MEWOI MEWOI1500D User manual

CONTENT

WARNING....................................................................... 1

I INTRODUCTION........................................................... 3

II ELECTRICAL SYMBOLS ............................................. 5

III TECHNICAL SPECIFICATIONS ................................. 5

IV. STRUCTURE............................................................. 8

V OPERATIONS ............................................................. 9

1. POWER-ON/OFF OF HVDETECTOR ........................................................ 9

2. POWER-ON/OFF OF PRINCIPAL MACHINE...............................................10

3. TEST OF HVCURRENT.........................................................................11

4. TEST LV CURRENT ..............................................................................14

5. TEST OF CT RATIO,POLARITY..............................................................16

6. DETECTION ON PHASE SEQUENCE ........................................................20

7.ALARM LAUNCH..................................................................................20

8. DATA RETENTION AND RELEASE...........................................................21

9. DATA STORAGE ...................................................................................21

10. DATA SEARCH ...................................................................................21

11. DATA DELETION.................................................................................22

12. DATA UPLOAD ...................................................................................22

VI. SETTINGS............................................................... 22

1. SET CT RATIO .....................................................................................23

2. SET ERROR..........................................................................................23

3. SET TIME.............................................................................................24

4. SET BACKLIGHT ...................................................... 24

VII. BATTERY REPLACEMENT.................................... 24

VIII. ACCESSORIES ..................................................... 25

-1-

Warning

Thanks for purchasing MEWOI1500D Three-Channel Wireless HV

CT Ratio tester (Full Name: Three-Channel Wireless High & Low

Voltage Current Transformation Ratio Error tester for Current

Transformer). For your better use of the product, please kindly

follow the rules below:

---Read the manual carefully. The operator shall fully

understand the guidelines set forth in the manual

before conducting field tests.

---Comply with the safety rules and notices set forth in

this manual strictly.

◆The safety shall come first when using this tester in any cases,

especially, in which the voltage circuit bears the voltage of AC100V

or more.

◆The tester shall be applied connecting insulating rod, with the

hand holding on the fifth rod, in case that the voltage circuit bearing

the voltage over 600V is to be tested.

◆Operators shall have accepted the rigid training and gained

related certification for high-voltage operation before conducting

field test with this tester, due to risk of high voltage lines.

◆Take notice of characters and symbols labeled on the face board

and back board.

◆It is prohibited to operate the instrument cover and insulating

rods under moisture condensation.

◆Please don’t place or store the tester under direct sunshine, in

-2-

high-temperature and moist or dewed places.

◆Take notice of the polarities of the battery when doing

replacement; remove the battery from the tester if you expect not

to use it for a long time.

◆Disassembly and maintenance of this tester shall be only done

by authorized operators.

◆Please don’t operate testers which clips and other parts are

broken.

◆Avoid attacking clips and maintain the tester regularly. Soft cloth

(e.g. glasses cloth), moistened by clean, antirust and dehumidified

lubricant (e.g. WD-40), instead of corrosive agent or rough issues

shall be used to gently rub down the tester.

◆Stop using and mothball, then leave it to authorized organization

for handling in case that continuing use can cause safety hazard

due to the performance of the tester itself.

◆The users shall follow the user manual to do safe operation

when contacting the dangerous signs “ ” labeled on the tester

or in manual.

◆The users shall follow the manual to do safe operation when

contacting the extremely dangerous sign “ ” on the tester or

in manual.

◆It is recommended to test the insulating strength for this tester

at least one time a year, (which insulating strength should be

AC100kV/rms between HV detector and the fifth insulating rod;

and be AC1000V/rms between the shell of LV current clamp and

principal machine).

-3-

I Introduction

MEWOI1500D Three-Channel Wireless HV CT Ratio tester is a

core technological product under the long-term strategy of

professional detecting techniques research on electric power

instruments developed by MEWOI, which is specific for the on-line

measurement and detection for primary and secondary current,

transformation ratio, error, phase (group) angle difference, polarity,

phase sequence, and leaker in the high & low voltage current

transformer and the voltage transformers in distribution system

under 70KV (such as 10kV or 35kV ), and is composed of high

voltage detector, three-channel low-voltage secondary current

clamps, principal machine, high-voltage insulating rods, monitoring

software, communication link, etc. it adopts the wireless

transmission signal that is capable of penetrating wall obstacles

with a direct-line transmission distance of about 30m.

MEWOI1500D tester is widely applicable to the current detection,

abstracting-proof of electricity and field operations of transformer

substations, power plants, electrical power inspection departments,

industrial and mining enterprises, inspection station, and electrical

maintenance departments.

Current clamp: it adopts the special alloy, the latest CT technology,

and the double shielding technology for a high accuracy, stability,

and reliability during continuous monitoring in the entire year.

Principal machine: it displays four sets of current signals, CT ratio,

phase angle difference , and polarity visually in one screen

simultaneously, which memory can store 1,500 sets of data; it is

available to set the auto-save interval time to monitor leaker.

-4-

HV detector breaks the traditional structure with an automatic

opening and closing functions, it is easy to clamp or release

measured wire by pressing or pulling back insulating rods, with

the advantages of safety and time-saving. The lightweight

insulating rod is characterized by thermo stability, moisture-proof,

strong shock resistance & bending resistance high-insulation, high

flexibility and so on.

Monitoring Software: Functions such as real-time monitoring,

historical data search, accessing, browsing, saving, and printing

data available; dynamic display;

MEWOI1500D ratio tester integrates the functions of

single-channel wireless HV CT tester, HV & LV clamp current

meter, HA current remote sensor, HA leaker tester, High accuracy

clamp leaker meter, phase detector, three-channel leaker

recorder ,etc.

-5-

II Electrical Symbols

Extremely dangerous! Operators shall rigidly follow the safety rules, or

the potential electric shock can cause personal injury or death.

Dangerous! Operators shall rigidly follow the safety rules, or the

potential electric shock can cause personal injury or death.

Warning! The safety rules shall be completely followed, or personal

injury or damage to equipments can arise.

Alternating current (AC)

Direct current (DC)

III Technical Specifications

Functions

The on-line measurement and detection for primary and

secondary current, transformation ratio, error, phase

(group) difference, polarity, phase sequence, and leaker

in the three-channel high & low voltage current

transformer and the voltage transformers

Power supply

HV Detector:DC6V alkaline batteries (1.5VAAA ×4)

Principal machine: DC6V alkaline batteries (1.5V AAA ×

4) 30-hour continuous operation available

Test mode

Clamp CT, HV 1CT, LV 3 CT double- shield

Transmission

mode

High-pressure tested data transmitted through wireless

network, with a linear transmission distance of 20m;

Range

HV detector 1st: 0.1mA ~ 1000A

LV current clamp 2nd: 0.01mA ~ 10A

Resolution

HV detector: 0.1mA; LV current clamp: 0.01mA

Primary circuit

test accuracy

(23 ℃±3 ℃,

below70% RH)

0.0mA~9.99A:±1%±5dgt

10.0A~49.9A:±2%±5dgt

50.0A~199.9A:±3%±5dgt

200A~600A:±4%±5dgt

601A~1000A:±5%±5dgt

Secondary

circuit test

accuracy

0.00mA ~10A :±1%±5dgt (three-channel being

displayed in one screen) (23℃±3℃ , less than

70%RH)

-6-

CT ratio

Three kinds of transformation ratio indications :

(1)convert the transformation ratio based on the

adjustable basic value of 5A for secondary circuit

current; (2)convert the transformation ratio based on

10kV-YY of 10kV/380V, that means 1st means the

current of the line under 380V, 2nd means the

secondary circuit current of CT under the 380V, and

then calculate the ratio between the 10KV line and the

secondary circuit;

(3)the measured current ratio can be calculated by the

measured CT ratio between the primary and secondary

circuit.

Reference

Range

Reference range of transformation: 0.00A ~ 99.99A, the

default secondary circuit current is transformed to 5A;

Range of Ratio

error

(F.Er)

0.0% ~ 9.9%, the error between the measured CT ratio

and the preset CT ratio

Range of CT

ratio

0000~9999/0.0A~9.9A

Range of Ratio

error

0.0%~9.9%, the principal machine can sound a alarm

of “beep - beep –beep” if the measured value is more

than the preset error.

Phase polarity

Symbol indicated for in-phase positive polarity

Symbol indicated for in-phase negative polarity

Indication of

Phase

Sequence

Cursor in clockwise rotation and “Positive Phase”

indicated for positive phase sequence

Cursor in counterclockwise rotation and “Negative

Phase” indicated for negative phase sequence

Indication of

Error

Symbol “Error” indicated if the tester can’t identify the

phases, polarity, and phase sequence properly;

Data Storage

1500 sets of dada memory; press the Left arrow key to

select data, and to save and auto-number the selected

data (the good condition of data available under

power-down or battery replacement)

Automatic

Recording

Interval Time

From 00 minutes to 99 minutes, the tester stops

automatic record if being set to 00 minutes; the principal

machine doesn’t shut down automatically if being set

from 01 minutes to 99 minutes.

-7-

Sampling rate

3 times / sec

Shift

Full-automatic shift

Dimensions

Principal machine:W75mm ×H170mm ×T30mm;

HV detector: W 76mm ×H 255mm ×T 31mm;

LV current clamp: W 70mm ×H115mm ×T 38mm;

Clamp Size

HV detector clamp: φ48mm

LV current clamp: 25mm ×30mm

Voltage

Less than 70kV voltage for line test(operation by being

connected to 5 insolating rods required)

Display Mode

LCD: 128dots ×64dots;

backlight available for dark areas

LCD Size:

44mm ×27mm;

Data Retention

Press the Left arrow key to retain the data ; press the

Left arrow key to cancel retention if the symbol “HOLD”

displays;

Data Search

Press the MEM key and the Arrow key to search data;

Overflow

Display

Overflow available if being out of range: the symbol “OL

A” displayed;

Zero-signal

indication

The symbol “---” is shown if the principal machine can’t

receive the signal from the HV detector;

Backlight

Control

Available; ON / OFF means to open /close the backlight;

Alarm prompt

The principal machine can sound an alarm of “beep -

beep –beep” if the measured value is more than the

preset error. and press the Right arrow key to launch or

stop the alarm function;

Auto power-off

Automatic power-off available after about 15 minutes as

of starting;

Battery voltage

The low- voltage symbol is displayed to remind user to

replace the battery if the battery voltage is lower than

4.8V;

Weight

Principal machine:240g (including batteries)

HV detector: 335g (including batteries)

LV current clamp: 150g ×3

Total weight: 10kg (including instrument box and the

insulating rods)

Requirements

on Interferences

No strong electromagnetic interference; no interference

from 433MHz and 315MHz channel

-8-

Operating

temperature

and humidity

-25℃~45℃; less than 80%Rh

Storage

temperature

and humidity

-10℃~60℃; less than 70%Rh

Insulating rod

size

Outer diameter φ32mm, inner diameter φ24mm, 1m

/piece, 5 pieces

Lead length of

LV current

clamp

2 m / Piece

Dielectric

strength

AC100kV/rms between HV detector cover and the 5th

insulating rod; the AC1000V/rms between the principal

machine and the LV current clamp shell between

Structure

Anti-leak type II (HV detector)

IV. Structure

-9-

1. HV detector clamp (including the boot sectors)

2. HV detector booting indicator

3. POWER key on HV detector

4. Connector of insulating rods (φ24mm)

5. RS232 interface, for data upload to computer

6. POWER key on principal machine

7. MEM key and arrows keys

8. LV current clamp CT1 Interface

9. LV current clamp CT2 Interface

10. LV current clamp CT3 Interface

11. Principal machine LCD displayer

12. LV current clamp output plug

13. LV current clamp clips (3 pieces)

14. LV current clamp leads

15. Insulating rods (5 pieces)

V Operations

Check if any damage exists for each part

before operating the tester; it can be put into

use only after being qualified.

Install the battery according to the

requirements set forth in the manual.

1. Power-on/off of HV detector

Press the POWER key to power on the HV detector, and the

POWER indicator lights, the HV detector begins to detect

automatically, and transmits the tested data to the principal

machine by wireless network. The HV detector can power-off

automatically when the POWER indicator flashes continually after

about 15 minutes as of booting, and the detector can shut down

automatically to save the battery power, after the POWER indicator

flashes for 30 seconds. When the POWER indicator flashes

-10-

continually, press the POWER key to make HV detector in

continuous running, and then press the POWER key again to

power off.

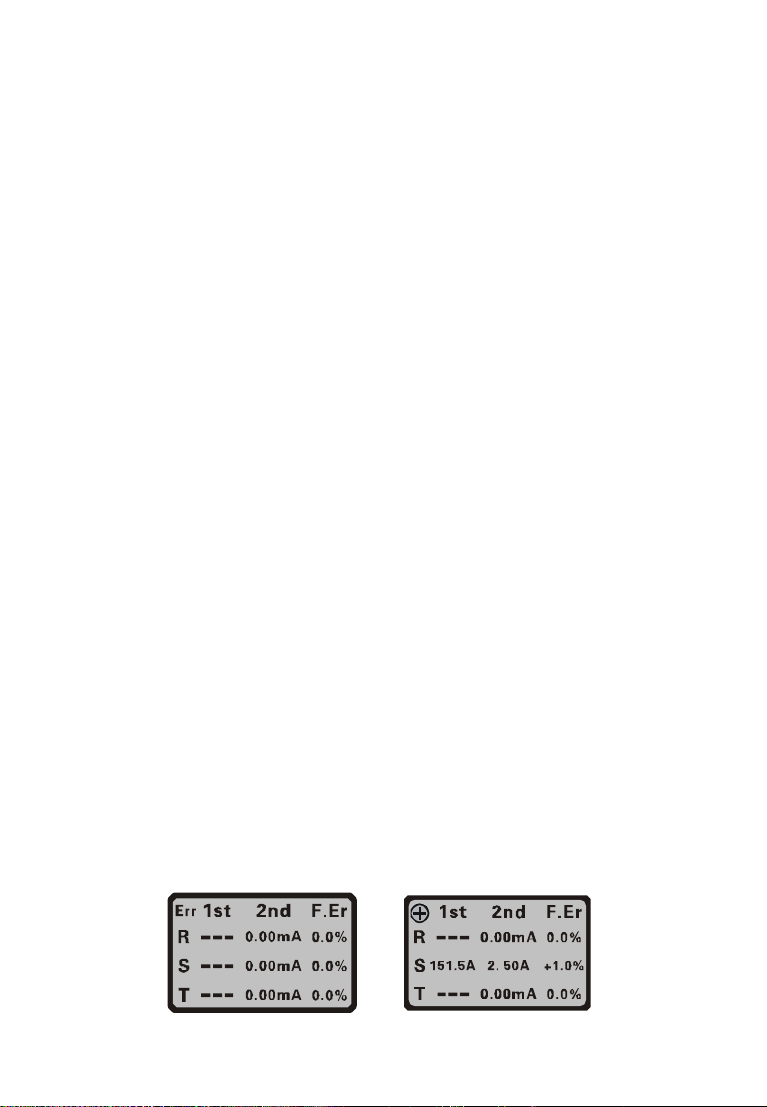

2. Power-on/off of principal machine

Press the POWER key to power on, then LCD begins to display,

the principal machine enters the test and receiving mode after a

normal booting (see below), 1st means the measured data of the

primary circuit on HV terminal, 2nd means the measured data of

the secondary circuit on LV terminal, F. Er means the error

between the measured CT ratio and preset CT ratio, R, S, and T

means the three phases respectively, and the data measured by

LV current clamps of CT1, CT2, and CT3 can be displayed on the

position of R, S, and T on screen respectively. the LCD can display

the symbol “- - -” if the principal machine doesn’t receive the signal

from primary circuit; the principal machine can detect the phase

and polarity firstly, if receives the data of the primary and the

secondary circuit normally, the primary circuit currents are

correspondingly visible on the phases of R, S, and T, both the error

and polarity can be displayed on the upper left corner of LCD. If the

symbol “Err” displays on the upper left corner of LCD display, it is

not available to detect the polarity properly, and the measured

currents of the primary circuit remain being displayed on the

R-phase.

-11-

The LCD flashes continually to prompt the soon power off after

about 15 minutes as of booting, and the principal machine can shut

down automatically to save the battery power, after the LCD

flashes for 30 seconds. When the LCD flashes continually, press

the POWER key to make the principal machine in continuous

running, and then press the POWER key again to power it off

3. Test of HV current

High voltage, very dangerous !Only qualified

personnel after training could conduct operation

on it. The operator should obey safety

regulations; otherwise there can be the danger of

electric shock resulting in personal injury or

casualty.

Only when all of the five insulating bars are

connected, can the high voltage line be detected,

otherwise there may be the danger of electric

shock resulting in personal injury or casualty.

Dangerous! It is prohibited to measure high

voltage line above 70V; otherwise there can be

danger of electric shock resulting in personal

injury or casualty.

Dangerous! Prohibited to detect the high current

wire above 1000A.

Prior to the detection, have the insulation bars

connected properly; finally have the detector

connected, for avoidance of any ground impact on

the HV detector.

Nothing but the special-made insulation bars

could be connected to HV detector.

After the detection, collect the insulating rod in

slant direction; first remove the HV detector, then

the insulation bars for the avoidance of ground

impact on HV detector.

-12-

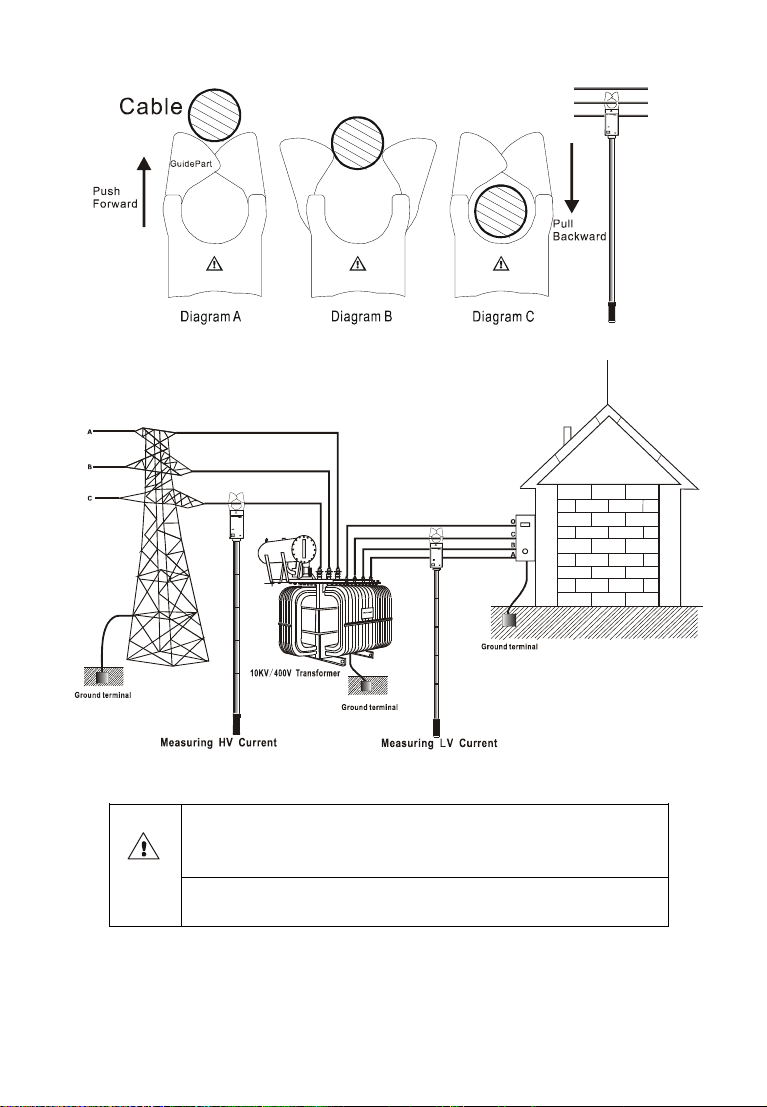

If the high voltage detector can be properly connected with 5

insulating rods and starts normally, please set the lead at the

center of boot sector on detector clamp (as shown in Figure A).

The boot sector on HV detector is perpendicular to the lead, Push

forward the insulating rod, the lead is clamped by the high voltage

detector which starts detecting and feedbacks to the principal

machine. Principal machine enters the detection and data

collection state after its normal starting up, If the principal machine

receives the signal sent by the high voltage detector, the primary

circuit current of high voltage end can be shown on R phase, If the

principal machine shows that the primary circuit current value is

“OL”, it is indicated that the primary circuit current exceeds the

upper limit of the high voltage detector. Push the insulating rod

backward, the high voltage detector is disconnected with the lead

(As shown in figure C). Please do keep the boot sector

perpendicular to the lead while removing.

The principal machine can detect the phase (group) differences

between the primary circuit and the secondary circuit firstly if

receives the signal from the primary circuit, and then determine the

polarity under in-phase; and the measured currents of the primary

circuit remain being displayed on the R phase if different phases;

the primary circuit currents are correspondingly visible on the

phases of R, S, and T, under in-group.

-13-

Notice: please take the instrument away from

the wire after the detection is finished for a

safe operation.

It is available to measure HA current/leaker by

the tester

-14-

4. Test LV current

High voltage, very dangerous !Only

personnel after training can conduct

operation on it. The operator should bear

safety regulations in mind; otherwise there

can be the danger of electric shock resulting

in personal injury or casualty.

Testing the LV current by the HV detector

available

Testing the 4 circuit currents or leakers by

the HV detector available

It is prohibited to insert LV current clamp for

an accurate measurement.

It is prohibited to use low voltage current

clamps to detect high voltage wire above

600V or 10A; otherwise there can be the

danger of electric shock resulting in

personal injury or casualty.

1) Connect three LV current clamps to the corresponding principal

machines, power on the machine into the test mode.

2) Vise the measured wires with the LV current clamp (Note: the

clip should be fully closed), observe the readings of the secondary

current, if the machine displays the symbol “OL A” while detecting

the secondary current, it is indicated that the measured secondary

current overflows the preset maximum of the LV clamp in the tester,

it is recommended to use the HV detector for its measurements.

The tester is capable of detecting three-channel or four-channel

current /leaker, please operate based on actual requirements.

-15-

3) Reference Diagram:

①Recording the circuit current

②monitoring leakers from equipment

③Detecting cable leakers in wall

④Detecting leaker from grounding wire

-16-

Clamp live wire and null line at the same time, to

measure leaker (note: total 2 wires)

Clamp the earth wire to measure the leaker of

earth wire of the tested electric equipment(note:

single wire)

Clamp the main wire to measure the total current

of main wire of the tested electric equipment(note:

single wire)

Use high voltage detector to measure the current

on low voltage wire in the places where its

indication is not easily accessible.

Please preset the automatic recording interval time for a

long-term record and monitoring of the current or leaker the

automatic recording interval time is available from 01 to 99 minutes,

it is recommended to switch off the backlight in order to reduce the

consumption of battery.

5. Test of CT ratio, polarity

【1st】: the current detected by single-channel HV

detector, the primary current for CT.

【2nd】: the current collected by three-channel LV

current clamp; the secondary current for CT.

【F.Er】:The error between the measured CT ratio and

the preset CT ratio.

【R, S, T】: indications of three phases; the in-phases

indicated on the same wire.

【】:the In-phase positive polarity; the phase-angle

difference is about from 0°to 25°or from 335°to 360 °.

【】:The in-phase negative polarity, the phase

angle difference is about from 155 °to 205 °; the

in-phase negative polarity means that the primary

current polarity is opposite to the secondary current

polarity under in-phase voltage; the current clamp

is oppositely operated between the primary current

and the secondary current. (Both the obverse side of

HV detector and the obverse side of LV current clamp

are the in-phase terminals for current input).

Table of contents

Other MEWOI Test Equipment manuals