3

INSTALLATION AND SET-UP

1. Check for Shipping Damage: Check the packaging and cabinet for shipping damage before and after unloading

the unit, and after removing all the packaging.

2. The receiver of this product is responsible for ling freight damage claims. This equipment must be opened

immediately for inspection. All visible damage must be reported to the freight company within 48 hours and must

be noted on freight bill at the time of delivery.

3. Concealed damage is your responsibility — you must advise the carrier of any loss or damage within 15 days

after receipt of the cabinet. If there is damage, retain the original packaging for inspectors.

4. After unpacking the cabinet, remove all tape and packing material from the inside as well as outside of the unit.

5. Any protective covers (plastic or paper sheet) on the sheet metal or clear door(s), if applicable, must also be

removed before turning the cabinet on.

WARNING: Onlyfactoryapprovedserviceagentsshouldattempttoservice,repairorreplaceelectrical

components,wiringorthepowercord.

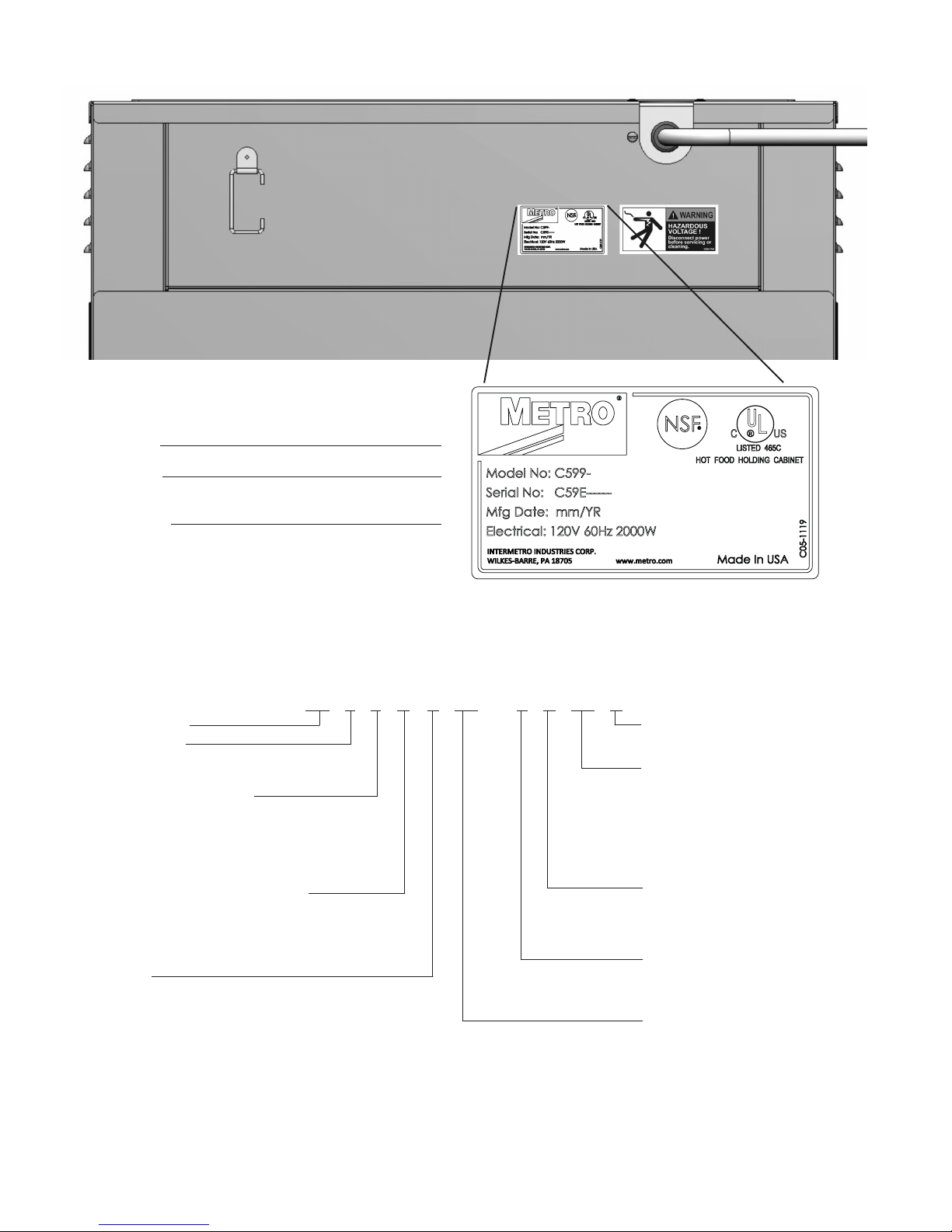

6. The power cord can be installed to exit the back

of the cabinet for wall outlets or out the top of the

cabinet for ceiling power drops. To change the

position of the power cord, rst make sure the

cabinet power switch is o and the power cord is

unplugged from any electrical outlet. Remove the

(7) screws holding the cabinet top in place. Lift

the rear portion of the cabinet top and slide it

away from under the front control bezel, removing it from the cabinet. Remove the (2) screws on the rear of the

cabinet that hold the cord bracket in place. Rotate the power cord bracket 90° to the desired position and reattach

it with the (2) screws to the back of the cabinet. Make sure the green ground wire connection and the wire nuts on

the black and white wires have not loosened. Do not alter

the wiring of the power cord to the cabinet. Replace the

cabinet top and the (7) screws holding it in place.

7. Refer to the data plate located near the power cord for the

electrical specications of cabinet. With the POWER switch

OFF, plug the cord into the appropriate rated, grounded

receptacle. Cabinets rated at 120V 2000W must be plugged into

125VAC 20 amp receptacle and must be used on an individual

branch circuit. Cabinets rated at 120V 1440W may be plugged

into either a 15 amp or 20 amp receptacle. Cabinets rated at 220-240V 1681-2000W must be plugged into a

250VAC, 15 amp receptacle.

8. The factory setting for temperature is Fahrenheit. To change the temperature display from Fahrenheit to Celsius a

jumper needs to be changed on the back of the controller circuit

board. Turn the cabinet o, unplug the cabinet from the electrical supply and remove the top of the cabinet (refer to

step #6). See the control wiring diagram below for the location

of jumper JP5. For Fahrenheit control, the jumper is on the

lower two pins. For Centigrade control, move the jumper from

the lower two pins to the upper

two pins. After changing

the jumper, replace the top,

plug the cabinet in, turn

the cabinet on and adjust

the temperature and low

temperature alarm settings

for the new units (°C or °F)

of temperature selected.

9. Your C5 cabinet is designed

to operate next to walls and

other kitchen equipment.

However, the greater the

clearance around the sides

and the top of the cabinet, the cooler the electrical components will operate. This may result in a longer life

expectancy for the electrical components.

Cord out

of the top

WARNING: Donotallowcombustiblematerialstobestoredoraccumulateon,underornexttothecabinet.Do

notblockanyventilationlouversorslots.

Cord out

of the

back

120V 120V 220/240V

15AMP 20AMP 15AMP

Outlet Outlet Outlet