17

8.Frequently-asked Questions (FAQs)

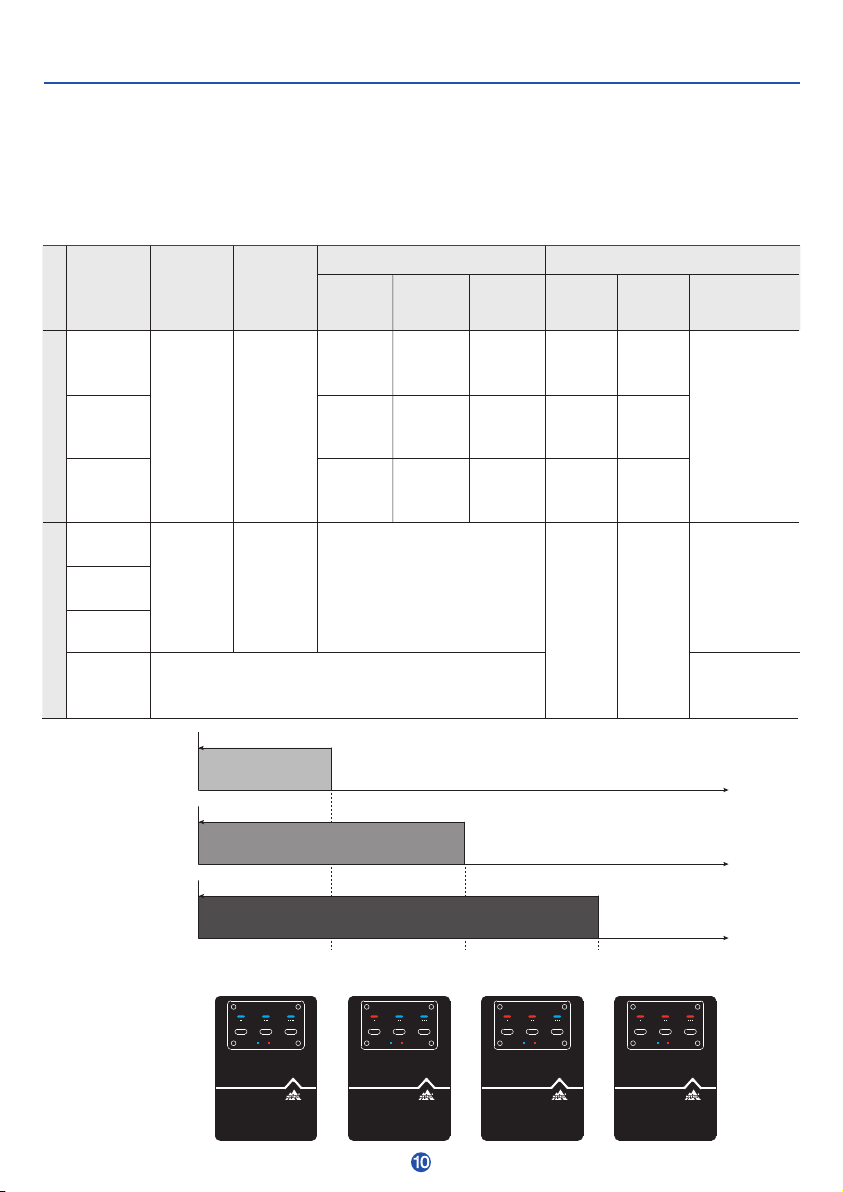

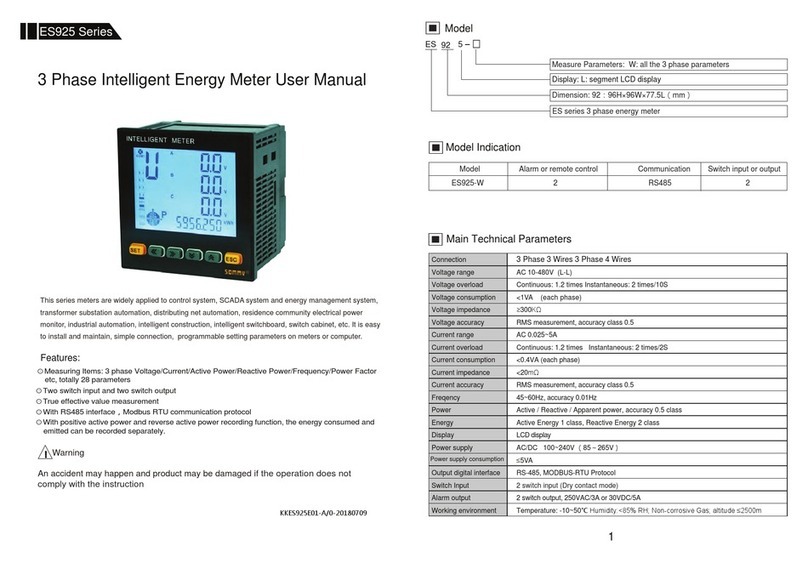

1. Specifications

Q.1-1

A.1-1

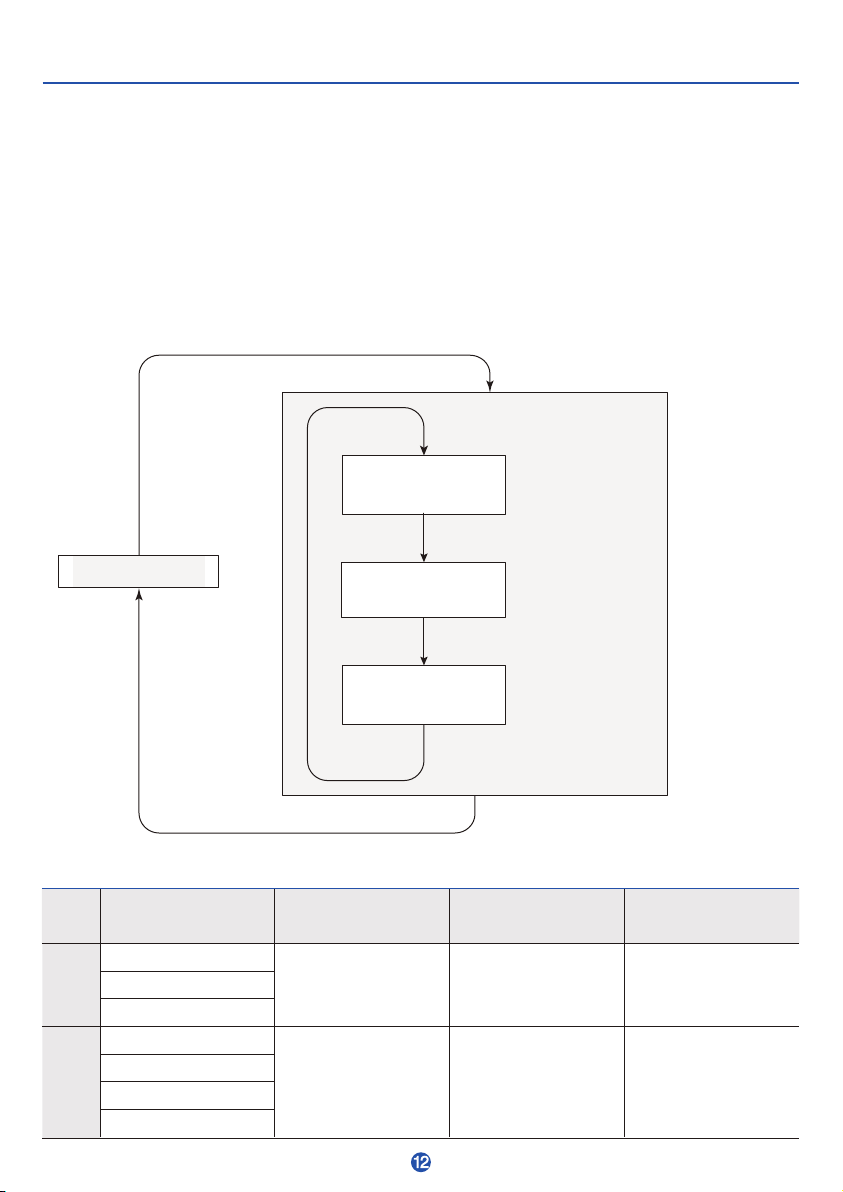

2. Wiring

Q.2-1

A.2-1

Q.2-2

A.2-2

Q.2-3

A.2-3

3. Pressure alarm

Q.3-1

A.3-1

Q.3-2

A.3-2

4. Determination mode

Q.4-1

A.4-1

Q.4-2

A.4-2

Q.4-3

A.4-3

Q.4-4

A.4-4

Is distance output as an absolute value?

No. Gaps are determined as being either above or below the master value only. (Refer to p.1)

Should the output line be connected to either the collector or the emitter?

No. This is the photocoupler output and must be connected to both.

Refer to the connection examples shown in "Wiring" (p.5) for information on how to connect it.

Does the output line switch between 24 V and 0 V?

No. This is the photocoupler output so it switches between conducting and isolated.

Refer to the connection examples shown in "Wiring" (p.5) for information on how to connect it.

Does the output line switch between 24 V and 0 V?

Yes. This is the photocoupler output so it does have polarity.

Refer to the connection examples shown in "Wiring" (p.5) for information on how to connect it.

When the machine first starts up, the LEDs blink purple and the supply pressure alarm output is OFF.

Is this a supply pressure alarm?

A supply pressure of 150 kPa is set for the master at the factory.

This could trigger the ±10 kPa alarm depending on the pressure being supplied.

Set the master first before use. (Refer to p. 13)

The pressure gauge shows that the machine is operating within the rated pressure range,

but a pressure alarm is triggered. Is this a failure?

First check for air leaks or blockages in the piping from the pressure gauge and machine,

as well as any connected devices that could be providing resistance.

The LEDs and determination output do not change. Is this a failure?

Check whether a pressure alarm has been triggered. (Refer to p. 8)

Check whether the machine is in determination mode. (Refer to p. 9)

The master may not have been set correctly.

Check the conditions and then set the master again.

If checking these shows no problems, check for blockage in the air nozzle, leakage unit,or piping;

air leaks from the sensor to the air nozzle (outside of the leakage unit);

or any devices connected that could be providing resistance.

The LEDs switch to normal but output stays OFF. Is this a failure?

The output cable may not be connected properly or may be disconnected.

Refer to the connection examples shown in "Wiring" (p. 5) for information on how to connect it.

The LEDs switch to normal but output stays ON.

The output cable may not be connected properly.

Confirm that it is connected with proper polarity.

Refer to the connection examples shown in "Wiring" (p. 5) for information on how to connect it.

The machine does not reach the repeat accuracy listed in the specifications table. Why?

The repeat accuracy listed in the specifications table is guaranteed only under recommended conditions.

Refer to the recommended values for gap distance, piping, and air nozzle shape. If different conditions

are being used, verify use on the actual machine to determine whether use is possible.