Meusburger T7 User manual

Rev. 1.00.03a | 23.06.23 11:09

Technische Änderungen vorbehalten

Meusburger Georg GmbH & Co KG

Kesselstraße 42 | 6960 Wolfurt | Austria

T +43 5574 6706

oce@meusburger.com

www.meusburger.com

T7

Start-up, Service and Operating Manual

CONTENT

1 Introduction 1

1.1 General information 1

1.2 Safety Instructions 2

1.3 Warranty conditions 2

1.4 Transport and storage 2

1.5 Disposal 3

1.6 Symbol meanings 3

2 Operation 5

2.1 Touch operation gestures 5

2.2 Image layout 5

2.3 Process data and parameter display 6

2.3.1 Standard 6

2.3.1.1 Selection of the number of zones per screen page 6

2.3.1.2 Select zone area 8

2.3.1.3 Background colour 8

2.3.1.4 Output value display (as bars) 8

2.3.2 Table 8

2.3.2.1 Select zone area / parameter 9

2.3.2.2 Background colours 9

2.3.3 All 9

2.3.3.1 Background colours 10

2.4 Entering input 10

2.4.1 Procedure for entering input 10

2.4.2 Copy zone parameters 12

2.4.3 Assign zone names 13

2.5 The controller unit 14

2.6 Login 14

2.7 Alarm status 15

2.8 Switch controller on/o 16

2.9 Info Centre 16

2.9.1 Code number 16

2.9.2 Position menu bar 17

2.9.3 Select language 17

2.9.4 Cleaning the screen 17

2.9.5 Communication parameters 17

2.9.6 User Management 17

2.9.7 Date / time 19

2.9.8 Hardware setup 19

2.9.9 System parameters 19

3 Start-up 20

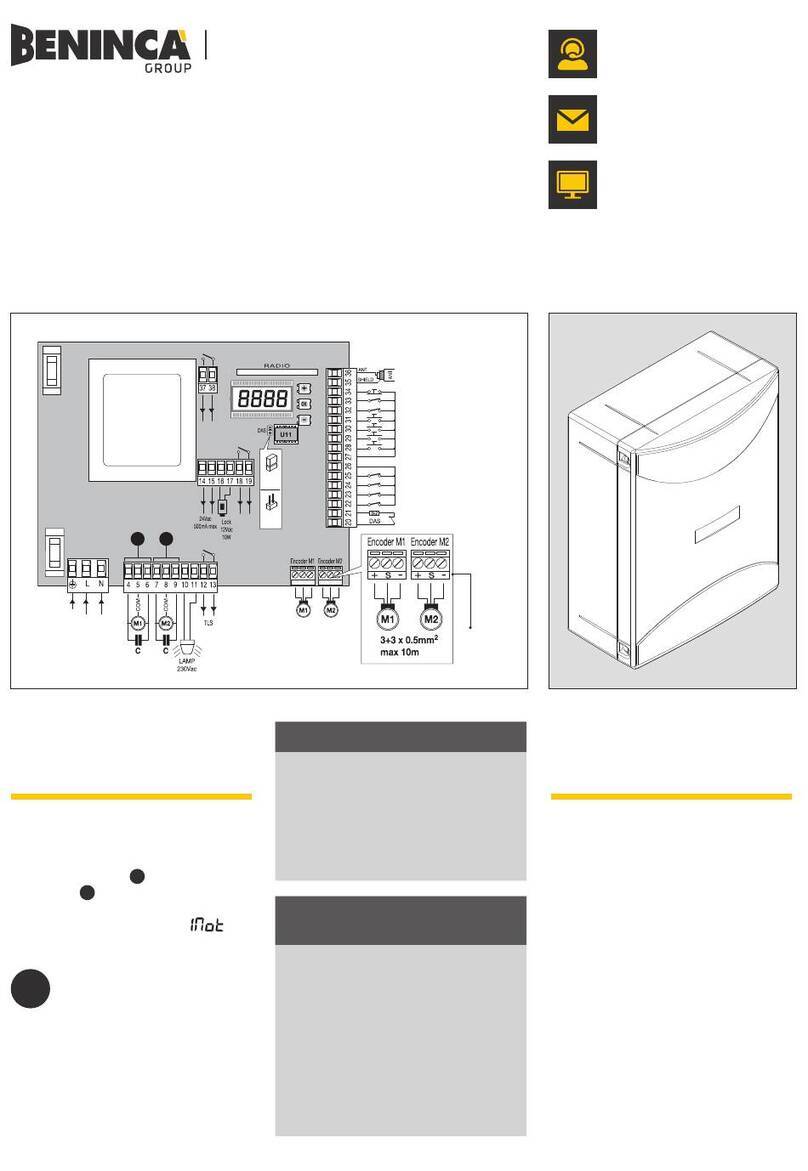

3.1 Electrical start-up 20

3.1.1 Power supply and digital outputs 20

3.1.2 Interfaces 20

3.1.2.1 Ethernet 20

3.1.2.2 CAN 21

3.2 Setup 21

3.2.1 Ethernet 22

3.2.1.1 Addressing 22

3.2.1.2 Integrate controller 22

3.2.2 CAN 24

3.2.2.1 Addressing 24

3.2.2.2 Interface settings 24

3.2.2.3 Integrate controller 24

3.3 Device update 26

3.3.1 Update device software 26

3.4 Installation of a third language 26

4 Technical data 27

4.1 Installation plan 27

5 Annex 29

5.1 Version history documentation 29

5.2 Accessories 29

Rev. 1.00.03a

Technical changes reserved 1

Chapter 1 - Introduction

1 INTRODUCTION

1.1 GENERAL INFORMATION

FUNCTION

The T7 is an operating and display unit for parameterisation and visualisation of systemp and flexotemp

control systems with the following features:

»Compact and sturdy unit for operation and display of one or more controller components

»Usable with systemp and flexotemp controllers

»7“ TFT display with capacitive touch screen

»Clear presentation of all process values

»Access to process-relevant parameters

»Supports MPI02/ MPI05

»Communication to control systems via CAN bus or Ethernet

»Placement independent from controller

The following functions are not intended:

»Project planning of flexotemp control systems. This can be done using the flexotempMANAGER tool.

SUPPORTED DEVICES

The T7 supports the following controller series:

Series Controller(s) CAN Ethernet

systemp II ETR132 II, ETS132 II, ETR 112

systemp net ETR 132 net, ETS132 net, ETR 112 net

systemp PNIO ETR132 PNIO, ETR 112 PNIO

flexotemp PCU

flexotemp PNIO PCU PNIO, PCU NEXT

flexotemp MPI 02 (under PCU/PCUPNIO)

flexotemp MPI 05

PURPOSE OF THIS DOCUMENTATION

This user manual contains information that you need for the start-up, operation and maintenance of the T7

operating unit.

TARGET GROUP

This documentation is intended for qualified personnel in the following fields:

»Operators, project planners and programmers

»Electrical specialists who assemble, connect and commission the product/system

LEGAL INFORMATION

This manual contains information that you must observe for your personal safety and to avoid damage to

property. Before the installation and operation of the product/system, please read through this start-up and

service manual completely and carefully.

QUALIFIED PERSONNEL

The product/system described in this documentation may only be handled by personnel qualified for the

respective task. The documentation associated with the respective task, in particular the safety instructions

contained therein, must be observed. Due to their training and experience, qualified personnel are able to

recognise the risks in handling these products/systems and avoid possible hazards.

All persons involved with the installation/start-up/maintenance/servicing of the device must

»strictly observe this start-up and service manual

»regard this start-up and service manual as part of the product

»maintain this start-up and service manual during the lifetime of the product

www.meusburger.com

2

Start-up, Service and Operating Manual T7

»pass on this start-up and service manual to all successive owners or operators of the product

»make sure that every obtained amendment is integrated in this start-up and service manual.

INTENDED USE

The T7 may only be used for the applications described in this technical documentation.

When properly used, the safety of the user and the device is guaranteed. The device may only be used

for its intended purpose.

DISCLAIMER

Uses other than those listed above are considered improper uses, and exclude the liability of the manufac-

turer/supplier for any related damage to persons or property and any consequential damage.

We have checked the contents of this publication for compliance with the hardware and software de-

scribed. Nevertheless, deviations cannot be ruled out, so we do not assume any guarantee for complete

compliance. The specifications in this publication are checked regularly and necessary corrections are

included in the following editions.

1.2 SAFETY INSTRUCTIONS

Before installation, handling or operation of the device, please read through this start-up and service

manual completely and carefully.

All persons responsible for the installation/start-up/operation/maintenance/servicing of the device must:

»be suitably qualified

»strictly observe this start-up and service manual

»regard this start-up and service manual as part of the product

»maintain this start-up and service manual during the lifetime of the product

»pass on this start-up and service manual to all successive owners or operators of the product

»make sure that every obtained amendment is integrated in this start-up and service manual.

1.3 WARRANTY CONDITIONS

This product is subject to the legal warranty time periods for errors or defects in production.

CONTENT OF THE WARRANTY

If a malfunction occurs due to a manufacturing fault, the manufacturer/supplier will repair or replace the

defective product at to their own discretion.

The following repairs are not covered by the warranty and are subject to a charge:

»Malfunctions after the legal deadlines have expired.

»Malfunctions caused through operating error and/or incorrect parameterisation by the user (if the de-

vice is not operated as described in the start-up and service manual).

»Malfunctions caused by other devices.

»Changes or damage to the device which do not originate from the manufacturer/supplier.

If you wish to use services within the framework of this guarantee, please contact the manufacturer/suppli-

er.

1.4 TRANSPORT AND STORAGE

TRANSPORT

The components of the T7 system are delivered in a robust carton, in shockproof packaging.

This ensures sucient protection under normal circumstances.

Rev. 1.00.03a

Technical changes reserved 3

Chapter 1 - Introduction

UNPACKING

Check the package and the product delivered for visible transport damage. If damage is identified, please

contact the transport company.

Damage to the system

Damaged parts can lead to damage to the system. Do not put any damaged components of the T7

system into operation!

STORAGE

If the unpacked device is not immediately put into operation, it must be stored so it is protected from dirt

and moisture.

Please refer to the technical specifications for permissible operating temperature and humidity. If there is

any dirt contamination, liquid penetration, condensation build up, damage or other breaches of the storage

conditions, start-up is not permitted until further action has been agreed with Meusburger Deutschland

GmbH.

1.5 DISPOSAL

Meusburger Deutschland GmbH as a manufacturer within the meaning of ElektroG (Electrical and Elec-

tronic Equipment Act), which implements the European WEEE directive 2002/96/EC in German law, is

registered under number WEEE registration number DE 66448978. The components of the T7 system are

considered here too.

1.6 SYMBOL MEANINGS

The following symbols and conventions are used in this document for quicker orientation:

Attention This symbol indicates references and information which are

decisive for the operation of the device. Failure to comply may

result in damage to the device or personal injury.

Information / notes This symbol indicates additional information and explanations,

which serve to provide better understanding.

Example With this symbol, a function is explained by means of an exam-

ple.

Operation This symbol explains the operating steps for a function.

Reference This symbol refers to information in another document.

FAQ FAQs (Frequently Asked Questions) are answered here.

Data on the internet This symbol refers to additional documents on the internet.

Installation / assembly This symbol indicates instructions for assembly and electrical

installation.

Settings This symbol provides information on the settings of the configu-

ration parameters.

www.meusburger.com

4

Start-up, Service and Operating Manual T7

REFERENCES IN THE OPERATING MANUAL

äCross reference: In the PDF version of the document the link brings you to the cross

reference.

Equations Calculation specifications and examples

<View> Menu points e.g. view are represented through a < > bracket.

{Project} Windows (e.g. project) are represented through a { } bracket.

n.a. not available / not applicable

Rev. 1.00.03a

Technical changes reserved 5

Chapter 2 - Operation

2 OPERATION

During operation, access to all setting values (configuration parameters, system settings of the controller,

and T7, ...) is controlled via one user 2.9.6 User Management . In this manual it is assumed that the user

Admin has full access to all data. If you do not have the appropriate rights, please contact the user with

full access rights to assign the setting or to give you rights to edit the setting value.

2.1 TOUCH OPERATION GESTURES

The following gestures are supported on the capacitive touch screen depending on the menu item.

Tapping (once)

Swiping left/right or up/down

Spread and pinch with 2 fingers

2.2 IMAGE LAYOUT

Screen pages in which process data is displayed are structured as follows.

ACurrent date and time

BType of display of process data (Standard, Table,

All). If the Standard display mode is selected, the

currently selected page and the total number of

pages are also displayed.

CShows the respective controller type, the interface

via which the T7 communicates with the controller

and the address of the controller.

DShows the status of the alarm outputs of the T7.

EThe menu for selecting the display mode of the

process data and calling up various functions. The

menu bar can also be placed on the left side of the

screen (2.9.2 Position menu bar),

Finformation field. This includes the display of the

process data selected in the menu.

www.meusburger.com

6

Start-up, Service and Operating Manual T7

2.3 PROCESS DATA AND PARAMETER DISPLAY

The process data (actual temperature values, temper-

ature set point values, output value, and heating cur-

rent) can be displayed in three variants. The display

mode is selected via the menu bar which appears

when you click on the ‘Views’ button.

2.3.1 STANDARD

In this display mode, the process values (actual temperature value, temperature set point value, heating

current, output value) are displayed by zone.

The ‘Standard’ display mode is ac-

cessed via the ‘Standard’ button, which

can be found under the menu item

‘Views’.

The T7 has saved the number of zones per page

selected in this display mode during the last use and

switches it on.

2.3.1.1 SELECTION OF THE NUMBER OF ZONES PER SCREEN PAGE

The number of zones displayed on one screen page can be selected. It also depends on the maximum

number of zones of the specific controller. The information displayed per zone depends on the number of

zones on the screen page.

Zone display Number of

zones per

screen page

Continuously visible process

values

Additionally selectable process

values

6 »Zone number / zone name

»Set point value

»Actual value

»Output value (numeric)

»Heating current

12 »Zone number / zone name

»Set point value

»Actual value

»Output value (numeric)

»Heating current

Rev. 1.00.03a

Technical changes reserved 7

Chapter 2 - Operation

Zone display Number of

zones per

screen page

Continuously visible process

values

Additionally selectable process

values

18 »Zone number / zone name

»Set point value

»Actual value

»Output value (numeric)

»Heating current

24 »Zone number / zone name

»Actual value

»Output value (numeric)

»Heating current

»Set point value

30 »Zone number / zone name

»Actual value

»Output value (bar)

»Set point value

»Heating current

»Output value (numeric)

36 »Zone number / zone name

»Actual value

»Output value (bar)

»Set point value

»Heating current

»Output value (numeric)

42 »Zone number / zone name

»Actual value

»Output value (bar)

»Set point value

»Heating current

»Output value (numeric)

48 »Zone number / zone name

»Actual value

»Output value (bar)

»Set point value

»Heating current

»Output value (numeric)

64 »Zone number / zone name

»Output value (bar)

»Actual value

»Set point value

»Heating current

»Output value (numeric)

The number of zones being displayed can be adjusted using a two finger swiping gesture.

A 2-finger spreading gesture increas-

es the displayed number of zones to

the next highest level.

A 2-finger pinching gesture reduces

the displayed number of zones to the

level below.

If not all process parameters can be displayed in the zone display for space reasons, an additional button

appears in the menu bar. This indicates which of the additionally selectable parameters is also displayed.

After tapping the button, the heating current is shown in the zone display.

Change the display in

the zone display

www.meusburger.com

8

Start-up, Service and Operating Manual T7

2.3.1.2 SELECT ZONE AREA

If the respective controller has more zones than the number of zones

shown on the screen page, a vertical swiping gesture can be used to

switch to the next or previous zones page by page.

The status bar at the top of the screen displays the page number of the currently displayed screen and the

total number of screen pages.

Currently the first page of a total of 8 pages is displayed.

2.3.1.3 BACKGROUND COLOUR

The background colours in the zone fields indicate the status of the zone.

The zone is passive. No output value is displayed at the control outputs.

The actual temperature value is within the tolerance limits specified in the controller.

The actual temperature value is above the tolerance limit specified in the controller.

The actual temperature value is below the tolerance limit specified in the controller.

2.3.1.4 OUTPUT VALUE DISPLAY (AS BARS)

When the output value is displayed in bar form, the colour indicates the status of the output value. The

length of the bar indicates the extent of output value (0 to 100% or 0 - 100%).

If the output value is greater than 0%, the zone is in heating mode.

If the output value is less than 0%, the zone is in cooling mode.

No output value is displayed if the actuating signal is 0%.

2.3.2 TABLE

In the ‘Table’ display mode, you can get a quick overview of the parameterisation of the controller. The

zone-specific parameters of all zones of the respective controller are displayed in tabular form. Process data

is not shown in this view.

The Table display mode is accessed via

the ‘Table’ button, which can be found

under the menu item ‘Views’.

Rev. 1.00.03a

Technical changes reserved 9

Chapter 6 - Operation

In this display mode, T7 reverts to the position in the

table when last used.

2.3.2.1 SELECT ZONE AREA / PARAMETER

Swiping gestures are used to access the screen area of the parameters for specific zones.

By swiping vertically you select the zones, by swip-

ing horizontally you get the desired parameters.

2.3.2.2 BACKGROUND COLOURS

Just like for the zone view, the colour of the zone field indicates the state of the control zone.

The zone is passive. No output value is displayed at the control outputs.

The actual temperature value is within the tolerance limits specified in the controller.

The actual temperature value is above the tolerance limit specified in the controller.

The actual temperature value is below the tolerance limit specified in the controller.

2.3.3 ALL

The ‘All’ display mode is intended for quick overview of the status of all zones on one screen page. Infor-

mation on the zone status is provided exclusively via the colour coding of the zones. No process data are

displayed in this display mode.

The all display mode is accessed via the

‘All’ button, which can be found under

the menu item ‘Views’.

www.meusburger.com

10

Start-up, Service and Operating Manual T7

2.3.3.1 BACKGROUND COLOURS

Just like for the zone view, the colour of the zone field indicates the state of the control zone.

The zone is passive. No output value is displayed at the control outputs.

The actual temperature value is within the tolerance limits specified in the controller.

The actual temperature value is above the tolerance limit specified in the controller.

The actual temperature value is below the tolerance limit specified in the controller.

2.4 ENTERING INPUT

Process and configuration parameters can be edited in all three display modes: Standard, Table, and All. An

example of this is entering temperature set point values.

To do this, tap on the zone which needs to be changed. The input dialogue for zone-specific parameters is

displayed, the selected zone is highlighted.

AZone list. None, one or more zones can be select-

ed. The selection can be made manually or via

the function keys.

BOverview field of zones. The selected zones are

highlighted in colour. This field provides an over-

view of the selected zones even if they are not

visible on the zone list.

CParameter list. Only one parameter can be select-

ed at a time.

DThe field displays the parameter selected in the

parameter list.

EInput area. The new value for the selected param-

eter is entered here. The field is dierent accord-

ing to the value range of the selected parameter

(numeric, binary, selection list).

FZone selection keys / function keys

2.4.1 PROCEDURE FOR ENTERING INPUT

Changing configuration parameters is shown below with the example of entering a new set point value.

Select zone

Rev. 1.00.03a

Technical changes reserved 11

Chapter 6 - Operation

The input dialogue is displayed.

The selected zone is marked and the parameter from

the last entry is selected in the parameter list.

Swipe vertically to navigate the parameter and zone

lists.

All zones can be selected or deselected with the

function keys in the menu bar on the right side of the

screen.

Enter the new setpoint in the numeric input area.

The enter key is coloured blue to indicate that the

entered value has not yet been transmitted to the

controller and stored there.

If the input screen is exited without confirmation at

this point, you are explicitly asked whether the entry

should be accepted or rejected.

After confirming the entry, the enter key turns grey

again. The changed value was transferred to the

controller and saved there.

INPUT AREA

The input area is displayed according to the data format of the selected parameter.

A numerical value is entered.

äKeys for the numeric input area

Binary information is entered.

www.meusburger.com

12

Start-up, Service and Operating Manual T7

A selection is made from a predefined selection list.

KEYS FOR THE NUMERIC INPUT AREA

Additional function keys provide support when entering numerical parameters.

The setting value is directly increased or decreased by one.

The function is only eective if several zones are selected.

The previous values are changed to the newly entered value.

For example, set point values of all selected zones are changed to 250°C.

The function is only eective if several zones are selected.

The previous values are decreased (minus sign) or increased (plus sign) by the newly

entered value.

For example, set point values of all selected zones are increased by 10°C.

Switch over sign. Required for entering negative values.

2.4.2 COPY ZONE PARAMETERS

Copy zone parameters from one zone to one or more zones with this function. This saves typing and pre-

vents incorrect entries when transferring zone parameters.

Select the zone to be used as a copy template for

other zones.

The zone parameter input screen appears.

Access the copy dialogue page.

Rev. 1.00.03a

Technical changes reserved 13

Chapter 6 - Operation

The zone parameter copy screen appears. It is divid-

ed into 4 areas.

»The one zone that is used as a copy template is

highlighted in the zone list on the left.

»The zone(s) that is/are to be copied to are select-

ed in the zone list on the right.

»The zone parameter(s) to be copied are selected

between the two zone lists.

»The menu bar on the right side contains the zone

overview and buttons for selecting zones and

parameters.

After selecting zones and parameters, copying is

carried out by clicking the copy zone button.

Close the ‘copy zone parameters’

screen page.

2.4.3 ASSIGN ZONE NAMES

For a better overview and easier allocation of the zones, zone names can be assigned.

Select the zone whose name is to be changed.

The input dialogue page is displayed.

If the name is to be changed for several zones at

once, these zones must be selected in the zone list.

For these, a consecutive number is appended to the

changed zone name in ascending order from 1.

Access the input screen to change the

zone name.

Change the zone name and confirm the entry.

www.meusburger.com

14

Start-up, Service and Operating Manual T7

The zone name or zone names have been changed.

They will be displayed directly in the zone list.

Close the zone parameter entry screen page. The

new zone names will be used on all screen pages

and windows.

2.5 THE CONTROLLER UNIT

You can connect more than one controller, but you can only view/work on one at a time through the T7,

not several at once. Project planning with the controllers must have been successfully carried out and the

controllers recognised by the T7 (3 Start-up).

Select the menu item ‘Controllers’ in the main menu

bar. A sub menu bar appears directly next to the

main menu bar. All controllers assigned in the project

planning are listed here.

Select the desired controller here.

It will then switch over to the selected controller. Dur-

ing the switching process, the adjacent information is

displayed on the screen.

2.6 LOGIN

The login function is to change users, for example to a user with more access rights. After selecting the

user, a field will appear where a password must be entered. After the password is entered correctly, you are

logged in with the access rights for that user.

The button in the menu bar shows the user currently logged in.

Logging out can be done manually by clicking on the logout button or will happen automatically after one

minute without input on the T7.

A total of three user levels are available:

»Standard (no password required)

»Prof (factory password: prof)

»Admin (factory password: admin)

Detailed information about the users and how their access rights can be modified can be found in chapter

Access in Info Centre

Rev. 1.00.03a

Technical changes reserved 15

Chapter 6 - Operation

2.9.6 User Management.

2.7 ALARM STATUS

If there is an alarm status in at least one zone, this is indicated by the red alarm button.

There is no alarm in any zone.

There is an alarm in at least one zone.

After tapping the button, the screen page with the alarms is opened.

This lists the active alarms per zone in tabular form.

The symbols for the alarms have the following meanings.

Excess temperature: The actual temperature value has exceeded the upper temperature limit.

Insucient temperature: The actual temperature value has fallen below the lower temperature

limit.

Sensor break

Sensor polarity reversal

Sensor short-circuit

The actual temperature value has exceeded the set maximum temperature.

Measured heating current is outside the set tolerance band around the comparison value (cur-

rent setpoint value). If 0A is measured as heating current, there is an interruption in the heating

current.

Current was measured with the control output switched o. There is a defective (alloyed) actu-

ator (solid state relay, Thyristor).

By clicking on one of the zones in the alarm screen

page, the alarms active for the zone are additionally

displayed as plain text information.

www.meusburger.com

16

Start-up, Service and Operating Manual T7

Detailed information on the reasons for the alarms and instructions on how to remedy them can be

found in the controller series manuals.

2.8 SWITCH CONTROLLER ON/OFF

This function can be used to switch the control outputs of all control zones of the specific controller on or

o.

2.9 INFO CENTRE

System settings for the T7 can be made in the Info Centre and system functions for the respective controller

can be accessed.

The Info Centre can be reached by swiping down

from the upper edge of the screen towards the

centre in one of the three screen pages with Process

Data Standard, Table, and All.

The Info Centre is displayed.

Information on the status of the T7 can be found on

the right side of the screen.

»Product name

»Hardware version number

»Serial number

»Software version

The status of both alarm outputs is also displayed.

2.9.1 CODE NUMBER

Accessing a code number prompts a defined function in the controller. The code number function support-

ed by each controller series can be found in the controller manuals.

Enter and confirm a code number using the numeric

keypad or select a function from the list.

Activate code number.

No alert appears when the function is trigged.

Table of contents

Popular Control Panel manuals by other brands

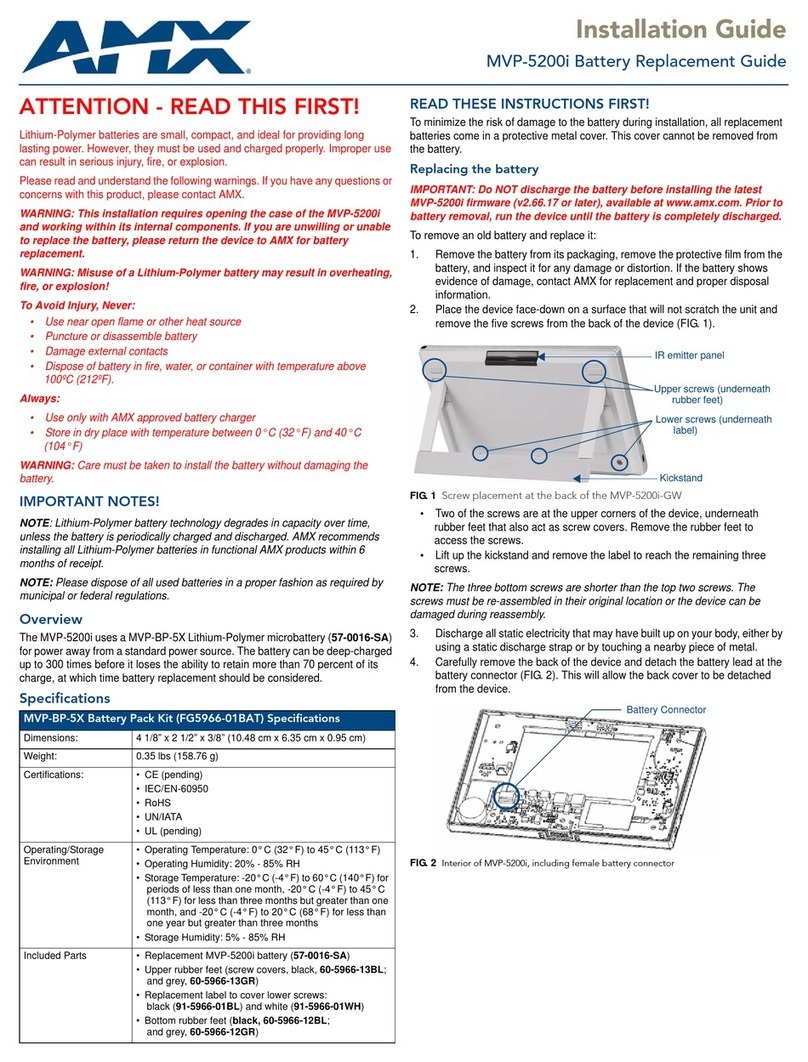

AMX

AMX Modero Viewpoint MVP-5200i installation guide

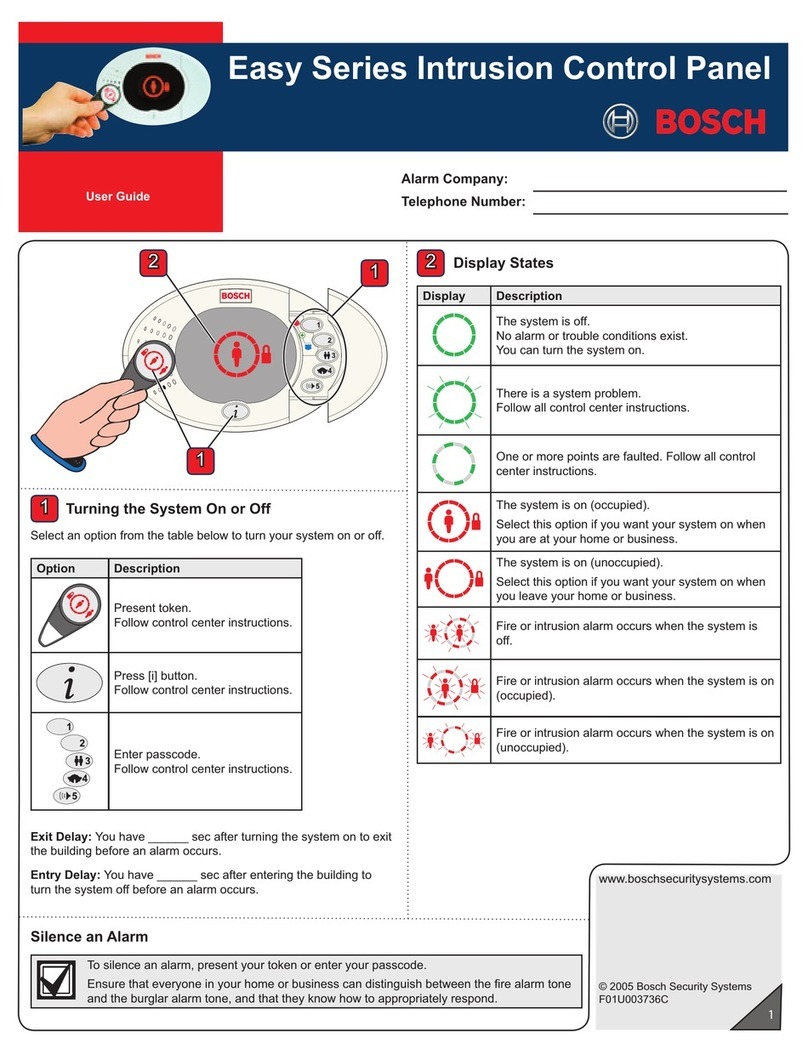

Bosch

Bosch Easy Series user guide

Marquis

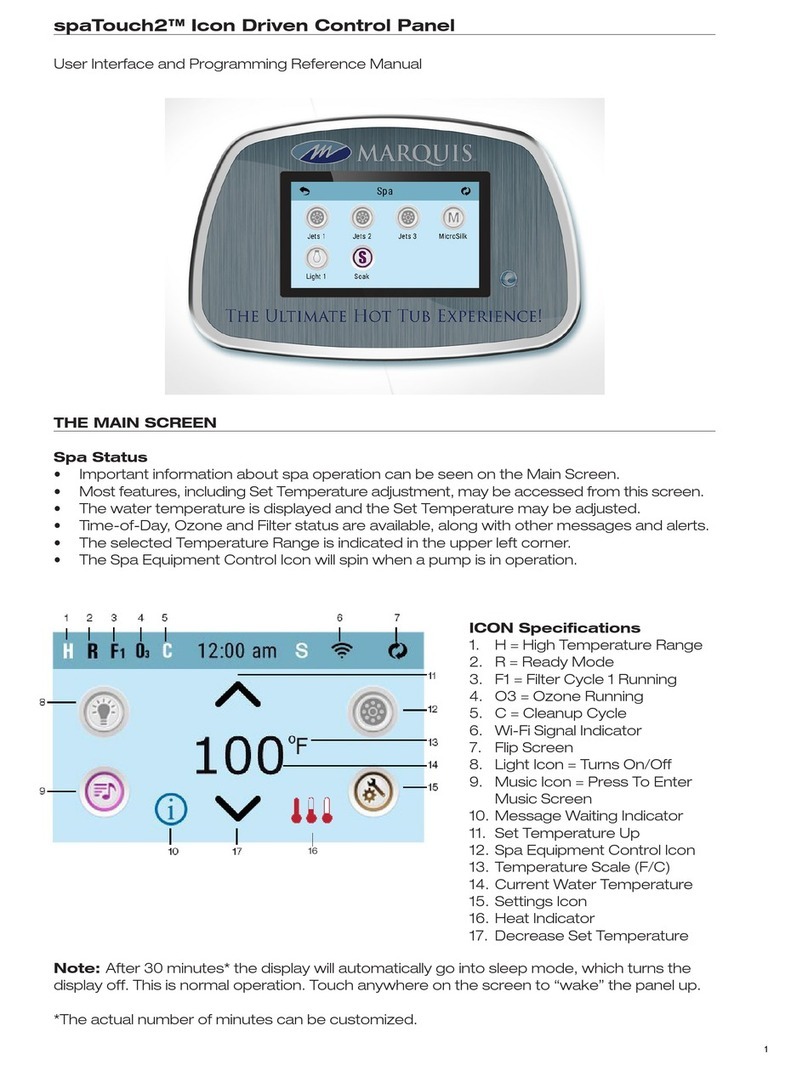

Marquis spaTouch2 User Interface and Programming Reference Manual

Belden

Belden Grass Valley NV9000 user guide

Bender

Bender COMTRAXX CP9 Series manual

Alderon Industries

Alderon Industries Check It Panel Operation, maintenance & installation manual