Metasys COMPACT Dynamic Installation instructions

Amalgamabscheider

COMPACT Dynamic

Gerätedokument

Einbau, Betrieb und Wartung

Amalgam Separator

COMPACT Dynamic

Equipment Logbook

Assembly, operation and maintenance

Récupérateur d’amalgame

COMPACT Dynamic

Livret d’appareil

Installation, fonctionnement et entretien

Separatore d’amalgama

COMPACT Dynamic

Verbale d’installazione

Montaggio, funzionamento e manutenzione

COMPACT

Dynamic

1

EN

EN

2

1. Index

The header on each page defines the user group particular information is

aimed at.

Chapter Page

1. Index 2

2. Explanation of the pictograms 2

3. General information 3

4. Application 4

5. Construction 4

6. Explanation of the type plate 4

7. Technical data 5

8. Functional description 5

9. Installation options 6

10. Guidelines for installation 7

11. Hose connections 8

12. Electrical connections 8

13. Description of the external display 9

14. Replacement of the collection container 10

15. Disposal of the full container 11

16. Maintenance, cleaning and disinfection 12

17. Service mode 13

18. Annual inspection 14

19. 5-year inspection 15

2. Explanation of the pictograms

iInformation

Caution!

General warning sign

Refer to instruction manual/booklet

Index Explanation of the pictograms

Practice personnel, technicians

3

EN

3. General information

The safety, reliability and performance of the appliance is

only guaranteed by METASYS if the following instructions are

observed:

Assembly, alterations or repairs may exclusively be carried out

by authorized service personnel in compliance with EN Standard

60601-1 (International Standard for Medical Electrical Apparatus, in

particular Part 1: General Rules for Safety).

The electrical installation must comply with the regulations of the IEC

(International Commission for Electrical Engineering).

The apparatus must exclusively be used in conformity with the

instructions for installation, operation and maintenance.

Only original parts may be used for repairs or replacements.

All the guidelines provided by the manufacturer on the correct use of

the amalgam separator COMPACT Dynamic are followed.

After commissioning, complete the proof of installation at the front

page of this manual and send this to METASYS in order to dene the

warranty period.

All inspection and service work must be entered into the device docu-

mentation at the rst pages of this manual

When requested by an authorized engineer, METASYS agrees to make

all documents available for the use of technically qualied service

personnel.

METASYSaccepts noresponsibility for damagescauseddue to external

factors, such as wrong installation, improper use of the apparatus or

unauthorized technical intervention.

Users must study equipment and assure themselves of its good

condition before every use.

Certificatesofrecyclingfortheamalgamwaste(providedbyrecycling

company) must be kept in accordance with national regulations.

When the complete amalgam separator is dismantled at the end of

its service life, it must be returned to the manufacturer for orderly

disposal.

General information

Practice personnel, technicians

1

2

Un= 24 V AC, ~50/60 Hz

Pmax = 100 VA

Vmax = 4,5 l/min

Z-64.1-2

COMPACT

Dynamic

METASYS Medizintechnik GmbH, Florianistr. 3

6063 Rum bei Innsbruck, Austria

Made in Austria

9876 CD - 123456

3.3

3.5

3.2

3.1

3.7

3.4

3

3.6

EN

4

Application Construction Explanation of the type plate

Practice personnel, technicians

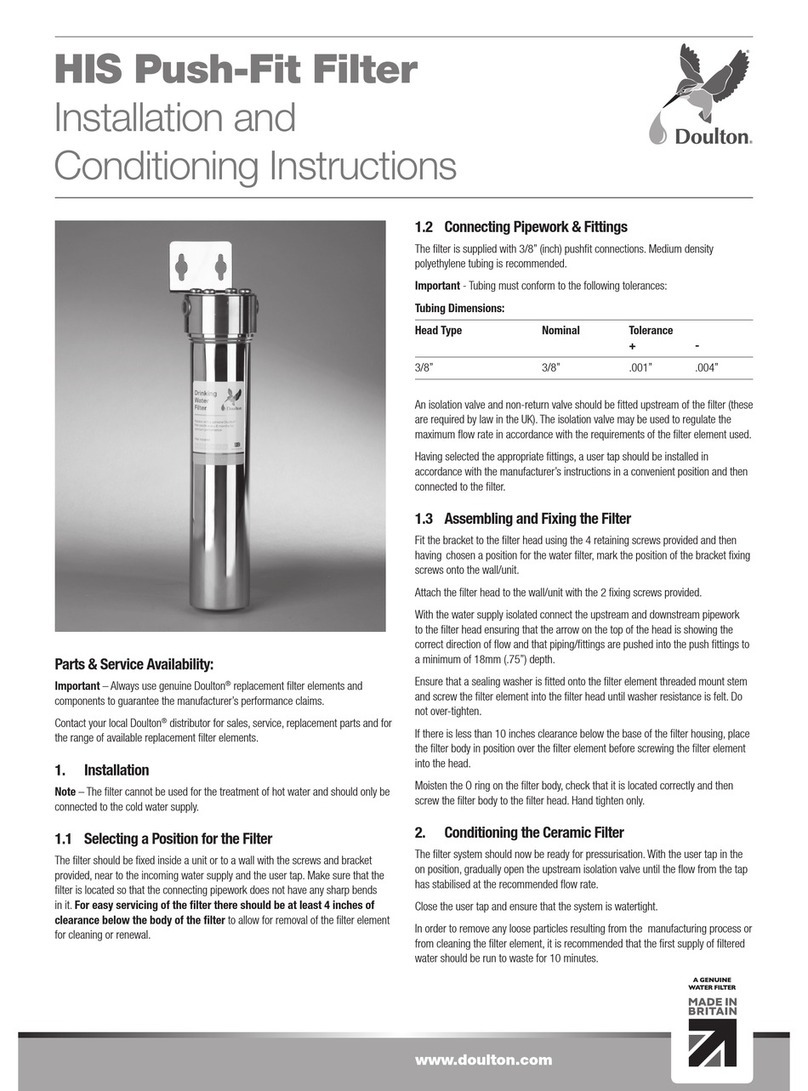

4. Application

The METASYS COMPACT Dynamic is a two-step individual amalgam

separator with integrated dynamic air/water separation.

5. Construction

The amalgam separator COMPACT Dynamic consists of 2 modules:

1 Module 1 Module 1 is the central component housing all the air,

water, and electrical connections. Module 1 contains

the wall mounting bracket and the electronic controls.

2 Module 2 Module 2 is the separating unit; the centrifuging

(dynamic) phase and the sedimentation phase of the

amalgam separation process take place here. Module

2 contains the collection container, the separator and

the centrifuge.

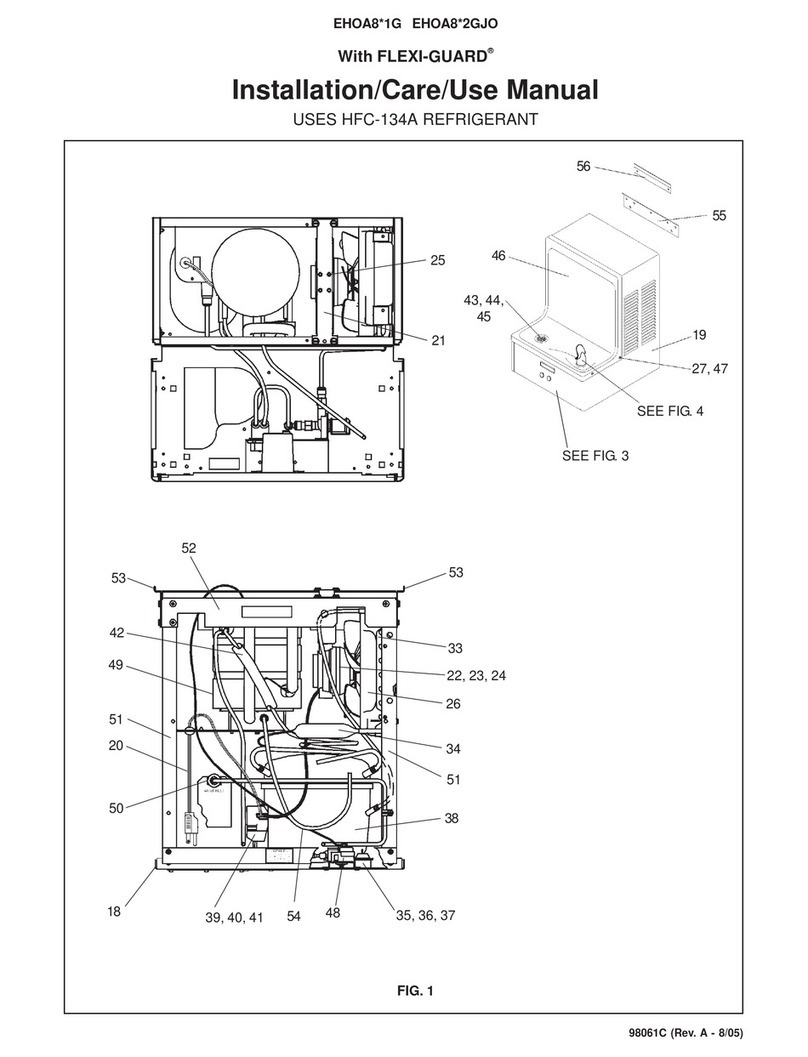

6. Explanation of the type plate

3 See illustration

The type plate is located on module 1.

3.1 Equipment type

3.2 Mains supply data

3.3 German Institute for Construction Technology Registration

Number

3.4 Serial number

3.5 Address of the manufacturer

3.6 CE conformity mark

3.7 Compliance symbol as per ÜZVO

4

5

151 mm

301 mm

173 mm

5.1

5.2

5.3

5.5

5.4

5.7

5.6

5.9

5.8

5

EN

Technical data Functional description

Practice personnel, technicians

7. Technical data

Power supply 24 V AC

Frequency 50/60 Hz

Max. current consumption 4 A

Instrument fuse 6,3 A T

Max. power input 100 VA

Low pressure range 80 mbar - 160 mbar

Separation rate 96,4 %

Collection container volume 300 cm3

Max. ambient temperature 40 °C

Possible suction systems wet or dry vacuum systems

Max. water ow rate 3.0 l/min at spittoon bowl

1.5 l/min at suction line

4see illustration

total dimensions (HxWxD) 301 x 173 x 110 mm

8. Functional description

5 See illustration

The waste water from the spittoon 5.6 is transported directly into

the collection container 5.1 which constitutes the rst phase

(sedimentation phase) of the amalgam separation process.

As soon as the level of liquid inside the collection container reaches the

range of the capacitive sensor, the motor 5.3 is started, which triggers

the pump 5.2 , as well as the centrifuge 5.4 and the rotor. The pump

pushes the water, which has been pre-cleaned through sedimentation,

into the centrifuge. Through the rotation of the centrifuge, the coarse

particles are ung to the walls of the two inner centrifuge chambers. The

cleaned water is continuously drained into the outlet 5.9 .

After one running period is over, the motor is short-circuited, which

causes the centrifuge to stop abruptly. Due to the continued rotation of

the water column, a self-cleaning effect takes place inside the centrifuge,

which rinses the heavy particles into the collection container.

When the suction hose is lifted off, the place selection valve is opened and

the motor is started. Thus, the pump, the centrifuge, and the separator

blades are set into rotation.

The suction current 5.7 is introduced through the separation chamber,

and is further accelerated in a circular manner by the fast rotating blades

of the air wheel 5.5 .

The solid and liquid constituents of the suction current are ejected

tangentially, while the air moves through the axis of the blades to the

suction engine 5.8 .

The ejected solid and liquid material is lead through a feeding hopper of

the centrifuge 5.4 and the above mentioned cycle starts again.

6

7

8

EN

6

Installation options

Practice personnel, technicians

9. Installation options

The COMPACT Dynamic allows a variety of different installation options:

6 Installation in the spittoon bowl

The direct installation of the amalgam separator into the spittoon bowl

should be preferred in order to keep tubes to the amalgam separator as

short as possible.

The amalgam separator should be installed in the spittoon in such a way

as to keep the vibration levels as low as possible.

7 Installation behind the patient’s head (12 o’clock)

If there is no spittoon in the treatment area and the suction system is

located behind the head of the patient, then the COMPACT Dynamic can be

installed inside a cabinet.

In this case the connection to the spittoon must be closed with a sealing

plug.

8Installation within an independent housing

Should it be impossible to integrate the amalgam separator into the

existing equipment, the COMPACT Dynamic can be tted in a shapely

housing which requires only a minimum amount of oor space.

The housing should be be mounted onto the connection box of the dental

unit. An external display and a transformer are already integrated into

the housing.

9

10

11

12

9.1

10.2

10.1

7

EN

Guidelines for installation

Technicians

10. Guidelines for installation

9 Fitting

iThe following space requirement must be met:

H x W x D = 350 mm x 215 mm x 120 mm

To reduce vibration, the device must only be tted to the supporting parts

of the treatment unit through the 3 holes in module 1 (do not remove

the swinging ttings!). The amalgam separator should be able to swing

freely, without any contact with any other part of the treatment unit

(cables, hoses, lids, etc.).

An electrical earth plate ( 9.1 ) must be tted behind

module 1 if the background is electrically conducting!

10 Prelter

If not already installed in the tube holder, a prelter 10.1

with a mesh width of max. 1 mm must be installed on the

suction side of the separator, in a place which is easily

accessible for the practice personnel.

The coarse lter 10.2 tted in the outlet of the spittoon may have a

maximum mesh width of 3 mm, and must not be removed while the

amalgam separator is in operation.

11 Hose connections

The hose connections leading to the COMPACT Dynamic must be kept

as short as possible to prevent pre-sedimentation.

Dirty dental hoses must be replaced during installation and must be

disposed of through DENTAL ECO SERVICE.

The amalgam separator must be connected to the waste water drain.

The waste water must be able to run freely so that the effectiveness of

the separator is not affected by any build-up of backwater.

Water driven saliva ejectors should not be used due to excessive water

consumption.

The rinsing of the spittoon bowl should be limited by a timer or special

button to a maximum of 30 seconds or max. water ow rate of 3 l/min

to allow a stop of the centrifuge.

12 Main switch

Please ensure that the amalgam separator is switched off at least once per

working day in order to measure the lling height. The connection of the

24 V AC power supply must take place after the device’s or the surgery’s

main switch.

14

14.11

14.1

14.1014.814.914.514.614.714.4

14.3

14.2

13

13.3

13.4

13.2

13.1

EN

8

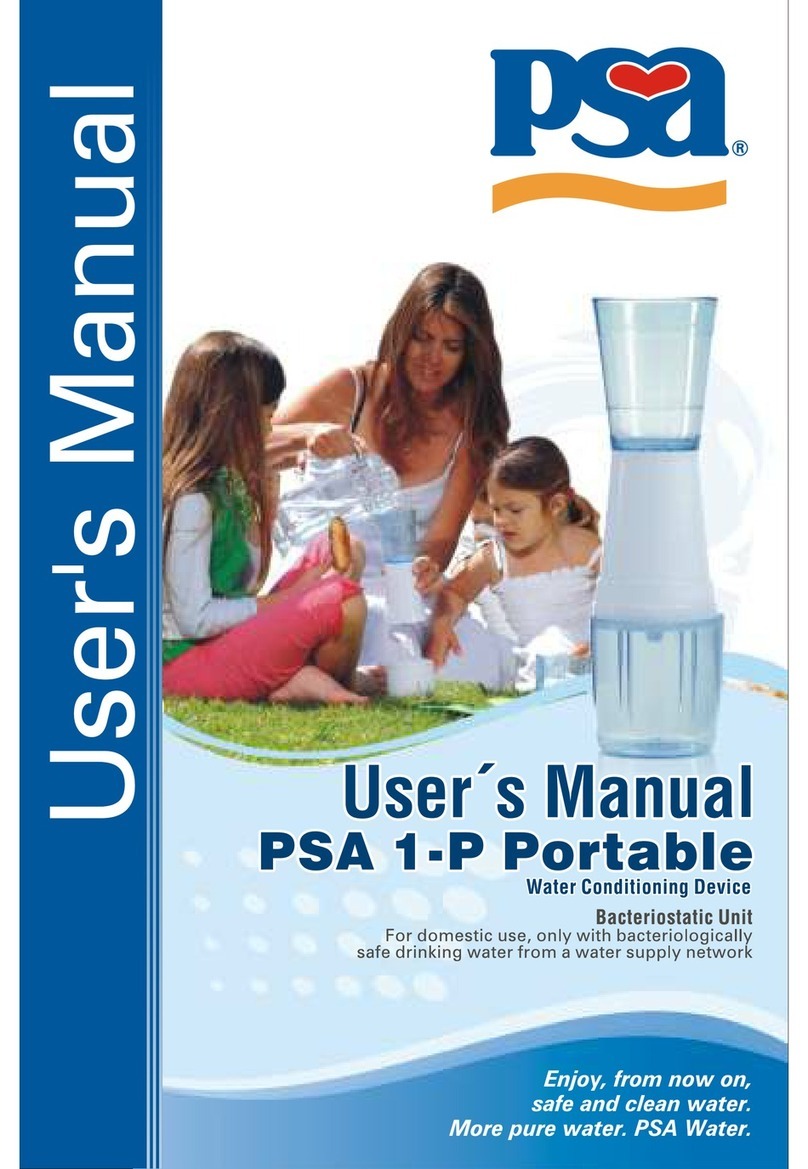

11. Hose connections

13 See illustration

13.1 Connection to spittoon waste water pipe

Ø 15 mm

13.2 Connection to suction hose (to the suction holder)

Ø 26 mm

13.3 Connection for vacuum hose (to suction engine)

Ø 26 mm

13.4 Connection for the waste water hose

Ø 15 mm

Order numbers of hose nozzles and adapters can be found in our spare

parts list.

All hose connections must be secured using hose clips!

Unnecessary connections must be closed with blind plugs!

12. Electrical connections

14 See illustration

14.1 D14: LED net (illuminated when power supply is on)

14.2 S1: fuse MST250/T 6,3 A/UN 250 V/ ICN 63 A (replace with same

type only!)

14.3 X3: power supply 24 V AC

The mains supply must be drawn through a safety

transformer which complies with IEC 601-1/VDE 0750 part 1/

DIN EN 60601-1 and IEC 60742 + A1/DIN EN 60742.

14.4 X2: motor connection (internal)

14.5 X6: interferring signal output to the unit

14.6 X8: suction current (external)

14.7 X7: suction holder signal (24 V AC when suction hose is removed)

14.8 X5: connection for the measurement of the lling height

14.9 X4: connection for the external display

14.10 X9: connection for the capacitive sensor

14.11 X10: terminal for the processor

Hose connections Electrical connections

Technicians

RESET

RESET

RESET

= leuchten = blinken

= permanent = flashing

= allumé = intermittent

= rimane accesa = lampeggiare

16.1

16.2

15.4

15.1 15.2 15.3

15

16

9

EN

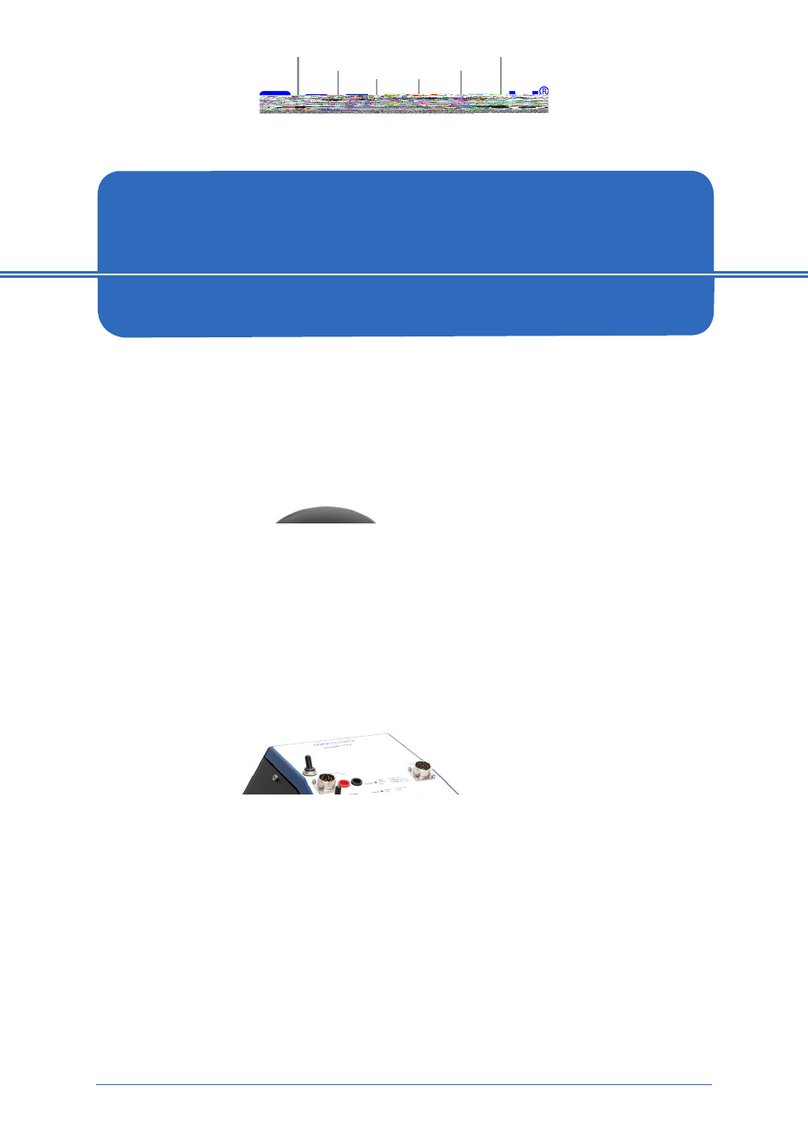

13. Description of the external display

15 See illustration

15.1 Control light 1: ready for operation

Ögreen illuminated:

unit is switched on

15.2 Control light 2: centrifuge error

Öred ashing and audible buzzer signal: Error!

see illustration 16 error messages

15.3 Control light 3: container full

Öyellow illuminated and audible buzzer signal which can be

turned off by pressing RESET: Collection container is 95% full

It is recommended that the collection container be replaced;

however, it is possible to continue operation until the container

is 100% full. As a reminder, the control lamp remains illuminated

and every time the unit is switched on, the buzzer signal is

activated.

Öyellow illuminated and audible buzzer signal which cannot be

turned off by pressing RESET: Collection container is 100% full

The collection container must be replaced immediately! Further

operation is not possible, as the suction valve remains closed.

15.4 Alarm RESET button

By pressing the RESET button, the audible 95% full buzzer warning

can be switched off.

16 Error messages

16.1 See illustration

Signal 1 15.1 green illuminated, signal 2 15.2 ashing red, audible

buzzer signal:

ÖError in the electronic system!

The buzzer is turned off by pressing the RESET button. Switch the main

button off immediately and after a short break (approx. 5 seconds) on

again. If the error signal remains please contact your service technician!

16.2 See illustration

Signal 2 15.2 ashing red, audible buzzer signal:

ÖCollection container has not been inserted properly!

The buzzer cannot be turned off, and no other signal illuminates. Please

refer to chapter 14 for the proper replacement of the collection container.

Description of the external display

Practice personnel, technicians

1

2

1

2

5

VASELINE

12

17 18

19 20

21 22

23

EN

10

14. Replacement of the collection container

Turn off the main switch of the unit!

Prepare a new collection container and take out the enclosed

disinfectant bag!

Wear protective gloves!

Remove the lid of the treatment unit.

17 Turn the locking bracket of the amalgam separator upwards,

holding the separator rmly.

18 Remove the amalgam separator by pulling it forwards out of

the unit and place it on a level, non-slip surface.

19 Hold the collection container rmly, and twist the top counter-

clockwise until the marking under the locking bracket and the

yellow marking on the collection container are aligned. Lift

up the top.

20 If the pump lter is soiled, remove it, clean over a drip tray,

and place back onto the pump housing.

21 Fit the top onto a new collection container in such a manner

that the yellow markings on the collection container and un-

der the locking bracket are aligned. Twist the top clockwise as

far as it will go. Check whether all the supporting clips of the

container are properly locked into place.

22 Grease the seal on the supporting element with vaseline.

23 Carefully insert the amalgam separator into its support, and

close the locking bracket.

Switch on the main switch of the treatment unit.

If the collection container has been replaced properly, the amalgam se-

parator runs for a short period of time and the external display indicates

„ready for operation“ (signal 1, green illuminated).

If the collection container has not been replaced properly, then signal 2

starts ashing on the external display, and a buzzing sound is audible. In

this case, turn off the main switch and carefully repeat the procedure as

described above (refer to pt. 5 & 7).

Replacement of the collection container

Practice personnel, technicians

24 25

26

27

28

AUSTAUSCHBEHÄLTER

für METASYS Amalgamabscheider und Luft/Wasser-Separatoren

EXCHANGE CONTAINER

for METASYS amalgam separators and air/water separators

COMPACT Dynamic

ECO CENTER

M1-L0.130/02 | 2019-03

MST 1

FINLAND ITALY SLOVAKIA

FRANCE LATVIA SLOVENIA

AUSTRIA

GERMANY NORWAY SWITZERLAND

CZECH REPUBLIC

AUSTRALIA

Sammelstellen | Collection Centers

Gritter Dental Pty Limited

29 / 55-59 Norman Street

Mortdale NSW 2223

DENTAL ECO SERVICE GmbH

Florianistr. 3

6063 Rum bei Innsbruck

ARGETA s.r.o.

Molenburk 155

67913 Sloup v Moravském Krasu

Remeo Oy

Linjatie 6

01260 Vantaa

METASYS France S.a.r.l.

9, bd Edmond Michelet

69008 Lyon

DENTAL ECO SERVICE GmbH

Am Ländbach 16

82481 Mittenwald

S.Eco Servizi Ecologici srl

Tel. +39 045 820 4880

www.metasys.com

SIA Thomas Freiberg

Dirnavu iela 135 – 413

1050 Riga

Dental Sør

Saltverket 6

4515 Mandal

DETOX s.r.o.

Coburgova 84/2263

917 00 Trnava

EKOL d.o.o.

Laze 18a

4000 Kranj

DHL Logistics (Schweiz) AG

Heldaustrasse 66

9470 Buchs

Besuchen Sie www.metasys.com/sammelstellen für weitere Informationen.

Please visit www.metasys.com/collection_centers for more information.

Depot | Dealer:

E-Mail:

Techniker | Technician:

Telefonnummer | Phone:

Für Techniker und Depot | For technicians and dealers

Bitte vor Rücksendung ausfüllen! | Please complete before return.

METASYS Medizintechnik GmbH

Florianistraße 3, 6063 Rum bei

Innsbruck, Austria

1+43 512 20 54 20

www.metasys.com

Für „AUSTAUSCH &RECYCLING“ Anweisungen befolgen

For “EXCHANGE &RECYCLING“ follow instructions

disinfection

1

max100%

95%

METASYS

MULTISYSTEM TYP1

23

Empfänger / Consignee

Absender / Sender

ECO TRANSFORM

Contact us for RECYCLING:

INTERNATIONAL

1+43 512 205420

GERMANY

1+49 8823 938 44 33

AUSTRIA

1+43 512 205420

For other countries please see side of the box or:

www.metasys.com/collection_centers

11

EN

15. Disposal of the full container

Wear protective gloves and face mask!

Avoid contact with the contents of the container!

The collection container is designed for single use. The reuse of a used

container violates the warranty regulations!

The full amalgam separator can be disposed of at the in-house

recycling company DENTAL ECO SERVICE - METASYS Group. Certi cates of

recycling need to be stored according to national law.

When the whole amalgam separator is disassembled at the end of its

operational life, it must be returned to the manufacturer for orderly

disposal.

The simplest method of disposal:

ECO TRANSFORM

!

24 Cut one end of the disinfectant bag enclosed with the new

container and empty it into the full container for nal

disinfection.

25 Close the full container rmly using the green lid which is

also provided with the new container, by twisting it clockwise.

Check if the lid is fully closed by holding the closed container

upside down over a drip tray (if required, re-tighten the lid).

26 Place the tightly closed collection container into the two half

polystyrene shells of the transport carton. Close the transport

carton according to the enclosed handling instructions.

27 Place the appropriate return label onto the transport box

for recycling at DENTAL ECO SERVICE ( more information on

recycling options in your country on: www. metasys.com)

28 Any amalgam residues from the pre lter must be collected

in a suitable container (e.g. METASYS ECO CENTER) and dis-

posed of properly with ECO TRANSFORM.

Operating the amalgam separator without a pre lter is not

allowed! Do not suck in residues from the pre lter!

Visit

www.metasys.com/collection_centers

to receive more information

about ECO TRANSFORM

Disposal of the full container

Practice personnel, technicians

return label

29

30

31

32

33

EN

12

16. Maintenance, cleaning and disinfection

29 See illustration

Shortly operate the spittoon bowl after every treatment!

30 See illustration

Suck off some water with each of the suction tubes after every treatment.

31 See illustration

Twice a day, after having sucked off some water, use the disinfectant

for suction systems and amalgam separators GREEN&CLEAN M2 (item

no: 60010201) or the cleanser GREEN&CLEAN CL (item no: 60010301).

Ideally a disinfection with GREEN&CLEAN M2 or a cleaning with

GREEN&CLEAN CL should be carried out before longer periods of

downtimes of the dental unit (e.g. lunch break, end of the working

day or holidays).

32 See illustration

The spittoon bowl should also be rinsed with GREEN&CLEAN M2 or

GREEN&CLEAN CL twice a day..

The operation of the amalgam separator COMPACT Dynamic without

prelter at the dental unit and/or at the central suction system is not

permitted!

Cleaning the prelter:

The prelter must be emptied and cleaned at least once a week. This may

also be carried out daily, depending on workload.

33 See illustration

The amalgam residue from the prelter box must be collected in the

METASYS ECO CENTER and disposed of properly with ECO TRANSFORM.

Maintenance, cleaning and disinfection

Practice personnel, technicians

RESET

RESET

RESET

RESET

RESET

RESET

RESET

PUSH 5 sec

RESET

2,5Hz

const.

34

35 36

37 38

39 40

const. const.

= leuchten = blinken

= permanent = flashing

= allumé = intermittent

= rimane accesa = lampeggiare

34.1 34.2

13

EN

17. Service mode

The electronic components of the COMPACT Dynamic amalgam separator

allow for the their functions to be checked using a service mode.

IMPORTANT! In order to resume normal operation or service

mode after the equipment has been switched off, wait at

least 5 seconds before switching it on again!

34 Entering the service mode

34.1 When switching the main switch on, press the RESET button on the

external display for at least 5 seconds.

ÖSignal 1 (ready for operation) ashes quickly (25 Hz)

34.2 As soon as signal 1 ashes, release the RESET button.

ÖSignal 1 ashes quickly (25 Hz)

Briey press the RESET button to start the motor.

The motor is stopped by pressing once again.

In case of a malfunction of the motor monitoring system (short-circuit

monitoring and monitoring of the running of the motor) the electronic

systems will not allow the motor to start.

The motor can be switched on and off at will by briey pressing the

RESET button.

Pressing the RESET button for approximately 5 seconds will change the

service mode from motor monitoring to testing the inlets and outlets.

(Release the RESET button after hearing a beep).

ÖSignal 1 ashes; signals 2 and 3 are steadily illuminated

Procedure for testing the inlets and outlets – see chapter 18 (annual

inspection).

Press the RESET button once again for approximately 4 seconds to end

the service mode.

ÖSignal 3 ashes (25 Hz):

The equipment switches from service mode to normal operation

ÖSignal 1 is permanently on

35 -40 Please contact your service technician if the following

malfunction messages appear:

35 Malfunction in the short-circuit monitoring

36 Malfunction in the monitoring of the running of the motor

37 Motor malfunction upon start-up

38 Current consumption of the motor when running is too high

39 Power supply to motor interrupted

40 Short-circuit of motor power supply

Service mode

Practice personnel, technicians

2.1

42

41

41.2

41.1

41.3

42.1

42.2

EN

14

18. Annual inspection

According to the German Institute of Construction Technology, the

display elements of the amalgam separator must be tested at least once

every year by an authorized technician.

METASYS mandatorily prescribes performing the annual inspection

(order no: 50040030).

Start the service mode, as described in chapter 17

Conduct a test run of the motor at least once

Continue checking the inlet and outlet

ÖSignal 1 ashes, signal 2 and 3 remain permanently lit

Remove the separator from the supports

Simulation of the display unit

41 See illustration

41.1 Cover only the lower light barrier of the lling height measurement

ÖSignals 1 and 3 ash, signal 2 remains permanently lit

41.2 Cover only the upper light barrier of the lling height measurement

ÖSignals 1 and 2 ash, signal 3 remains permanently lit

41.3 Cover both the light barriers of the lling height measurement

ÖSignals 1, 2 and 3 ash

Replace the separator into its supports.

42 See illustration

42.1 Press button to rinse spittoon bowl

42.2 Water level rises up to the switching point of capacitive sensor

ÖBuzzer sounds

Pull up a suction hose (= activate SV7 signal)

Magnetic valve closes (passage of suction current)

Place suction hose back in its holder

To terminate the service mode, keep the RESET button pressed again

ÖSignal 3 ashes

ÖSignal 3 ashes (25 Hz): The instrument changes over from the service

mode into the normal mode

ÖSignal 1 remains permanently lit

Duringtheannualinspection,werecommenda prophylacticreplacement

of the following parts by an authorized technician: amalgam collection

container, sealing unit, separation rotor, pump lter.

iEach annual inspection must be recorded in the Equipment

Logbook!

Annual inspection

Practice personnel, technicians

43

43.1 43.1

43.2

44.3

43.5

43.8

43.4

43.6 43.9

43.7

15

EN

19. 5-year inspection

In accordance with the German Waste Management Regulations, amalgam

separators must be examined at intervals of no longer than 5 years.

Conduct the annual inspection, as described in chapter 18.

Check whether the amalgam separator is correctly mounted and

connected.

Rinse the suction hose and the spittoon bowl with at least one

liter of clean water and the specically designated disinfectant

GREEN&CLEAN M2.

43 Visual control of the centrifuge

Wear protective gloves!

Switch the main switch off!

Remove the separator from the wall mounting bracket.

43.1 Remove the four screws on top of the device using a Torx 20

43.2 Remove the lid of the separator (use the screwdriver at the

backside).

ÖDo not remove the inlet sealing of the separator!

43.3 Detach the separation rotor by removing the plug at the center of

the rotor using pointed pliers, loosening the internal hex nut and

lifting up the rotor. (ATTENTION: left handed threads!)

43.4 Pull off the pump hose at the back of the separator at the upper

connection

43.5 Lift up the centrifuge inlet

43.6 Lift up the centrifuge chambers

Carry out a visual check of the centrifuge chambers for contamination;

centrifuge chambers which show excessive signs of deposits or

sedimentation of solid material must be replaced!

Finally, reassemble in the reverse order. It is important that all screws are

xed and screwed in as far as they go.

ATTENTION! Make sure the four pins 43.7 are inserted in

the holes on the bottom of centrifugal chamber. Also, the

square of the separation rotor 43.8 must click-t into the

upper side of the centrifuge 43.9 .

iThe 5-year inspections must always be recorded in the

Equipment Logbook!

5-year inspection

Practice personnel, technicians

METASYS ... makes the difference!

2019-07 ZK-55.019/06 Druck- und Satzfehler vorbehalten! / Subject to printing and setting errors!

Visit us at:

METASYS Medizintechnik GmbH

Florianistraße 3, 6063 Rum bei Innsbruck, Austria

1+43 512 205420 | 5+43 512 205420 7

GERMANY

+49 8823 938 44 33

FRANCE

+33 4 37 90 22 15

ITALY

+39 045 981 4477

Table of contents

Other Metasys Water Filtration System manuals