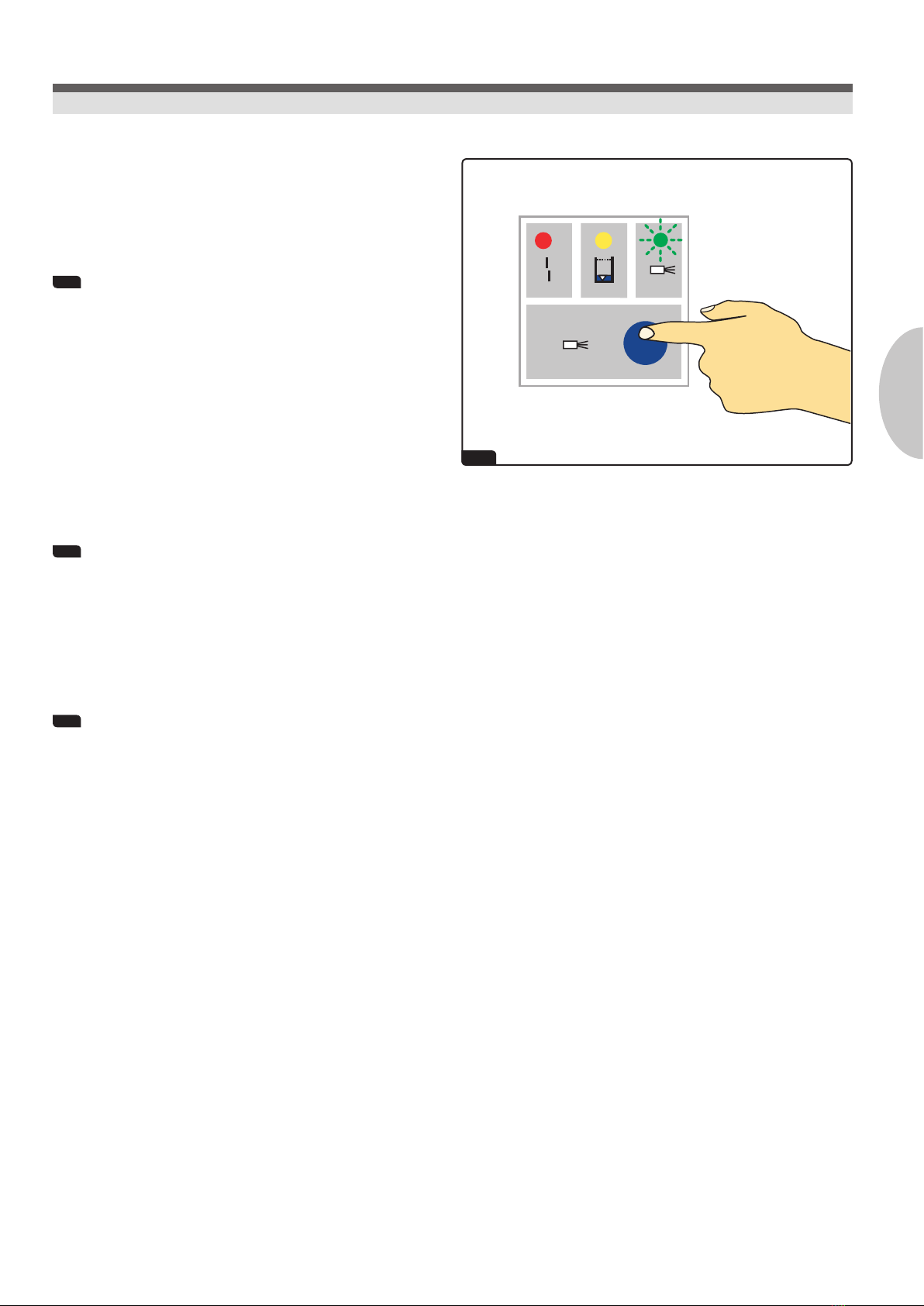

12. Hygiene system H1 - control panel

28 See illustration

28.1 Control light 1 (red): Malfunction

ashing red and 5-times beeping in the event of a fault;

additional short beep each time the suction hose is lifted,

red ashing signal remains; hygiene system not functional,

suction operation still possible:

Membrane break - suctioning functional but no cleaning and

disinfection

red light ashing without signal: Press the PUSH button

once; if this does not work then an electrical fault exists:

Check electronics!

28.2 Control light 2: Empty tank warning

yellow light and single beep whenever the suction tubes are

lifted:

Change the H1 cartridge or H1 pouch!

28.3 Control light 3: Program in use

green light on, suction hose in place:

ready for operation

green light on, suction hose in use:

continuous cleaning in progress

green light ashing slowly (approx. 3 sec):

initial cleaning in progress

green light ashing quickly (approx. 1 sec):

special cleaning in progress

28.4 Start button for special cleaning program

Press PUSH once to activate.

Hygiene system H1 - control panel

Practice personnel, technicians

30

29

29.1

29.2

29.3

29.4

29.5

29.6

29.7

29.8

30

30.6

EN

12

13. Electronic circuit board

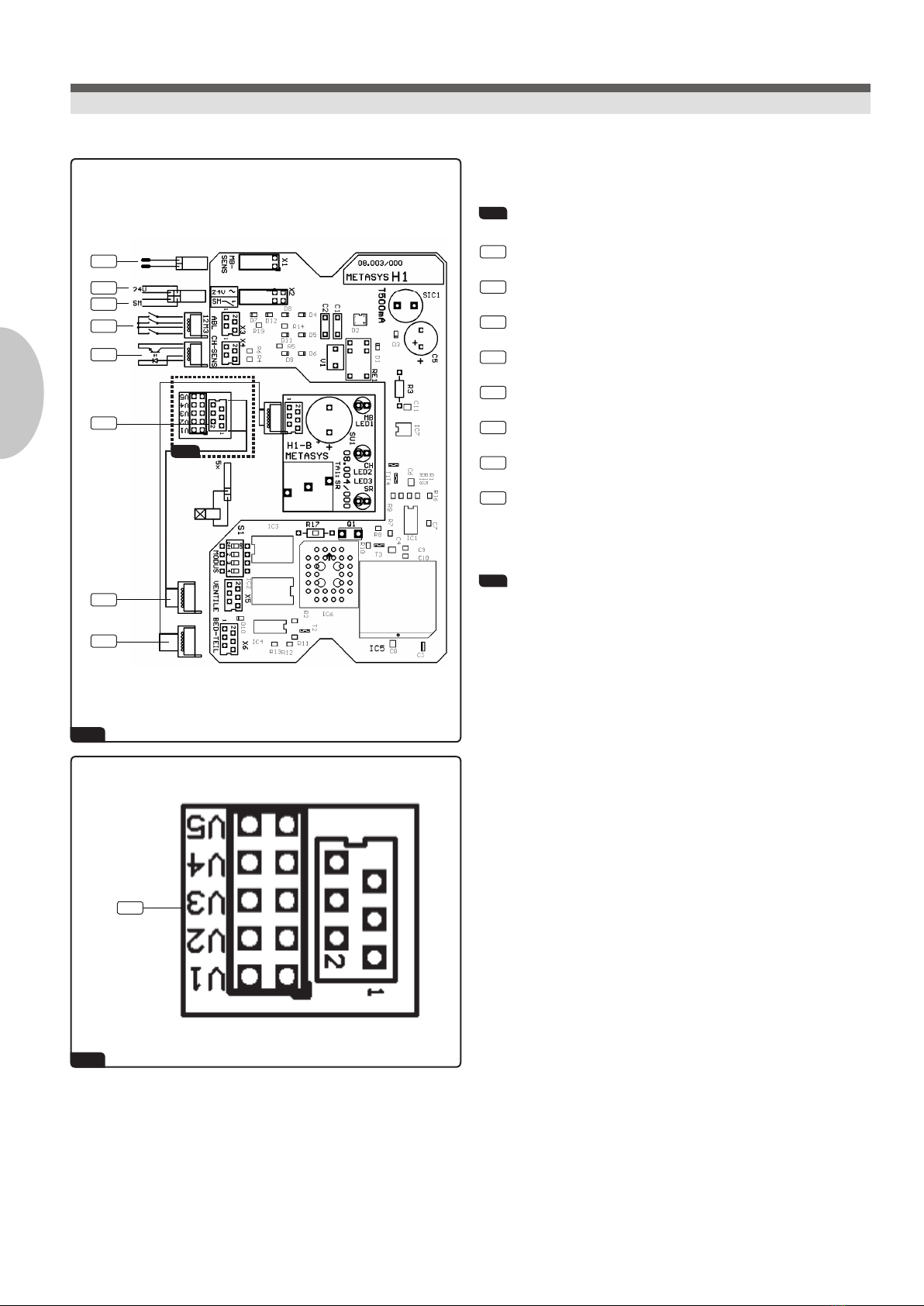

29 Wiring diagram, see illustration

29.1 Membrane rupture sensor (X1 - MB- SENS)

29.2 Voltage supply 24 V ~(X2 - 24V ~)

29.3 Start of suction motor (X2 - SM)

29.4 Suction tube holder 1, 2 and 3 (X3 - ABL)

29.5 Sensor chemical tank (X4 - CH- SENS)

29.6 Valves V1 - V5 (X5 - VENTILE), 6-pole

29.7 Control panel (X6 - BED- TEIL)

29.8 Vacuum switch

30 Transition board, see illustration

V1 H2O

V2 GREEN&CLEAN H1

V3 Knee valve, right

V4 Knee valve, left

V5 Additional valve for third suction hose

Electronic circuit board

Technicians

31

32

ON

OFF

ON

OFF

31.2

31.1

32.1 32.2

13

EN

13. Electronic circuit board

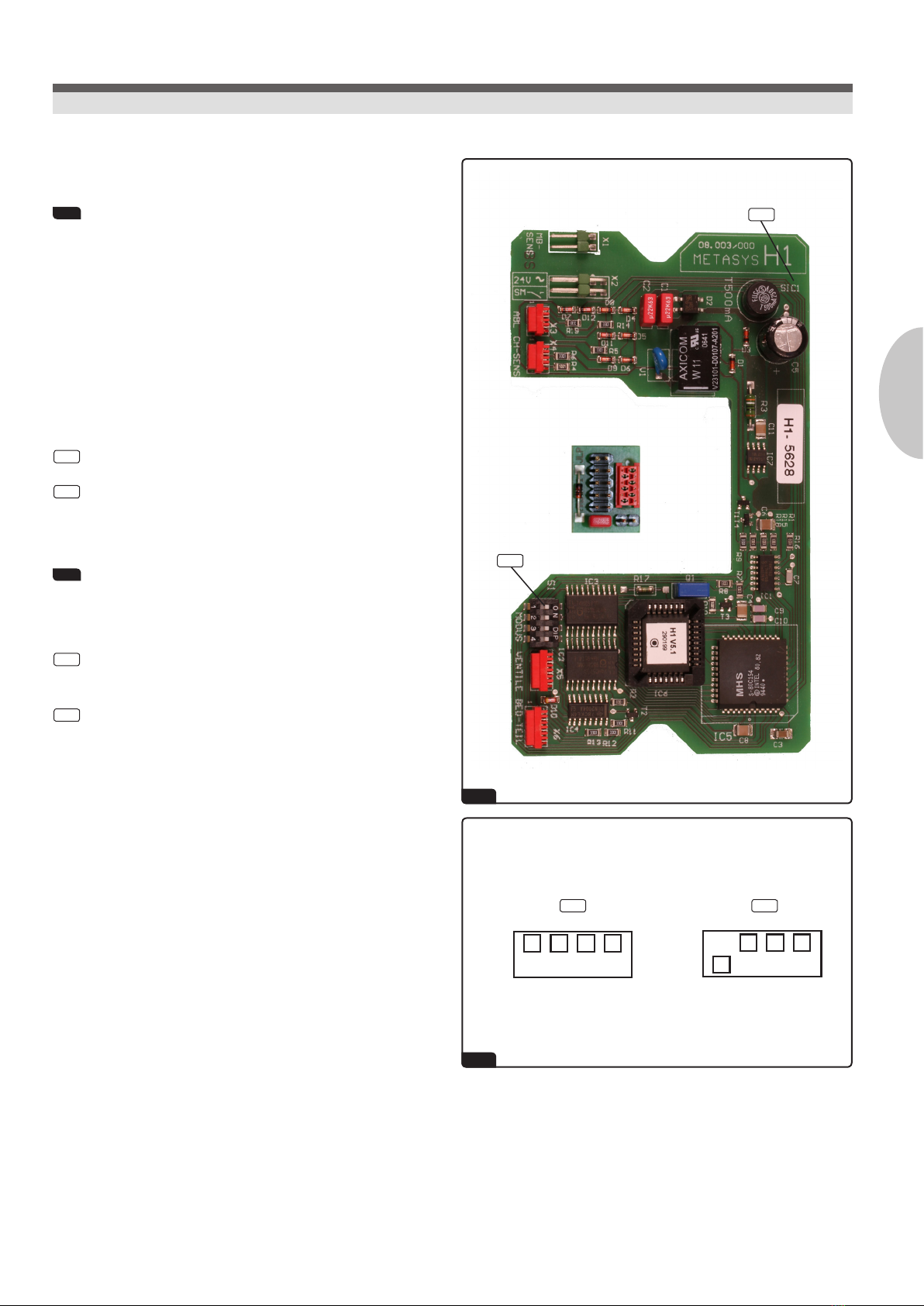

31 See illustration

The voltage supply must be provided by a safety transformer that complies

with IEC 601-1 / VDE 0750 part 1 or DIN VDE 0551.

If the output contact X2 should switch electrical connections which are

not of type BF, a cut-off relay that complies with IEC 601-1, section 20.2,

insulation B-a must be used.

This cut-off relay is switched through the output contact X2, whereupon

the operating voltage used must be the same as of the H1 system.

31.1 H1 mode setting

31.2 SIC1. fuse (750m A/T; wired in)

32 H1 mode setting, see illustration

Switch 1:

32.1 Standard

1 - two suction hoses

32.2 3 suction hoses

0 - three suction hoses

Electronic circuit board

Technicians

33

34

35

36

1

4

2

3

Vaseline

PUSH

3

33.2

33.3

33.1

34.1

34.2

EN

14

14. Inspections

We recommend an annual service check of the Hygiene System H1 by an

authorised technician.

15. Cleaning and disinfection

The below mentioned parts can be cleaned and disinfected as follows:

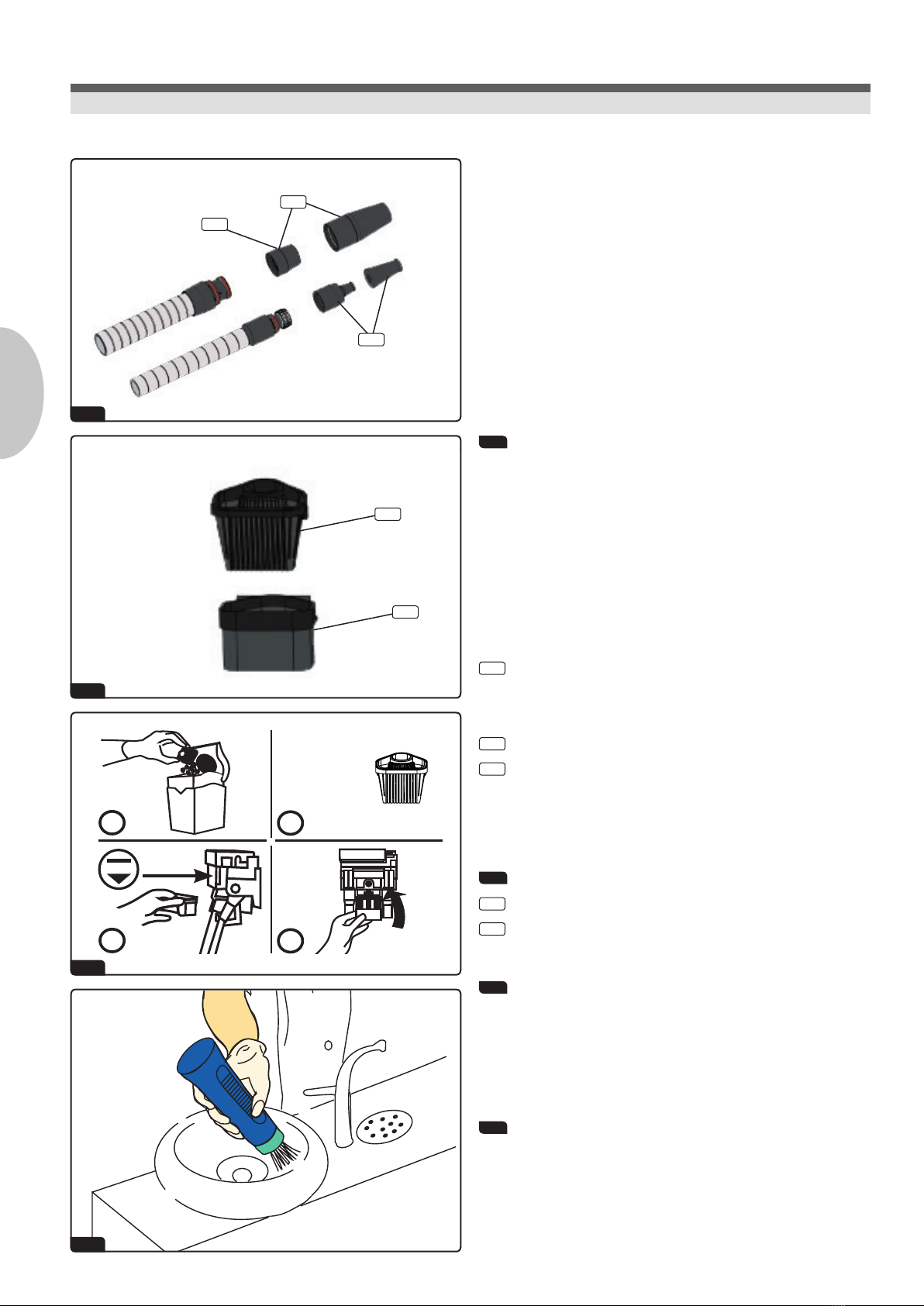

33 Handpieces, see illustration

(This applies to METASYS handpieces only!)

The handpieces may be disassembled as follows: Switch off the unit and

pull the handpieces from the connecting piece of the tube with a gentle

twist.

Upon reassembly make sure that the O-rings are lubricated and in place,

and slide back the handpieces with a twist.

Small suction tube:

33.1 Handpiece, small - order no: 50010047

Large suction tube:

33.2 Handpiece, large - order no: 50010048

33.3 Distributor, large - Order no: 50010001

Grease the o-rings with vaseline after cleaning!

34 Prelter, see illustration

34.1 Filter rake - order no: 55010001

34.2 Filter cup - order no: 50010008

35 Lubricate the sealing lip with vaseline and place back properly!

The entire suction tubes can be disinfected with alcohol-free surface

disinfectants, such as GREEN&CLEAN MK or GREEN&CLEAN SK (wipe

disinfection). It is also possible to clean the suction tubes under running

water.

36 Cleaning the cuspidor, see illustration

We recommend GREEN&CLEAN MB to clean the cuspidor.

Do not use household cleaners because these can lead to malfunctions of

the suction system!

Inspections Cleaning and disinfection

Practice personnel, technicians

37 38

39

40

META SYS

METASYS

15

EN

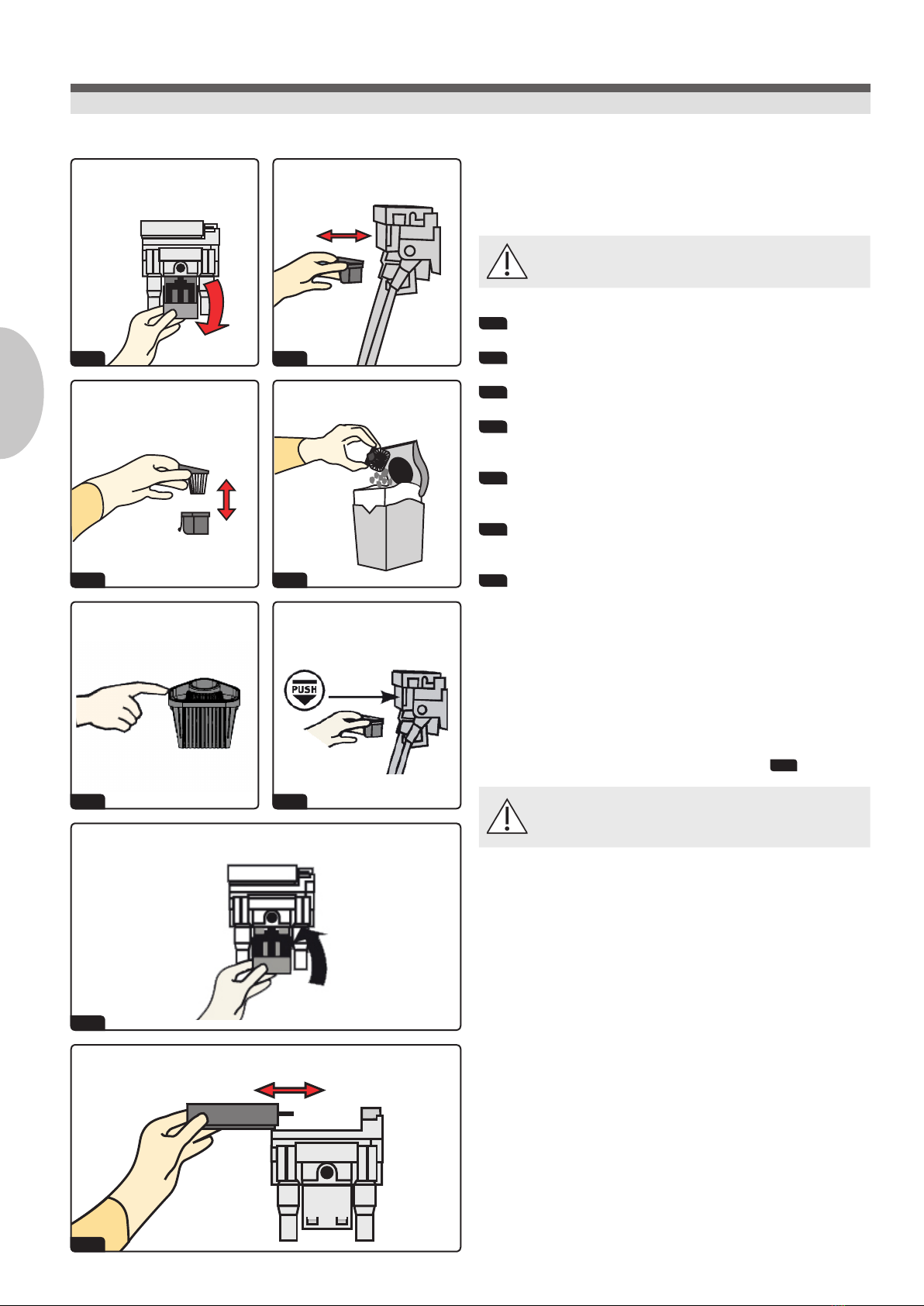

16. Relling the H1 cartridge

A rell set is included in the scope of delivery!

37 Open the closure of cartridge

Attach key onto bayonet socket of cartridge.

Turn the key counter-clockwise.

38 Remove cover lid of the cartridge

Remove the cap.

Pull out plunger with cartridge seal.

39 Attach the lling adapter

Open the screw cap of the rell pouch.

Attach the short end of the adapter to the rell pouch.

Attach the long end of the adapter to the cartridge.

40 Rell the cartridge

Fill up the cartridge with GREEN&CLEAN H1 until the maximum level

is reached.

Remove adapter after use and rinse with water.

Close the rell pouch.

Insert plunger with cartridge seal in lling opening.

Attach the bayonet socket and turn the key clockwise.

17. Disposal

When the complete device is de-installed at the end of its service life

it must be returned to the manufacturer or disposed of appropriately in

accordance with the national regulations.

Refilling the H1 cartridge Disposal

Practice personnel, technicians

METASYS Medizintechnik GmbH

Florianistraße 3, 6063 Rum bei Innsbruck, Austria

1+43 512 205420 | 5+43 512 205420 7

METASYS ... makes the difference!

Visit us at:

GERMANY

+49 8823 938 44 33

FRANCE

+33 4 37 90 22 15

ITALY

+39 045 981 4477

2019-05 H1-55.005/01 Druck- und Satzfehler vorbehalten! / Subject to printing and setting errors!

Table of contents

Popular Dental Equipment manuals by other brands

Deldent

Deldent JETPOLISHER 2000 instructions

DentalEZ

DentalEZ StarDental Star Simplicity FX instruction manual

Instrumentarium

Instrumentarium Orthopantomograph OP200 D user manual

Ivoclar Vivadent

Ivoclar Vivadent Programat EP 5010 operating instructions

DENTAURUM

DENTAURUM Herbst IV Instructions for use

Gendex

Gendex Expert DC installation manual

HAGER WERKEN

HAGER WERKEN PRAXIPOL PS II Instructions for use

Renfert

Renfert Waxlectric light I instruction manual

Renfert

Renfert POWER quick start guide

Dentsply Sirona

Dentsply Sirona CEREC Primescan AC Unpacking and installation instructions

Wassermann

Wassermann HSS-99 Replacement manual

Jorvet

Jorvet J0453 user manual