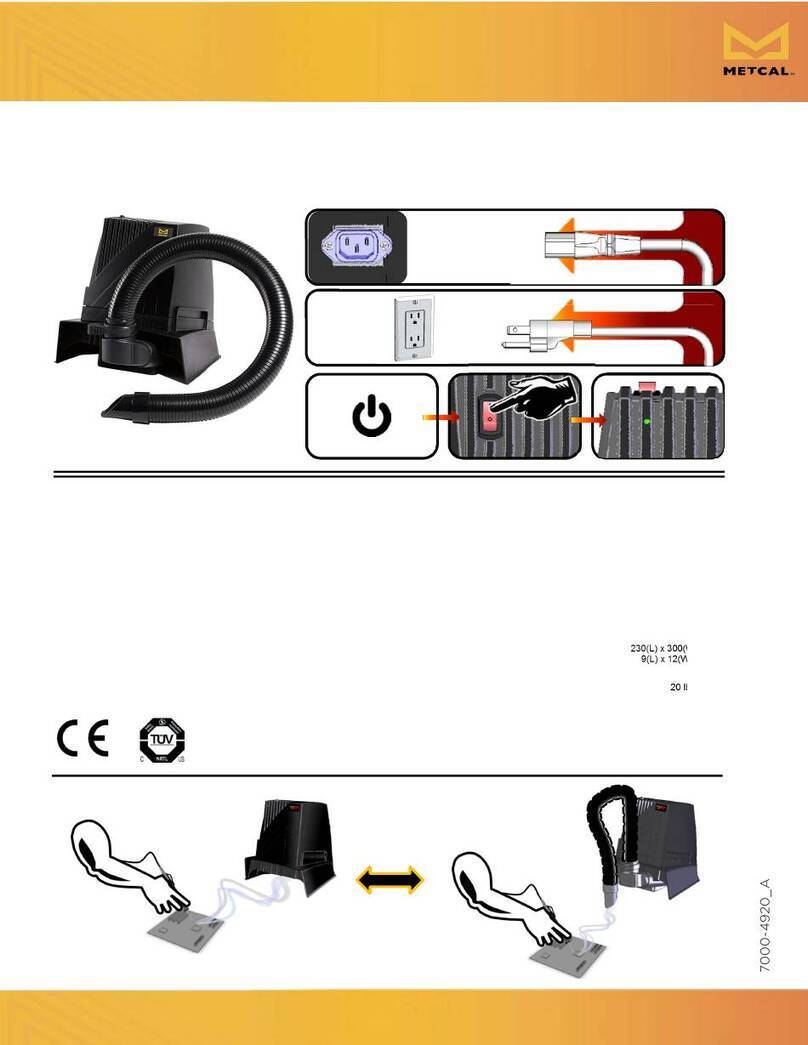

Connect the unit power cord into the outlet on the side of the system. Plug the power cord into a

grounded wall socket.

Warning!

To provide protection against the risk of electrical shock, connect to properly grounded outlets only.

Connect the unit to exhaust arms (optional) per installation instructions. To power up system, depress

the power switch, located on the bottom right of the unit. (Red indicates “Power On” position)

Operator can expect a delay of a few seconds before hearing fan running. This is due to a built-in

motor “Soft-start feature”.

Position the exhaust arms to optimize the fume capture.

Follow maintenance procedures below.

5. Maintenance and Cleaning

5.1. Filter Unit - Maintenance and Safety

The Fume Extraction System is designed with low maintenance in mind. The housing is ESD

safe plastic. Here are a few tips to keep your system running in top shape:

To clean, use a light wipe with a gentle cleaner to prevent buildup of particulate and flux residue

(be sure unit is turned off while cleaning).

Do not block the exhaust outlets; this will cause the operating temperature of the system to rise, potential

damaging the unit, and drop in performance.

Do not defeat the filter interlock switch. Running the system without a filter will allow particulate and flux

residue to adhere to the blower and decrease the life of the system and increase noise.

Do not lift system while operating

Be sure to handle filters with care.

5.2. Filter Replacement Timing

Model BVX-201

When fumes are filtered inside the unit, the particulates captured will start clogging the filter over time.

The coarse particles are collected in the pre-filter while fine particles will be collected in the HEPA

filter. The clogging will result in a reduction of the airflow, which may reduce the amount of fumes

extracted from the work area. This condition may not necessarily require filter replacement. One step

is to move the optional extraction arms closer to application if possible. If the fumes are not extracted

any longer to previous satisfaction level, filter replacement is required. When the filters are blocked,

an alarm will start to sound. See section 5.4 for filter replacement procedures.

Warning!

Do not attempt to clean filters. Attempted cleaning can damage filters and cause potential risk to

health and equipment.

Notice: Metcal recommends replacement of main filters annually as a minimum. Regular changing of

the pre-filter will prolong the life of the main filter (HEPA/Carbon). Use only original replacement

filters.

Model BVX-203

This model features a deep-bed gas filter, which generally does not clog and reduce airflow as

common with HEPA filters. Replace both filters, pre-filter and carbon filter as soon as odors become

noticeable.