Electric heated fryers 600 series (30363) 11/32

appliance installed to the terminals, marked by

the symbol (unipotential system).

Important information specifically relating to

appliances in the DROP-IN series

– The appliance must be installed in strict

compliance with the directions given in the

attached drawings.

– Appliances should only be installed on units

made of metal (and not wood and/or other

flammable materials).

– Take particular care with the power lead: the

channelways must be perfectly smooth with no

sharp corners and/or edges. The lead must not, at

any point, be subjected to temperatures of more

than 50°C above normal room temperature.

START-UP

Function check

– Start-uptheappliancefollowingtheinstructions

given; check function regularity and make sure

that the controls and heating elements are in

good working order, testing them with the

various function positions.

– The appliance is equipped with an internal

safety thermostat for each well, which cuts off

the power supply to the heating elements

whenever the main temperature regulator is

faulty.

– If necessary consult paragraph “Analysis of

several failures”.

Nominal heat input check

– After installation and at each maintenance

intervention check the heat input of the

appliance.

– The nominal heat input is stated in the

“Technical data” table.

– The appliance operates at the nominal heat

inputwhenthe electrical power istheone stated

in Table T1.

ATTENTION If the power supply value is not

within the limits indicated in Table T1, interrupt

the operation of the appliance and contact the

electricity delivery body.

ANALYSIS OF SEVERAL FAILURES

Heating elements do not heat up

– Check fuse valves

– Main switch off

– Insufficientpowerorwrongelectricalconnection

– Temperature regulation thermostat faulty

– Safety thermostat activated (because the main

temperature regulator is faulty). To reset the

safetythermostat, remove thescrew sealing the

thermostat access hole on the control panel.

Reset the thermostat, pressing with a pointed

tool (e.g. slender screwdriver).

Diffcult or lacking temperature adjustment

INSTALLATION INSTRUCTIONS

WARNINGS

Installation, adjustments and maintenance of the

appliances must be done by authorized installers,

in accordance with the safety standards in force.

Themanufacturerdeclines any responsibility

if such obligation is not observed.

INSTALLATION

Positioning

– The overall/connection dimensions and the

technical data are stated in the pages in the

appendix.

– Install the appliances only in sufficiently aired

rooms.

– Position appliances at least 10 cm from the

nearby walls. Such distance can be less when

the walls are incombustible or protected by a

thermal insulator.

– The appliances are not suitable for built-in

installation.

Assembly

– Remove the film which protects the external

panels. Any glue remaining on these is to be

removed with a suitable solvent.

In line union of the appliances

– Put the appliances next to eachother and level

them at the same height.

– Unite the appliances using the special union

joint-coverings supplied upon request.

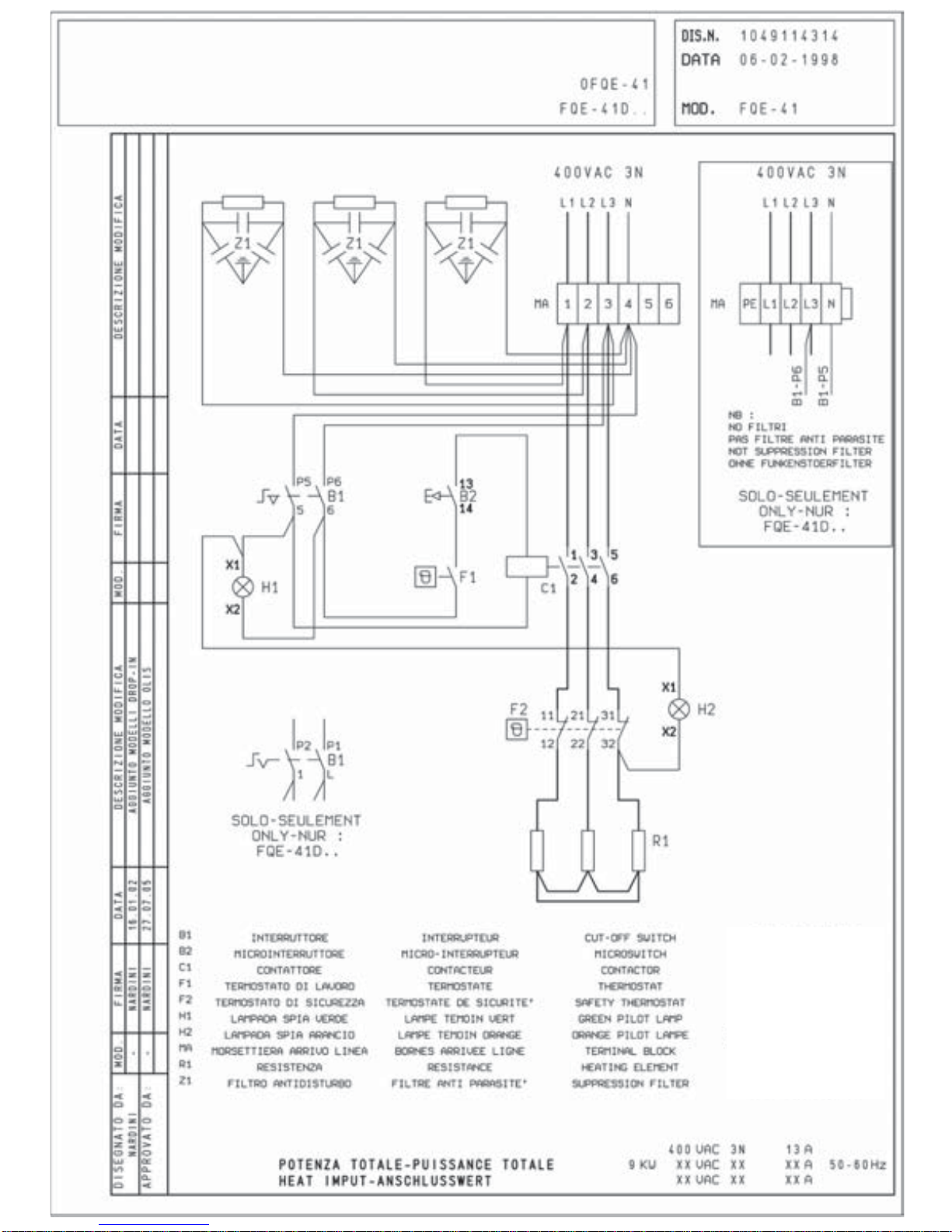

Electrical connections

– The appliances are designed to operate at the

voltage indicated on the rating plate.

– Each appliance must be connected to an

independent mains supply of suitable capacity

(totalpower indicated in “Technicaldata”table)

viaan input terminal boardwithflexible rubber

cable, insulated at a level not below H07RN-F.

– Make sure that the cables lenght allows for the

live wires to disconnect from terminal block

before the yellow/green ground wire, in case of

simultaneous pull.

– Automaticcutoutomnipolarswitchesofsuitable

capacity (with contacts opening to at least 3

mm)andhighly sensitive automatic differential

protective devices must be fitted. These must

ensure that there is no direct or indirect contact

between live components and fault currents

and the ground, in accordance with current

regulations (maximum admissible leakage

current 1 mA/kW).

Earth and unipotential connections

– Appliances must be earthed on terminals

marked with the symbol .

– Connectthemetallicstructureofeveryelectrical