Metrol RC Series User manual

RC series

Instruction Manual

■Technical conformity marks

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1-this device may not cause harmful interference. and

2-this device must accept any interference received,

Including interference that may cause undesired operation.

Metrol Co., Ltd.

Model : RC-R02

Power : DC24V

R 001-A00052

CMIITID: 2012DJ3661

Made in Malaysia

FCCID:AORMETROLRCR02

This device complies with

Part 15 of the FCC Rules.

Operation is subject to the

following two conditions:

1-

this device may not cause

harmful interference. and

2-

this device must accept

any interference received,

Including interference that

may cause undesired

operation.

Metrol Co., Ltd.

Model : RC-K3E

Power : 3.6V

R 001-A00026

CMIITID: 2012DJ3660

Made in Japan

FCCID:AORMETROLRCK3E002

www.baysupply.com

INDEX

1.

Beforeusing

Terms ofWarranty

Usage precautions

2.

Basicspecification

3.

Software specification

Transmitter

Receiver

4.

Matching transmitter and receiver

5.

Parameter switch (DIP switch)

Details of parameter switch (DIP switch)

Details of LED display

. . . . . . . . . . . . . . . . . . . . P1−2

. . . . . . . . . . . . . . . . . . . . P3

. . . . . . . . . . . . . . . . . . . . P5−6

. . . . . . . . . . . . . . . . . . . . P7

. . . . . . . . . . . . . . . . . . . . P8

. . . . . . . . . . . . . . . . . . . . P9

. . . . . . . . . . . . . . . . . . . . P11−13

. . . . . . . . . . . . . . . . . . . . P14−16

6.

Transmission range when combining transmitter and receiver

. . . . . . . . . . . . . . . . . . . . P17

7.

Receiverinstallation

8.

Transmitterinstallation

Stylus attachment

Installing the battery

Attachment of the transmitter to shank

Stylus centering adjustment

9.

Maintenance

10.

Troubleshooting

. . . . . . . . . . . . . . . . . . . . P19

. . . . . . . . . . . . . . . . . . . . P21

. . . . . . . . . . . . . . . . . . . . P22

. . . . . . . . . . . . . . . . . . . . P23

. . . . . . . . . . . . . . . . . . . . P24

. . . . . . . . . . . . . . . . . . . . P25

. . . . . . . . . . . . . . . . . . . . P27−28

4

www.baysupply.com

1.

Beforeusing

■Terms of Warranty

We endeavor to achieve zero claims and complaints rate with respect to product quality assurance.

Although malfunctions are a problem that comes before the warranty and even one should be

prevented, malfunctions cannot be prevented through our efforts alone. We would therefore like

to request that our customers have an understanding of the functions and specifications of

applicable products as indicated in our catalogs, instruction manuals and web site to ensure

that they are used properly under specified conditions.

Furthermore, applicable products are designed and manufactured primarily for general

industrial use.

Therefore, we would also like to request our customers to cooperate in employing a safe

design for preventing accidents, fires and the like through providing of fail-safe measures,

preventing operational errors and employing redundant safety designs.

1

Applicableproducts

The warranty defined below is applicable to products manufactured and sold by METROL (to

be referred to as the "applicable products").

2

Warrantyperiod

The warranty for applicable products is valid for one year and three months from the original

delivery date to the location designated by the customer.

*The initial three months are assumed to be a preparation period until use of the products

following purchase.

3

Range of coverage

a.

A replacement product will be provided on an exchange basis or the malfunctioned product

will be repaired free of charge within the warranty period. If the product is or becomes

defective and that at the sole discretion of METROL, the defects due to faulty materials or

workmanship.

However, applicable products will not covered by the warranty in the case of the following

malfunctions even within the warranty period.

( I ) Malfunctions occurred due to use of a product in a manner that deviates from

standards, specifications, environments, usage procedures or usage precautions

described in the catalog, instruction manual or specifications.

( II ) Malfunctions having occurred for reasons other than those attributable to the delivered

product.

(III) Malfunctions having occurred due to modifications or repairs made by someone else

other than the Metrol representative.

(IV) Malfunctions or damage that results from external causes outside our control which

shall include accident fire disaster, other nature disaster or other force majeure.

2

www.baysupply.com

b.

The range of coverage is limited to warranty of the applicable product only, and any other

secondary loss or damage resulting from the malfunction of an applicable product is not

covered by the warranty.

c.

Please be aware that charges for service (including installation, de-installation on-site

confirmation and repairs) are not included in the price of products.

4

Applications

Applicable products are designed and manufactured as general-purpose products used in

ordinary industrial environments.

In the case of incorporating an applicable product in an apparatus, machine or system,

please confirm the suitability of the application along with any related standards, regulations

and restrictions.

With respect to the applications indicated below in particular, customers are requested to

conduct necessary tests on an actual product in advance after consulting with the

manufacturer regarding usage conditions and other details.

a.

Applications for which usage conditions or environment are outside those presumed by the

manufacturer or applications unable to be confirmed as being appropriate by the

manufacturer when using applicable products.

b.

Applications likely to have an effect on human life or property (such as nuclear power

equipment, transportation machinery or medical devices), applications used in public

utilities (such as electricity, gas or water lines), or applications applying correspondingly

thereto.

c.

Applications in harsh environments (special environments requiring heat resistance, vacuum

andthelike)

*Although METROL believes that sound reliability in harsh environments is one of the

characteristics of our products, there are still cases in which it is difficult to ascertain actual

circumstances.

Since there is the potential for accidents in such cases, customers are requested to have an

understanding of protective structures, materials and so forth and provide additional covers

and other equipment as necessary.

5

Other matters

The contents of this catalogue, including specific models and, specifications, and any

other contents, are subject to change without notice at METROL’s sole discretion.

Although the utmost care has been taken in producing this manual, the manufacturer is

not responsible for any damages incurred as a result of clerical or other errors in this

manual.

3

www.baysupply.com

1.

Beforeusing

■

Usageprecautions

1

Battery

The transmitter comes with two 1 / 2AA size lithium metal batteries (non-rechargeable).

Please dispose of used batteries in accordance with laws and regulations relating to the

environment and safety regulations in your area. Do not attempt to recharge these batteries.

When replacing the battery, confirm that the battery is of the recommended or applicable

type, and confirm that the battery is inserted while correctly aligning the electrodes in

accordance with the procedure described in this manual and the indications on the product.

Please refer to the instruction manual of the battery manufacturer for guidelines relating to

specific battery applications, safety and disposal.

・Please confirm that all batteries are inserted with the electrodes correctly aligned.

・Do not store batteries in locations subject to direct sunlight or rain.

・Do not allow the battery to be heated or incinerated.

・Do not intentionally discharge the battery.

・Do not allow the battery to be short-circuited.

・Do not disassemble the battery, subject the battery to excessive pressure, drill holes in the

battery or allow it to be deformed.

・Take precautions so that the battery is not accidentally swallowed. Store the battery in a

location out of the reach of children.

・Do not allow the battery to become wet.

2

Glasswindow

The transmitter has a glass window. In the case the glass window should happen to be

broken, handle the product carefully to prevent injury.

3

Installation

Please confirm that the following guidelines are strictly observed at the responsibility of the

person performing installation work to ensure that the product functions properly.

・Please install while placing the interface at an adequate distance from electrical noise

generation sources such as transformers or servo amplifiers.

・Connect all 0V / ground connections to a central ground terminal on the machine.

(The grounding and shielded cables of all devices can be connected to ground.)

This is extremely important, and failure to do so can cause the generation of an electrical

potential between the product and ground.

・Connect all shields as indicated in the user's guide.

・Place cables at an adequate distance from large-current cables such as motor and other

power cables as well as high-speed data cables.

・Try to keep cable lengths as short as possible at all times.

4) Product usage

Use of this product in a manner other than that specified by METROL may cause a decrease

in the guaranteed performance and functions of the product.

5

www.baysupply.com

2.

Basicspecification

The transmitter communicates with the receiver using 2.4GHz ISM band.

The receiver receives touching signal, battery alarm signal and communication alarm signal from

the transmitter and outputs the decoded signals to CNC controller through the cable.

ThissystemgainsFCC,CE, TELEC(JAPAN),SRCC(CHINA)andRoHS,WEEEcertification.

2-1

Common specification

2-2

Transmitter specification

Communication

Bi-direction

Antenna

Onboard chipantenna

Contact signal

1 point NC

LED display

1LED(Red:signaloutputoftransmitter)

Powersource

1/2AAthionylchloridebattery

Oncebatteryisinstalledtothebatteryholder,thecurrentconsumptionstarts.

Forlong-termstorage,itisrecommendable toremovethebattery fromthe batteryholder.

Weight(excluding a shank)

Withbattery:290g/Withoutbattery:280g

Battery life(calculation)

Standbymode :200 days

5% use(72min/day) :87 days

Continuous use

:180 hours

2-3

Receiver specification

Communication

Bi-directional

Antenna

1/4λ dipoleantenna

Transmission range

Max.15m

IDcontrol

ReceiverperformscommunicationexclusivelywiththetransmitterusingitsIDnumber

aftercouplingoperation.

LED display

4LEDs(Blue:Power,Orange:Batteryalarm,Green:Communicationstatus,Blue:

Skipsignaloutputoftransmitter)

Parameter switch

DIP Switch onboard8bit

Output signal

φ7.2/14 cores oil resistant cable with watreproof connector

Input:power source(DC24V), Mcode(powerON/OFFsignal)

Output: Skipsignal(Probe status 2a),Probestatus1,Batteryalarm,Probestatus 2b)

Response speed

Min.1ms

(FromtransmitterturnsONuntilreceiverskipsignalactivates.However,thisdependsoncommunicatinstatus)

Powersupplyvoltage

24V±10%

Current consumption

Max.100mA(24V ±10%)

Data rate

2MbpS.

RFput

Max.0dBm(withoutantenna)

Sensitivity

Max.-82dBm(withoutantenna)

Protective structure

IEC IP67

Frequency range

2400 - 2480 MHz

No.ofchannels

37

Channeloccupationwidth

2MHz

Modulation

FSK (DSSS)

6

www.baysupply.com

2-3-1

Wiring diagram

2-3-2

LEDdisplay

System status is displayed with four LED shown at right.

・Power LED :Indicates status of power supply.

:Standby (approxmately 60 seconds after

machine tool power is switched on)

:Normal power supply status

・Com. LED :Indicates communication status between transmitter and receiver.

:Communication status decreased or interrupted, or searching for connection

:Normal communication status

・Batt.LED :Indicates battery status of transmitter.

OFF :Battery normal

:Recommed replacing the battery (low residual charge)

:Battery dead

*During the matching procedure, it indicates completion of matching mode (refer to P9)

・Touch LED :Indicates the signal output of the transmitter.

OFF:Contact OFF (transmitter signal output OFF)

:Contact ON (touch probe signal output ON)

4.7kΩ

BLUE

BLUE/BLACK

VIOLET

VIOLET / BLACK

GREEN

GREEN / BLACK

WHITE

BROWN

YELLOW

GRAY

ORANGE

+24V

PROBE STATUS 1

+24V

LOWBATTERY

+24V

ERROR

MACHINE START +

MACHINE START0V

SKIP +

SKIP0V

PROBE STATUS 2b

RED

BLACK

GREEN/ YELLOW

+24V(12V-30V)

0V

MACHINE GROUND

7

www.baysupply.com

3.

Software specification

3-1

Transmitter

Transmitter has 3 modes.

1

Sleep mode

When M code (power ON signal) does not exist, transmitter operates in the Sleep mode to

suppress power consumption.

Transmitter periodically attempts to make communication witht the receiver.

Transmitter and receiver communicate with each other and exchange data every 14 - 27

seconds, if the communication is possible.

In this communication, transmitter sends the battery alarm signal to the receiver while receiver

sends the channel information to transmitter.

In case it stays incommunicable for 30 seconds or longer, it changes channels automatically.

When the transmitter is incommunicable with the receiver, it attempts to communicate by

changing channels.

Once the communication is established, its functions will be recovered within 4 seconds.

2

Measuring mode

Once the transmitter received M code (power ON signal) from the receiver, it enters Measuring

mode.

In this Measuring mode, transmitter communicates with receiver every 2ms.

In case the communication is not successful, the transmitter immediately changes channels.

The LED of the transmitter turns on when the contact touches a workpiece.

The transmitter enters Sleep mode automatically if it stays incommunicable for 1 minute.

Even in this case, the transmitter returns to Measuring mode soon after M code (power ON

signal) is sent from the receiver.

3

Matching mode

This mode is the initial setting.

In this wireless communication system, the transmitter stores ID number.

By using ID number, it performs matching with the receiver so that the receiver stores ID.

Once ID number is stored in the receiver, it performs communication exclusively and is never

affected by any other communication systems.

This ID number (transmitter) is stored nonvolatile.

Note: Matching is necessary every time transmitter is exchanged.

8

www.baysupply.com

3-2

Receiver

Receiver has 3 modes.

1

Sleep mode

Receiver watches 2400-2480 MHz range anytime and find out the empty channel.

It waits until M code (power ON signal) is sent, continuously sending radio wave state (empty

channel information) to the transmitter.

If the communication with the transmitter is successful, the Com. LED (Green) of the receiver is

turned on.

If the communication cannot be achieved, the Com. LED (Green) flashes.

In the Sleep mode, no alarm signal is output to a control device even if the communication is

abnormal.

Batt. LED (Orange) flashes or lights up when the battery runs out, but the receiver does not

output alarm signal.

2

Measuring mode <After receiving Measuring ON Signal (M code)>

After the receiver sends M code (power ON signal) to the transmitter, receiver and other system

enters the Measuring mode.

Then it waits for the sensor ON signal from transmitter. At the same time, it prepares for

sending all alarm signal to control device.

All LEDs become active.

*

* It depends on battery state at the time of input of M code, and is effective only for 10 seconds.

When M code (power OFF signal) is sent from a control device, receiver transmits it to the

transmitter. Then both receiver and transmitter enter the Sleep mode from the Measuring mode.

3

Matching mode

This mode is the initial setting.

The receiver stores the ID number of transmitter in order not to be affected by any similar

signals.

This ID number (transmitter) is stored nonvolatile.

Note: Matching is necessary every time the transmitter is exchanged.

LED

LEDdisplay

Output signal

PowerLED (Blue)

Power supply status(Lit: Normal, Flashing: in preparation)

Com.LED(Green)

Communication Status(Lit: Normal, Flashing: Bad communication)

Error(Lit:ON)

Batt.LED (Orange)

Battery Status (Flashing: Low battery, Lit: Dead battery)

Error(Flashing:ON)

TouchLED(Blue)

Output signal from transmitter(Lit: Contact ON, Unlit: Contact OFF)

Probe status, skip

9

www.baysupply.com

4.

Matching transmitter and receiver

It is necessary to match the transmitter and receiver when first installing the system.

Matching is also required when replacing either the transmitter or the receiver.

Matching can be performed anywhere within the range of movement of the system.

1

Receiver matching procedure

1)

Remove the cover of the receiver.

2)

Switch the parameter switch #8 (DIP switch) on the receiver to OFF.

Parameter switch

ON

2

Transmitter matching procedure

1)

Remove the cover of the transmitter and affix it again (Restart the transmitter).

①Removethebatterycover

with a screwdriver or coin

②Reinsertthebattery ③Affixthebatterycover

2)

Matching is completed when the Batt. LED lights.

3

Matching mode completion procedure

1)

Switch the parameter switch (DIP switch) #8 on the receiver to OFF.

OFF

2)

Complete the matching procedure by attaching the receiver cover.

Note : The matching procedure is performed to record the transmitter ID number in the receiver and

prevent interference by other radio signals.

Once the matching procedure has been performed, further matching is not required provided

the transmitter is not replaced (or repaired).

Power. LED

Com. LED

Batt. LED

Touch.LED

LEDFlashing/

LEDFlashing

LEDFlashing

LEDOFF

LEDON

1 2 3 4 5 6 7 8

Parameter switch

1 2 3 4 5 6 7 8

Power. LED LED Flashing/

LEDON

Com. LED LEDFlashing

Batt. LED LEDOFF

Touch.LED LEDOFF

10

www.baysupply.com

5.

Parameter switch (DIP switch)

5-1

Details of parameter switch (DIP switch)

PROBESTATUS1

PROBESTATUS2a,2b LOWBATTERY NC(Nomallyclose)

ERROR NC(Nomallyclose)

NC NC

MACHINESTARTLEVEL

PULSE

(Nomallyclose)PULSE(Nomallyclose)MatchingmodeON

ON

Mode changeover

switch

1 2 3 4 5 6 7

8

NO NO

NC

LEVEL (Nomally open)LEVEL

(Nomally open)(Nomally close)

PULSE

MatchingmodeON

Note: The waveform is the signal output after M code (power ON signal) is applied.

Parameter switch No.

ON/OFF

Output signal

Description

1

OFF

PROBESTATUS1

LEVELoutput

ON

PROBESTATUS1

PULSE output

2

OFF

PROBESTATUS1

NO (Nomallyopen)

ON

PROBESTATUS1

NC (Nomally close)

1 = OFF Sensor ON SensorOFF

2 = ON OFF

ON

1, 2 = ON 40ms

OFF

ON

1, 2 = OFF Sensor ON

OFF

SensorOFF

ON

1 = ON

2 = OFF

OFF

ON

40ms

12

www.baysupply.com

Probe status 2a = Skip signal

Parameter switch No.

ON/OFF

Output signal

Description

3

OFF

PROBESTATUS2a,2b

LEVELoutput

ON

PROBESTATUS2a,2b

PULSE output

4

OFF

PROBESTATUS2a,2b

NO (Nomallyopen)

ON

PROBESTATUS2a,2b

NC (Nomally close)

Parameter switch No.

ON/OFF

Output signal

Description

5

OFF

LOW BATTERY

NO (Nomallyopen)

ON

LOW BATTERY

NC (Nomally close)

Parameter switch No.

ON/OFF

Output signal

Description

6

OFF

ERROR

NC (Nomally close)

ON

ERROR

NO (Nomallyopen)

6 = OFF Error occured

OFF

ON

6 = ON Error occured

OFF

ON

5 = OFF Battery dead

OFF

ON

5 = ON Battery dead

OFF

ON

3 = OFF Sensor ON SensorOFF

4 = ON OFF

ON

3, 4 = ON 40ms

OFF

ON

3, 4 = OFF

Sensor ON

SensorOFF

OFF

ON

3 = ON

4 = OFF

OFF

ON

40ms

13

www.baysupply.com

5. Parameter switch (DIP switch)

Parameter switch No.

ON/OFF

Output signal

Description

7

OFF

MACHINE START

PULSE input

ON

MACHINE START

LEVELinput

Parameter switch No.

ON/OFF

Description

8

OFF

Normal mode

ON

Matching mode

Note: All parameter switches (DIP switches) were in OFF position at the factory default

7 = OFF

20ms

≦

H

L

10ms

≦

1stPULSE 2ndPULSE 3rdPULSE

M code (Measuring start) M code (Measuring finish) M code (Measuring start)

7 = ON M code (Measuring start) M code(Measuring start)

H

L M code (Measuring finish) M code (Measuring finish)

14

www.baysupply.com

5-2

Details of LED display

1.

Power LED flashing

2.

Com. LED flashing

1)

Transmitting NG 2) Transmitting NG

3)

Unstable communication in Measuring mode: early stage

4)

Incommunicable in Measuring mode:output the error signal

5)

Inside memory problem

200ms

Repeat

OFF 200ms

ON

160ms

160ms

440ms

Repeat

OFF

80ms

80ms

80ms

11ms

Repeat

OFF 1ms

ON

160ms

1680ms

Repeat

OFF

80ms

80ms

ON

1700ms

Repeat

OFF

300ms

500ms

ON Repeat

OFF 500ms

15

www.baysupply.com

5. Parameter switch (DIP switch)

6)

Matching phase

Seeking for the channel Matching complete

3.

Batt. LED flashing

1)

Matching phase

2)

Inside memory problem

4.

Touch LED

1)

Inside memory problem

200ms

ON

Repeat

OFF 200ms

ON

OFF

Sensor ON

SensorOFF

ON

200ms

Repeat

OFF

200ms

ON

500ms

Repeat

OFF

500ms

ON

OFF

Matching complete

DIP switch #8 OFF

ON

840ms

Repeat

OFF

160ms

ON

420ms

Repeat

OFF

80ms

16

www.baysupply.com

easuring start

4.

I/O circuit

PROBESTATUS1

ERROR

LOW BATTERY

MACHINE START

PROBE STATUS 2a (SKIP)

PROBESTATUS2b

5.

Output waveform of the receiver

MachineON

Mcode

(M )SensorOFF Commnucation

Mcode

10 sec.afterM code

easuringstart restoration (Measuringcomplete) (Measuringstart)

Receiver

ready SensorON Communication

error Batterydead (M M code )Battery

exchange

PROBE

STATUS1

OFF

ON

LOW

BATTERY

ERROR

OFF

ON

OFF

ON

SKIP(PROBE OFF

STATUS 2a) ON

Note: These waveforms are output when all parameter switches (DIP switches) are in OFF position at

the factory default setting.

PROBESTATUS2b

Max 50V 500mA

0V

SKIP +

Max 50V 500mA

SKIP0V

4.7kΩ MACHINESTART+

Max 70mA

MACHINESTART0V

+24V

Max 55V 50mA

ERROR

+24V

Max 55V 50mA

LOW BATTERY

+24V

Max 55V 50mA

PROBESTATUS1

Other manuals for RC Series

1

This manual suits for next models

2

Table of contents

Other Metrol Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

In-situ

In-situ MP TROLL 9500 quick start guide

Krom Schroder

Krom Schroder DMG S2601 operating instructions

Unit

Unit UT118A operating manual

Spot-on

Spot-on General Titanium Series instruction manual

Audio Control

Audio Control R-130 operating manual

Aquametro

Aquametro CONTOIL DFM Mounting and operating instructions

Challenger Optics

Challenger Optics CO-OPM-PON Interactive operating manual

Elecfreaks

Elecfreaks TOOCA Laser 1 user manual

Tinker & Rasor

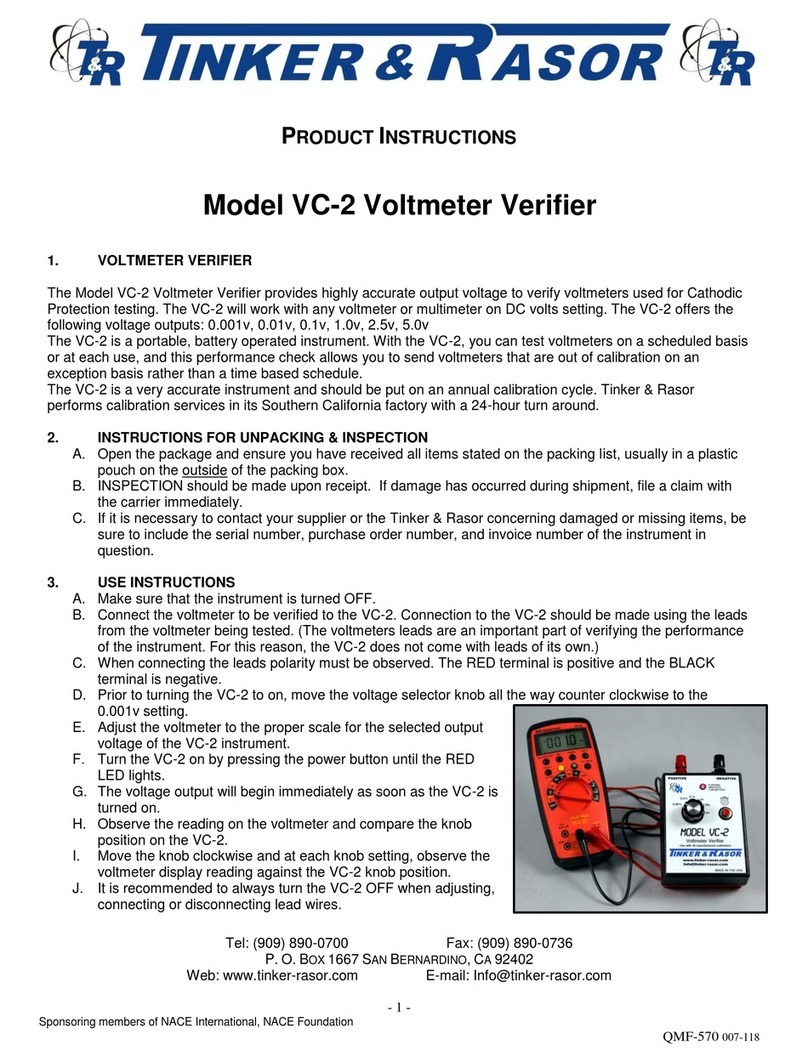

Tinker & Rasor VC-2 Product instructions

Aqualytic

Aqualytic SD 60 operating manual

Unit

Unit UT30A operating manual

Sel

Sel BOX BASIC RI 3000 Profibus-DP instruction manual