MEWOI MEWOI-HLY200A User manual

Contact Resistance Tester

MEWOI-HLY200A

User manual

www.mewoi.com

2

1

warning

To prevent electric shock、human injuries, please read below information

carefully before using this instrument:

Only qualified person can operate this instrument

Please don’t use the instrument in wet environment

To prevent damage to this product or other product connect to this

product, or other possible danger, please use this product within

specified range.

To prevent static electricity induction of the instrument body, please

connect the mainframe with grounding before test.

because the input and output terminal、test post may with voltage,

when you plug in or pull out the test wire、power socket, may cause

electric spark, please be careful to avoid electric shock, pay attention to

human safety.

To prevent danger of fire or electric shock, please read this manual

carefully before use the instrument, and ensure each rated value and

sign of instrument are normal.

Once suspect the safety protection function of the instrument is

weaken, please put the product in non-operating state immediately, and

be sure it won’t be operated accidentally.

When the test wire connected to the electriferous terminal, please

don’t connect or disconnect arbitrarily, if the product was electriferous

accidentally, please don’t touch the exposed connection point or area.

Please check the test wire before using them. Please don’t use

defective insulation wire or wire with metal exposed. Please check the

continuity of the test wire.

Please use the power wire and connector which was matched with

the country or area’s voltage and socket.

When the cover of the instrument was open, please don’t use the

product.

2

Note to keep ventilated smooth of instrument vents, please don’t

block air vents, and avoid affecting cooling.

Please only use the spare fuse which was specified in this manual

During test, please don’t turn on or turn off the power frequently,

avoid damaging the instrument or reducing the accuracy of test results.

If any abnormal situation during test, please cut off the power

immediately

Please don’t place the product outdoor or get wet by rain, and don’t

use the product in environment with explosion gas、water vapor or

dust.

When the product working abnormal, please contacts the

manufacturer timely, and please don’t maintain by yourself.

Our company reserves the right to modify this manual, and won’t

further notice at that time. The discrepancies of product and manual please

refer to actual product.

3

CONTENT

Ⅰ、Summary.......................................................................................4

Ⅱ、Safty precautions..........................................................................4

Ⅲ、Performance features....................................................................5

Ⅳ、Technical specification.................................................................6

Ⅴ、Operation and function introduction............................................7

Ⅵ、Testing and operation method......................................................8

Appendix 1:contact (loop) resistance basic knowledge ............14

Appendix 2:circuit breaker conductive contact(loop) resistance

Standard reference value....................................................................15

Ⅶ、Standard configuration...............................................................16

After sale service...........................................................................16

4

Ⅰ、Summary

The good or bad of conductivity of breaker(hereinafter referred

to as switch) conductive circuit, play an important role in guarantee

the safety operation of switch. The conductivity performance can be

reflected by the value of conductive circuit resistance. For this reason

IEC standard and manufacturers all required testing the circuit

resistance, and also have prescribed index for the circuit resistance of

each kind switch. Before, normally use double bridge. But, because

the voltage and current value are very small, when there are

impurities between dynamic and static contact or the contact got

surface oxidation, the dispersivity of test data is larger. At the same

time, the anti-interference performance of bridge is not good, so the

national standard requires that must test with DC more than 100A.

The circuit resistance tester is a product developed by our company

which in order to meet GB50150-2006 and DL/T 845.4-2004

regulations, and it was widely used in measurements of various

switch’s contact resistance、circuit resistance, cable and wire、weld

joint contact resistance.

Ⅱ、Safety precautions

1、Operator must have common sense to operate electrical

equipment or instrument.

2、Please read operating manual carefully before use this

5

instrument.

3、The adjustment and maintenance of the instrument must be

done by specialized persons, don’t fix by yourself.

4、The instrument should avoid strenuous vibration, avoid heat

and direct sunlight.

5、This instrument was designed to test purely resistive circuits,

can not use to test inductive circuits.

6、Can’t dismantle test wire during test.

7、The grounding wire must connect correctly.

Ⅲ、Performance features

1、The test current value is big, completely conform the

national standard requirement which related to contact resistance

test.

2、The test current was came from the 100A/200A high

precision switch type constant current power supply, without

manual adjust, the test is rapid and accurate.

3、Adopt four terminal connections; effectively eliminate the

influence to the test result from resistance of test wire.

4、Test speed is fast.

5、Working long hours, equipped with overheat protection

6

circuit; the instrument is reliable and steady.

6、Easy and simple operation, light weight.

Ⅳ、Technical specification:

1、Test Current :

Model

Test Current

HLY100A

50A、100A

HLY200A

100A、200A

2、Testing range:

Model

Test Current

Testing Range

HLY100A

50A

1-1999.9μΩ

100A

HLY200A

100A

200A

3、Minimum resolution :0.01μΩ

4、Accuracy :1%±0.5μΩ

5、Power supply :AC220V±10%50Hz

6、Consumed power :

Model

Power

HLY100A

≤500W

HLY200A

≤1000W

7、Operating temperature :-20℃~40℃

9、Relative humidity :≤80%RH,non-condensate

10、Weight :

7

model

weight

HLY100A

5 Kg

HLY200A

6 Kg

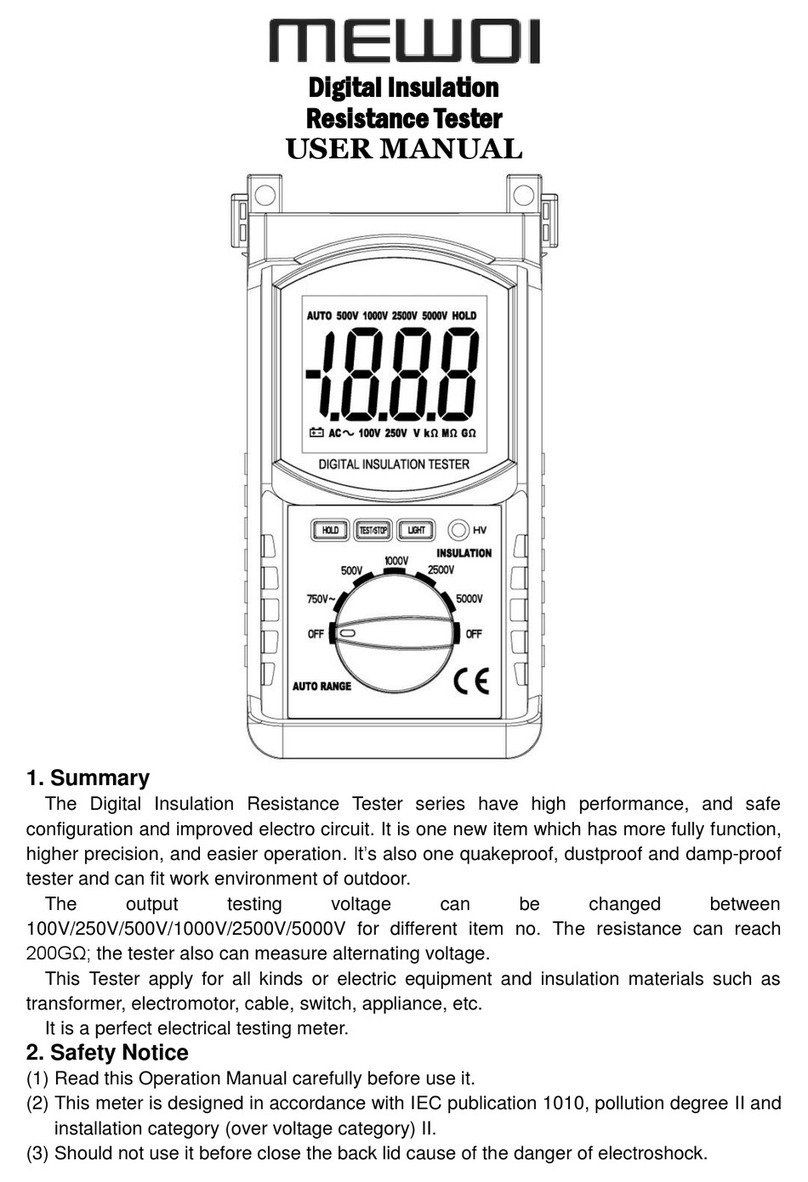

Ⅴ、Instrument operation and function introduction

Contact resistance tester panel as shown in picture 1:

1、Power:Power socket and switch have fuse box and filter inside,

it’s the component to control and protect and filtering the power of

the instrument.

2、I+、I-: Refers the current output terminal, provide constant

current for testing product by specified test wire.

3、U+、U-: Refers the input terminals of test product voltage.

4、Display: show test results, contact resistance value and output

current value.

5、Reset key: instrument initialization, the instrument is in the

ready state.

6 :Instrument protective grounding terminal

8

Picture 1 Contact resistance tester panel

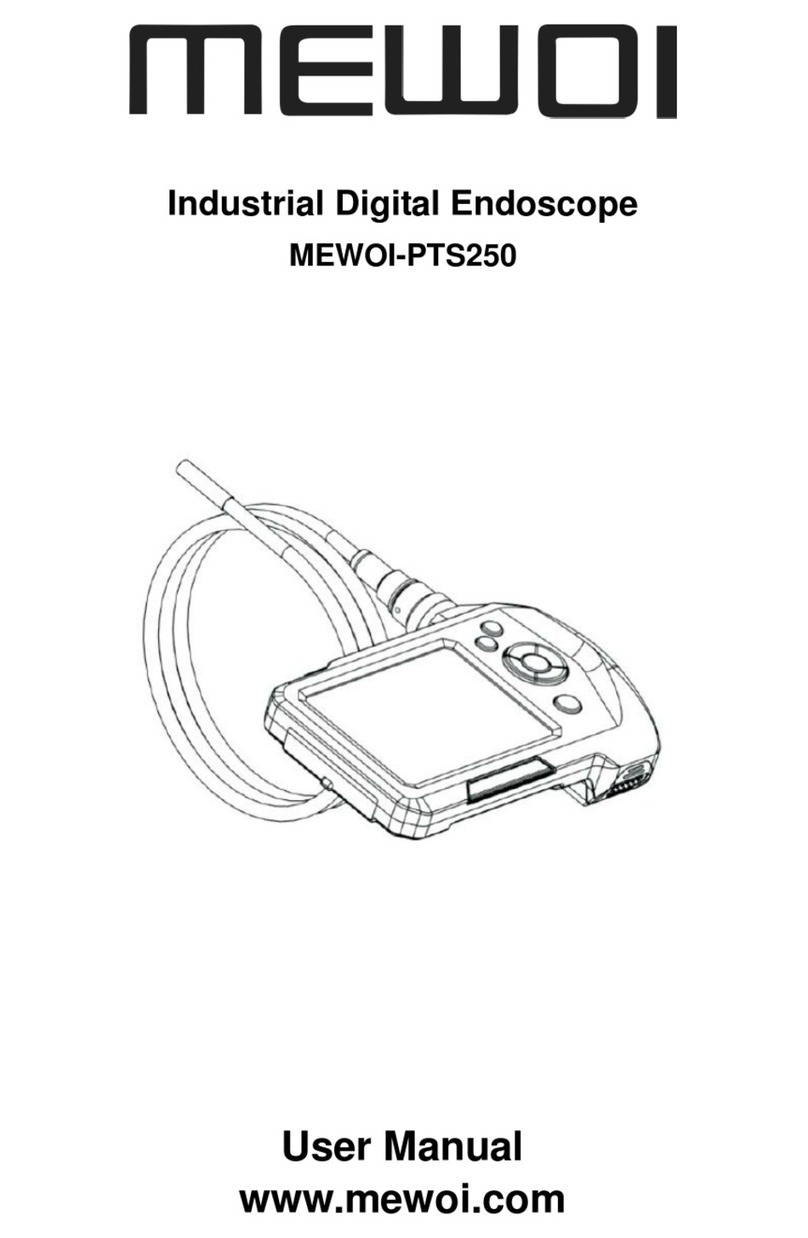

Ⅵ、Testing and operation method

1、Connection method: as shown in picture 2,put the specified wire

red to red, black to black, the thick current wire connect to I+、I-

terminal and tighten, the thin voltage wire connect to the U+、U-

terminal and tighten, the two clamp clamped to both ends of the

testing product.

9

Picture 2 testing connection chart

Note: the connection surface of the clamp should contact the

product reliably.

2、Start-up interface: turn on the power switch, the display will

show the interface shown in picture 3,after few seconds will

automatic skip into the main interface.

Picture 3: start-up interface

picture 4: keyboard

10

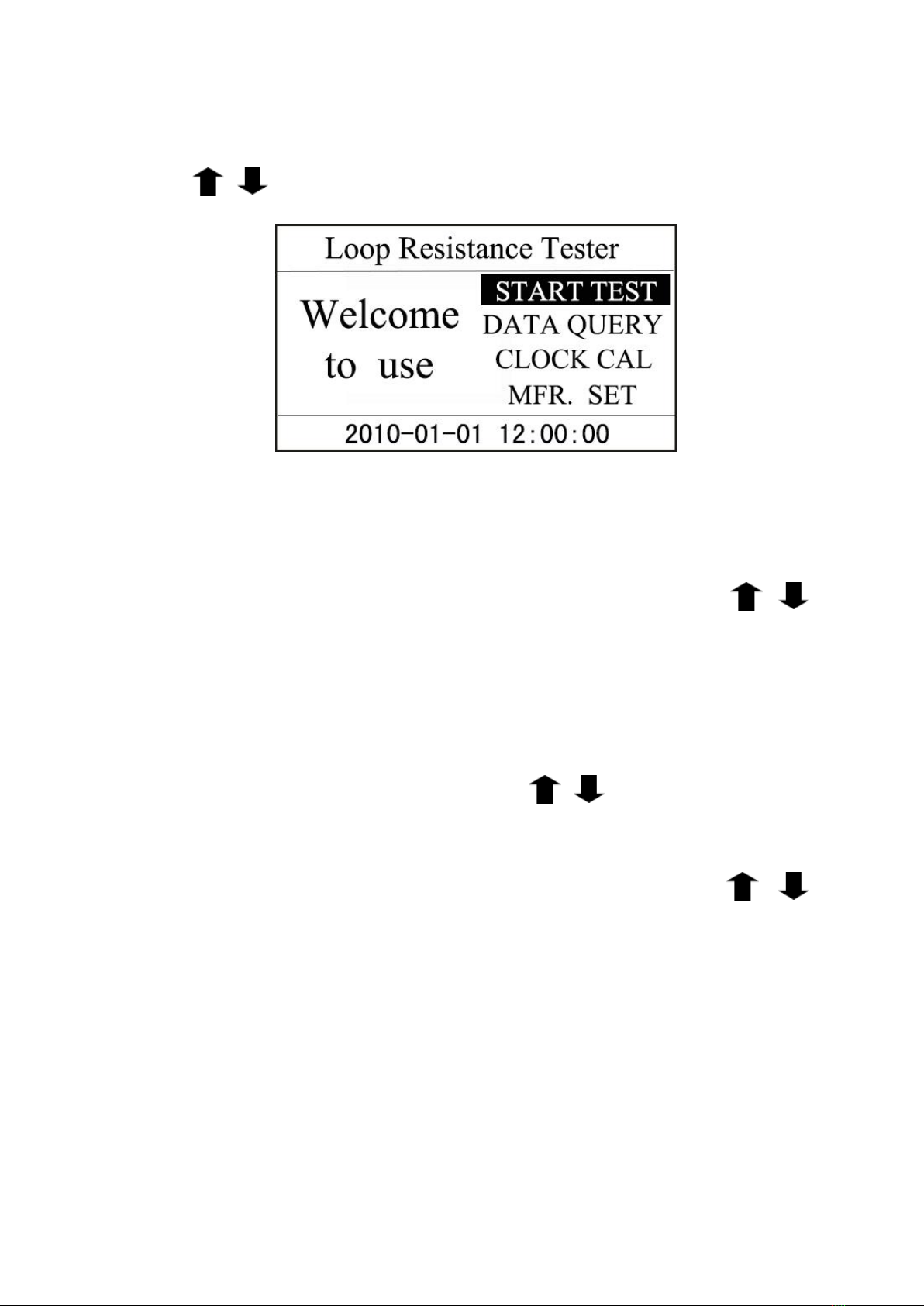

3、Main interface: the main interface shown as picture 5. Press

key choose function , press key OK enter function menu.

Picture 5: main interface

4.Test: after choose START TEST in main interface, go into the

interface of current selection as picture 6, press key

choose current, please refer to corresponding measuring range,

choose the right current. Press ESC go back to main interface,

press OK start test, at the same time remind “testing……”. Test

result shown as picture 7, press key choose PRINT or

SAVE, press ESC go back to main interface. This instrument has

function of automatically stop.. As well, press key

choose PRINT or SAVE, press ESC go back to main interface.

11

Picture 6 : interface

Picture 7

5.Data query: after choose DATA QUERY in main interface, go into

query interface as picture 8. Press key choose

function ,press key ESC go back to main interface,press key OK

execute the selected function.

Previous Next :Use to turn pages.

Print: print the test results saved in DATA QUERY.

Delete: delete all the saved test results.

12

When the data is full, there is a reminder “storage is full”. Please

press key RST go back to main interface.

picture 8

6.Clock calibration: after choose CLOCK CALIBRATION in main

interface, go into the clock calibration interface.

Key use to change the value of selected position .

Press key OK, cursor move right, when move to the last position

“second”, press key OK again, the modified time will be saved.

Press key ESC, cursor move left, when move to the first

13

position“year”, presses key OK again, the modified time will not

be saved.

7.Manufacturer setting: this option is for manufacturer to debugging

and setting, customer please doesn’t operate.

8.Reset: after finish testing, press key RST, the instrument output

current will cut off, and the displayer will go back to initial state,

and can rewiring, execute the next measurement or removal the

test wire and power wire and finish testing.

9. Temperature warning: when the temperature inside the instrument

is too high, the interface will show” Temperature warning,

Cooling now,Please wait...”,at the same time, the buzzer will

warn, at this moment should wait the instrument temperature get

back to normal, and then continue to use the product.

14

Appendix 1:Contact resistance basic knowledge

1、What is contact resistance?

Contact resistance is the additional resistance when the static contact touch dynamic

contact.

2、Breaker contact resistance was made up of which part?

Was made up of contract resistance and surface resistance of dynamic、static contact area.

3、Unqualified reasons of breaker contact resistance?

—Contact burn out when switch big short circuit current.

—When the construction adjust not good or fixed not securely, cause change stroke,

when over stroke was badly unqualified, cause contact pressure and contact area

changed.

—After adjustment and installation of breaker, not operate for a long time, cause

dynamic、static contact got surface oxidation, contact area resistance increase.

—Long-time working cause spring deformation, decrease the contact pressure.

—Mechanical wear of mechanical part after long-time working.

—For low-oil breaker, also can be the reason of unqualified acid value of insulating oil,

when it appear acid and corrode the surface. Or because of the floating impurities in oil,

and tiny carbon、metal dust between dynamic、static contact caused by switch short

circuit current, can increase the contact resistance.

4、The factors influencing resistance.

—Material property: hardness、chemical property、mechanical strength and electrical

resistivity of metallic compound.

—Contact mode: point contact、line contact、surface contact.

—Contact surface situation: when the contact surface form oxidation film(except

silver),the resistance of oxidation film is much bigger than the metal.

—Contact pressure.

—Roughness of contact surface.

15

Appendix 2:Breaker conductive contact resistance reference value

model

loop resistance of

each phase

model

loop resistance of

each phase

SN1-10

<95

DW1-60G

200

SN2-10G

75

SW1-110

700

SN4-10

50—60

SW2-110I

180

SN4-20

50—60

SW3-110

160

SN4-10G

20

SW4-110

300

SN4-20G

20

SW6-110

180—220

SN5-10

100

SW2-220

400

SN6-10

80

SW4-220

600

SN10-35

<75

SW6-220

<400

DW1-35

550

SW7-220

<190

DW1-60

500

KW1-220

400

DW3-110

1100—1300

KW2-220

170

DW2-110

800

KW3-220

110

KW1-110

150

KW4-220

130

KW3-110

45

DW2-220

1520

KV4-110A

60

DW3-220

1200

DW3-110G

1600—1800

SW6-330

>600

16

Ⅶ、Standard configuration

mainframe

One piece

specified test cable

One set

power wire

One piece

fuse

Two piece

After-sales service

1. Our company gives one year warranty for sold product. If user

wants maintenance please contact our after-sales department.

2. During warranty period if happen any following situation, we will

charge a cost price for maintenance:

1)Failure or damage caused by clash during user using or

moving the product.

2)The product was not kept properly by user, cause instrument

ooze water、affected with damp、clash or light fire and so on.

3)Failure or damage caused by maintenance from user or

other entrusted unit by user.

4)Failure or damage caused by wrong connection from user.

5)Failure or damage caused by force majeure(like fire disaster、

flood disaster、natural disaster and so on)

6)Failure or damage caused by connect to other equipment

not according to this manual.

7)Faulty product has no warranty card and unable to

determine it is within warranty period.

17

Your Testing Specialist

Table of contents

Other MEWOI Test Equipment manuals

Popular Test Equipment manuals by other brands

Bahco

Bahco BBT60A Original instructions

Alcochem Hygiene

Alcochem Hygiene UV-A MOBILE TESTER instruction manual

Myron L

Myron L ULTRAPEN PT4 quick start guide

Rohde & Schwarz

Rohde & Schwarz CMW-KM750 user manual

Keysight

Keysight P9241 SCPI Programmer's Guide

OTC

OTC 3052S PARTS LIST & OPERATING INSTRUCTIONS