EN | Table of contents

2

Table of contents

1. Notes ....................................................................................................................................................4

1.1. General instructions............................................................................................................................................................................................................ 4

1.2. Explanation of the symbols................................................................................................................................................................................................. 4

1.3. Copyright notice.................................................................................................................................................................................................................. 5

2. Intended use........................................................................................................................................6

2.1. Indication............................................................................................................................................................................................................................. 6

2.2. Contraindication.................................................................................................................................................................................................................. 6

2.3. Target group........................................................................................................................................................................................................................ 6

3. Safety-related information .................................................................................................................7

3.1. General safety-related information...................................................................................................................................................................................... 7

3.2. Safety instructions............................................................................................................................................................................................................... 7

3.3. Warnings............................................................................................................................................................................................................................. 7

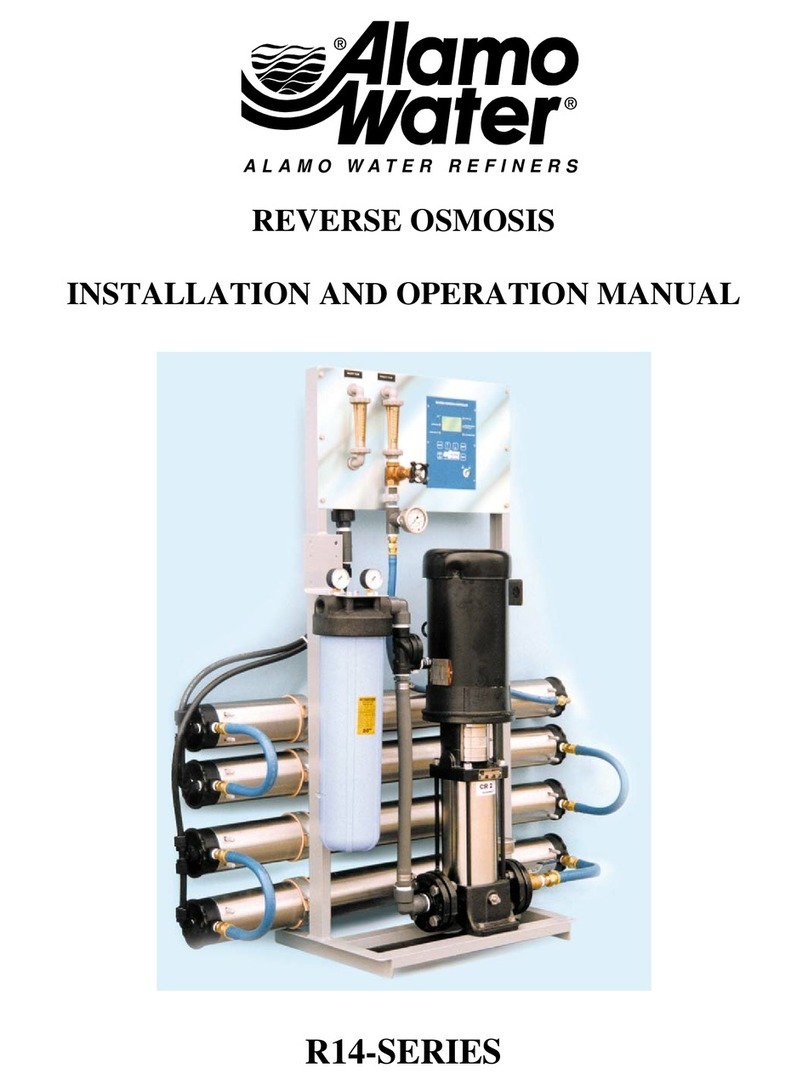

4. Product description ............................................................................................................................8

4.1. Product description ............................................................................................................................................................................................................. 8

4.2. Technical data / performance data...................................................................................................................................................................................... 8

4.3. Type plate ........................................................................................................................................................................................................................... 8

4.4. Construction........................................................................................................................................................................................................................ 9

4.5. Functional description......................................................................................................................................................................................................... 9

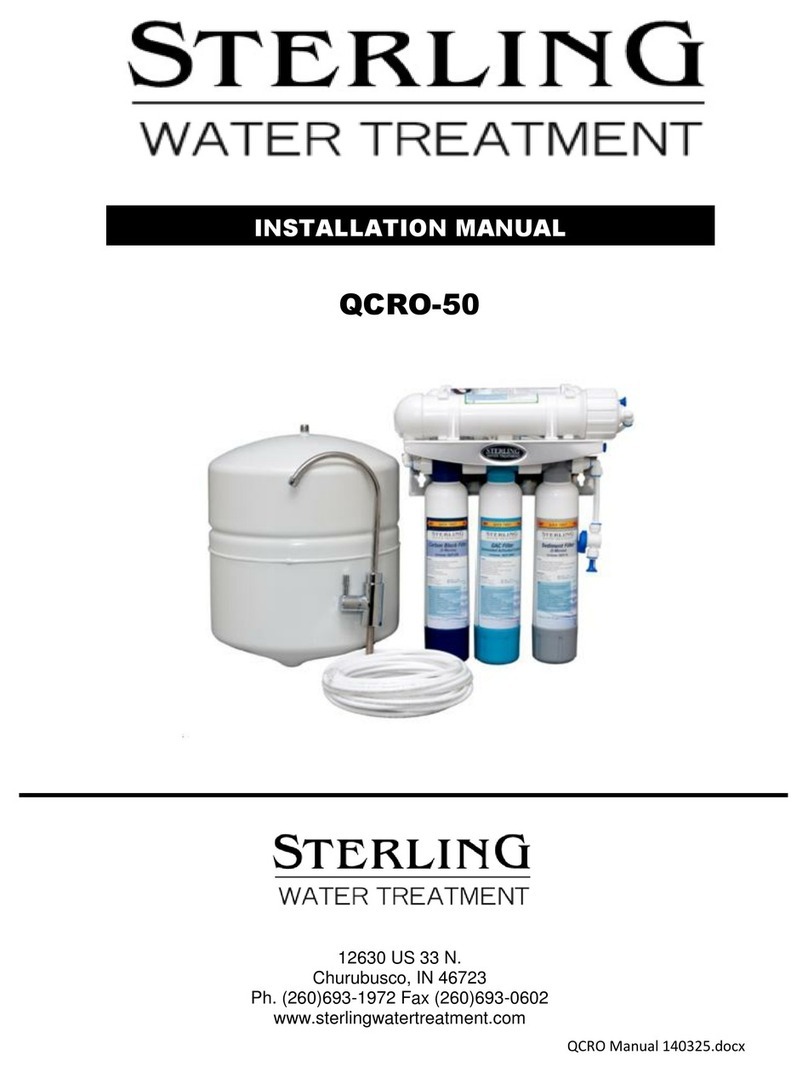

5. Preparation for use ...........................................................................................................................11

5.1. Transport and storage........................................................................................................................................................................................................11

5.2. Installation requirements....................................................................................................................................................................................................11

5.2.1. Assembly variants ..............................................................................................................................................................................................11

5.2.2. Pipe and hose connections ............................................................................................................................................................................... 12

5.2.3. Connection dimensions..................................................................................................................................................................................... 13

5.2.4. Filter .................................................................................................................................................................................................................. 13

5.3. Installation, assembly and commissioning........................................................................................................................................................................ 13

5.3.1. Installationandassemblyofoptionalaccessories,retrotpartsandspareparts ............................................................................................. 15

5.3.1.1. Retrottingthenon-returnvalveforcentrifugepump........................................................................................................................................ 15

5.3.2. Connecting to other devices.............................................................................................................................................................................. 16

5.4. Electronics ........................................................................................................................................................................................................................ 16

5.4.1. Electrical connections........................................................................................................................................................................................ 17

6. Use .....................................................................................................................................................18

6.1. Normal operation .............................................................................................................................................................................................................. 18

6.2. External and internal displays........................................................................................................................................................................................... 18

6.2.1. External display................................................................................................................................................................................................. 18

6.2.2. Internal display .................................................................................................................................................................................................. 18

6.3. Error messages................................................................................................................................................................................................................. 19

7. Care and maintenance......................................................................................................................20

7.1. Regular cleaning measures .............................................................................................................................................................................................. 20

7.1.1. Daily cleaning with GREEN&CLEAN M2 .......................................................................................................................................................... 20

7.1.2. Cleaning the centrifuge inlet probe.................................................................................................................................................................... 20

7.2. Maintenance and service.................................................................................................................................................................................................. 21

7.2.1. Replacement of the collection container ........................................................................................................................................................... 21

7.2.2. Disposal of the collection container................................................................................................................................................................... 23

7.2.3. Normal operation test........................................................................................................................................................................................ 24

7.2.4. 1-year service kit ............................................................................................................................................................................................... 25

7.2.5. 5-year service kit ............................................................................................................................................................................................... 26

7.2.5.1. Visual check of the centrifuge ........................................................................................................................................................................... 26

7.2.6. Replacement of module 2 ................................................................................................................................................................................. 27

7.2.7. Replacement of module 3 ................................................................................................................................................................................. 27

7.2.8. Replacement of the magnetic valve .................................................................................................................................................................. 27

7.2.9. Replacement of inlet main body........................................................................................................................................................................ 28

8. Decommissioning .............................................................................................................................29

8.1. Disassembly...................................................................................................................................................................................................................... 29

8.2. Recycling and disposal ..................................................................................................................................................................................................... 29

9. Annex .................................................................................................................................................30

9.1. REF numbers and scope of delivery................................................................................................................................................................................. 30

9.1.1. Accessories, service kits, collection containers and spare parts....................................................................................................................... 30

9.1.2. Accessories....................................................................................................................................................................................................... 30

9.2. Warranty conditions .......................................................................................................................................................................................................... 38

9.3. Change history.................................................................................................................................................................................................................. 39