Metasys 2412 Series Service manual

Fire Initiating Devices and Notification Appliances Technical Manual 408

Conventional Products Section

Technical Bulletin

Issue Date 1095

© 1995 Johnson Controls, Inc. 1

Code No. LIT-408150

Introduction Page 3

●

General Description 3

Installation Procedures 7

●

General Information 7

●

Mounting 7

●

Spacing 8

●

Wiring Installation Guidelines 8

●

Installation 9

●

Tamper-Proof Feature 10

Testing and Maintenance Procedures 11

●

Testing 11

●

Maintenance 14

●

Limitations 16

2412, 2412TH, 2424, and 2424TH

Direct Wire Photoelectronic Smoke Detectors

2 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 3

Introduction

This document contains important information about installing and

operating direct wire smoke detectors. These conventional detectors are

manufactured by System Sensor for use with Johnson Controls systems. If

you install this detector for someone else to use, you must leave a copy of

this document with the user.

These instructions apply to System Sensor detectors for mounting, wiring,

installation, testing, and maintenance. Follow only those instructions that

apply to the model you are installing.

Before you install any direct wire smoke detectors, read and be familiar

with:

●The Guide for Proper Use of System Smoke Detectors Technical

Bulletin in the Fire Initiating Devices and Notification Appliances

Technical Manual (FAN 408) that provides detailed information on

detector spacing, placement, zoning, wiring, and special applications

●or, for non-United States installations, applicable codes and standards

specific to the country and locality of installation

Failure to follow these directions may result in failure of this device to

report an alarm or trouble condition or respond properly to an alarm

condition. Johnson Controls is not responsible for devices that have been

improperly installed, tested, or maintained by others.

!

CAUTION: Equipment hazard. Do not use in potentially

explosive atmospheres. Do not leave unused

wires exposed.

The 2412 and 2424 photoelectronic smoke detectors utilize state-of-the-art

optical sensing chambers. These detectors are designed to provide open

area protection, and are to be used with UL Listed control panels only.

The 2412 applies to 12 volt panels and operates at 12 VDC, and

the 2424 applies to 24 volt panels and operates at 24 VDC. The detectors’

operation and sensitivity can be tested in place. Models 2412TH and

2424TH have the same specifications as models 2412 and 2424; however,

they feature a built-in fixed temperature (135°F) thermal detection unit.

General

Description

2412 and 2424

Direct Wire

Detectors

4 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

Each detector includes a Light Emitting Diode (LED) that provides a local

visual indication of the detector’s status. The LED blinks every ten

seconds as an indication that power is applied to the detector and lights

continuously in alarm. The detector has the provision for the connection

of an optional model RA400Z remote annunciator. The RA400Z provides

a visual indication of an alarm in the connected detector, and mounts to a

single gang box.

These detectors also have the latching alarm feature. The alarm can be

reset only by a momentary power interruption.

Each detector contains one set of Form-A contacts for connection to the

alarm-initiating circuit, and one set of Form-C auxiliary contacts.

Supervision of detector power is accomplished by installing a power

supervisory End-of-Line (EOL) relay module (A77-716 series) at the end

of the detector power circuit. When power is applied to and through the

detectors, the EOL power supervisory module is energized. Its relay

contacts close and provide a closed series circuit in the control panel’s

alarm-initiating circuit. A power failure or a break in the detector power

circuit de-energized the EOL module. The relay contacts open and trigger

a trouble signal at the control panel.

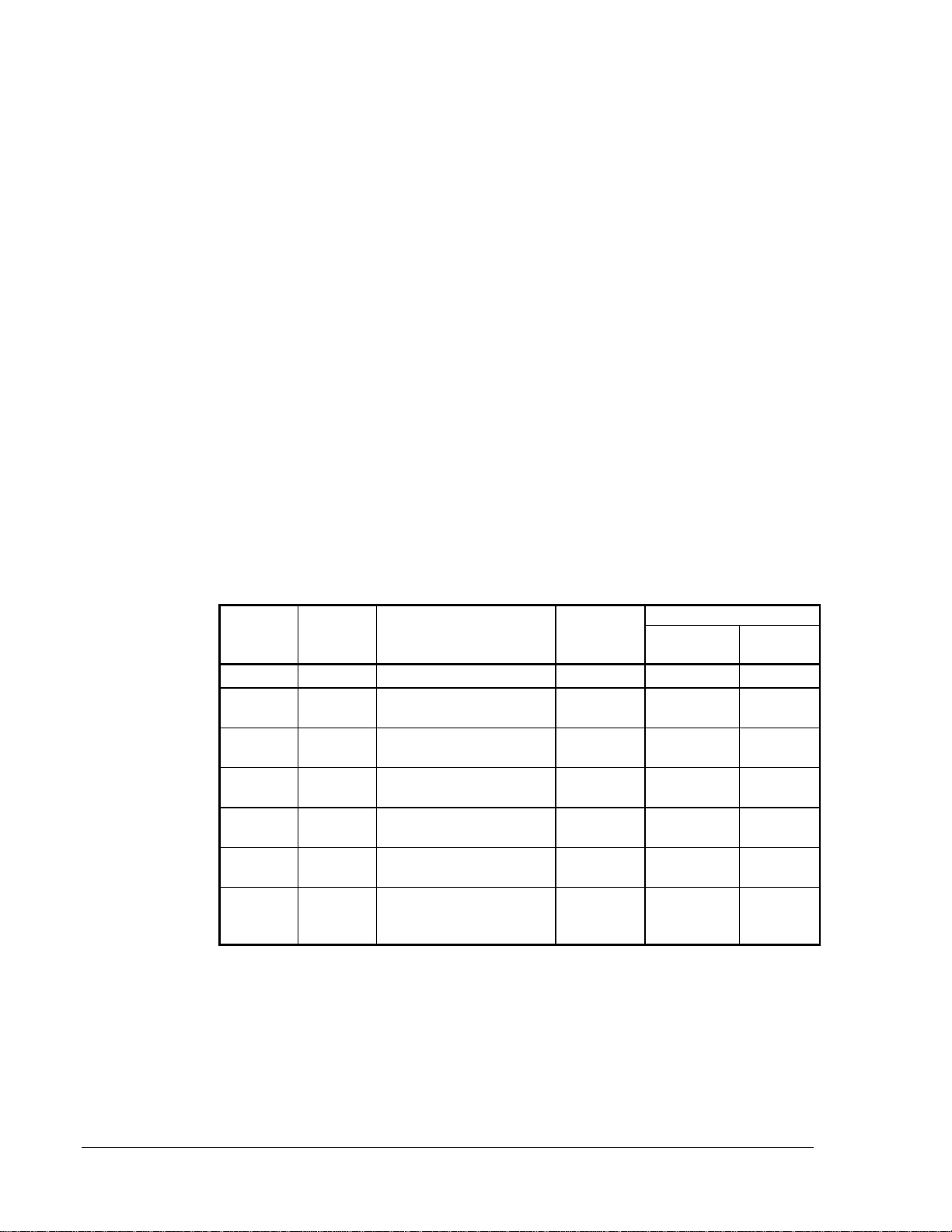

Table 1: 2400 Series Direct Wire Smoke Detectors

Model Control Description Operating Current Consumption

Panel Voltage Standby

(Min) Alarm

(Max)

2400 2-wire Photo Detector 12/24 VDC 120 µA —

2400TH 2-wire Photo Detector with Fixed

Heat Sensor 12/24 VDC 120 µA —

2400AT 2-wire Photo Detector with Fixed

Heat Sensor and Horn 24 VDC 120 µA 67 mA

2400AIT 2-wire Photo Detector with

Isolated Heat Sensor 24 VDC 120 µA 67 mA

2412AT 4-wire Photo Detector with Fixed

Heat Sensor and Horn 24 VDC 120 µA 51 mA

2424AT 4-wire Photo Detector with Fixed

Heat Sensor and Horn 24 VDC 120 µA 43 mA

2424AIT 4-wire Photo Detector with

Isolated Heat Sensor and

Horn

24 VDC 120 µA 43 mA

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 5

Table 2: Specifications Summary

Specifications

Diameter 5.5 in. (140 mm)

Height 3.19 in. (81 mm)

Add 0.5 in. (13 mm) for all models with a “T” suffix

(i.e., 2400TH)

Weight 0.7 lb (318 g)

Operating Temperature Range Models 2412 and 2424--32 to 120°F (0 to 49°F)

Models 2412TH and 2424TH--

32 to 100°F (0 to 38°C)

Operating Humidity Range 10 to 93% RH, Non-condensing

Maximum Air Velocity 3,000 ft/min. (15m/s)

Latching Alarm Reset by momentary power interruption

Minimum of 0.3 seconds to reset

Fixed Temperature Head Detector 135°F (57°C)

Electrical Ratings 2412 2424

System Voltage 12 VDC 24 VDC

Maximum Ripple Voltage 4 volts Peak-to-Peak

Supply Voltage (Min./Max.) 11.3/17 VDC 20/29 VDC

Reset Voltage (Control panel must

fall below 2.4 volts to reset.) 0.73 VDC Minimum 0.8 VDC Minimum

Standby Current 120 Microamperes Maximum

Alarm Currents (Min./Max.) 35/77 Milliamperes 21.3/40.6 Milliamperes

The alarm and auxiliary relay operate within the specified voltage ratings.

Startup Time (Internal Power

Supply Needs to Charge) 34 Seconds Maximum

EOL Relay A77-716B

Reset Time 0.3 Seconds

Relay Contacts - Resistive or Inductive Load (60% power factor)

Form-A:

Contact Maximum Current 2.0A @ 30 VAC/DC

Form-C* 1.0A @ 125 VAC

2.0A @ 30 VAC

* Contact rating for Canadian

installations 0.6A @ 110 VDC

2.0A @ 30 VDC

6 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 7

Installation Procedures

This section contains installation information for 2412, 2412TH, 2424,

and 2424TH direct wire smoke detectors. Instructions are given for

mounting the detector, and basic wiring information is provided.

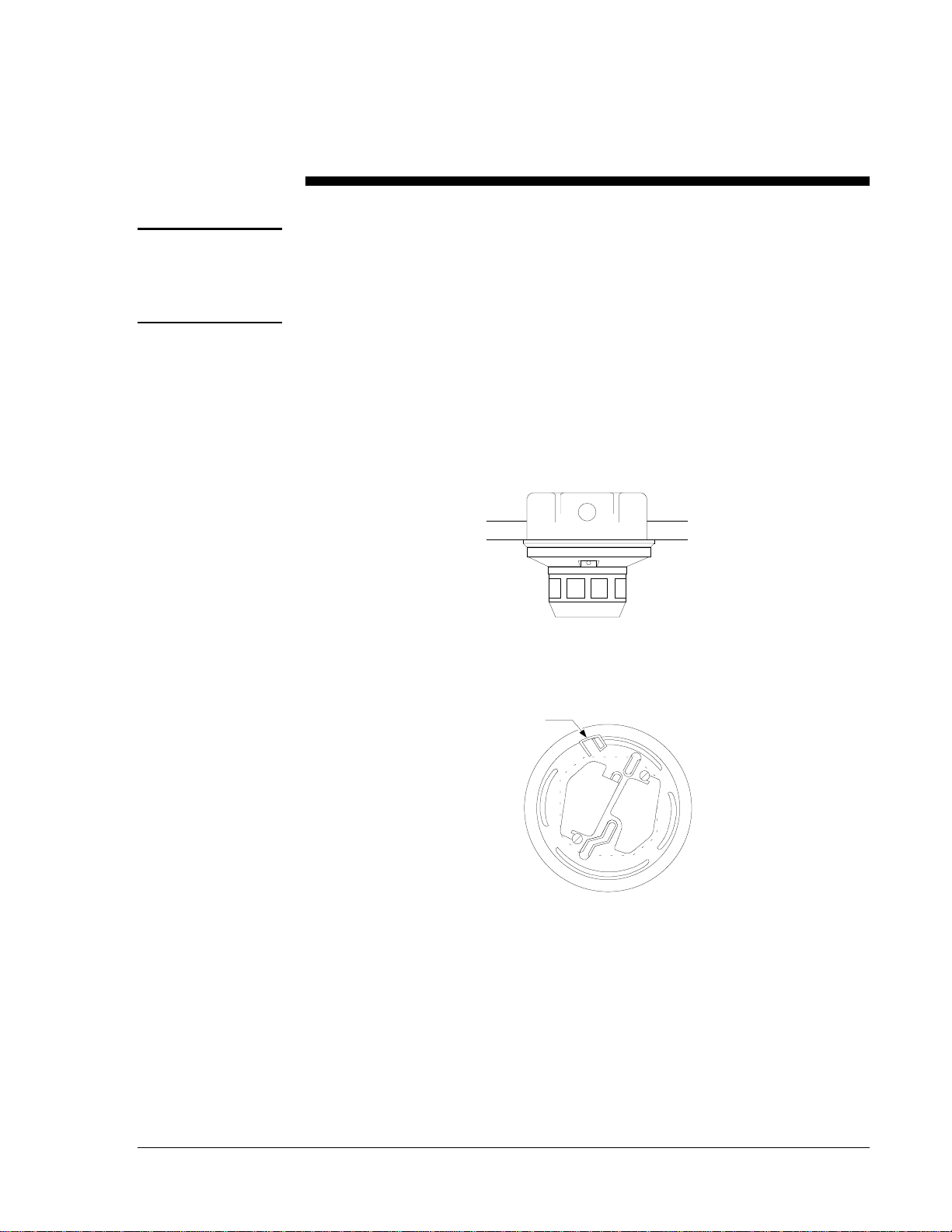

Each 2412 and 2424 detector is supplied with a mounting bracket kit that

permits the detector to be mounted in either of two ways:

●directly to 3-1/2 inch (88.9 mm) or 4 inch (101.6 mm) octagonal box,

1-1/2 inch (38.1 mm) deep electrical box (Figure 1)

●to a 4 inch (101.6 mm) square electrical box using the plaster ring

with the supplied mounting bracket kit

flmount2

Figure 1: Flush Mounting of 2412/2424 Smoke Detector

on 3-1/2 Inch and 4 Inch Octagonal Box

Tamper

Resistant Tab

mountbrk

Figure 2: 2412/2424 Smoke Detector Mounting Bracket

To make detector tamper-proof, break off the tab extension at the scribed

line (Figure 2). For more information, refer to the Tamper-Proof Feature

section in this technical bulletin.

General

Information

Mounting

8 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

NFPA-72-National Fire Alarm Code defines the spacing requirements for

smoke detectors. Typically, this is 30 feet when the detectors are installed

on a smooth ceiling. Room configuration and operating environment may

require a reduction in the standard maximum 900 square foot coverage for

each detector. However, all installations must comply NFPA-72-National

Fire Alarm Code and/or special requirements of the authority having

jurisdiction.

All wiring must be installed in compliance with the National Electrical

Code, all applicable local codes, and any special requirements of the local

authority having jurisdiction. Proper wire gauges should be used. The

conductors used to connect smoke detectors to control panels and

accessory devices should be color-coded to reduce the likelihood of wiring

errors. Improper connections can prevent a system from responding

properly in the event of a fire.

For Initiating Device Circuit (IDC) wiring (the wiring between

interconnected detectors as well as the control panel), it is recommended

that the wire be no smaller than No. 18 American Wire Gauge (AWG)

(1.0 square mm). However, the screws and clamping plate in the detector

can accommodate wire sizes up to No. 12 AWG (3.3 square mm). The use

of twisted pair wiring for the detection/power (+ and -) wires is

recommended to minimize the effects of electrical interference.

Smoke detectors and alarm system control panels have specifications for

allowable IDC resistance. Consult the control panel manufacturer’s

specifications for the total IDC resistance allowed for the control panel

being used before wiring the detector IDC circuit.

To make wire connections:

1. Strip about 3/8 inch of insulation from the end of the wire.

2. Slide the bare end of the wire under the clamping plate.

3. Tighten the clamping plate screw.

Note: For system supervision, do not loop wire under Terminals 1 and 2.

This NotThis

wirguide

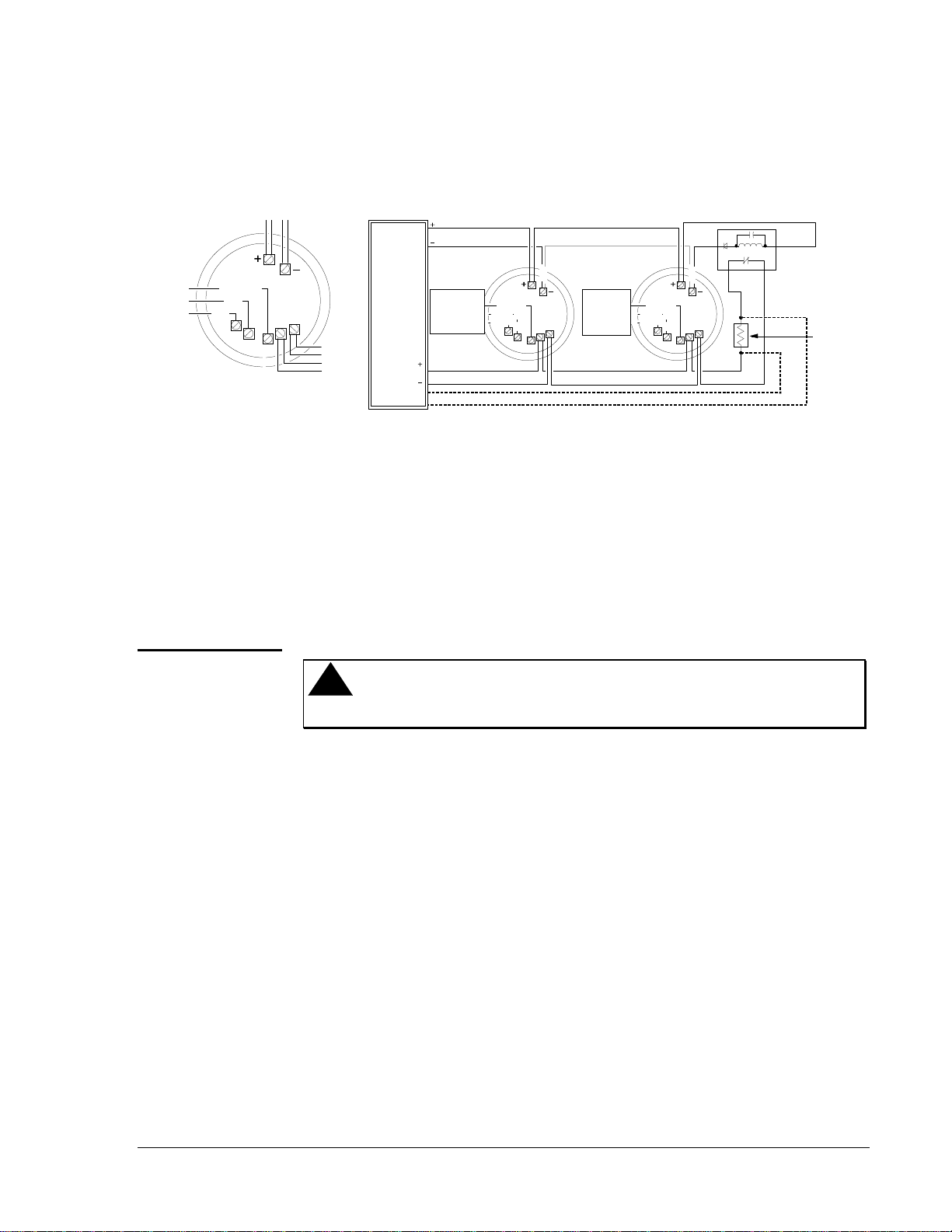

Figure 3: Electrical Connections

Note: If remote annunciator is not used, polarity to the detector may be

reversed.

Spacing

Wiring

Installation

Guidelines

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 9

Please note carefully the wiring diagram for a typical 4-wire detector

system shown in Figure 4. Contacts are shown in standby mode and will

transfer in alarm condition.

Figure 4: Wiring Diagram for the 2412/2424 Series Detector Used

with a 4-Wire Control Panel

The detectors are marked with a compatibility identifier located as the last

digit of a five-digit code stamped on the back of the product. Connect

detectors only to compatible control units as indicated in the Device

Compatibility Technical Bulletin in the Fire Management Accessories

Manual (FAN 445).

!

WARNING: Shock hazard. Remove power from IDCs before

installing detectors.

1. Mount the detector mounting bracket to the electrical backbox.

2. Enable the tamper-proof feature. For instructions see the

Tamper-Proof Feature section of this technical bulletin.

3. Wire the detector following the Wiring Installation Guidelines.

4. Line up arrows on the detector with arrows on the mounting bracket.

5. Turn the detector clockwise until it clicks into place.

6. After all detectors have been installed, apply power to the control unit.

7. Test the detector as described in the Testing section of this

technical bulletin.

8. Reset the detector at the system control panel.

9. Notify the proper authorities that the system is in operation.

smkwire2

Class A O ptional W irin

g

EOL Power

Supervision

Rela

y

Module...

Su

g

g

ested

EOL

Resistor

Power to

Detectors

UL Listed

Control

Panel

IDC

2

1

4

5

6

78

Common

N/O

N/C

Alarm

Contacts

Form-A

N/O

Auxiliar

y

Contacts

Form-C

Power

3

2

1

4

5

6

78

Common

N/O

N/C

(Optional)

Releasing

Devices

3

2

1

4

5

6

7

8

Common

N/O

N/C

(Optional)

Releasing

Devices

Installation

10 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

Dust covers can be used to help limit dust entry to the detector, but they

are not a substitute for removing the detector during building construction.

If detectors are mounted in a construction area, with or without the dust

cover in place, each detector should be thoroughly cleaned, inspected, and

tested after construction is complete. Remove any dust covers before

placing the system in service.

This detector includes a tamper-proof feature that prevents removal of the

detector without the use of a tool.

To make the detector tamper-proof:

1. Break off the smaller tab at the scribed line on the tamper-proof tab on

the detector mounting bracket (Figure 2).

2. Install the detector.

To remove the detector from the bracket once it has been made

tamper-proof:

1. Use a small screwdriver to depress the tamper-proof tab located in the

slot on the mounting bracket.

2. Turn the detector counterclockwise for removal.

The tamper-proof feature may be defeated by breaking and removing

the plastic lever from the base. However, this prevents using the

feature again.

Tamper-Proof

Slot

dirwirtm

Mountin

g

Bracket

Mountin

g

Screw

Mountin

g

.....

Screw.....

Figure 5: Tamper-Proof Slot

Limiting

Exposure to Dust

Tamper-Proof

Feature

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 11

Testing and Maintenance

Procedures

Before testing, notify the proper authorities that the smoke detector system

is undergoing maintenance and will be temporarily out of service. Disable

the zone or system undergoing maintenance to prevent unwanted alarms.

After a detector is set into alarm by one of the following test methods and

the alarm activating device is removed from the detector, the system

should be reset at the control panel before testing any additional detectors.

After all testing is complete and the system is returned to its normal

configuration, notify the proper authorities that the system is back in

service.

All detectors must be tested after installation and periodically thereafter.

Testing methods must satisfy the authority having jurisdiction. Detectors

offer maximum performance when they are tested and maintained in

compliance with National Fire Protection Association (NFPA)

72-National Fire Alarm Code.

Before testing the detector, check to ensure that the LEDs are blinking.

If they are not, the detector has lost power (check the wiring) of it is

defective (return it for repair).

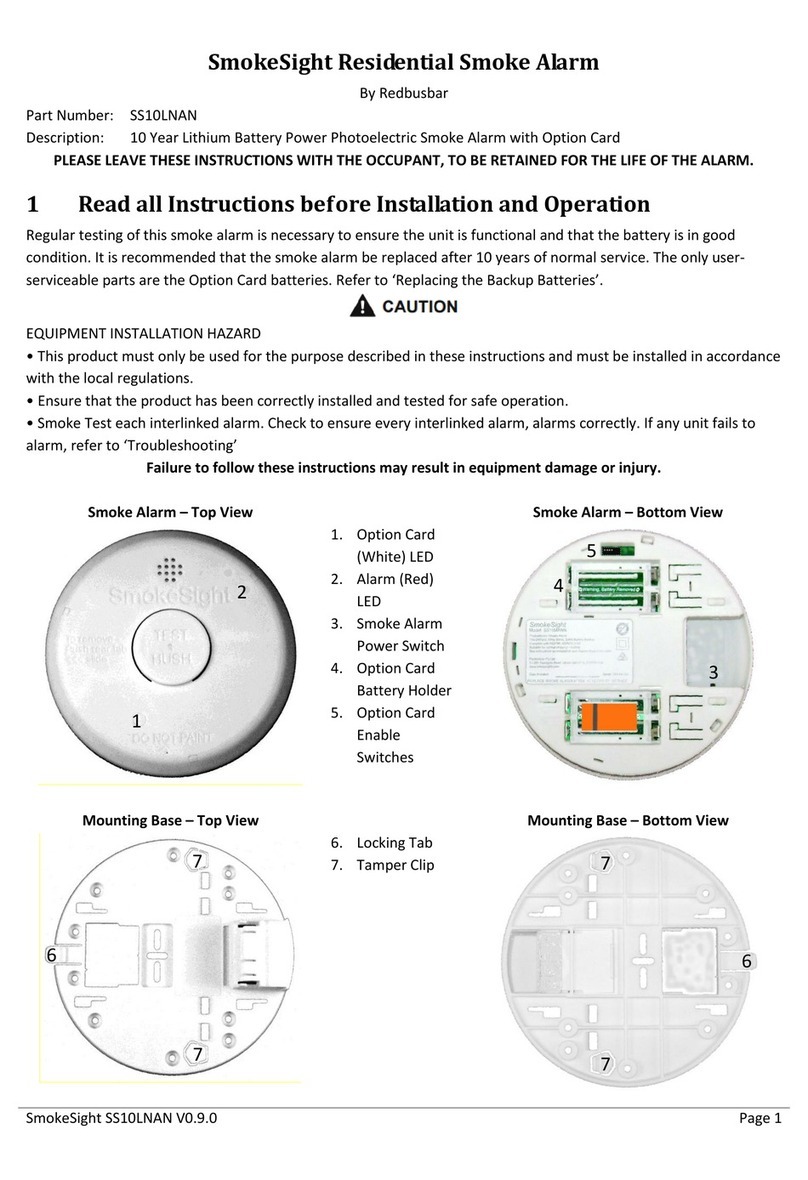

Functional Test--Recessed Test Switch

1. Find the test switch is located on the detector housing (Figure 6).

2. Press and hold the recessed test switch with a 0.1 inch maximum

diameter tool. The LED on the detector should light and report an

alarm condition to the control panel on the IDC within five seconds.

Calibrated Test Card (R59-18-00)

1. Remove the detector cover by placing a small bladed screwdriver in

the side slot of the detector cover.

2. Twist it slightly until the cover can be turned counterclockwise for

removal.

3. Insert the NO ALARM end of the test card fully into the test slot

(Figure 7), then slide it counterclockwise until it stops. The detector

should not alarm after 20 seconds.

4. Remove the test card by sliding it clockwise before removing.

Testing

Testing the 2412

and 2424 Series

Detectors

12 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

5. Insert the ALARM end.

6. Check that the LED latches on within 20 seconds, indicating alarm

and annunciating the panel.

7. Put the cover back by gently rotating it clockwise until it locks

in place.

testswc3

Test Module

Socket

LED

Push recessed test switch

with a 0.1 inch max. diameter tool.

Recessed

TestSwitch

Figure 6: Top and Side Views Showing Position of Test Switch

Test Module (MOD400R or MOD400)

The MOD400R or MOD400 test module is used with an analog or digital

voltmeter to check the detector sensitivity as described in the test module

manual.

Aerosol Generator (Gemini 501)

1. Set the aerosol generator to represent 4%/ft to 5%/ft obscuration as

described in the Gemini 501 manual.

2. Use the bowl-shaped applicator to apply aerosol until unit alarms.

3. Clean and retest detectors that fail these tests as described in the

Maintenance section of this technical bulletin.

4. Return the detectors for repair if they still fail these tests.

5. Notify the proper authorities that the system is back online.

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 13

Direct Heat Test (Models 2412TH and 2424TH only)

To test the bimetallic thermal collector on the models 2412TH and

2424TH, follow these instructions:

1. Use a low powered heat gun or blow dryer, and aim the heat source

across the detector.

2. Hold the heat source about 12 inches (30 cm) from the detector to

avoid damaging the plastic. When the heat rises to greater than

135°F, the detector will latch in alarm.

3. After the test, the bimetallic collector will self-restore.

Detectors that fail these tests should be cleaned as described in the

Maintenance section of this technical bulletin and retested. If the detectors

still fail these tests, they should be replaced or returned for repair.

Notify the proper authorities that the system is back online when tests are

complete.

14 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

Detectors should be cleaned and tested after exposure to smoke or fire.

Before removing the detector, notify the proper authorities that the smoke

detector system is undergoing maintenance and will be temporarily out of

service. Disable the zone or system undergoing maintenance to prevent

unwanted alarms. After maintenance is performed on a detector, it should

be functionally tested to assure proper operation.

After maintenance and testing is complete and the system is returned to its

normal configuration, notify the proper authorities that the system is again

in service.

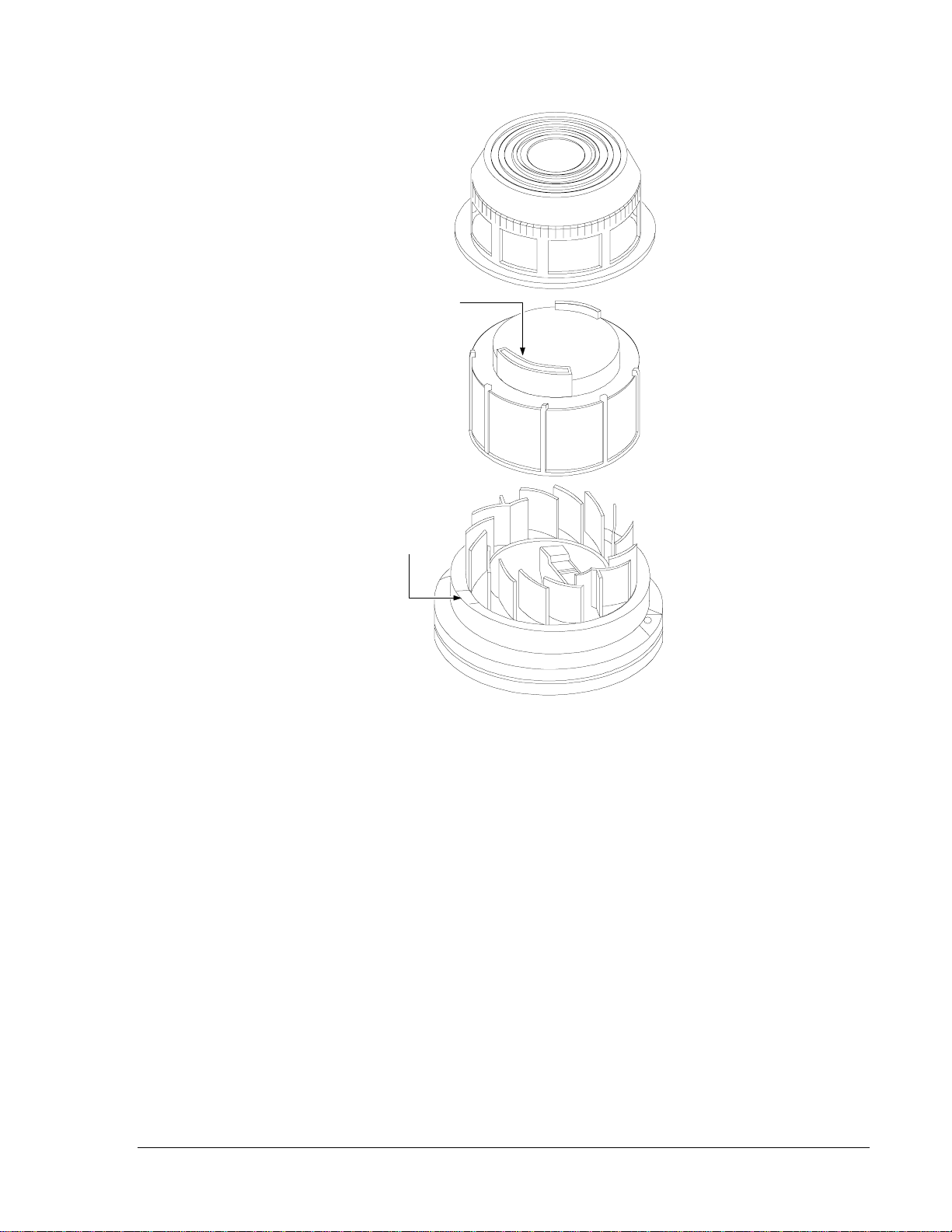

1. Remove the detector cover by placing a small bladed screwdriver in

the side slot of the detector cover (Figure 7).

2. Twist it slightly until the cover can be turned counterclockwise for

removal.

3. Vacuum the screen carefully without removing it. If further cleaning

is required, continue with Step 4 otherwise skip to Step 9.

4. Remove the screen by pulling it straight out (Figure 7).

5. Vacuum the inside.

6. Clean the vaned chamber piece by vacuuming or blowing out dust and

particles.

7. Replace the screen. Align the arrow on top with the test module

socket of the detector.

8. Carefully push the screen onto the base, making sure it fits tightly to

the chamber.

9. Replace the cover by gently rotating it clockwise until it locks in

place.

10. After cleaning a detector, test the detector with the Calibrated Test

Card (Model R59-18-00) as previously described.

11. Notify the proper authorities that the system is back online.

Maintenance

Cleaning the 2412

and 2424 Series

Detectors

Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors 15

cov&scr5

Removable

Head Cover

Cleanable Screen

P/N RS24

(

w/o Thermal

)

.....

Test Slot

Vaned Chamber

Head Cover

RemovalSlot

Figure 7: Removal of Cover and Screen for Cleaning

16 Conventional Products—2412, 2412TH, 2424, and 2424TH Direct Wire Photoelectronic Smoke Detectors

This smoke detector is designed to activate and initiate emergency action,

but will do so only when used in conjunction with other equipment.

This detector is designed for installation in accordance with NFPA

Standards 71 and 72.

●Smoke detectors cannot work without power. Alternating Current

(AC) or Direct Current (DC) powered smoke detectors will not work

if the power supply is cut off for any reason.

●Smoke detectors will not sense fires which start where smoke does

not reach the detectors. Smoke from fires in chimneys, in walls, on

roofs, or on the other side of closed doors may not reach the smoke

detector and alarm it.

●A detector may not detect a fire developing on another level of a

building. For this reason, detectors should be located on every level

of a building.

●Smoke detectors have sensing limitations. Ionization detectors offer a

broad range fire-sensing capability, but they are better at detecting

fast, flaming fires than slow, smoldering fires. Photoelectronic

detectors sense smoldering fires better than flaming fires. Because

fires develop in different ways, and are often unpredictable in their

growth, neither type of detector is always best, and a given detector

may not always provide warning of a fire. In general, detectors

cannot be expected to provide warnings for fires resulting from

inadequate fire protection practices, violent explosions, escaping gas,

improper storage of flammable liquids like cleaning solvents, other

safety hazards, or arson.

This detector is UL Listed to operate in a maximum air velocity of

3000 ft./min. Air velocity, along with other factors, may affect

detector sensitivity. See the 1993 NFPA-72-National Fire Alarm

Code, Appendix B for information.

●Test your smoke detector system per NFPA 72-National Fire Alarm

Code, or codes and standards specific to the country of installation, at

least semiannually. Clean and take care of your smoke detectors

regularly. Taking care of the fire detection system you have installed

will measurably reduce your product liability risks.

Limitations

Controls Group FAN 408

507 E. Michigan Street Fire Initiating Devices and Notification Appliances Technical Manual

P.O. Box 423 Printed in U.S.A.

Milwaukee, WI 53201

This manual suits for next models

5

Table of contents

Other Metasys Smoke Alarm manuals