Metek 920 User manual

Model 920 Multi-Gas Analyzer

Operator’s Guide

With Essential Health and Safety Requirements

PN 903-8765, Rev. E

Canada

A DIVISION OF AMETEK PROCESS & ANALYTICAL INSTRUMENTS

Western Research

ii | Model 920 Multi-Gas Analyzer

© 2014–2019 AMETEK Canada, A Division of AMETEK Process & Analytical Instruments Printed in Canada

This manual is a guide for the use of the Model 920 Multi-Gas Analyzer. Data herein has been veried and validated and is believed adequate for the

intended use of this instrument. If the instrument or procedures are used for purposes over and above the capabilities specied herein, conrmation of

their validity and suitability should be obtained; otherwise, AMETEK does not guarantee results and assumes no obligation or liability. This publication is

not a license to operate under, or a recommendation to infringe upon, any process patents.

Oces

For other offices not listed here, visit us at www.ametekpi.com.

USA – HEADQUARTERS

150 Freeport Road

Pittsburgh, PA 15238, USA

Tel: 412-828-9040

Toll Free: 800-537-6044

Fax: 412-826-0399

USA – Delaware

455 Corporate Boulevard

Newark, DE 19702, USA

Tel: 302-456-4400 (Main)

800-537-6044 (Service)

800-222-6789 (Ordering)

Fax: 302-456-4444

USA – Texas

4903 West Sam Houston Parkway North

Suite A-400

Houston, TX 77041, USA

Tel: 713-466-4900

Toll Free: 1-800-634-8990

Fax: 713-849-1924

CANADA

AMETEK Canada

2876 Sunridge Way N.E.

Calgary, AB, T1Y 7H9, Canada

Tel: 403-235-8400

Toll Free: 800-661-9198

Fax: 403-248-3550

INDIA

AMETEK Instruments India Pvt. Ltd.

1st Floor, Prestige Featherlite Tech Park

Plot 148, EPIP Phase II

Whitefield, Bengaluru – 560066, Karnataka, India

Tel: 91-80-6782-3200

Fax: 91-80-6782-3232

GERMANY

AMETEK GmbH

Rudolf-Diesel Strasse 16

D-40670 Meerbusch, Germany

Tel: 49-2159-9136-0

Fax: 49-2159-9136-39

FRANCE

AMETEK – APIF

Rond point de l’epine des champs

Buroplus Bat D

78990 Elancourt, France

Tel: 33-1-30-68-89-20

Fax: 33-1-30-68-89-29

CHINA

AMETEK Commercial Enterprise (Shanghai) Co. Ltd.

Part A First Floor, 460 North

Fute Road

Waigaoqiao Free Trade Zone

Shanghai, 200131, China

Tel: 86-21-5868-5111

Fax: 86-28-5866-0969

Beijing Branch

Tel: 86-10-8526-2111

Fax: 86-10-8526-2141

Chengdu Branch

Tel: 86-28-8675-8111

Fax: 86-28-8675-8141

Guangzhou Branch

Tel: 86-20-8363-4768

Fax: 86-20-8363-3701

MIDDLE EAST – Dubai

P.O. Box 17067

Jebel Ali Free Zone

Dubai, UAE

Tel: 971-4-881-2052

Fax: 971-4-881-2053

SINGAPORE

AMETEK Singapore Pte. Ltd.

No. 43, Changi South

Avenue 2, #04-01

486164 Singapore

Tel: 65-6486-2388

Fax: 65-6481-6588

Contents | iii

Contents

Offices .................................................................................................................................. ii

Safety Notes ....................................................................................................................... ix

Electrical Safety.................................................................................................................. ix

Grounding.......................................................................................................................... ix

Personnel and Equipment Safety Information.............................................................. x

Warnings ....................................................................................................................... x

Cautions ...................................................................................................................... xii

Warning Labels................................................................................................................ xiii

Environmental Information .......................................................................................... xiii

UV Source Lamps Disposal ........................................................................................... xiii

Electromagnetic Compatibility (EMC)......................................................................... xiv

Special Warnings and Information................................................................................ xv

Equipment Used in Hazardous Locations............................................................. xv

EU Declaration of Conformity ...................................................................................... xvi

Warranty and Claims....................................................................................................xviii

CHAPTER 1 OVERVIEW....................................................................................................... 1-1

About the Analyzer......................................................................................................... 1-2

Sample Flow .............................................................................................................. 1-3

About the Analyzer Sample System............................................................................. 1-3

Temperature Control System......................................................................................... 1-8

Sample/Vent Lines .................................................................................................... 1-8

Measuring Cell.......................................................................................................... 1-8

Working in This Manual ................................................................................................ 1-9

Supplemental Information – Where Can I Find It?................................................. 1-10

CHAPTER 2 SPECIFICATIONS ........................................................................................... 2-1

Methodology.................................................................................................................... 2-1

Standard Ranges....................................................................................................... 2-1

Response Time................................................................................................................. 2-2

Accuracy............................................................................................................................ 2-2

Repeatability .................................................................................................................... 2-2

Calibration........................................................................................................................ 2-2

Linearity............................................................................................................................ 2-2

Zero Stability.................................................................................................................... 2-2

Cross-Talk.......................................................................................................................... 2-2

Temperature Drift............................................................................................................ 2-3

24-Hour Zero Drift .......................................................................................................... 2-3

Customer Connections................................................................................................... 2-3

Analog Outputs ........................................................................................................ 2-3

Digital Communication ........................................................................................... 2-3

iv | Model 920 Multi-Gas Analyzer

Maximum Sample Gas Pressure ................................................................................... 2-4

Electrical Requirements.................................................................................................. 2-4

Maximum Start-Up Power ..................................................................................... 2-4

Supply Voltage .......................................................................................................... 2-4

Status Relays .................................................................................................................... 2-4

Sample Gas Flow Rate.................................................................................................... 2-4

Ambient Limits ................................................................................................................ 2-5

Temperature............................................................................................................... 2-5

Humidity.................................................................................................................... 2-5

Maximum Altitude ................................................................................................... 2-5

Sample Transport ............................................................................................................ 2-5

Instrument Air Requirements ....................................................................................... 2-5

Physical Dimensions (on Backpan).............................................................................. 2-5

O2Concentration Signal (Optional)............................................................................. 2-6

Speed of Response.................................................................................................... 2-6

Accuracy..................................................................................................................... 2-6

Repeatability.............................................................................................................. 2-6

24-Hour Zero Drift ................................................................................................... 2-6

Temperature Drift..................................................................................................... 2-6

Electrical Classification ............................................................................................ 2-6

SO2Concentration Signal (Optional) .......................................................................... 2-7

Full-Scale Maximum................................................................................................. 2-7

Cross Interference .................................................................................................... 2-7

Linearity..................................................................................................................... 2-7

Reproducibility ......................................................................................................... 2-7

Temperature Coefficient.......................................................................................... 2-7

Speed of Response.................................................................................................... 2-7

Zero Stability ............................................................................................................. 2-7

NOxConcentration Signals ........................................................................................... 2-8

Full Scale Maximum................................................................................................. 2-8

Cross Interference .................................................................................................... 2-8

Linearity..................................................................................................................... 2-8

Ambient Temperature Coefficient.......................................................................... 2-8

Reproducibility ......................................................................................................... 2-8

Speed of Response.................................................................................................... 2-8

Zero Stability ............................................................................................................. 2-8

Cable Entry Ports, Type 200 Disconnect Enclosure.................................................... 2-9

Approvals and Certifications......................................................................................... 2-9

ATEX and IECEx Certificates and Analyzer Markings..................................... 2-10

Purged Analyzer ATEX and IECEx Certificates and Markings....................... 2-10

Systems with 30 psia Pressure Transducer (Maximum 63 kPag

Sample Gas Pressure) ..................................................................................2-18

Systems with 100 psia Pressure Transducer (Maximum 350 kPag

Sample Gas Pressure) ..................................................................................2-18

Heater Plate ATEX and IECEx Certificates and Marking................................ 2-19

Disconnect Enclosure Type 200 ATEX and IECEx Certificates and Marking . 2-26

Contents | v

CHAPTER 3 INSTALLATION AND START-UP................................................................... 3-1

Safety Considerations..................................................................................................... 3-2

Pre-Installation Requirements....................................................................................... 3-2

Storage Prior to Installation .................................................................................... 3-2

Uncrating and Inspecting the Analyzer................................................................ 3-3

Tools and Equipment Required.............................................................................. 3-4

Installing the Mechanical Components....................................................................... 3-5

Installing the Analyzer............................................................................................. 3-5

Location and Environment.................................................................................. 3-5

Installing the Optical Bench Assembly ................................................................. 3-7

Installing the Sample System................................................................................ 3-12

Installing the Sample Probe, SCU, or Steam Jacketed Sample/Vent Valves...... 3-12

Installing the Sample and Vent Lines................................................................ 3-13

Installing the Steam Lines (if Used).................................................................. 3-19

Installing Insulation Around the Valve Assemblies.......................................... 3-20

Installing the Instrument Air Line ................................................................... 3-21

Installing the Span/Zero Gas Lines................................................................... 3-22

Connecting I/O Signals, Alarm Relay Contacts, and AC Power ............................ 3-23

Start-Up and Verification ............................................................................................. 3-29

Purged Analyzers ................................................................................................... 3-30

Powering Up the Analyzer.................................................................................... 3-32

Start-Up Diagnostic Checklist .......................................................................... 3-37

Sample System Leak Check .................................................................................. 3-40

Manually Zeroing the Analyzer........................................................................... 3-42

Setting the Zero Gas Flow Rate............................................................................ 3-43

Setting the Sample Gas Flow Rate and Sample Response Time..................... 3-44

Normal Operation......................................................................................................... 3-45

Recording Initial Readings.................................................................................... 3-45

Recording PMT Signals.................................................................................... 3-45

Recording Initial Sample Response Time .......................................................... 3-46

Analyzer Configuration ............................................................................................... 3-47

CHAPTER 4 CONTROLLER / USER INTERFACE............................................................. 4-1

Introduction to the User Interface................................................................................ 4-2

User Interface Components.................................................................................... 4-2

Messages/Information Displayed on the User Interface.................................... 4-4

Navigating From the User Interface...................................................................... 4-5

Working in RUN Mode....................................................................................... 4-6

Working in CFG Mode........................................................................................ 4-6

Working in CAL Mode ........................................................................................ 4-7

Navigation Examples .......................................................................................... 4-8

Entering Passwords to Change Analyzer Parameter Settings........................... 4-10

Changing the Password for CFG / CAL Mode.............................................4-10

RUN / CFG Mode Quick Reference Sheet – Keystroke Commands.................. 4-12

CAL Mode Quick Reference Sheet – Keystroke Commands.............................. 4-13

vi | Model 920 Multi-Gas Analyzer

Working in the RUN / CFG Operating Modes ......................................................... 4-14

RUN / CFG Mode – F1 Commands ..................................................................... 4-15

RUN / CFG Mode – F2 Commands ..................................................................... 4-17

RUN / CFG Mode – F3 Commands ..................................................................... 4-20

RUN / CFG Mode – F4 Commands ..................................................................... 4-21

RUN / CFG Mode – F5 Commands ..................................................................... 4-23

RUN / CFG Mode – F6 Commands ..................................................................... 4-25

Configuring the Analyzer Control Functions ................................................... 4-28

Output Signal Assignment (OSA)..............................................................4-28

Assigning Output Signals With the Track-and-Hold Function

Enabled/Disabled .........................................................................................4-29

Analog Input Channels – Micro-Interface Board.............................................. 4-30

Display I/O Board Analog Input Signals ....................................................4-31

Working in the CAL Operating Mode ....................................................................... 4-32

CAL Mode – F1 Commands.................................................................................. 4-33

CAL Mode – F2 Commands.................................................................................. 4-34

CAL Mode – F3 Commands.................................................................................. 4-35

CAL Mode – F4 Commands.................................................................................. 4-36

CAL Mode – F5 Commands.................................................................................. 4-37

CAL Mode – F6 Commands.................................................................................. 4-39

Setting Up Analyzer Calibration Functions ....................................................... 4-40

Flow Control (Sample) Modes........................................................................... 4-40

Analyzer Control Mode (Automatic Control by Analyzer).........................4-41

Continuous Backpurge Flow Mode (Manual Control by Operator) ...........4-42

Continuous Sample Flow Mode (Manual Control by Operator).................4-42

Continuous Zero Gas Flow Mode (Manual Control by Operator)..............4-42

Continuous Calibration Gas Flow Mode (Manual Control by Operator)...4-43

Setting Calibration Gas Timers............................................................................. 4-44

Timer0, Timer1, Timer2..................................................................................... 4-44

Integration Timer (IntTime).............................................................................. 4-45

Auto-Calibration Interval Timer (ACal) ........................................................... 4-45

Auto-Zero Interval Timer (AZInt).................................................................... 4-45

Setting the Sample Delay Timer (SDelay) ........................................................ 4-46

Manual Zero/Span.................................................................................................. 4-47

Manual Zero...................................................................................................... 4-47

Manual Span..................................................................................................... 4-47

Spanning Dual Range....................................................................................... 4-51

Solenoid Valve Control ...................................................................................... 4-53

Calculated Result Name ..............................................................................4-54

SSR Output Assignment .................................................................................. 4-55

Auto-Zero/Auto-Span ............................................................................................ 4-58

Manual Start of Auto-Zero ............................................................................... 4-60

Timed Start of Auto-Zero .................................................................................. 4-60

Manual Start of Auto-Span............................................................................... 4-61

Contents | vii

Auto-Calibration ..................................................................................................... 4-62

Timed Start of Auto-Calibration ....................................................................... 4-62

Manual Start of Auto-Calibration..................................................................... 4-63

Remote Start of Auto-Calibration ..................................................................... 4-64

Analog Output Calibration ................................................................................... 4-66

Probe Blow-Back Control (Optional) ................................................................ 4-68

CHAPTER 5 MAINTENANCE AND TROUBLESHOOTING............................................... 5-1

Safety Considerations..................................................................................................... 5-1

Preventive Maintenance ................................................................................................ 5-2

Analyzer Preventive Maintenance Schedule....................................................... 5-3

Expo Technologies MiniPurge®System With eTimer (Optional) Preventive

Maintenance Schedule......................................................................................... 5-6

Preventing, Detecting, and Locating a Plug in the Sample System................. 5-6

Changing Out Replaceable Parts ........................................................................... 5-8

Measuring Cell Maintenance.............................................................................. 5-8

Replacing the Source Lamps.............................................................................. 5-17

When Do Source Lamps Need to be Replaced?............................................5-17

About the Source Lamps ..............................................................................5-17

Source Lamp Replacement...........................................................................5-18

When is an Auto-Setup Required / Not Required?......................................5-25

Auto-Setup Completion Number.................................................................5-25

PMT Level and PMT Balance .....................................................................5-26

Auto-Setup Fault Messages and Corrective Action.....................................5-27

The Auto-Setup Sequence ............................................................................5-28

Manipulating the Completion Number, PMT Level, and PMT Balance ....5-29

Chopper Assembly Maintenance ....................................................................... 5-31

Replacing Parts in the Heater Plate................................................................... 5-40

Optional HAG Sample Probe Preventive Maintenance.................................... 5-54

Examining and Caring For the Flamepaths ....................................................... 5-55

Disconnect Enclosure Flamepath (Joining Surfaces)......................................... 5-56

Heater Plate Flange Flamepath (Joining Surfaces)............................................ 5-57

Troubleshooting and Diagnostics ............................................................................... 5-58

Host Controller Board Alarm Conditions and Corrective Action .................. 5-60

Microcontroller Board Alarm Conditions and Corrective Action .................. 5-68

Analyzer Reset ........................................................................................................ 5-72

viii | Model 920 Multi-Gas Analyzer

CHAPTER 6 SERVICE AND PARTS.................................................................................... 6-1

Technical Support............................................................................................................ 6-1

Returning Equipment..................................................................................................... 6-2

?? ANSWERS TO YOUR QUESTIONS ??................................................................... 6-3

AMETEK SERVICE and AFTERMARKET SALES SUPPORT............................ 6-3

Recommended Preventive Maintenance Spare Parts ............................................... 6-4

Optical Bench/Measuring Cell Spare Parts........................................................... 6-4

Expo Technologies MiniPurge®System With eTimer Spare Parts.................... 6-5

Sample Conditioning Unit (SCU) Spare Parts ..................................................... 6-6

Spare Analyzer Fuses ............................................................................................... 6-7

Replacement Boards................................................................................................. 6-9

Oven Heater Spare Parts ....................................................................................... 6-10

Ordering a Hard Copy of the Analyzer Operator’s Guide .............................. 6-10

CHAPTER 7 GLOSSARY...................................................................................................... 7-1

User Interface Abbreviations......................................................................................... 7-1

Abbreviations and Terms Used in This Manual ......................................................... 7-2

APPENDIX A – DRAWINGS...................................................................................................A-1

Ribbon Cable Interconnect (WX-102836).................................................................... A-2

GP Lower Enclosure to Electronics Wiring, CE Analyzers (WX-102810) .............. A-3

Heater and Sensor Wiring, GP/Div 2 Analyzers (WX-102851)................................ A-4

Heater and Sensor Wiring, CE/Zone 1 Analyzers (WX-102852) ............................. A-5

Lower Cabinet Wiring, CE/GP Analyzers, 120V (100-1341-3) ................................. A-6

Lower Cabinet Wiring, CE/GP Analyzers, 240V (100-1342-3) ................................. A-7

Signal Wiring, PD/GP/Div 2/CE/Zone 1 Analyzers (WX-102815) ........................... A-8

Wiring Diagram, All Seals, Zone 1 Analyzers (100-1343-10).................................... A-9

± 15V and 5V Power Supply DC Wiring, GP/Div 2/CE/Zone 1 Analyzers

(WX-102811) .................................................................................................................. A-10

24V Power Supply DC Wiring, CE/Zone 1 Analyzers (WX-102812)..................... A-11

RS-232 Communications Cable Wiring (300-9480).................................................. A-12

RS-232/RS-485 Module Wiring, CE/Zone 1 & GP/Div 2 Analyzers (100-2185) ... A-13

Microcontroller Board (100-0117) .............................................................................. A-14

Host Controller Board (Display Interface) (100-0138) ............................................ A-15

Model 9xx-Series Analyzer Type 200 Disconnect Enclosure Details.................... A-16

SUPPLEMENTAL INFORMATION ........................................................................................S-1

Contents | ix

Safety Notes

WARNINGS, CAUTIONS, and NOTES contained in this manual emphasize critical instructions

as follows:

An operating procedure which, if not strictly observed, may result in personal injury or envi-

ronmental contamination. Essential Health and Safety Requirements are also included in

– but are not limited to – Warnings.

An operating procedure which, if not strictly observed, may result in damage to the equipment.

Important information that should not be overlooked.

Electrical Safety

High voltages are present in the analyzer housings. Always shut down power source(s) before

performing maintenance or troubleshooting. Only a qualified electrician should make electrical

connections and ground checks.

Any use of the equipment in a manner not specified by the manufacturer may impair the safety

protection originally provided by the equipment.

Grounding

Instrument grounding is mandatory. Performance specifications and safety protection are void if

instrument is operated from an improperly grounded power source.

Verify ground continuity of all equipment before applying power.

!

WARNING

!

CAUTION

NOTE

!

CAUTION

x | Model 920 Multi-Gas Analyzer

Personnel and Equipment Safety Information

This section describes important safety information to avoid personal injury and damage to the

equipment while installing, operating, maintaining, or servicing the equipment. All safety regu-

lations, standards, and procedures at the analyzer location must be followed.

All personnel involved with the installation, start-up, operation, maintenance, service, or trou-

bleshooting of the analyzer must review and follow these Warnings and Cautions.

Warnings

Review and follow these Warnings to avoid personal injury or environmental contamination.

Always disconnect main AC power and/or external power sources to the analyzer before open-

ing any covers or doors on the analyzer to check or perform maintenance on any components

within the enclosures.

If it is necessary to open the analyzer’s covers or doors while the circuits are live, test the area

for flammable gases (and proceed only when the area is safe).

Purged Analyzer (Hazardous Location) Applications

To work on the analyzer with it powered up and its Electronics Enclosure door open, the Purge

Bypass Switch must be in the “BYPASS” position.

When the Electronics Enclosure door is open, take appropriate precautions to avoid electrical

shock. Hazardous voltages are present inside.

All electrical connections, adjustments, or servicing of the analyzer should be performed only

by properly trained and qualified personnel.

All electrical connections, materials, and methods (plus all safety policies and procedures) must

be made in compliance with local wiring regulations and electrical code for the hazardous area,

and be approved by the Owner Company.

Follow appropriate regulatory and/or company procedures to lock out the analyzer while work-

ing on its electronics.

Before working on the sample system, confirm that the system is purged with Zero gas and is

isolated (blocked in) from the sample stream.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Contents | xi

Because ultraviolet radiation can harm your eyes, avoid direct viewing of the light emanating

through the end window of the source lamp. If the source lamp must be viewed while ener-

gized, wear safety glasses that block ultraviolet radiation.

The Analyzer Oven enclosure and components within the Analyzer Oven are hot; take precau-

tions to avoid burning yourself.

Purged Analyzer (Hazardous Location) Applications

[Special Conditions for Safe Use]

The analyzer may only be energized by using the Purge Bypass Switch with permission of

the works manager or his proxy. The permission may only be given when it is made sure that

during the time the system is energized by using this switch an explosive atmosphere is not

present or when the necessary protective measures against explosion hazard have been taken

(“hot permit”).

The analyzer enclosure may not be opened when an explosive atmosphere is present.

Purged Analyzer (Hazardous Location) Applications

Do not apply power to the analyzer if there is damage (scratches, indentations, or wear) to any

flamepath (on the Oven Heater or Disconnect Enclosure). Applying power to an analyzer with

a damaged flamepath is dangerous and could result in serious injury or death, or serious dam-

age to equipment. See “Examining and Caring for the Flamepaths” in Chapter 5.

Replace parts immediately if damage or wear is apparent. Contact AMETEK if there is any

doubt about the integrity of any flamepath.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

xii | Model 920 Multi-Gas Analyzer

Cautions

Review and follow these Cautions to avoid damaging the equipment.

The electronic circuit boards and other static-sensitive components should be stored and trans-

ported in static-shielding carriers or packages.

For electrical-shock protection, the analyzer must be operated from a grounded power source

that has a securely connected protective-ground contact.

If it becomes necessary to handle any of the electronic circuit boards, do not subject the boards

to static discharge. The ideal solution is a static-safe work area. Since such areas typically

are not available at analyzer installation sites, the use of a wrist strap connected directly to a

ground is recommended. If a wrist strap is not available, you should at the very least touch the

metal chassis (to ground yourself) before handling or touching the boards.

When handling the source lamps, it is very important not to touch the lamp windows because

residual oils from the fingers will absorb ultraviolet light. The window is the flat surface at the

end of the narrow glass tube. The lamp assembly is fragile and should be handled with care.

Purged Analyzer (Hazardous Location) Applications

M25 x 1.5, 6H cable entries are provided for Power (1 entry) and Signals (2 entries). See the

Model 9xx-Series Analyzer Type 200 Disconnect Enclosure Details drawing in Appendix A

for cable entry locations. In all cases, all unused cable entry ports must be plugged with a certi-

fied Ex d plug.

For Division 1/Zone 1 Installations, all cable entry glands (one power cable entry and two

signal cable entries) into the flameproof Disconnect Enclosure must be Ex d certified. Conduit

or cable seals that comply with the flameproof enclosure cable entry sealing requirements of the

local authority must be installed at the entries to the disconnect enclosure.

For Division 2/Zone 2 Installations that do not use the Disconnect Enclosure, use a suitable

cable entry device with a sealing ring that meets the local requirements for entries into pres-

surized enclosures.

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

Contents | xiii

Warning Labels

These symbols may appear on the instrument in order to alert you of existing conditions.

Protective Conductor Terminal

(BORNIER DE L’ECRAN DE PROTECTION)

Schutzerde

Caution – Risk of electric shock

(ATTENTION – RISQUE DE DÉCHARGE ÉLECTRIQUE)

Achtung – Hochspannung Lebensgefahr

Caution – Refer to accompanying documents

(ATTENTION – SE RÉFERER AUX DOCUMENTS JOINTS)

Achtung – Beachten Sie beiliegende Dokumente

CAUTION – Hot Surface

(ATTENTION – SURFACE CHAUDE)

Achtung – Heiße Oberäche

Environmental Information

This AMETEK product contains materials that can be reclaimed and recycled. In some cases the

product may contain materials known to be hazardous to the environment or human health.

In order to prevent the release of harmful substances into the environment and to conserve

our natural resources, AMETEK recommends that you arrange to recycle this product when it

reaches its “end of life”.

Waste Electrical and Electronic Equipment (WEEE) should never be disposed of in a munici-

pal waste system (residential trash). The Wheelie Bin marking on this product is a reminder to

dispose of the product properly after it has completed its useful life and been removed from

service. Metals, plastics, and other components are recyclable and you can do your part by doing

one of the following steps:

• When the equipment is ready to be disposed of, take it to your local or region-

al waste collection administration for recycling.

• In some cases, your “end of life” product may be traded in for credit towards

the purchase of new AMETEK instruments. Contact your dealer to see if this

program is available in your area.

• If you need further assistance in recycling your AMETEK product, contact our

office listed in this manual.

UV Source Lamps Disposal

AMETEK recommends that all UV lamps – whether they are new, used, or damaged in any way

– need to be disposed of in an environmentally safe manner.

Most UV lamps do not contain restricted substances listed under the European RoHS 2 direc-

tive. However, special handling requirements are required for some lamps if they are broken.

Two examples include Cadmium and Beryllium lamps. Refer to a current Material Safety Data

Sheet (MSDS) for handling any lamp where the glass envelope has been broken and which has

exposed the metal cathode in the centre of the lamp.

xiv | Model 920 Multi-Gas Analyzer

Electromagnetic Compatibility (EMC)

Read and follow the recommendations in this section to avoid performance variations or dam-

age to the internal circuits of this equipment when installed in harsh electrical environments.

The various configurations of the Model 920 Multi-Gas Analyzer should not produce, or fall

victim to, electromagnetic disturbances as specified in the European Union’s EMC Directive

(if applicable to your application). Strict compliance to the EMC Directive requires that certain

installation techniques and wiring practices are used to prevent or minimize erratic behavior of

the Analyzer or its electronic neighbors. Below are examples of the techniques and wiring prac-

tices to be followed.

In meeting the EMC requirements, the various Analyzer configurations described in this manual

rely heavily on the use of metallic shielded cables used to connect to the customer’s equipment

and power. Foil and braid shielded I/O and DC power cables are recommended for use in other-

wise unprotected situations. In addition, hard conduit, flexible conduit, and armor around non-

shielded wiring also provides excellent control of radio frequency disturbances. However, use of

these shielding techniques is effective only when the shielding element is connected to the equip-

ment chassis/earth ground at both ends of the cable run. This may cause ground loop problems in

some cases. These should be treated on a case-by-case basis. Disconnecting one shield ground may

not provide sufficient protection depending on the electronic environment. Connecting one shield

ground via a 0.1 microfarad ceramic capacitor is a technique allowing high frequency shield bond-

ing while avoiding the AC-ground metal connection. In the case of shielded cables the drain wire

or braid connection must be kept short. A two-inch connection distance between the shield’s end

and the nearest grounded chassis point, ground bar or terminal is highly recommended. An even

greater degree of shield performance can be achieved by using metallic glands for shielded cable

entry into metal enclosures. Expose enough of the braid/foil/drain where it passes through the

gland so that the shield materials can be wrapped backwards onto the cable jacket and captured

inside the gland, and tightened up against the metal interior.

Inductive loads connected to the low voltage “Alarm Contacts” are not recommended. However, if

this becomes a necessity, adhere to proper techniques and wiring practices. Install an appropriate

transient voltage suppression device (low voltage MOV, “Transzorb,” or R/C) as close as possible to

the inductive device to reduce the generation of transients. Do not run this type of signal wiring

along with other I/O or DC in the same shielded cable. Inductive load wiring must be separated

from other circuits in conduit by using an additional cable shield on the offending cable.

In general, for optimum protection against high frequency transients and other disturbances, do

not allow installation of this Analyzer where its unshielded I/O and DC circuits are physically

mixed with AC mains or any other circuit that could induce transients into the Analyzer or the

overall system. Examples of electrical events and devices known for the generation of harmful

electromagnetic disturbances include motors, capacitor bank switching, storm related transients,

RF welding equipment, static, and walkie-talkies.

!

CAUTION

Contents | xv

Special Warnings and Information

Equipment Used in Hazardous Locations

Refer to Chapter 2 – Specifications for details about the suitability of this equipment in hazard-

ous locations. This analyzer must not be commissioned until a person trained in the area of

evaluating equipment for use in hazardous classified locations has confirmed that this equip-

ment and its installation are in compliance with the requirements for the area.

Explosion Hazard – Do Not Disconnect Equipment Unless Power Has Been Switched Off or

the Area is Known to be Non-Hazardous.

Risque d’explosion – Avant de déconnecter l’équipement, coupez le courant où vous assurez

que l’emplacement est designé non dangereux.

All input and output wiring must be in accordance with wiring methods authorized for the area

classification by the authority having jurisdiction. Ex d glands or stopping boxes (seals) must

be installed on flameproof enclosures and sealing glands must be used for connections made

directly to the pressurized enclosure.

!

WARNING

!

Avertissement

xvi | Model 920 Multi-Gas Analyzer

EU Declaration of Conformity

PN 903-8594 Rev M

EU Declaration of Conformity

Manufacturer’s Name: AMETEK Canada

A Division of AMETEK Process & Analytical Instruments

(ISO 9001:2008 Registered)

Manufacturer’s Address: 2876 Sunridge Way N.E.

Calgary, Alberta, Canada T1Y 7H9

Phone: (403) 235-8400 / Fax: (403) 248-3550

EU Representative Address: AMETEK Precision Instruments Europe GmbH

Rudolf-Diesel-Str. 16

D-40670 Meerbusch, Germany

Phone 49-2159 91 36 0 / Fax: 49-2159 91 36 80

Declare under our sole responsibility that the products:

Product Names: Model 9xx-Series Photometric Analyzers

Model Numbers: 900/930/909/910/919/920

Markings: II 2 G Ex db eb ia pxb IIB T3 Gb (Model 9XX Purged Analyzers)

II 2 G Ex db IIB T3 Gb (900 Series Heater Plate)

II 2 G Ex db IIB T6 Gb (Disconnect Enclosure Type 200)

Conform to the following EU Standards and Directives:

Electromagnetic Compatibility Directive 2014/30/EU using the following standards:

IEC/EN 61326-1 Electrical equipment for measurement, control and laboratory use – EMC requirements –

Part 1: General requirements.

IEC/EN 55011 (CISPR 55011) Radiated Electromagnetic Emissions, Class A 30 MHz to 1 GHz.

IEC/EN 55011 (CISPR 55011) Conducted Electromagnetic Emissions, Class A.

IEC/EN61000-3-2 Limitsforharmoniccurrentemissions(equipmentinputcurrent≤16Aperphase).

IEC/EN61000-3-3 Limitationofvoltagechanges,voltageuctuationsandickerinpubliclow-voltagesupply

systems,forequipmentwithratedcurrent≤16Aperphaseandnotsubjecttoconditional

connection.

IEC/EN 61000-4-2 Testing and measurement techniques – Electrostatic discharge immunity test.

IEC/EN61000-4-3 Testingandmeasurementtechniques–Radiated,radio-frequency,electromagneticeld

immunity test.

IEC/EN 61000-4-4 Testing and measurement techniques – Electrical fast transient/burst immunity test.

IEC/EN 61000-4-5 Testing and measurement techniques – Surge immunity test.

IEC/EN 61000-4-6 Testing and measurement techniques – Immunity to conducted disturbances, induced by

radio-frequencyelds.

IEC/EN61000-4-8 Testingandmeasurementtechniques–Powerfrequencymagneticeldimmunitytest.

IEC/EN 61000-4-11 Testing and measurement techniques – Voltage dips, short interruptions and voltage

variations immunity tests.

Restriction of Hazardous Substances Directive 2011/65/EU (RoHS 2).

Low Voltage Directive 2014/35/EU using the following standards:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use – Part 1. General requirements.

Pressure Equipment Directive 2014/68/EU

Article 4, Paragraph 3

Page 1 of 2

Canada

A DIVISION OF AMETEK PROCESS & ANALYTICAL INSTRUMENTS

Western Research

Contents | xvii

EU Declaration of Conformity

The object of the declaration described [herein] is in conformity with the relevant Union harmonization

legislation (Directive 2014/34/EU):

EN 60079-0:2012+A11:2013 General requirements

EN60079-1:2014 Equipmentprotectionbyameproofenclosures‘d’

EN60079-2:2014 Equipmentprotectionbypressurizedenclosures‘p’

EN60079-7:2015+A1:2018 Equipmentprotectionbyincreasedsafety‘e’

EN60079-11:2012 Equipmentprotectionbyintrinsicsafety‘i’

CerticateNumber: KEMA02ATEX2341X(Model9XXPurgedAnalyzers)

KEMA 02ATEX2255 X (900 Series Heater Plate)

KEMA 01ATEX2219 X (Disconnect Enclosure Type 200)

NotiedBody: DEKRACerticationB.V.0344

Meander 1051, 6825 MJ Arnhem

The Netherlands

____________________________

Randy Meads

Quality Assurance Manager

Calgary, Alberta, Canada

February 12, 2019

Page 2 of 2

Canada

A DIVISION OF AMETEK PROCESS & ANALYTICAL INSTRUMENTS

Western Research

xviii | Model 920 Multi-Gas Analyzer

Warranty and Claims

We warrant that any equipment of our own manufacture or manufactured for us pursuant to our specifications

which shall not be, at the time of shipment thereof by or for us, free from defects in material or workmanship under

normal use and service will be repaired or replaced (at our option) by us free of charge, provided that written notice

of such defect is received by us within twelve (12) months from date of shipment of portable analyzers or within

eighteen (18) months from date of shipment or twelve (12) months from date of installation of permanent equipment,

whichever period is shorter. All equipment requiring repair or replacement under the warranty shall be returned to

us at our factory, or at such other location as we may designate, transportation prepaid. Such returned equipment

shall be examined by us and if it is found to be defective as a result of defective materials or workmanship, it shall

be repaired or replaced as aforesaid. Our obligation does not include the cost of furnishing any labor in connection

with the installation of such repaired or replaced equipment or parts thereof, nor does it include the responsibility

or cost of transportation. In addition, instead of repairing or replacing the equipment returned to us as aforesaid,

we may, at our option, take back the defective equipment, and refund in full settlement the purchase price thereof

paid by Buyer.

Process photometric analyzers, process moisture analyzers, and sample systems are warranted to perform the in-

tended measurement, only in the event that the customer has supplied, and AMETEK has accepted, valid sample

stream composition data, process conditions, and electrical area classification prior to order acknowledgment. The

photometric light sources are warranted for ninety (90) days from date of shipment. Resale items warranty is limited

to the transferable portion of the original equipment manufacturer’s warranty to AMETEK. If you are returning

equipment from outside Canada, a statement should appear on the documentation accompanying the equipment

being returned declaring that the goods being returned for repair are Canadian goods, the name of the firm who

purchased the goods, and the shipment date.

The warranty shall not apply to any equipment (or part thereof) which has been tampered with or altered after

leaving our control or which has been replaced by anyone except us, or which has been subject to misuse, neglect,

abuse or improper use. Misuse or abuse of the equipment, or any part thereof, shall be construed to include, but

shall not be limited to, damage by negligence, accident, fire or force of the elements. Improper use or misapplications

shall be construed to include improper or inadequate protection against shock, vibration, high or low temperature,

overpressure, excess voltage and the like, or operating the equipment with or in a corrosive, explosive or combustible

medium, unless the equipment is specifically designed for such service, or exposure to any other service or environ-

ment of greater severity than that for which the equipment was designed.

The warranty does not apply to used or secondhand equipment nor extend to anyone other than the original

purchaser from AMETEK. Should the Buyer’s technical staff require the on-site assistance of AMETEK’s agents or

employees for service calls covered by this warranty clause, the Buyer shall pay travel time plus actual travel and

living expenses.

THIS WARRANTY IS GIVEN AND ACCEPTED IN LIEU OF ALL OTHER WARRANTIES, WHETHER EXPRESS OR

IMPLIED, INCLUDING WITHOUT LIMITATION AND WARRANTIES OF FITNESS OR OF MERCHANTABILITY

OTHER THAN AS EXPRESSLY SET FORTH HEREIN, AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON

OUR PART. IN NO EVENT SHALL WE BE LIABLE UNDER THIS WARRANTY OR ANY OTHER PROVISION OF

THIS AGREEMENT FOR ANY ANTICIPATED OR LOST PROFITS, INCIDENTAL DAMAGES, CONSEQUENTIAL

DAMAGES, TIME CHANGES OR ANY OTHER LOSSES INCURRED BY THE ORIGINAL PURCHASER OR

ANY THIRD PARTY IN CONNECTION WITH THE PURCHASE, INSTALLATION, REPAIR OR OPERATION

OF EQUIPMENT, OR ANY PART THEREOF COVERED BY THIS WARRANTY OR OTHERWISE. WE MAKE NO

WARRANTY, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTIES OF FITNESS OR

OF MERCHANTABILITY, AS TO ANY OTHER MANUFACTURER’S EQUIPMENT, WHETHER SOLD SEPARATELY

OR IN CONJUNCTION WITH EQUIPMENT OF OUR MANUFACTURE. WE DO NOT AUTHORIZE ANY

REPRESENTATIVE OR OTHER PERSON TO ASSUME FOR US ANY LIABILITY IN CONNECTION WITH

EQUIPMENT, OR ANY PART THEREOF, COVERED BY THIS WARRANTY.

Overview | 1-1

OVERVIEW

This chapter provides an overview of the various sub-systems that make

up the AMETEK analyzer and its sample system, and where to find

supplemental information for optional equipment.

1-2 | Model 920 Multi-Gas Analyzer

About the Analyzer

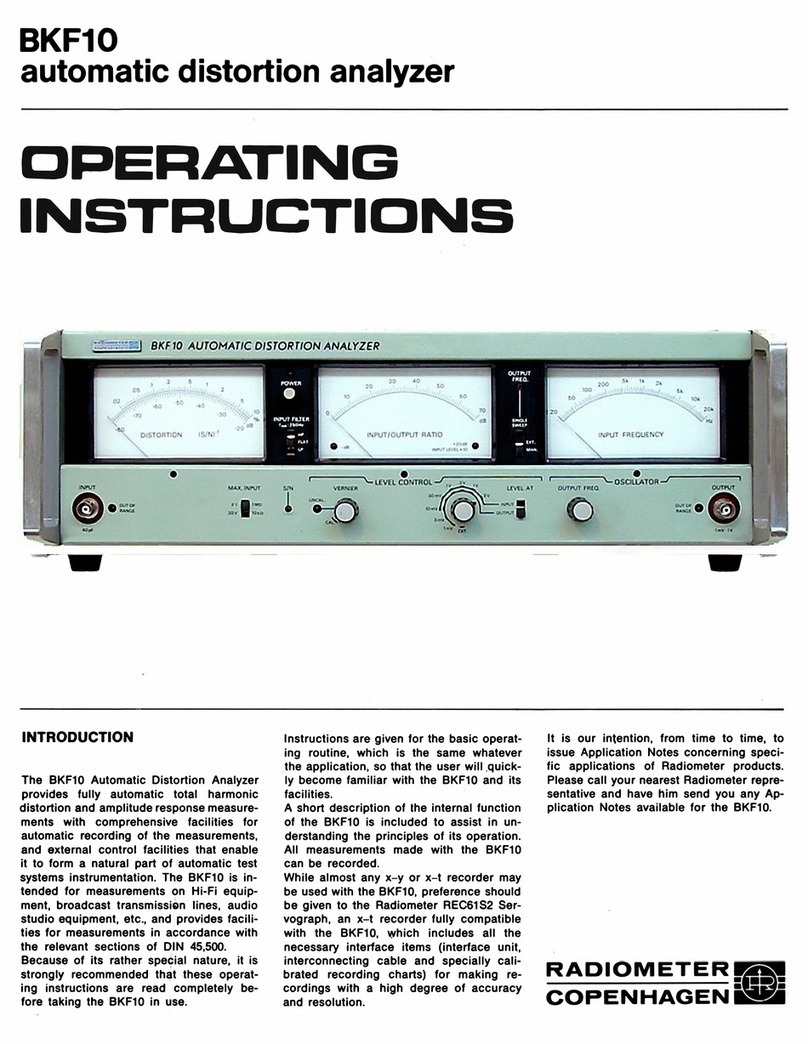

The analyzer is comprised of (Figure 1-1):

• Two ultraviolet light sources (source lamps)

• Chopper Wheel (Filter Wheel) containing up to six interference filters

• Beam Splitter

• Front-surfaced mirrors

• Gas Measuring Cell (contained within an Oven). A pressure transduc-

er monitors the pressure at the outlet of the Measuring Cell.

• Two matched Photodetectors

Figure 1-1.

Analyzer schematic.

Table of contents

Other Metek Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PRECISION DIGITAL

PRECISION DIGITAL Loop Leader PD683 manual

Sensaphone

Sensaphone IMS-4000 user manual

Hach

Hach Polymetron 9586 user manual

Rockwell Automation

Rockwell Automation Sensia Qrate Scanner 3100 Installation, operation & maintenance manual

Macnaught

Macnaught MX Series instruction manual

Aerospace Logic

Aerospace Logic OPT200XX Series Operation guide