MEWOI MEWOI4000 User manual

Digital Earth Resistance Tester

CONTENT

Warning................................................................................................... 1

I.Introduction........................................................................................ 3

II.Measuring Range and Accuracy................................................... 4

III.Technical Specifications................................................................ 4

IV.Tester Structure.............................................................................. 6

V.Measuring Principle........................................................................ 7

VI. Function Quick Check..................................................................... 8

VII. Operation Methods......................................................................... 8

1.Switch On/Off............................................................................ 8

2.Battery Voltage Check................................................................ 8

3.Insert and Connection of Rods................................................... 8

4.Grounding Voltage Measurement............................................... 9

5.Wire Resistance Verification.................................................... 10

6.Precision Measurement............................................................ 10

7.Simple Measurement.................................................................11

8.Backlight Control..................................................................... 13

9.Alarm Settings.......................................................................... 13

10.Data Lock/Storage.................................................................. 13

11.Data Reading/Deletion........................................................... 13

12.Data Upload ........................................................................... 14

VIII. Battery Replacement.................................................................. 14

IX.Accessories.................................................................................. 15

-1-

Warning

Thanks for your purchase of MEWOI4000 Digital Earth

Resistance Tester of our company. For better use of the

product, please make sure:

---read this user manual in details.

---abide by the safety regulations and precautions strictly.

The tester is conforming to IEC61010 on design, production

and test.

Under any circumstance, it shall pay special attention on

safety in use of this tester.

Please don’t use high-frequency signal generators like mobile

phone and etc. to avoid error during measuring.

Pay attention to words and symbols stick on the Tester.

It shall make sure that tester and accessories are in good

condition before use; it can be used only when there is no

damaged, naked or broken part in testing wires or insulation

layer.

During measurement, it is forbidden to touch bare conductors

and circuit under measurement.

Before measurement, please confirm whether FUNCTION

rotary switch has been set within the proper measuring range.

Confirm that connector plug of lead has been inserted in the

tester interface closely.

Please don’t impose over 600V A.C. or D.C. voltage on the

part between testing end and interface. Otherwise, it may have

damage on the tester.

Please don’t measure in an inflammable place. The flame

-2-

sparkle maybe cause explosion.

During usage of tester, please stop using it when exposed

metal is caused by broken enclosure or testing wires.

Please don’t keep or store the tester in the spot with

high-temperature and moisture, or condensation, and under

direct daylight radiation for a long time.

For replacing battery, please confirm testing wire has moved

apart the meter, and FUNCTION rotary switch is in “OFF”

position.

Please put the used batteries in appointed collection place.

The Tester has no auto shut-off function. Please set

FUNCTION rotary switch to “OFF” after usage.

When the meter displays battery low voltage symbol ,and

you need to replace the battery in time.

If the Tester is not going to be used for a long period, remove

the battery.

Pay attention to measuring range and usage environment

stipulated for the Tester.

This measuring device is only to be used, disassembled,

adjusted and repaired by qualified personnel with authorization.

When it may cause hazard by continuous use for the reason

of the Tester itself, it shall immediately stop using it and deposit it

at once, leaving it for disposal by authorized agency.

For risk of danger icon in manual , users must perform

safety operations strictly in compliance with the manual content.

-3-

- 2-

I.Introduction

MEWOI4000 Digital Earth Resistance Tester is specially

designed and manufactured for field measurement, adopting the

latest digital and micro-processing technology, 3-pole or 2-pole

method for earth resistance measurement, with a unique function

of wire resistance verification, anti-interference capability and the

ability to adapt to the environment, to ensure high precision, high

stability and reliability for prolonged measure, which is widely used

in electric power, telecommunications, meteorology, oil field,

construction, lightning protection, industrial electrical equipment

and other earth ground resistance measurement.

MEWOI4000 Digital Earth Resistance Tester has a unique

function of wire resistance verification ,more accurate on

measuring on-site low value earth ground resistance, which can

avoid error caused by resistance change due to prolonged usage

of testing wire; avoid error caused by testing wire that is failed to be

fully inserted into tester interface or by poor contact; avoid error

caused by users’ replacing or lengthening testing wires.

MEWOI4000 Digital Earth Resistance Tester is composed of

host machine, monitoring software, testing wires, communication

wires and others. The large LCD display of host machine is with

blue backlight and bar graph indicating that can be seen clearly. At

the same time it can store 400 sets of data, fulfilling historical

inquiry and online real-time monitoring through monitoring

software, dynamic display, with the maximum, minimum, and

mean indicators, with alarm settings and alarm indicator, and with

the functions like historical data access, reading, preservation,

report forms, printing and so on.

-4-

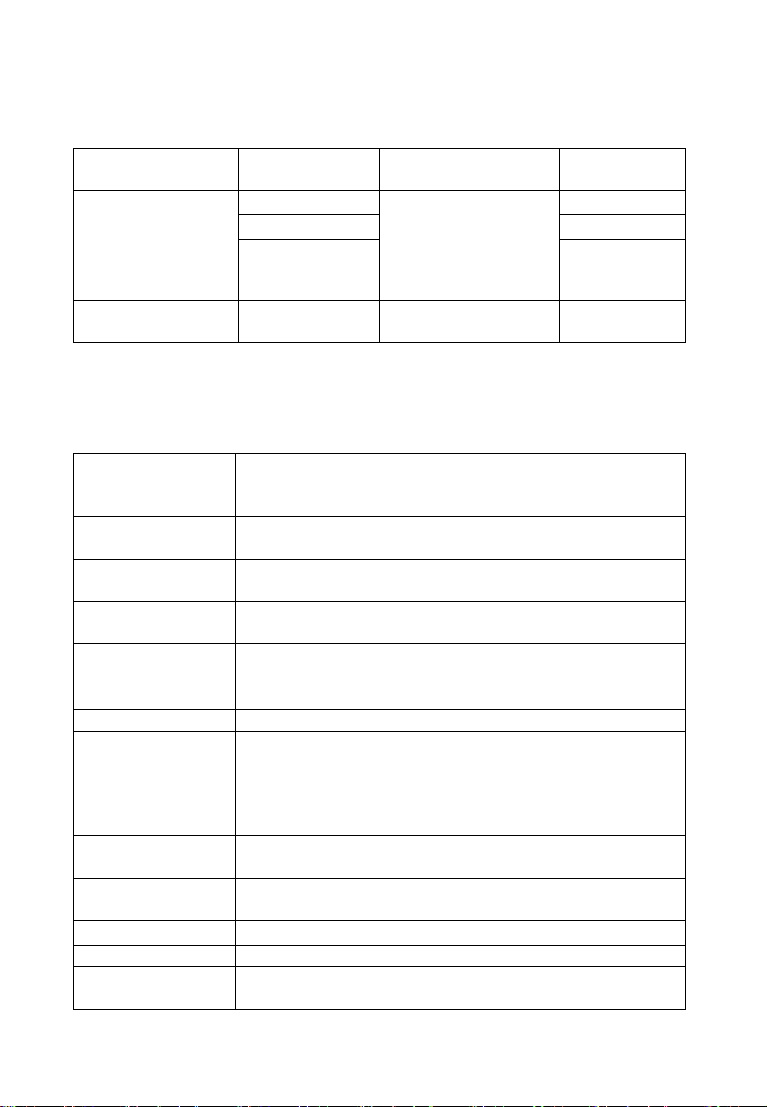

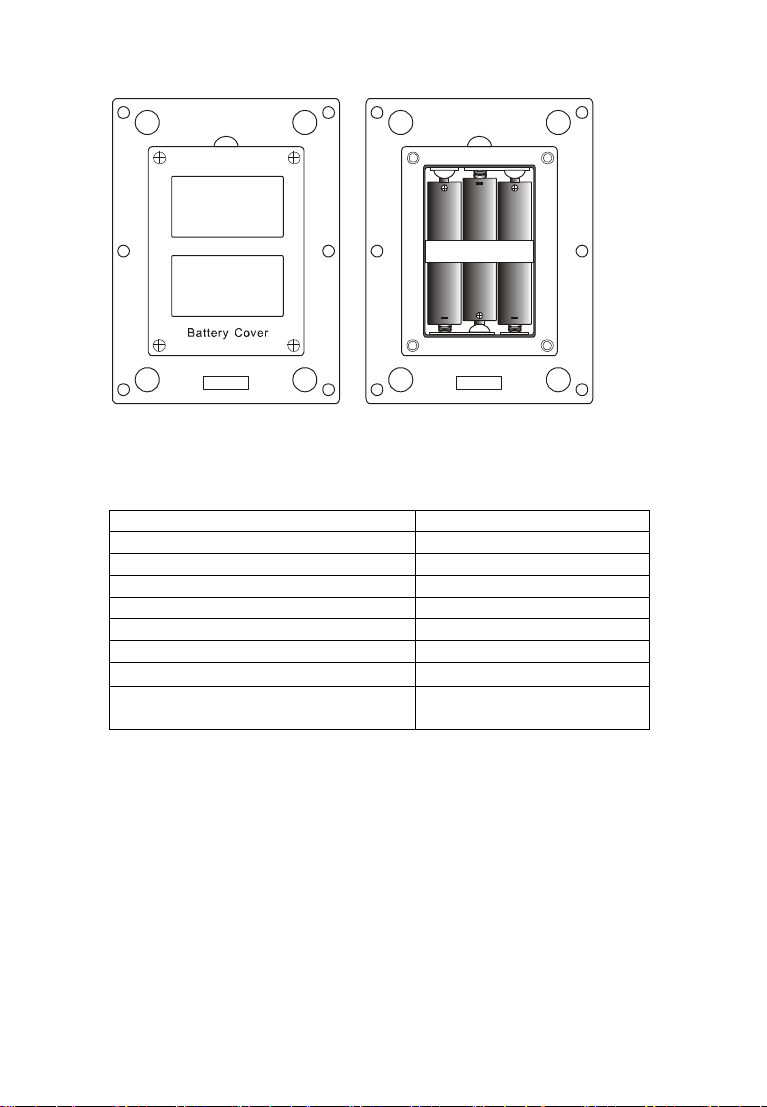

II.Measuring Range and Accuracy

Measuring

Functions

Measuring

Range

Accuracy

Resolution

Earth Ground

Resistance

0.01Ω~20Ω

±1%rdg±3dgt

(Auxiliary earth

ground resistance

100Ω±5%,voltage

to ground<10V)

0.01Ω

0.1Ω~200Ω

0.1Ω

1Ω~2000Ω

1Ω

Earth Ground

Voltage

0~600V AC

±1%rdg±3dgt

1V

(Remark: 23℃±5 ℃,below 75%rh)

III.Technical Specifications

Function

Earth ground resistance measurement, voltage to

ground measurement, low value resistance

measurement

Power Supply

DC 9V(Zi-Mn dry battery R14S 1.5V 6 PCS,

continuous standby for 300 hours )

Backlight

Controllable blue backlight, suitable for use in dark

place.

Measuring

Mode

Precise 3-pole measurement, simple 2-pole

measurement

Measuring

Method

Earth ground resistance: rated current change-pole

method, measurement current 3mA Max,820Hz;

Voltage to ground: average value rectification

Data Mode

Average value, maximum, minimum

Wire Resistance

Verification

Avoid error caused by testing wire that is failed to be

fully inserted into tester interface or by poor contact or

by users’ replacing or lengthening testing wires,

making it more accurate for earth ground resistance

measurement.

Display Mode

4-digital super-large LCD display, blue screen

backlight

Measuring

indicator

During measurement, LED flash indicator, LCD count

down display

LCD Dimension

128mm×75mm;Display field:124mm×67mm

Dimension

L×W×H: 215mm×190mm×95mm

Testing Wires

Three wires: each for Red 20m, Yellow 10m, and

Green 5m

-5-

Simple Testing

Wire

2 wires: each for Red 1.6m and Green 1.6m

Auxiliary

grounding rod

2 PCS:Φ10mm×150mm

Measuring Rate

Voltage to ground: about 3 times/second; earth

ground resistance: about 5 seconds/time

Measuring

Times

Over 5000 times

(Measuring 10Ω for one time on 20Ω range and take a

pause for 25s)

Circuit Voltage

Measuring voltage to ground: measuring below AC

600V

RS232 Interface

Possess RS232 interface, software supervision,

storage data can be uploaded to computer, saved or

printed.

Communication

Wire

One piece of RS232 communication wire, with length

1.5m

Data Storage

400 sets, flash display “FULL”icon to indicate storage

is full

Data Hold

Data hold function: “HOLD”icon display

Data Read

Data read function: “READ” icon display

Overflow

Display

Exceeding measuring range overflow function: “OL”

icon display

Alarm Function

When measuring value exceeds alarm setting value,

there is “Toot-toot-toot” alarm hint

Battery Voltage

When battery voltage decreases to about 7.8V,

battery voltage low icon will display, reminding to

replace battery.

Power

Consumption

Backlight:25mA Max

Standby: 25mA Max(Backlight shut off)

Measurement:70mA Max(Backlight shut off)

Weight

Tester:1443g(including battery)

Testing Wires:847g(including simply testing wires)

Auxiliary grounding rod:468g(2 PCS)

Meter bag:915g

Working

Temperature &

Humidity

-10℃~40℃;below 80%rh

Storage

temperature &

humidity

-20℃~60℃;below 70%rh

-6-

Overload

Protection

Measuring earth ground resistance: between each

interfaces of E-P、E-C,AC 280V/3 seconds

Insulation

Resistance

Over 10MΩ(between circuit and enclosure it is 500V)

Withstanding

Voltage

AC 3700V/rms (Between circuit and enclosure)

Electromagnetic

Features

Wireless frequency electromagnetic field

Protection Type

IEC61010-1 、IEC1010-2-31 、IEC61557-1,5 、

IEC60529(IP54)、Pollution etc. 2、CAT Ⅲ300V

IV.Tester Structure

-7-

1. LCD 2. Button area 3. Rotary switch for selecting function

4. RS232 interface 5. Interface of testing wires

6. C(H)interface: Current electrode

7. P(S) interface: Voltage electrode

8. Einterface: Earth electrode 9. Testing wires

10. Auxiliary grounding rod 11. Simple grounding wires

12. Testing probe 13. Safety alligator clip

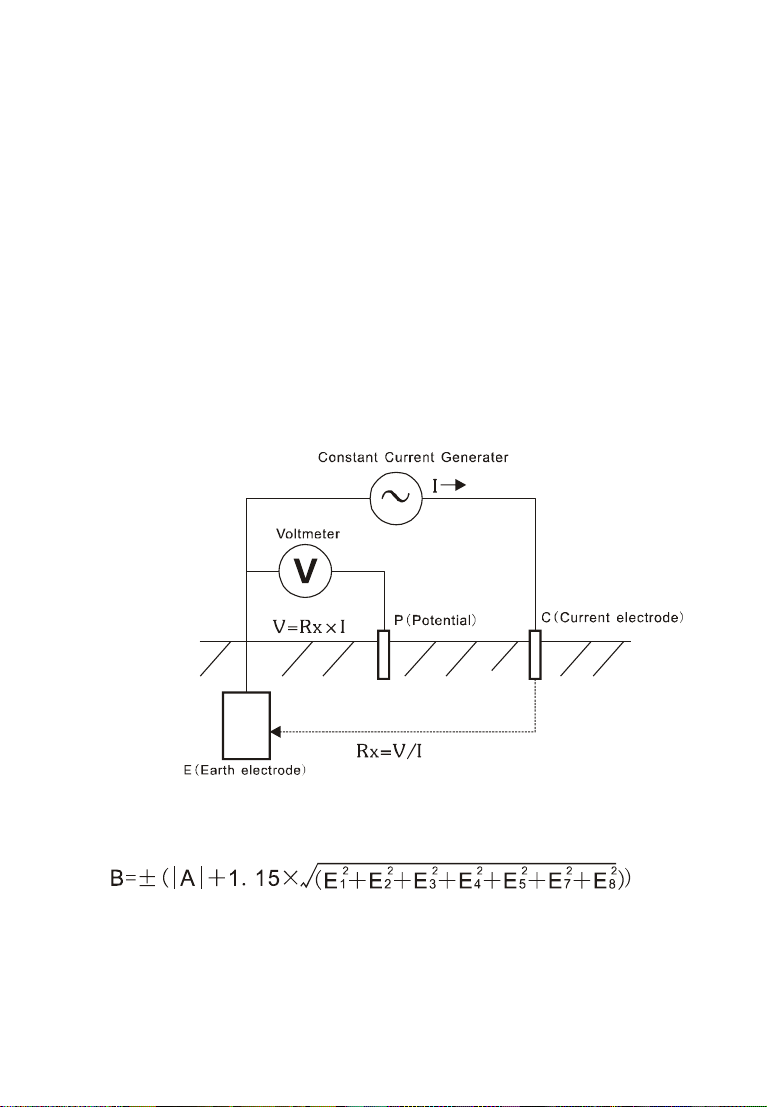

V.Measuring Principle

1. Voltage to ground measurement adopts average value rectification method.

2. Earth resistance measurement with fall-of-potential method. AC constant

current I (3mA Max, 820Hz) is applied between the measurement object E

(earth electrode) and C(current electrode), and finding out the potential

difference V between Eand P(potential electrode).

Rx=V/I

3.Maximum Operating Error:Operating error(B) is an error obtained within the

rated operating conditions, and calculated with the intrinsic error(A), which is

an error of the instrument used, and the error(E) due to variations.

A:Intrinsic error

E1:Variation due to position change

E2:Variation due to power supply voltage

E3:Variation due to temperature change

E4:Variation due to interference voltage change

-8-

E5:Variation due to contact electrode resistance

E7:Variation due to system frequency change

E8:Variation due to system voltage change

VI. Function Quick Check

FUCTION rotary

switch

Switch on/off ,Function shift, Switch gear

Up/down arrow

button

Data read/numerical value settings

Backlight button

Backlight control

START button

Start measuring

MODE button

Maximum, Minimum or Average value

mode, Move cursor

CLR button

Clear data/Delete data

MEM button

Data lock/storage/reading

AL button

Alarm function start/alarm critical value

settings

VII. Operation Methods

1.Switch On/Off

Rotate FUNCTION rotary switch to fulfill switch on and off. When rotary

switch button displays “OFF”for shut-off. The Tester has no auto shut-off

function, so please shut it off after usage in case of battery consumption

saving.

2.Battery Voltage Check

After switch on, if LCD displays low battery voltage icon “ ”,which

indicates that battery voltage is low, and please replace the battery in

compliance with instructions. Adequate battery power can ensure the

accuracy of measurement.

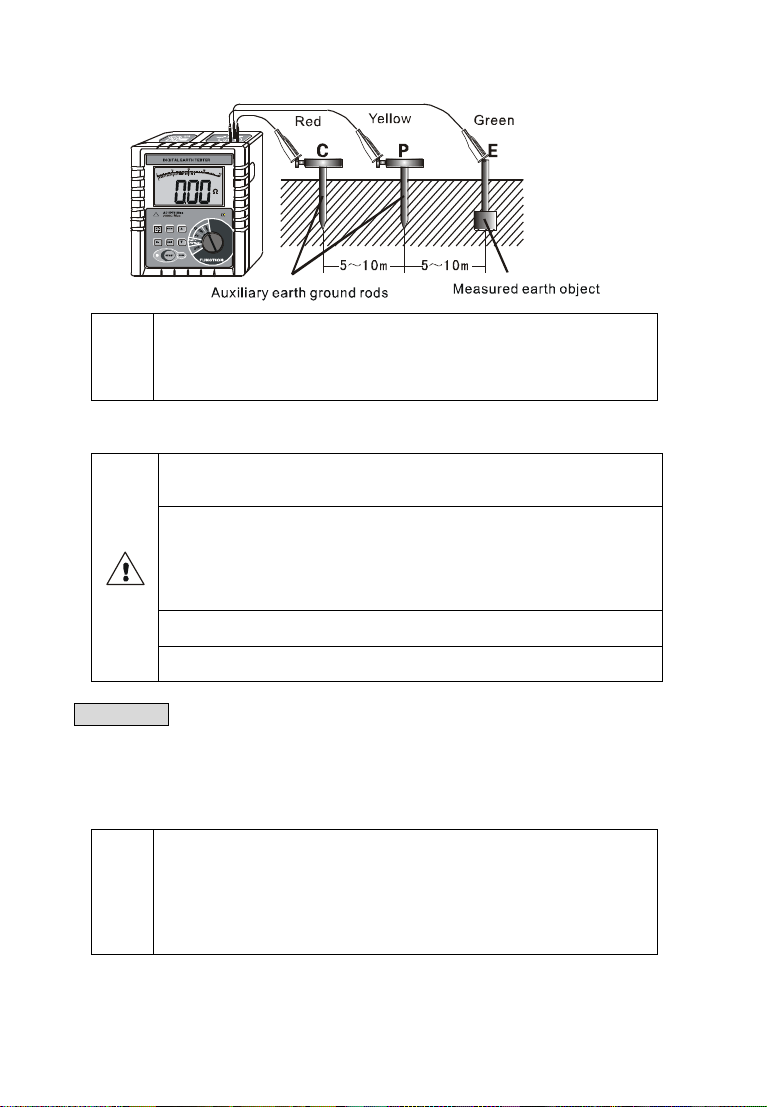

3.Insert and Connection of Rods

Shown as the following figure, stick the auxiliary earth rods Pand Cinto

the ground deeply. They should be aligned at an interval of 5-10m from the

earthed equipment under test. Connect the green wire to the earthed

equipment under test, the yellow wire to the auxiliary earth rod P and the red

wire to rod C from terminals E, P and C of the instrument in order.

-9-

Note

Please try to insert auxiliary grounding rod into moist soil. In case of dry

soil, sand, or gravel land, it requires adding water to keep auxiliary

grounding rod inserted place wet. In case of concrete place, it shall keep

auxiliary grounding rod flat and add water, and cover wet towels on earth

ground rod before measurement.

4.Grounding Voltage Measurement

Please make sure testing wire plug has been totally inserted into testers

corresponding interface and it may cause measurement value error for

incomplete insert or poor contact.

The tester cannot be used for commercial power supply voltage

measurement. For special situation that needs to measure, it can only

use P, E interface to connect for measurement. It is not allowed to

measure commercial power voltage in the case of short circuit of P, C

interface. Otherwise, measuring voltage in the grounding circuit of cutout

switch may cause cutout switch start.

On measuring grounding voltage, please do not impose over 600V

voltage on measurement connectors.

On measuring grounding voltage, please do not touch measured bare

conductors in case of electric shock.

After connecting of auxiliary grounding rod and testing wire, shift

FUNCTION rotary switch to “EARTH VOLTAGE”position. LCD display

voltage value to ground. Please note the measured voltage shall NOT exceed

600V.

In general, for measuring grounding voltage, it is only to connect the

testing wires corresponding to P, E interface.

Note

Before measuring earth ground resistance, firstly please

confirm voltage to ground must be lower than 10V.

Otherwise, the measurement value may cause excessive

error. At that time, firstly cut off power on measured

grounding equipment and make resistance measurement

after the grounding voltage is reduced.

-10-

5.Wire Resistance Verification

In order to improve precision and stability of field measurement of earth

ground resistance, avoid error due to wire resistance change due to prolonged

usage of testing wires; avoid error due to testing wire that is failed to be fully

inserted into tester interface or by poor contact; avoid error due to users’

replacing or lengthening testing wires and etc., wire resistance verification is

specially designed, as to "20Ω"grade, which is more accurate on low value

resistance measurement.

After connection of testing wire and the Tester, connect the other end of

all testing wires in short circuit, as the following figure, set FUNCTION rotary

switch to the corresponding earth ground resistance measurement position,

press button to start verification. During verification, LED indicator flashes,

LCD displays, and after verification, LED displays wire resistance value and

stores it. For this time switch on, it will automatically deduct the verified wire

resistance value from earth ground resistance measurement.

It will not preserve the verified wire resistance value on switching off. It

needs re-verification for next time switching on.

6.Precision Measurement

Please make sure testing wire plug has been totally inserted into testers

corresponding interface and it may cause measurement value error for

incomplete insert or poor contact.

As to low value earth ground resistance measurement, it will be more

accurate after wire resistance verification.

On measuring grounding voltage, between E and C interface, it will occur

the maximum voltage about 50V! Please do not impose voltage on

measurement interface. Please pay attention to avoiding electric shock

accident.

On measuring earth ground resistance, testing wires cannot be mixed

around, which shall be measured separately.

Try to choose the spot with more water to deeply bury auxiliary grounding

rods P and C, in order to reduce auxiliary earth ground resistance and

thus reduce indication error.

-11-

There are 3 types of display modes for earth ground resistance

measurement:

P:---- Average Value Display

H:---- Maximum Display

L:---- Minimum Display

The default display on booting is average value, and press MODE button

to switch display mode.

Precision measurement earth ground resistance adopts three-wire

connection. After connection of auxiliary grounding rod and testing wires, set

FUNCITON rotary switch to "2000Ω", press "START" button to start

measuring. During measurement, LED indicator flashes, LCD count down

displays, and after measurement, LCD displays measured values. If the

display values are too small, set it to "200Ω", "20Ω" in turn, that is to choose

the most appropriate gear position for measurement. The value displayed on

the most appropriate position is the measured earth ground resistance value.

After measurement, press MODE button to check for the maximum,

minimum and average value in this measurement.

After measurement, it may delete current measured values by pressing

CLR button.

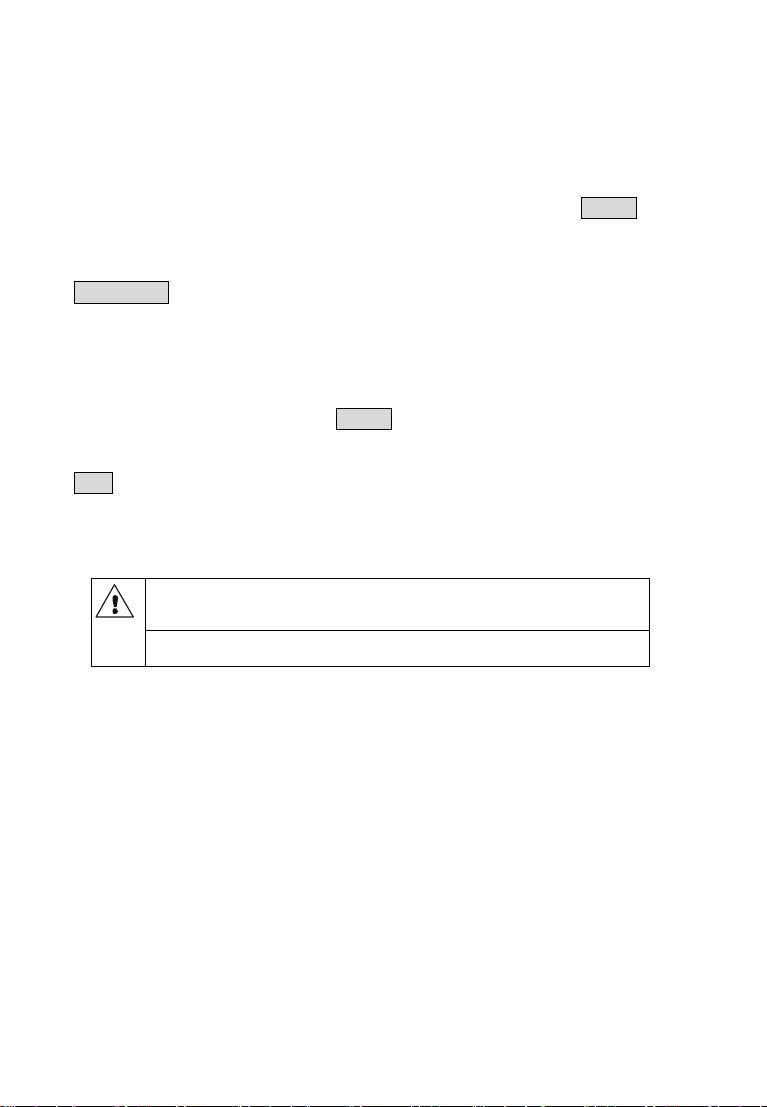

7.Simple Measurement

When select commercial use power supply system earth as auxiliary

earth electrode, it must use detector to confirm that is it the earth ground

electrode for commercial use power supply system.

It is forbidden to use this Tester to confirm earth electrode of commercial

use power supply system

This method is a simple method for measurement that does not use

auxiliary grounding rod, taking the earth electrode with the minimal existing

earth ground resistance value as auxiliary earth electrode, and connecting by

two simple testing wires (in which C, P interfaces are in short circuit). It can

make use of metal pipes, fire hydrants and other metal buried objects,

common grounding of commercial electric power system or lightning

protection earth ground electrode and others to replace auxiliary grounding

rods C, P, and pay attention to remove oxide layer on the connection point of

the selected metal auxiliary grounding object when making measurement.

Earth ground resistance simple testing wire connection is as following

figure, and refer to precision measurement for other operations.

-12-

Simple method for measurement of earth ground resistance, its reading

on Tester is the total value of earth ground resistance value of measured

grounding object and that of commercial grounding object, namely:

RE=RX+re

In which: RE is the Tester reading value;

RX is the earth ground resistance value of measured

grounding object;

re is the earth ground resistance value of common grounding

object like commercial use power system.

Then, the earth ground resistance value of measured grounding object is:

RX=RE-re

Adopting simple method for measurement of earth ground resistance

shall try to select the grounding object with low value as the auxiliary

earth ground electrode and thus the tester reading value can be more

approaching to true value. Please take precedence in selecting metal

water pipes, fire hydrants as auxiliary earth electrode when measuring,

and refer to the following figure for application.

-13-

Note

Simple method for measurement of earth ground resistance also needs

to confirm that voltage value to ground must be lower than 10V. If the

voltage value is over 10V, the measurement value of earth ground

resistance may cause error and at that time, it shall firstly cut off power

on measured grounding equipment and make resistance measurement

after the grounding voltage is decreased.

8.Backlight Control

After startup, press button to turn on or off backlight. The backlight

function is suitable to dark spot. It will default backlight turn-off for each

startup.

9.Alarm Settings

After startup, press button for a brief time to open or shut off alarm

function, press button for a long time (about 3 seconds) to enter alarm

critical value settings, press or to change current digital, press

button to move cursor and then press button to store and exit. When

measurement value is larger than alarm critical settings value and it has

opened alarm function, the Tester will flash and display icon and give out

“toot-toot-toot--”alarming sound.

10.Data Lock/Storage

Startup or after measurement, press button to lock current

displayed data, showing , icon and automatically store with serial

numbers. If storage is full, the Tester will display icon. Each group of

stored data includes maximum, minimum and average value. And then press

button to remove lock.

As shown in the left figure below: the lock measurement data is 5.1Ω, as

the 19th group of data storage.

11.Data Reading/Deletion

Startup or after measurement, press button for a longer time (over

-14-

3 seconds) to enter data reading, press or button to select reading

data group number by step value 1, press or button constantly to

select reading data group number by step value 10, press button to read

the maximum, minimum and average value of this group of data, and then

press button to exit from reading.

On reading if there is no storage data, LCD will display “- - - -”, see the

above right figure.

Under data reading status, press button to enter data deletion, press

or to select “no” or “YES”, selecting “no”and then pressing “MEM”

button for not deleting return data reading status, selecting “YES”and then

pressing “MEM”button for deleting stored data and it will show as above right

figure after deletion.

12.Data Upload

Make good connection of company with RS232 communication wire of

the Tester, switch on the Tester and run monitoring software, and if the

software displays that interface is open and the connection is successful,

then it can read the stored historical data, upload to company and preserve.

Monitoring software has the function of online real-time monitoring

and historical inquiry, dynamic display, with the maximum, minimum, and

average value indication, with alarm value settings and alarm indicator, and

the function of historical data access, reading, preserve, print and other

functions.

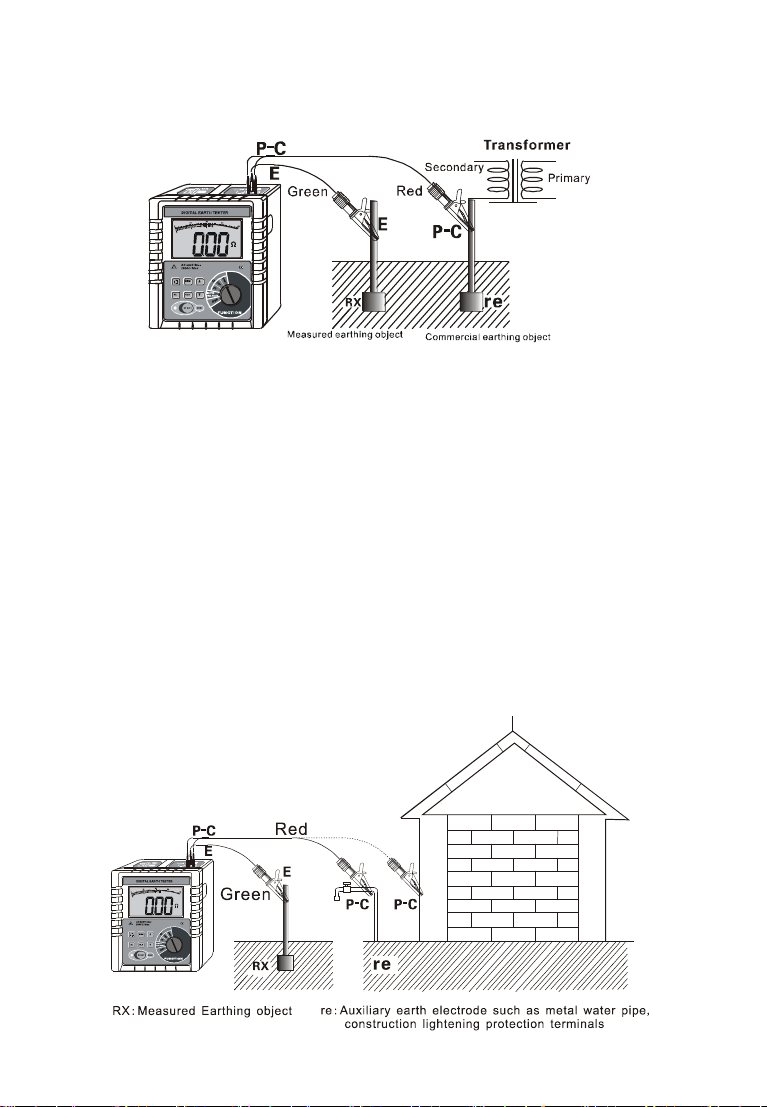

VIII. Battery Replacement

Please don’t replace battery in flammable spot

Please don’t replace battery during measurement

Pay attention to battery polarity and specification, and don’t

mix use of new and used battery to avoid damage on Tester

When the enclosure of Tester is wet, please do not open

battery cover

Please put the used batteries in appointed collection place.

1. Switch off; making sure that the Tester is under switch-off state.

2. Loosen the four screws on battery cover at the bottom of the Tester, and

open battery cover.

3.Replace new battery, pay attention to battery polarity and specification,

close battery cover, and fasten screw.

4. Switch on verification, otherwise re-operate.

-15-

IX.Accessories

Tester

1 PC

Tester Bag

1 PC

Auxiliary Grounding Rod

2 PCS

Monitoring Software Disk

1 Copy

RS232 Communication Cable

1 PC

Testing Wire

3 PCS

Simple testing wire

2 PCS

Zinc-manganese dry battery

6 PCS(R14S 1.5V)

Manual/Warranty card/Qualification

Certificate

1 Copy

Your Testing Specialist

Table of contents

Other MEWOI Test Equipment manuals