4 Conventional Products—1400, 1412, and 1424 Direct Wire Ionization Smoke Detectors

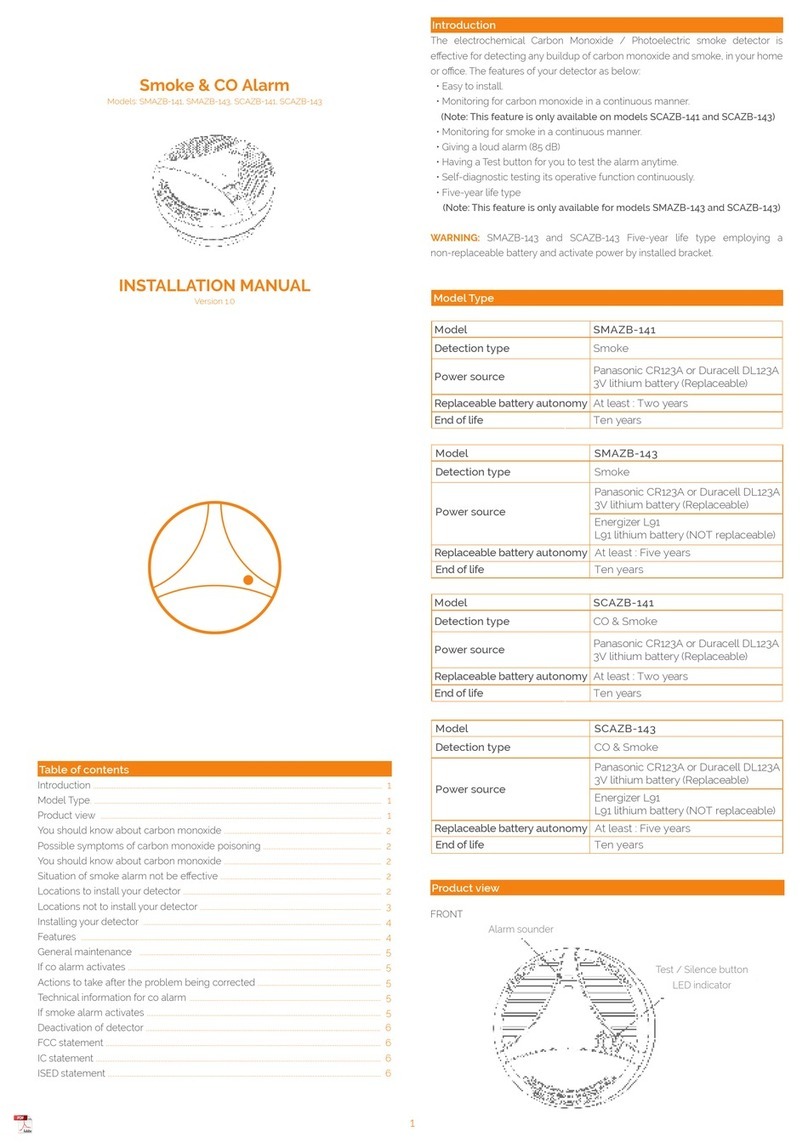

Table 1: 1400 Specifications Summary

Diameter 5.5 in. (140 mm)

Height 3.12 in. (80 mm)

Weight 0.7 lb (310 gm)

Operating Temperature 32 F to 120oF (0 to +49oC)

Latching Alarm Reset by momentary power interruption

Operating Humidity 10% to 93% RH, Non-condensing

Electrical Ratings

System Voltage 12/24 VDC

Maximum Ripple Voltage 4 volts peak to peak

Startup Capacitance 0.02 uF Maximum

Min/Max Operating Voltage Model 1400 (8.5 to 35 VDC)

Model 1412 (11.3 to 17.3 VDC)

Model 1424 (20-29 VDC)

Standby Current 8.5 VDC Minimum

35 VDC Minimum

100 uA Maximum

Alarm Ratings 4.2 VDC Minimum at 10 mA

6.6 VDC Minimum at 100 mA

Alarm current must be limited to 100 mA maximum by the control panel. If used, the

RA400Z Remote Annunciator operates within the specified detector alarm currents.

Reset Voltage 2.5 VDC Minimum

Reset Time 0.3 seconds Maximum

Startup Time 35 seconds Maximum

Maximum Air Velocity 1,200 ft/min

The 1412 and 1424 dual-chamber ionization smoke detectors utilize

state-of-the-art, unipolar sensing chambers. These detectors are designed

to provide open area protection, and to be used with UL Listed 4-wire

control panels. The 1412, for 12 volt panels, operates at 12 VDC, and the

1424, for 24 volt panels, operates at 24 VDC. The detectors’ operation

and sensitivity can be tested in place. These detectors are listed to UL 268

and are latching type system detectors.

Each detector includes an LED that provides a local visual indication of

the detector’s status. The LED blinks every ten seconds as an indication

that power is applied to the detector and lights continuously in alarm.

These detectors also have the latching alarm feature. The alarm can be

reset only by a momentary power interruption.

Each detector contains one Form-A (SPST-NO) contact for connection to

the alarm-initiating circuit, and one Form-C (SPDT-NO/NC) set of

auxiliary contacts. Both sets of contacts are activated when the detector is

in alarm. Supervision of detector power is accomplished by installing a

power supervisory End-of-Line (EOL) relay module (A77-716 series) at

the end of the detector power circuit.

1412 and 1424

Detectors