Bender COMTRAXX CP9 Series User manual

Manual ENCP9xx-x_D00406_00_M_XXEN/04.2020

COMTRAXX® CP9xx-x – Control Panel

Customised alarm indicator and operator panel for medical locations

and other areas

2 CP9xx-x_D00406_00_M_XXEN/04.2020

Service and support for Bender products

First-level support

Technical support

Carl-Benz-Strasse 8 • 35305 Grünberg • Germany

Telephone: +49 6401 807-760

0700BenderHelp *

Fax: +49 6401 807-629

E-mail: support@bender-service.de

Available on 365 days from 7.00 a.m. to 8.00 p.m. (MEZ/UTC +1)

* Landline German Telekom: Mon-Fri from 9.00 a.m. to 6 p.m.: 6.3 cents/30 sec.;

remaining time: 6.3 cents/min.

Mobile phone: higher, depending on mobile phone tariff

Repair service

Repair, calibration and replacement service

Londorfer Strasse 65 • 35305 Grünberg • Germany

Telephone: +49 6401 807-780 (technical issues) or

+49 6401 807-784, -785 (commercial issues)

Fax: +49 6401 807-789

E-mail: [email protected]

Field service

On-site service

Telephone: +49 6401 807-752, -762 (technical issues) or

+49 6401 807-753 (commercial issues)

Fax: +49 6401 807-759

E-mail: fieldservice@bender-service.de

Mon-Thu 7.00 a.m. to 4.00 p.m., Fri 7.00 a.m. to 1 p.m. (MEZ/UTC +1)

CP9xx-x_D00406_00_M_XXEN/04.2020 3

COMTRAXX® CP9xx-x – Control Panel

Table of Contents

1 General instructions .........................................................................5

1.1 How to use this manual..............................................................................................5

1.2 Indication of important instructions and information ...................................5

1.2.1 Signs and symbols ........................................................................................................5

1.3 Training courses and seminars.................................................................................5

1.4 Delivery conditions.......................................................................................................5

1.5 Inspection, transport and storage ..........................................................................6

1.6 Warranty and liability...................................................................................................6

1.7 Disposal of Bender devices........................................................................................6

1.8 Safety .................................................................................................................................7

2 Product description ...........................................................................9

2.1 Intended use...................................................................................................................9

2.2 Device features ........................................................................................................... 10

2.3 Applications .................................................................................................................17

2.4 Function......................................................................................................................... 17

2.5 Software products used........................................................................................... 18

2.6 BMS page of the CP9xx-x alarm indicator and operator panel.................18

2.7 Address configuration and termination............................................................ 18

3 Mounting and connection............................................................. 19

3.1 Mechanical installation ............................................................................................ 19

3.1.1 General description................................................................................................... 19

3.1.2 Opening and closing the front plate ..................................................................20

3.1.3 Removing the front plate of CP915 and CP924..............................................22

3.2 Mounting instructions.............................................................................................. 23

3.2.1 Mounting a flush-mounting enclosure with bezel frame enclosure ...... 24

3.2.2 Cross section view flush-mounting enclosure with bezel frame .............25

3.2.3 Cross section view flush-mounting enclosure with bezel frame for

cavity wall mounting ................................................................................................ 26

3.3 Fastening, cable entry .............................................................................................. 27

3.3.1 Fastening....................................................................................................................... 27

3.3.2 Cable entry ................................................................................................................... 27

3.4 Electrical connection................................................................................................. 29

4 Important information................................................................... 31

5 Technical data.................................................................................. 33

4 CP9xx-x_D00406_00_M_XXEN/04.2020

CP9xx-x_D00406_00_M_XXEN/04.2020 5

COMTRAXX® CP9xx-x – Control Panel

1 General instructions

1.1 How to use this manual

This manual is intended for qualified personnel working in electrical engineering and

electronics!

Part of the device documentation, in addition to this manual, is the enclosed

"Safety instructions for Bender products".

Read the manual before mounting, connecting and commissioning the device.

Always keep the manual within easy reach for future reference.

1.2 Indication of important instructions and information

I Danger!Indicates a high risk of danger that will result in death or serious injury if not

avoided.

I Warning! Indicates a medium risk of danger that can lead to death or serious injury if not

avoided.

I Caution!Indicates a low-level risk that can result in minor or moderate injury or damage to

property if not avoided.

i

Information can help to optimise the use of the product.

1.2.1 Signs and symbols

Disposal Temperature range Protect from dust

Protect from mois-

ture

Recycling RoHS directives

1.3 Training courses and seminars

www.bender.de -> Know-how -> Seminars.

1.4 Delivery conditions

The conditions of sale and delivery set out by Bender apply. These can be obtained from Bender

in printed or electronic format.

The following applies to software products:

“Software clause in respect of the licensing of standard software as part of de-

liveries, modifications and changes to general delivery conditions for products

and services in the electrical industry.”

Die Elektroindustrie

6 CP9xx-x_D00406_00_M_XXEN/04.2020

General instructions

1.5 Inspection, transport and storage

Check the shipping and device packaging for transport damage and scope of delivery. The follow-

ing must be observed when storing the devices:

1.6 Warranty and liability

Warranty and liability claims in the event of injury to persons or damage to property are excluded

in case of:

• Improper use of the device.

• Incorrect mounting, commissioning, operation and maintenance of the device.

• Failure to observe the instructions in this operating manual regarding transport, com-

missioning, operation and maintenance of the device.

• Unauthorised changes to the device made by parties other than the manufacturer.

• Non-observance of technical data.

• Repairs carried out incorrectly.

• Use of accessories and spare parts not recommended by Bender.

• Catastrophes caused by external influences and force majeure.

• Mounting and installation with device combinations not recommended by the manufac-

turer.

This operating manual and the enclosed safety instructions must be observed by all persons

working with the device. Furthermore, the rules and regulations that apply for accident preven-

tion at the place of use must be observed.

1.7 Disposal of Bender devices

Abide by the national regulations and laws governing the disposal of this device.

For more information on the disposal of Bender devices, refer to

www.bender.de -> Service & support.

CP9xx-x_D00406_00_M_XXEN/04.2020 7

COMTRAXX® CP9xx-x – Control Panel

1.8 Safety

If the device is used outside the Federal Republic of Germany, the applicable local standards and

regulations must be complied with. In Europe, the European standard EN 50110 applies.

I Danger!Risk of fatal injury due to electric shock! Touching live parts of the system carries the

risk of:

• A fatal electric shock

• Damage to the electrical installation

• Destruction of the device

Before installing and connecting the device, make sure that the installation has been de-ener-

gised. Observe the rules for working on electrical installations.

8 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

CP9xx-x_D00406_00_M_XXEN/04.2020 9

COMTRAXX® CP9xx-x – Control Panel

2 Product description

2.1 Intended use

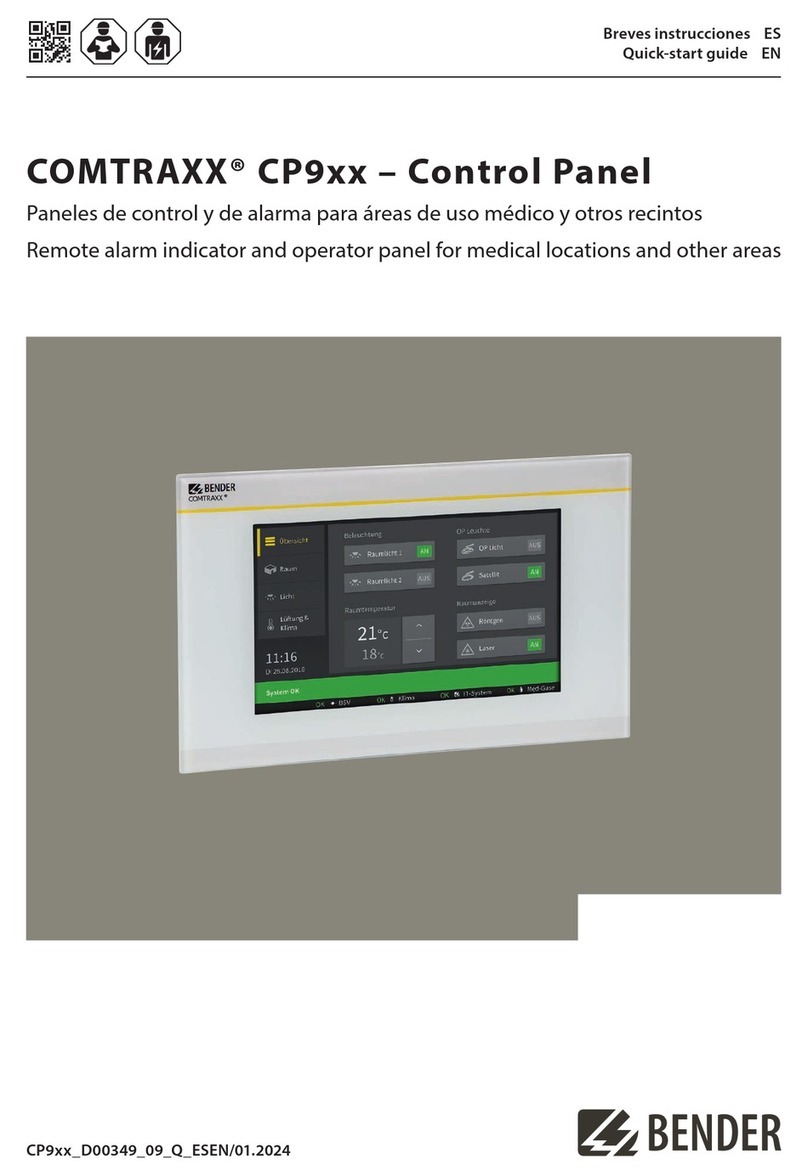

The CP9xx-x alarm indicator and operator panels are intended for use in medical facilities as well

as industrial and single-purpose buildings.

They are used for:

• Display and visualisation of operating, warning and alarm messages

• Central control and parameter setting of BMS bus devices (BMS = Bender Measuring

Device Interface)

• Output of visual and acoustic warning messages

• Indication of measured values and setting of limit values for the purpose of measured

value monitoring of BMS-capable Bender monitoring systems, such as MEDICS®, RCMS

or EDS.

In addition, they are used for display, control and operation of:

• Operating theatre tables

• Supply systems for medical gases

• Air conditioning and ventilation systems

• Room lighting

• Communication systems

• Third-party systems

All technical devices installed in one alarm indicator and operator panel constitute a technical

centre in the respective room. Please heed the limits of the area of application indicated in the

technical specifications. Any other use than that described in this manual is regarded as improper.

Intended use implies:

• System-specific settings

• Observation of all information in the operating manual

• Compliance with test intervals

10 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

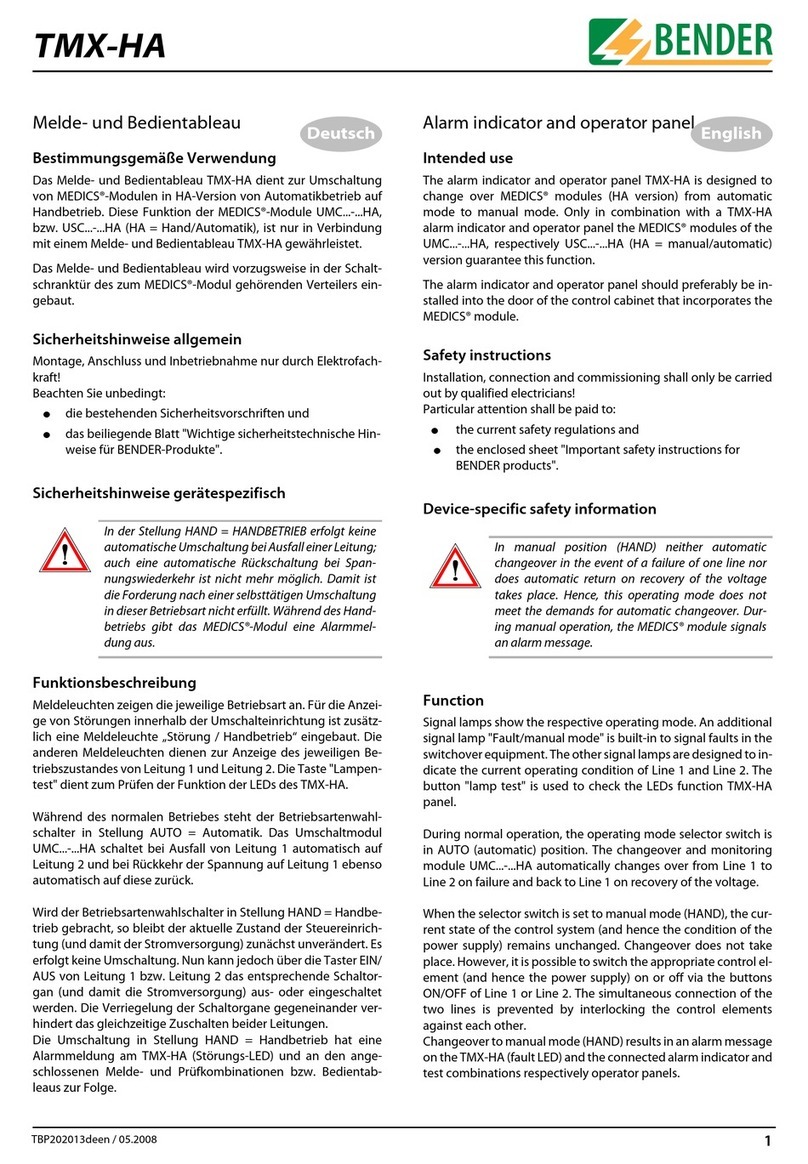

2.2 Device features

The CP9xx-x series includes the following variants of customised alarm indicator and operator

panels:

• CP9xx-F (only with front foil)

• CP9xx-G (only with glass front plate)

• CP9xx-H (with front foil and glass front plate)

The following basic types are described in the CP9xx-x series:

CP907-F, CP915-F, CP924-F with

front foil Control Panel with

COMTRAXX®

CP9xx-F alarm indicator and operator panels are equipped

with a front foil behind which the various

touch monitors are installed.

CP907-F Alarm indicator and operator panel with complete CP907

(B95061080) integrated behind a foil (installation with

inspection window and retaining frame).

CP915-F Alarm indicator and operator panel with PCAP touch mon-

itor (15.6", 16:9 format).

CP921-F Alarm indicator and operator panel with resistive touch

monitor (21.5", 16:9 format).

CP924-F Alarm indicator and operator panel with resistive touch

monitor (24", 16:9 format). For the 24" version, the highly

transparent foil is used.

CP915-G and CP924-G with glass

front plate in bezel frame or

mounting frame

The CP915-G and CP924-G alarm indicator and operator

panels cannot be equipped with any further components

or accessories.

CP9xx-H Alarm indicator and operator panels with glass front plate

and foil front (15.6", 24", 16:9 format)

i

Since with the matt, antibacterial front foil the display surfaces of the monitors and also in-

spection windows of other components must be coated for better transparency, the use of the

highly transparent foil is preferred.

i

Foil touch panels are individually programmed and are usually connected to a remote or exter-

nal I/O control unit, which in turn is set up and parameterised individually according to the

project. Depending on the requirements, the CP9xx-x alarm indicator and operator panel can

be provided with one or two front plates. The front plates are usually hinged on the right or left

and right side.

i

The individual and project-related elevation illustrations, circuit diagrams, programming and

datasheets are also an important part of this manual. These must also be read and observed

prior to commissioning and operation.

CP9xx-x_D00406_00_M_XXEN/04.2020 11

COMTRAXX® CP9xx-x – Control Panel

Some implementation examples are given below:

Fig. 2–1 CP915-F in bezel frame enclosure with individual, project-specific internal components

12 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

Fig. 2–2 CP921-F in bezel frame enclosure with individual, project-specific internal components

CP9xx-x_D00406_00_M_XXEN/04.2020 13

COMTRAXX® CP9xx-x – Control Panel

Fig. 2–3 CP921-F with two front plates in bezel frame enclosure.

Lower front plate with individual, project-specific internal components

14 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

Fig. 2–4 CP924-F with two front plates in bezel frame enclosure.

Right front plate with individual, project-specific internal components

Fig. 2–5 CP915-F with mounting frame with individual, project-specific internal components

CP9xx-x_D00406_00_M_XXEN/04.2020 15

COMTRAXX® CP9xx-x – Control Panel

Fig. 2–6 CP924-F with two front plates in bezel frame enclosure (including examples of customised indi-

vidual internal components)

Fig. 2–7 CP924-H with two front plates in bezel frame enclosure, upper front plate glass, lower front plate

with foil front (including examples of customised individual internal components)

16 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

Fig. 2–8 CP924-F with two front plates in bezel frame enclosure (irongrey, including examples of custom-

ised individual internal components)

Fig. 2–9 CP924-H with two front plates in bezel frame enclosure

Left front plate glass, right front plate foil front and individual, project-specific internal components

CP9xx-x_D00406_00_M_XXEN/04.2020 17

COMTRAXX® CP9xx-x – Control Panel

Fig. 2–10 CP924-H with two front plates with bezel frame enclosure

Upper front plate glass, lower front plate with foil front and individual, project-specific internal compo-

nents

2.3 Applications

• Optimum visualisation on the display tailored to the user

• Integration of compatible Bender products (ISOMETER®, ATICS®, RCMS, EDS, LINETRAXX®

and MEDICS® systems, universal measuring devices and energy meters)

• Individual instructions in case of alarms (optionally available)

• Selective notification to different users in case of alarms

• Control and regulation of systems such as air conditioning or blinds control.

2.4 Function

CP9xx-x alarm indicator and operator panels can be integrated into the existing EDP structure like

PCs, if required. Contact your IT administrators in this regard. After connection to the network and

compatible Bender products, all system devices can be accessed from any PC via a web browser.

In this way, all important system information is directly available.

Verified web browsers: Microsoft Internet Explorer, Mozilla Firefox, Google Chrome

Each alarm indicator an operator panel is individually configured and tailored to the requirements

of the user.

18 CP9xx-x_D00406_00_M_XXEN/04.2020

Product description

2.5 Software products used

CP9xx-x alarm indicator and operator panels are equipped with the COMTRAXX® user interface. It

is described separately in the "COMTRAXX®" manual.

2.6 BMS page of the CP9xx-x alarm indicator and operator panel

The majority of Bender devices communicate via the internal BMS bus.

The CP9xx-x alarm indicator and operator panel can be operated as a master or as a slave.

i

The CP9xx-x alarm indicator and operator panel is to be operated as master when:

- Parameters are queried or changed

- Specific control commands are given

Please note that not all BMS masters can surrender their master function!

2.7 Address configuration and termination

To ensure proper functioning of the CP9xx-x alarm indicator and operator panel, correct address

assignment and termination is of utmost importance.

i

On delivery, the systems are pre-programmed according to the project agreements and the ad-

dressing is correct.

i

Multiple assignment of addresses

The default system name on all Bender BCOM devices is "SYSTEM". If several systems with the

same system name are integrated into the same network, addresses are assigned twice. This

leads to transmission errors. Always enter a unique BCOM system name during initial setup.

i

On delivery, all project-specific settings are available.

CP9xx-x_D00406_00_M_XXEN/04.2020 19

COMTRAXX® CP9xx-x – Control Panel

3 Mounting and connection

3.1 Mechanical installation

3.1.1 General description

The mechanical design of the enclosure for flush mounting with bezel frame is oriented toward

longevity and particularly suited for the high hygienic requirements in medical locations. The en-

closures are all custom made to suite the technical and mechanical requirements on site.

The actual flush-mounting enclosure is made of stiff, grey 4 mm PVC plastic or 3 mm aluminium

with an extruded aluminium profile of natural aluminium colour.

The bezel frame covers a gap of up to 13 mm. Please refer to the chapter „3.2.1 Mounting a

flush-mounting enclosure with bezel frame enclosure“ for more information

The size of the circular gap between the bezel frame and the front plate is 0.5 mm.

The front plate features a concealed seal to offer the highest possible level of protection.

The front plate is attached to the bezel frame with concealed hinges. The location of the hinges

are according to the individual elevation illustrations.

CP9xx-G alarm indicator and operator panels have a glass front plate without hinges. The glass

front plate is retained in the enclosure by a snap-in mechanism.

I Caution!Damage to the glass front plate!

Placing the suction lifter in the middle and pulling only at this point may damage the glass

front plate.

The necessary PCBs and components are attached to the front plate using bolts. Other electrical

components are connected to the components located on the mounting plate via a flexible hose.

The mounting plate can be easily removed from the flush-mounting enclosure to install it. The ca-

ble connections between the front plate and the mounting plate do not need to be disconnected.

Since no other components are attached to the rear side of the enclosure except for the mount-

ing plate, the technician has sufficient space for installation.

Please observe chapter „3.2 Mounting instructions“ and chapter „3.3 Fastening, cable entry“.

20 CP9xx-x_D00406_00_M_XXEN/04.2020

Mounting and connection

3.1.2 Opening and closing the front plate

According to the subsequent standards, the enclosure may only be opened using keys or tools

(e.g. a suction lifter):

• VDE 0660-600-1, -2, chap. 8.4.2.3

• IEC/EN 61439-1, -2, chap. 8.4.2.3

Each alarm indicator and operator panel is supplied with a suction lifter, which is normally at-

tached to the cable harness. Take out the suction lifter before closing the panel front.

The suction lifter is your "key" to the alarm indicator and operator panel. Keep it close to the alarm

indicator and operator panel (see „3.1.3 Removing the front plate of CP915 and CP924“).

I Caution! Damage to the bezel frame and seal!

Do not use a screw driver or knife to open the front plate. The bezel frame and the seal may be

damaged.

Refer to the elevation illustrations to see on which side the door/hinges are mounted. Open the

front plate by placing the suction lifter at the lower corner on the opposite side of the hinges.

In order to prevent unintentional opening of the front panel due to protruding components (e.g.

socket-outlets, operating theatre table controls), which provide a possible of holding point for

opening, the front panel is secured by a safety screw (fillister head M4x10 mm with rosette) locat-

ed in the middle of the side opposite to the hinges.

Pull the suction lifter to open the front.

To close the alarm indicator and operator panel, lift off the front plate slightly holding onto the

suction lifter and start pressing from the lower corner adjacent to the hinges all the way around

the front plate.

Make sure that the spring catches are firmly pressed into the slot of the frame and the plate sur-

face is not higher than the bezel frame.

Other manuals for COMTRAXX CP9 Series

8

This manual suits for next models

9

Table of contents

Other Bender Control Panel manuals

Bender

Bender COMTRAXX CP305 User manual

Bender

Bender PRC487 User manual

Bender

Bender COMTRAXX CP9 I Series User manual

Bender

Bender COMTRAXX CP9 Series User manual

Bender

Bender TM800 User manual

Bender

Bender COMTRAXX CP9 Series User manual

Bender

Bender COMTRAXX CP9 Series User manual

Bender

Bender COMTRAXX CP9 Series User manual

Bender

Bender COMTRAXX CP305 User manual

Bender

Bender COMTRAXX CP9 Series User manual