3

INTRODUCTION

The aim of this manual is to give information, instructions and warnings on the split

box for air to water heat pumps. The manual is to be used by installers and plumbers as

well as by end users, since it contains important safety indications.

The manual is a part of the split box and it is to be conserved with care, since it

contains important installation and maintenance instructions that can be useful to

assure a long life time and an efficient operation.

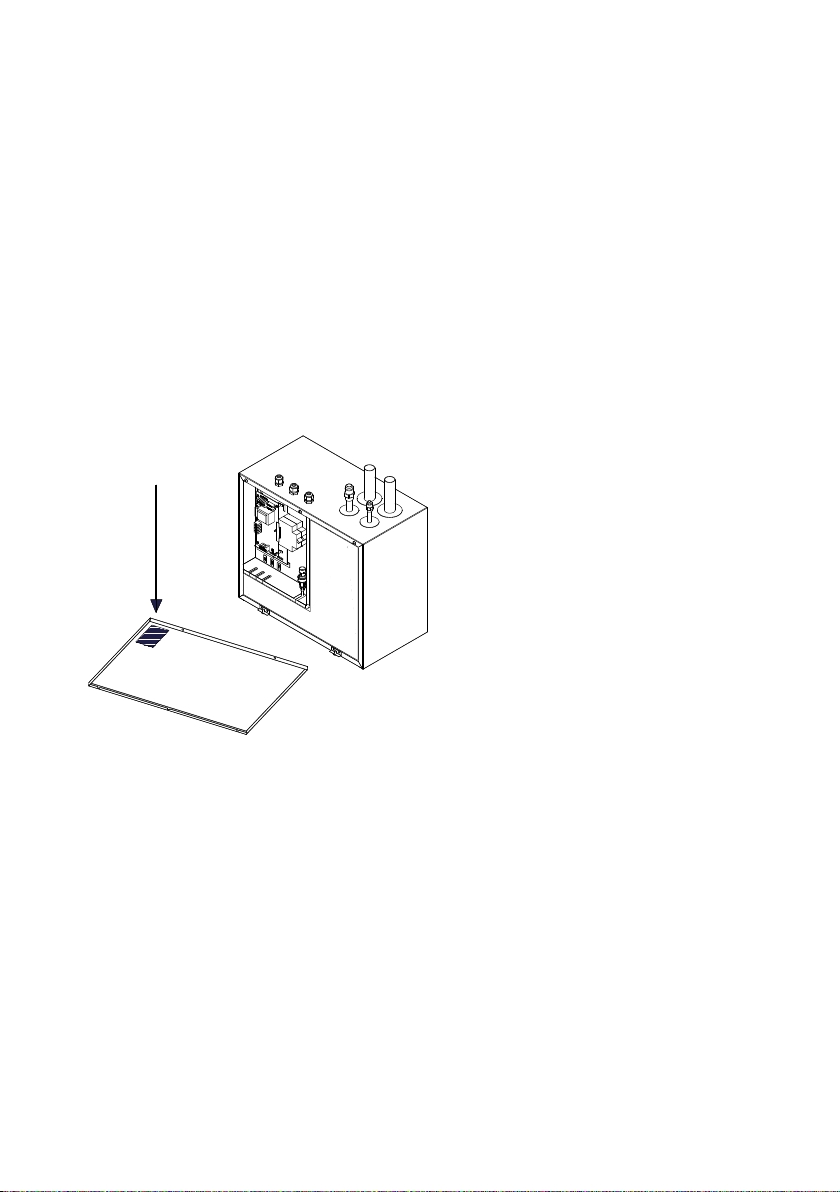

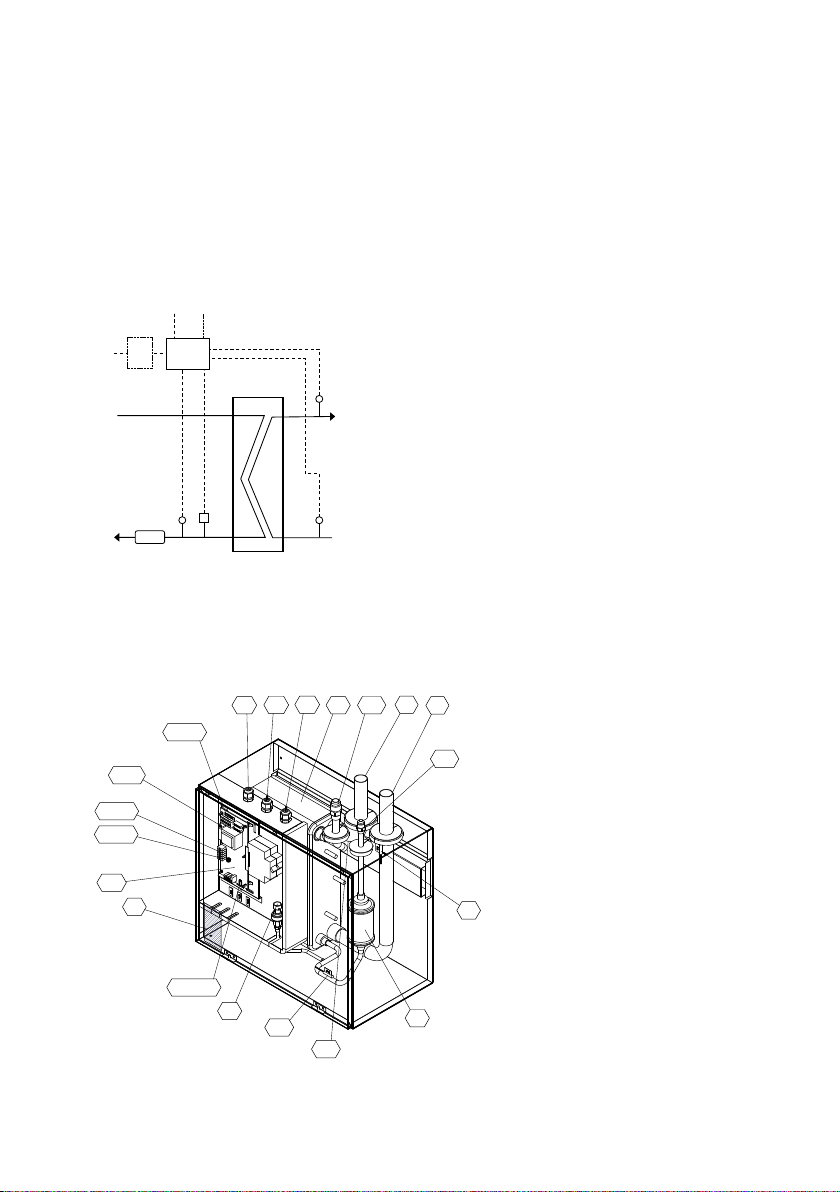

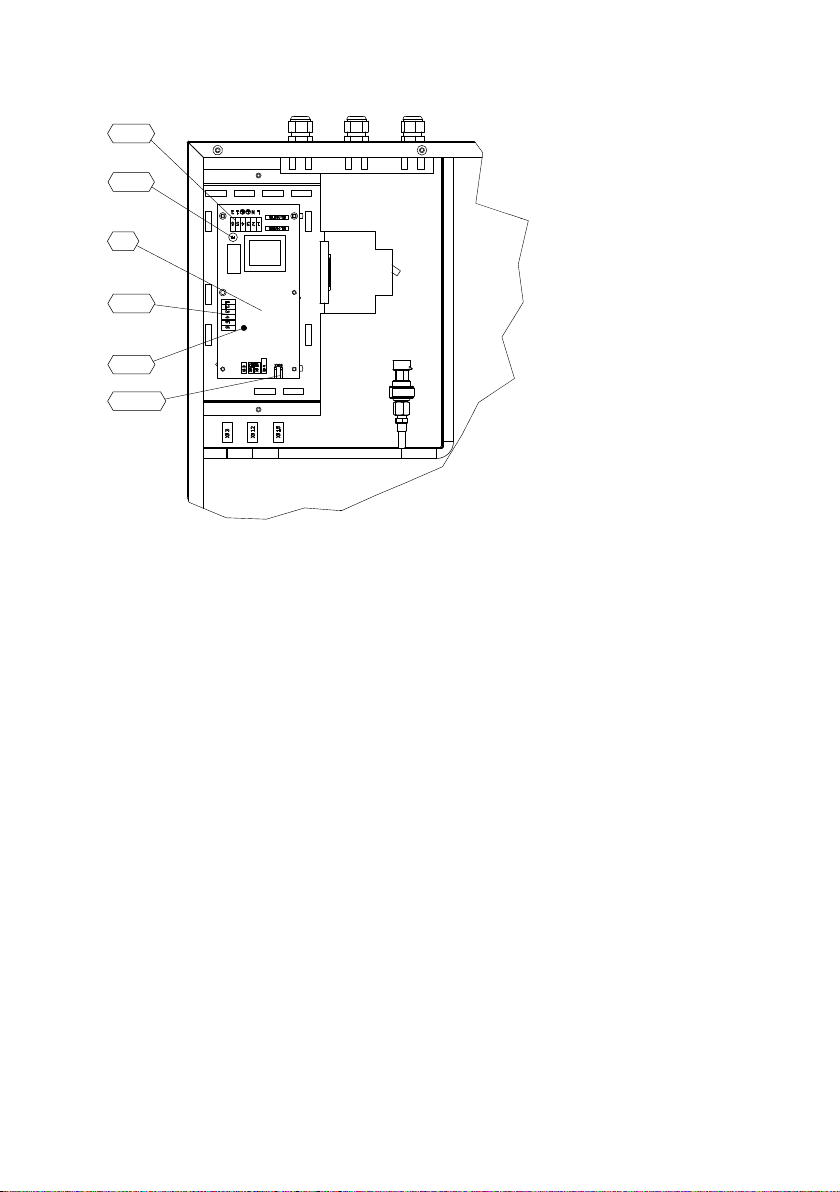

1. ABOUT THE PRODUCT

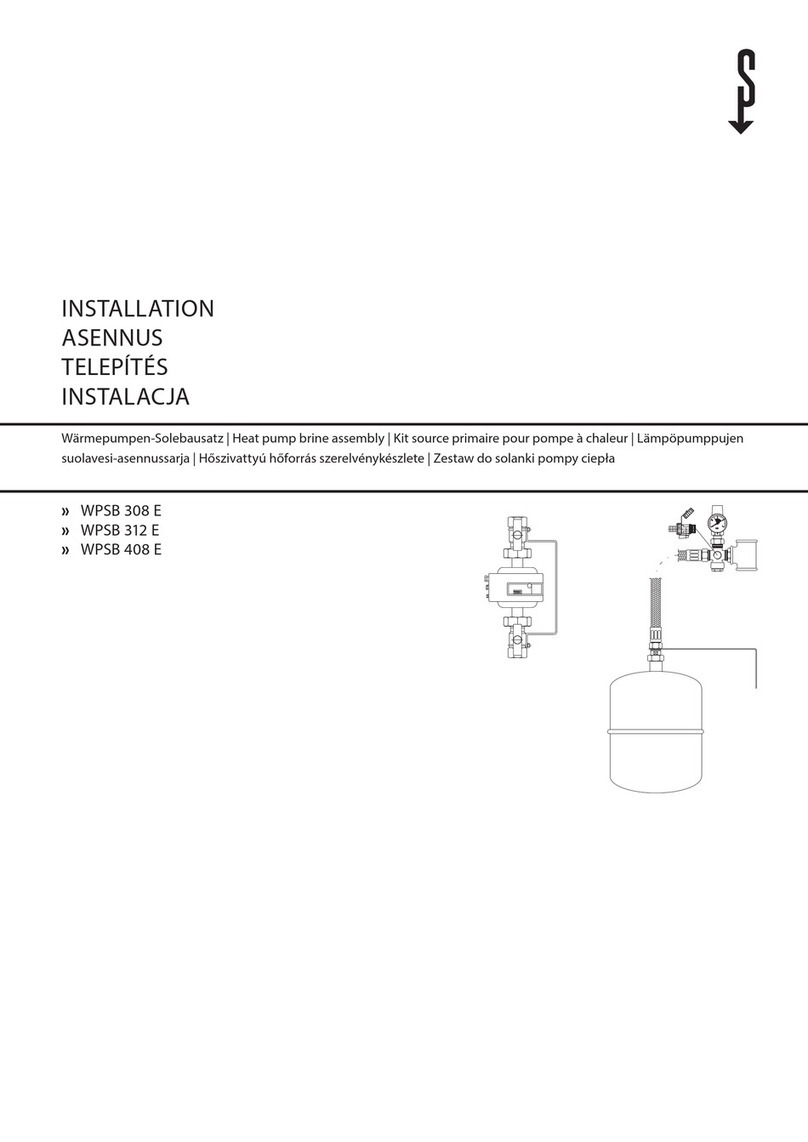

The product is an indoor condenser unit that has been designed according to EU

directives. The product is intended for co-operation with an air to water heat pump for

space heating and hot water production for domestic use. The unit has been designed

to be ready for installation. The unit is intended for refrigerant R410A.

The unit is delivered with the refrigerant circuit charged with nitrogen to avoid

contamination and ingress of water.

The unit is equivalent to the HBS 05 in terms of performance.

1.1. Safety precautions

• The product shall be installed, commissioned, repaired only by qualified technicians.

• Incorrect installation can result in damages of properties and injuries to people and

animals.

• The unit shall be disconnected from the power supply when the cover is off.

• The unit shall not be used by children or people with limited physical or mental

capacity.

• Children should be supervised to ensure that they do not play with the appliance.

• Cleaning and maintenance shall not be made by children without supervision.

• Do not place flammable materials in contact or close to the unit.

• The water system and the refrigerant system should be installed as stated in the

manual.

• When in service, the unit should not be placed in sub-zero temperature areas.

• When not in service, the unit can be placed in sub-zero temperature areas, but all the

water in the heat exchanger and associated pipe work should be removed.

• The unit should be used only for its specified use. The manufacturer is not liable for

any damages due to failure to observe this manual.

• Take all the possible precautions to avoid incidents.

• The product is intended for R410.