CMC-1001 2 Installation Guide

© 2014 KMC Controls, Inc. 107-019-01B

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

Important Notices

The material in this document is for information pur-

poses only. The contents and the product it describes

are subject to change without notice. KMC Controls,

Inc. makes no representations or warranties with respect

to this document. In no event shall KMC Controls, Inc.

be liable for any damages, direct or incidental, arising

out of or related to the use of this document.

Maintenance

No routine maintenance is required. Each compo-

nent is designed for dependable, long-term reliabil-

ity, and performance. Careful installation will also

ensure long-term reliability and performance.

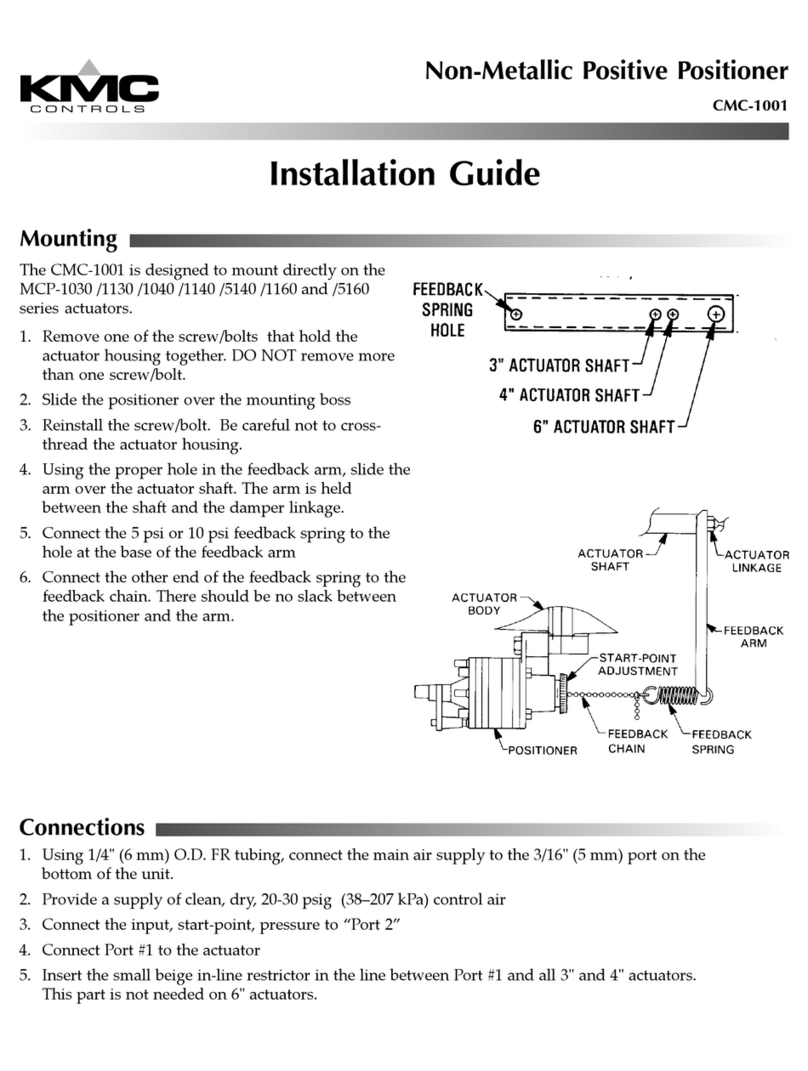

Adjustments and Calibration

Once connections are complete and supply air is

applied, turn the start-point adjustment dial until the

actuator begins to move.

For example, a start point of 4 psi with a 5 psi span

spring will yield an operating range of 4–9 psi.

Connections

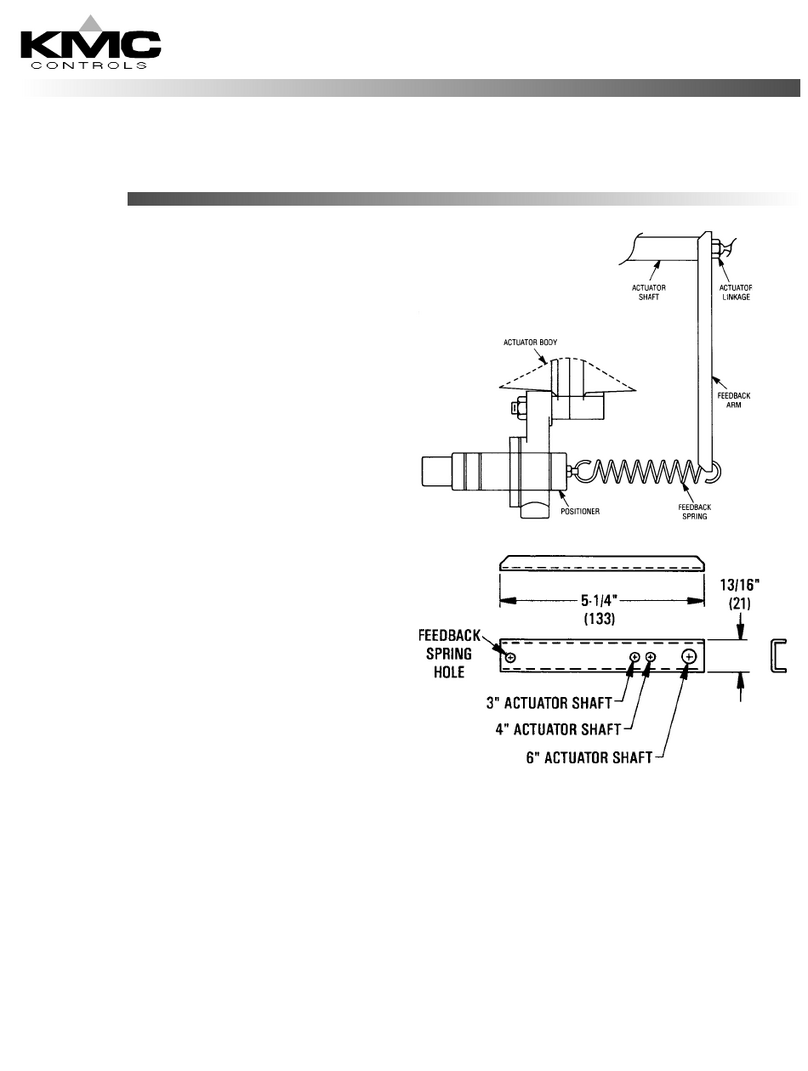

1. Using 1/4" (6 mm) O.D. FR tubing, connect the

main air supply to the center 3/16" (5 mm) port.

Provide a supply of clean, dry, 20–30 psi (38–207

kPa) control air.

2. Connect the control signal to Port 2 (input).

3. Connect Port 1 (output) to the actuator. For 3" and

4" actuators (only), insert the small beige in-line

restrictor (VTD-2500) in the line between Port 1

and the actuator. The restrictor is not needed for

6" actuators.

More Information

For accessories, speci-

cations, and other

information, see the

CMC-1001 Data Sheet

on the KMC web site

(www.kmccontrols.

com).

CAUTION

Pneumatic devices must be supplied with clean, dry

control air. Any other medium (e.g., oil or moisture

contamination) will cause the device to fail.