MGE UPS Systems SA 2 Operating instructions

SA 2 & SA 2 IU

Medical Suction Collection Containers

Operating and Maintenance Manual

M.G. Electric (Colchester) Ltd

Altbarn Close, Colchester, Essex, CO4 9HY, United Kingdom

Tel: +44 (0) 1206 842244, Fax: +44 (0) 1206 845849

e-mail: sales@mgelectric.co.uk www.mgeworldwide.com

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 2 of 16

Dear Customer,

We take this opportunity to thank you for purchasing a SA Medical Suction Unit. Please read the

operating instructions and listed precautions thoroughly before attempting to operate the unit. MG

Electric manufactures its range in accordance with the requirements of BS EN ISO 9001 and BS EN

ISO 13485

INDEX

1. SAFETY INSTRUCTIONS 4

2. GENERAL DESCRIPTION 5

3. INSTRUCTIONS FOR USE 6

3.1

Before Operating Unit

3.2

SA 2 Set Up

3.3

Operating Environment

3.4

Connection

3.5

SA 2 Overflow Protection Valve

3.6

Cleaning Procedure

3.7

Transport

3.8

Storage

3.9

Instructions by Medical Staff to Patients

4. MAINTENANCE 10

4.1

Daily Procedures

4.2

General Layout

5. RECOMMENDED SPARES 11

5.1

Recommended Spares

6. TECHNICAL SPECIFICATION 12

6.1

General Dimensions

6.2

End of Life

7. NOTES 13

8. OTHER PRODUCTS IN THE SA RANGE 16

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 3 of 16

Return of Medical Equipment

Should you wish to return any equipment to MG Electric (Colchester) Limited (MGE), or one of our

designated distributors, Health Service Guideline HSG (93) 26 Decontamination of equipment prior

to inspection, service or repair) must be adhered to. Failure to follow this guideline will invalidate

any warranty claims and result in the equipment being destroyed.

Definition of symbols used in these instructions:

The Instruction for use must be referred to!

Manufacturers’ details and date of

manufacture

Safety Warning

Disposal in accordance with directive

2012/19/EU

Temperature Limits

Humidity Limits

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 4 of 16

1. SAFETY INSTRUCTIONS

The safety of the patient and SAM suction unit operator are the first priorities. It is therefore vital that

the following precautions are strictly observed:

WARNING!!!

•No modification of this equipment is allowed.

•Only original and approved spare parts and collection container systems must be used with

MG Electric products – failure to use original or approved spares will invalidate the warranty

and may cause injury or damage the SA 2/SA IU.

•Other than for routine daily procedures, any maintenance or repairs to MG Electric products

must be carried out by fully trained and qualified Electro-Biomedical engineer/technician

(EBME) or an authorised MG Electric dealer. Such persons are to be familiar with the relevant

standards, rules, accident prevention regulations, and operating conditions as a result of their

training, experience, and instruction. They are qualified to carry out the required activities and

in doing so recognize and avoid potential hazards. All testing on SA suction units should be

in accordance with ISO 10079-1

•Contamination may be present on any components. When cleaning or replacing any part of

the SAM suction unit appropriate protective clothing and gloves MUST be worn to avoid

contamination. Disposal of contaminated parts must be according to local protocols.

•Store the manual in a safe place, so that it is available to the trained personnel at all times.

•All SA 2 and SA IU collection containers must be securely mounted when in use.

•SA 2 and SA IU collection containers are NOT suitable for use in an MRI environment.

•The overflow valve may not operate fully against frothing. To prevent frothing anti-foam agent

maybe used.

•When replacing a full SA 2, be aware of its weight and ensure handling the container is

comfortable to avoid the possibility of spillage.

•Transport of the suction unit with a full SA 2 or SA IU collection container attached is not

advised.

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 5 of 16

2. GENERAL DESCRIPTION

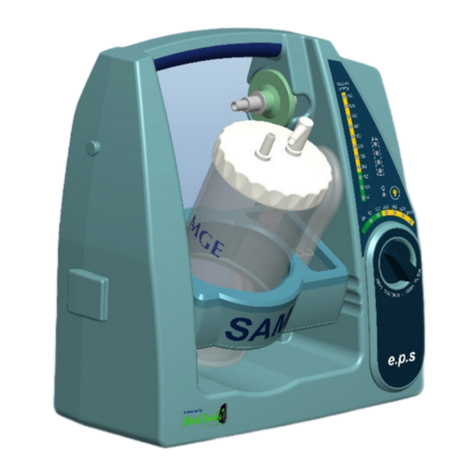

SA 2

- Reusable collection container with a nominal capacity of 2 litres, used for the collection of

body fluids during suction therapy.

SA 2 IU

- A specialist version of the SA 2 collection container with a wide bore patient connection

for Intra-Uterine procedures.

All further references of SA 2 in this manual refer to both SA 2 and SA 2 IU connection containers.

The SA 2 includes a sealed top with integral shut-off valve, an integral handle and tube connections.

The shut-off valve provides prevent from contamination of the SA suction unit. The SA 2 is

connected to the SA suction unit via a moulded ‘V’ bracket and has graduations at intervals of 250

millilitres for volume indication.

The collection container does not come into contact with the patient under normal use – there are no

contra-indications.

The SA 2 collection container is fitted as standard to all SA suction units, and are connected to the

SA suction unit via a moulded vacuum connector of the same type as that fitted to the filters.

•Place the SA 2 in the bracket. Connect the tubing from the filter to the angle

connector in the centre of the lid.

•Connect the patient tube to the patient connection.

•Turn on the aspiration unit.

•Check the desired vacuum is established.

•After the suction procedure – disconnect the patient tube.

Patient

Connection

Filter

Angled

Connector

Angled

Connector

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 6 of 16

3. INSTRUCTIONS FOR USE

3.1 Before Operating Unit

BEFORE operating your new SA 2 collection container, please read the following instructions

carefully.

Become thoroughly familiar with the operation and maintenance of the SA 2 before use. Only

persons trained in its use should operate the suction unit.

3.2 SA 2 Set Up

Warning! When replacing a full SA 2 collection container, be aware of its weight and

ensure handling the container is comfortable to avoid the possibility of spillage.

Transport of the suction unit with a full SA 2 attached is not advised.

Warning! The SA 2 must be securely mounted when in use.

The SA 2 collection container is fitted as standard to all SA suction units, and are connected to the

SA suction unit via a moulded vacuum connector of the same type as that fitted to the filters.

•Place the SA 2 in the bracket. Connect the tubing from the filter to the angle

connector in the centre of the lid.

•Connect the patient tube to the patient connection.

•Turn on the aspiration unit.

•Check the desired vacuum is established.

•After the suction procedure – disconnect the patient tube.

3.3 Operating Environment

Operation of the SA 2 must be within the following ambient condition.

+40°C

-5°C

%

80%

30%

Temperature Humidity

Warning! Never operate a SA suction unit in the presence of flammable gas such as

anaesthetic agents. This is an Explosion hazard!

An anti-foam agent may be put into the SA 2, without disinfectant solution, before use to reduce the

possibility of frothing. It should not however, be placed into the SA 2 for extended storage periods.

3.4 Connection

The silicon service tube (∅6mm I/D with 3mm minimum wall thickness) must be connected between

the filter and the vacuum port on the SA 2 lid. The tube has an elbow connector on each end for

fitting to the filter and for fitting to the ‘VACUUM’ port of the SA 2. The silicon tubing used in

conjunction with this equipment is a replaceable item. It should be changed regularly according to the

level of usage and where it has become in any way contaminated or damaged.

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 7 of 16

3.5 SA 2 Overflow Protection Valve

The SA 2 is fitted with an overflow valve designed to shut off the vacuum when the fluid level reaches

1750ml, this will stop suction from the suction unit. When the valve operates, the suction unit must be

switched off and the full SA 2 replaced by an empty one. For SA suction units with two collection

containers and where appropriate the full SA 2 collection container may be replaced by the second

SA 2 through operation of the changeover valve located on the top of the unit.

It should be noted that even after the overflow valve has shut off, fluid might continue to be drawn into

the SA 2 to an extent dependent upon the level of vacuum in the SA 2 at the time when the valve

closed.

Warning! The overflow valve may not operate fully against frothing. To reduce frothing

anti-foam agent may be used. Liquid sucked through to the pump will cause

damage - As a precaution, a hydrophobic filter should be fitted to prevent liquid

passing through.

3.6 Cleaning Procedure

Warning! Contamination may be present on any components. When cleaning or

replacing any part of the SA 2 appropriate protective clothing and gloves

MUST be worn to avoid contamination. Disposal of contaminated parts must

be according to local protocols.

Warning! Solvent-based cleaning agents or abrasive cleaners must not be used on any

SA 2. Minimise contact with cleaning solution and rinse well immediately with

warm water. Prolonged immersion of parts in water above 60°C causes loss of

material properties and must be avoided. Do not soak in dilute or neat

disinfectant, as this will cause damage.

Warning! The black ‘O’ seal is a re-usable item but must not be autoclaved.

The SA 2 collection container is made from Medical Grade Polycarbonate and is autoclavable up to

138°C. The SA 2 must be cleaned and sterilised between uses. The SA 2 is connected to the

aspiration unit via silicon tube and two vacuum connectors. The tubing and connectors are

replaceable items and should be changed regularly according to the level and type of usage and when

it has become in any way contaminated or damaged. The black ‘O’ seal is a re-usable item but must

not be autoclaved.

The SA 2 can be cleaned, disinfected and sterilised by most of the well-known methods employed in

practice. Under certain conditions, however, contact with cleaning, disinfecting and sterilising media

may cause some damage, which manifests itself in the form of stress cracking. This usually leads to a

reduction in mechanical strength. This manual contains no specific recommendations as to suitable

cleaning agents and disinfectants for the SA 2because the choice is many, and the composition of

such products can change.

In order to avoid mechanical stress to the SA 2, it is advisable not to clamp or stack them during

cleaning, disinfection or sterilization.

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 8 of 16

3.6.1 Cleaning of Jar and Lid

In many cases it is sufficient to clean with warm or hot water to which some weakly acidic, neutral or

weakly alkaline cleaning agent has been added.

•Cleaning is a pre-requisite for all types of decontamination. Sterilisation will not be

effective on a jar that is still soiled. In addition, proteinaceous matter may become

baked onto the surface.

•Gloves, apron and eye protection must be worn when cleaning by hand.

•The jar, lid and other parts must be separated before cleaning to ensure all

surfaces that may be contaminated are cleaned.

•Special attention should be paid to the overflow valve assembly and passageway

attached to the lid.

•Always pre-clean SA 2 parts under water and in a deep sink using detergent and

hot water to remove visible contamination - A soft brush may be used.

•Items must be examined after the cleaning process, to ensure that all visible soiling

is removed.

•Rinse well to remove any cleaning agent and avoid surface damage.

3.6.2 Cleaning of the ‘O’ Ring Seal

In many cases it is sufficient to clean the ‘O’ seal with warm or hot water to which some weakly acidic,

neutral or weakly alkaline cleaning agent has been added. The ‘O’ ring seal is a re-usable item but

must not be autoclaved. Thoroughly dry the ‘O’ seal after cleaning. Inspect the ‘O’ ring seal after

cleaning to ensure it is not cracked or damaged in any way. Replace if necessary.

3.6.3 Sterilisation

Sterilising by steam autoclaving -

•Ensure removal of all visible soiling.

•The SA 2 must be dried prior to sterilisation. This reduces the likelihood of lime

scale build up and ensures adequate steam penetration.

•The SA 2 jar should be inverted on the tray.

•Sterilise in a high temperature Autoclave at 138°C for a minimum of 3 minutes.

In contrast to standard autoclaving conditions, i.e., 121°C for 15 to 30 minutes, the SA 2 may be

subjected to temperatures up to 138°C, thus reducing the amount of time needed for sterilisation.

When sterilising with steam, germicides and detergents must be rinsed thoroughly from parts prior to

autoclaving. Failure to thoroughly remove germicides and detergents from the parts prior to

autoclaving may cause accelerated degradation. Permanent immersion of parts in steam causes loss

of material properties and must be avoided.

Care must be taken to ensure that the SA 2 parts are not damaged by substances added to the

boiler feed water, such as alkaline corrosion inhibitors, and that the SA 2 jar is positioned in such a

way that no condensation can accumulate inside it as this may also cause damage.

The SA 2 complies with ISO 10079-1 and will undergo 30 sterilisation cycles before deformation may

become visible. Stress cracking and fracture may occur after further autoclave cycles. As a rule, it is

possible to sterilize the SA 2 many times before gradual chemical decomposition reduces the

mechanical strength to a level where it is no longer adequate for its application. Sterilization tests

have shown that even after 100 cycles of 30 minutes each at 120 to 125°C, the material still retains

comparatively good impact strength.

Service UK Health and Safety Act – The unit must be decontaminated internally and externally and

certified as such before returning for service. Help Line 01932 355277

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 9 of 16

3.7 Transport

The SA 2 will be adequately boxed and protected to ensure no damage occurs during normal

transportation of goods, providing the ambient conditions are within the following parameters:

Temperature max +60°C min -20°C Humidity max +80% min +30%

-20°C

There are no restrictions for land, air, or sea transport.

3.8 Storage

SA 2 must be stored in a dry, dust-free, well-ventilated environment. The storage environment

should not exceed the temperature and humidity conditions stated below. Avoid direct sun or UV

exposure and shield nearby sources of heat. The equipment should be stored in its original

packaging providing no damage is evident. Protect against ground moisture by storing on a shelf or

wooden pallet.

Temperature max +60°C min -20°C Humidity max +80% min +30%

-20°C

3.9 Instructions by Medical Staff to Patients

When the equipment is required by a patient for home use, Medical Staff must fully instruct the patient

on the safe operation of the equipment. In the event of equipment contamination or failure, the patient

must be advised to switch off the suction unit and contact the authority who loaned the equipment.

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 10 of 16

4. MAINTENANCE

With the need for hospitals to be able to ensure SA 2 collection containers are compatible with their

Sterile Services Department prior to purchase - the following information is provided for guidance and

the procedure outlined may be adapted to suit current practise.

Warning! Contamination may be present on any components. When cleaning or

replacing any part of the SAM unit appropriate protective clothing and gloves

MUST be worn to avoid contamination. Disposal of contaminated parts must

be according to local protocols.

Warning! No modification of this equipment is allowed.

4.1 Daily Procedures

•An anti-foam agent may be put into the SA 2, without disinfectant solution, before

use to prevent the possibility of frothing. It should not however, be placed into the

container for extended storage periods.

•Examine the collection container for damage. Replace if necessary.

•Examine the external tubing for ageing, damage, or contamination and replace if

necessary, using equivalent tubing.

4.2 General Layout

SA 2 SA 2 IU

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 11 of 16

5. RECOMMENDED SPARES

5.1 Recommended Spares

Only original and approved spare parts must be used with all SA 2 collection containers – failure to

use original spares will invalidate the warranty and may cause injury and/or damage to suction unit.

All spares can be purchased by the user from MG Electric directly. Not all available spares are listed

below. Please contact the MG Electric sales team for a full list. (sales@mgelectric.co.uk)

It is recommended that only competent persons should undertake the replacement of spare parts.

5.1.1 Collection Container Components

SA 2 2 litre autoclavable collection container SAM 2

SA 2 IU 2 litre autoclavable Intra-Uterine collection container SAM 2 IU

SA 2 bottle top assembly MSP1047

SA 2 IU bottle top assembly MSP1071

SA 2 overflow valve – 10pk MSP1048

SA 2 top grommets – 10pk MSP1049

SA 2 jar (No bottle top included) – 4pk MSP1050

SA 2 ‘O’ ring – 10pk MSP1051

5.1.2 Associated Components

Disposable bacterial filters – 24pk MSP1002

Disposable hydrophobic filters – 24pk MSP1003

Elbow connector and ‘O’ rings – 10pk MSP1004

Silicone tube (OD ∅12mm) – 25M MSP1156

SA patient tubing – 2M MSP1351

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 12 of 16

6. TECHNICAL SPECIFICATION

6.1 General Dimensions

Free air-flow (litres/minute): 50 lt/min nominal*

Vacuum: 700mmHg*

Performance classification: High vacuum High flow (ISO 10079-1)

Nominal collection container capacity: 2 Litres

Patient Connection: ∅6mm I/D bore – SA 2 ∅9mm I/D bore – SA 2 IU

*Measurements are quoted at sea level

6.2 End of Life

IMPORTANT INFORMATION

Correct disposal of the product in accordance with EC directive 2012/19/EU

At the end of its life, the product must not be disposed of as urban waste.

It must be taken to a special local authority differentiated waste collection centre or to a dealer

providing this service.

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 13 of 16

7. NOTES

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 14 of 16

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 15 of 16

SA 2 & SA 2 IU

Operation and Maintenance Manual

Manual 160 Issue 06

Page 16 of 16

8. OTHER PRODUCTS IN THE

SA

RANGE

Mains Powered Suction

SA 12 - General ward high vacuum suction unit

SA 14 – Twin jar minor operating theatre high vacuum suction unit

SA 15 - Intra-uterine aspirator suction unit

SA 16 – Twin jar intra-uterine aspirator suction unit

SA 17T - Thoracic Theatre suction unit

SA 17W - Thoracic Ward suction unit

SA 18 - Intensive care low vacuum suction unit

SA 19 - Twin jar Intensive care low vacuum suction unit

SA 35 - Major operating theatre high vacuum suction unit

SA 36 - Twin jar intra-uterine aspirator unit

SA S – Micro suction unit

Portable Suction

SA HSPY - General high vacuum suction unit

SA EPS - Battery powered portable suction unit (Neonatal Option available)

SA AUVAC - Portable foot operated suction unit

SA TVAC - Disposable, hand operated suction unit

Oxygen Flowmeters

SA XYFW - Oxygen flowmeter

SA XYHU - Oxygen humidifier

Pipeline Regulators

SA 50 - High vacuum pipeline regulator with remote probe

SA 51 - High vacuum pipeline regulator with direct probe

SA 52 - Low vacuum pipeline regulator with remote probe

SA 53 - Low vacuum pipeline regulator with direct probe

SA 54 - High vacuum pipeline regulator - remote probe & mobile trolley

Research and Development

Since 1954, when MGE produced their first surgical suction units, the SA range has become

accepted as the industry standard, both in the U.K. and throughout the world.

In recent years, the SA range has been greatly extended, with models now available for portable,

electrical suction and central suction requirements. They have been completely re-designed, using

lightweight, robust materials, achieving greater efficiency, and making them easier to clean and

operate. All MGE equipment is manufactured and assembled to very high standards of quality at the

modern factory in Colchester in accordance with BS EN ISO 9001 Quality Management System, BS

EN ISO 13485 and the Medical Device Directive 93/42/EEC.

© Copyright M.G. Electric (Colchester) Limited

All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

Manual 160 Issue 6 May 2022

This manual suits for next models

1

Table of contents

Other MGE UPS Systems Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Johnson & Johnson

Johnson & Johnson ETHICON LAPRA-TY Suture Applier Optimized Device Performance Guide

DARAY

DARAY X740 Operating & installation manual

Riester

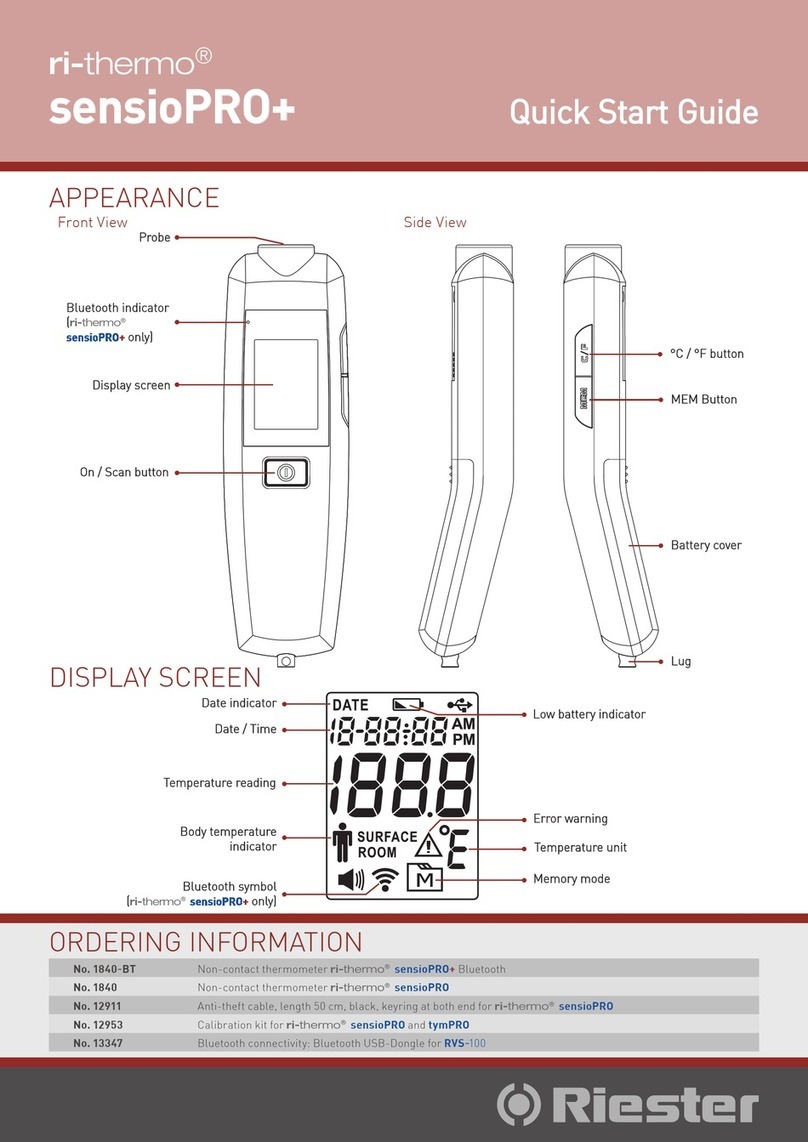

Riester ri-thermo sensioPRO+ quick start guide

SCALEO

SCALEO S19 21 001 user manual

Dräger

Dräger Infinity Acute Care System M540 Instructions for use

Ropox

Ropox Hudson 40-25023 User Manual, Mounting instruction