Micatrone MRP-2000 User manual

MRP-2000

Dok.nr: Mi-247gb / 2006-02-09

APPLICATION

MRP-2000 is a differential pressure controller with

two set points intended for controlling positive, neg-

ative or differential pressure on air and gases in

combustion plants and air treatment systems.

MRP-2000 has a 3-point control output: increase

signal, no signal or decrease signal.

FUNCTION

MRP-2000 features special control parameters de-

veloped by Micatrone to manage rapid changes

without self-oscillation and overshoot.

qNeutral zone around the set point value:

the controller is passive (no output signal).

qPulse zones on each side outside of the neutral

zone: the controller gives short pulses.

qPulse length: time length of the pulse.

qPulse separation time: time between pulses.

Through pulsing the actuator in the pulse zone (out-

side the neutral zone) the control sequence slows

down to eliminate the risk of self-oscillation around

the set point value.

Both the pulse length and the pulse separation time

are adjustable to match different operating in-

stances. LEDs indicate which set point value is con-

nected. If there is no phase on terminal 3 then set

point value 1 is connected. If there is a phase on ter-

minal 3 then set point value 2 is connected. The

LEDs “increase” and “decrease” show the control

output signal.

qOutside the pulse zone the controller provides

an continuous output signal.

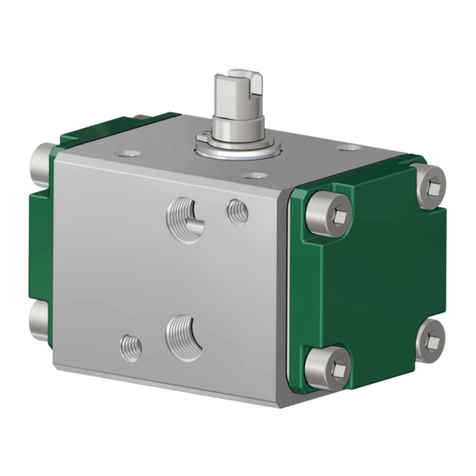

DESIGN

MRP-2000 is designed with three interconnected

circuit boards, I/O board, measurement board and

the display board. 4-digit indicator with character for

negative values and 6 LEDs for status indication.

Readable and programmable from the outside.

ABS plastic case equipped with four threaded holes

for cable glands. Two pressure outlets for HT-plastic

tube 8/6 which can easily be removed for replace-

ment with other couplings with male R1/8" thread.

Use a counter hold on the coupling closest to the

case when assembling and dismantling the tubes or

fittings.

INSTALLATION

MRP-2000 is mounted via 4 screws, max Æ4 mm.

The location of the holes is shown back of the enclo-

sure. Do not place the unit on a warm surface.

Connect power supply according to the electrical

connection. Check that the controller is marked with

the correct power supply voltage. If using cable

glands without a nut on the inside, glands with

grommet must be used to avoid damage to the

threads on the enclosure. Remember to remove the

transparent protective cover from the front panel af-

ter finished installation.

PRESSURE CONNECTION

The pressure connection should be made with

Micatrone’s pulse line sets to ensure a tight and

safe function.

MRP-2000 is available with three different mea-

surement ranges which run through zero:

-300...+300 Pa, -3...+3 kPa and -7.5...+7.5 kPa.

The metering socket is connected via the HT-plastic

hose 8/6 like this:

1. If MRP-2000 shall control a pressure that is com-

pared to atmospheric pressure, the pressure con-

nection should be made on the +socket

(right-hand). This applies whether the pressure is

positive or negative compared with the atmosphere.

The -socket should remain open.

2. If MRP-2000 shall control a differential pressure,

the lowest pressure compared with the atmospheric

pressure is connected to the -socket (left-hand).

The higher pressure should be connected to the +

socket.

© AB MICATRONE 2006-02-09 [H:\ Apps \ Typeset \ Mima \ Mi-247gb_060209.vp]

Differential Pressure Controller

with 3-point control output

catrone®

Operating and Installation guide

PGM ESC

Prog, mode

Set point 1

Set point 2

Increase

Decrease

Pa

0228

HandZero

DAMPING

Superimposed “noise” frequently occurs when

pressure measuring from e.g. burners, fans, etc.

It is possible to set different damping (time constant)

for the pressure sensor. On delivery MRP-2000 is

set to 3.5 seconds attenuation.

1. Open the cover.

2. On the midmost circuit board is a 2-way

miniature switch (DIL-switch) in the

left-hand lower corner.

3. Set the required damping option in

seconds as set out below.

4. Refit the cover.

PROGRAMMING

Hold down the PGM key for 3 seconds and the dis-

play will switch from the actual value to the first pa-

rameter P00 in the list of parameters. The list of pa-

rameters includes eight parameters, the first, P00,

can not be changed.

Browse through the list of parameters by pressing

the ¸¹ keys and this will display P00, P01, P02,

P03, P04, P05, P06 and P07.

Pressing the PGM key for the parameter in question

shows the set value.

The set value is changed by pressing PGM after

which the left-hand digit starts to flash. Use the ¸¹

keys to change digit and when the required digit is

shown, press the PGM key. The next digit to the

right will then start to flash and can be changed.

Continue along the entire row to the right and press

the PGM key. The unit responds by flashing the re-

quired value three times to acknowledge program-

ming has been successful.

Negative values are entered by pressing the ¹-key

repeatedly when programming the left most digit

displayed until the digit turns over from positive to

negative numbers. Remaining digits are then pro-

grammed as described above until the entire pa-

rameter value is entered.

Ongoing programming can be cancelled before the

last digit is completed by pressing the ESC key.

After programming a value you can return to the list

of parameters by pressing the ESC key.

Par.

no

Description Range Factory

default

P00 Programme ver-

sion

X.XX the current

programme

version, not

re-program-

mable

P01 Set point 1 -300..300 Pa

-3000..3000 Pa

-7500..7500 Pa

0Pa

0Pa

0Pa

P02 Set point 2 -300..300 Pa

-3000..3000 Pa

-7500..7500 Pa

0Pa

0Pa

0Pa

P03 Neutral zone 2..15 Pa

2..150 Pa

2..375 Pa

2Pa

20 Pa

50 Pa

P04 Pulse zone 1..75 Pa

1..750 Pa

1..1875 Pa

10 Pa

100 Pa

250 Pa

P05 Pulse length 200..3000 ms 500 ms

P06 Pulse separation

time

200..3000 ms 1000 ms

P07 Forced operation 0 = decrease,

1= increase

0 (decrease)

Set point value

Set point value 1 is programmed in P01 and Set

point value 2 in P02. Both set point values have the

same neutral zone and pulse zone.

Neutral zone

When the actual value lies in the neutral zone, the

controller gives no increase or decrease pulses.

The neutral zone is programmed in P03 and lies

symmetrical around the active set point value.

Pulse zone

When the actual value lies outside of the neutral

zone and in the pulse zone, the controller gives in-

crease or decrease pulses.

The size of the pulse zone is programmed on P04.

The pulse length is programmed in P05 and the

pulse separation time between pulses in P06. The

pulse zones are stated in Pa and lie above and be-

low the neutral zone with equal values (P04).

When the actual value is outside the pulse zone, the

controller gives a continuous increase or decrease

output signal.

Switching set point values

Switching between set point 1 and 2 is done by con-

necting power to terminal 3.

No power on terminal 3:

Set point 1 (P01) is activated.

Power on terminal 3:

Set point 2 (P02) is activated

Note ! Power on terminal 3 must be of the same

phase as connected on terminal 1.

This method permits, e.g. a stage burner to use dif-

ferent set point values for stage 1 and stage 2.

2

© AB MICATRONE 2006-02-09 [H:\ Apps \ Typeset \ Mima \ Mi-247gb_060209.vp]

Damping selection:

0,1 sec. 1,0 sec. 3,5 sec. 4,5 sec.

damping of the pressure measurement

Forced operation

As long as terminals 13 and 14 are connected elec-

trically via an external potential-free contact a con-

tinuous increase or decrease signal is given.

The forced signal can be set to either increase or

decrease in parameter P07.

Manual operation

Activated by pressing the PGM/ESC keys simulta-

neously until the display starts to flash, approxi-

mately 3 seconds. The display flashes in manual

mode. As along as the ¸key is held down an in-

crease signal is given and when the ¹key is held

down a decrease signal is given. Manual operation

is immediately cancelled by pressing the ESC key,

or automatically after 30 minutes has elapsed since

the last key was activated.

Manual operation takes over the controller’s stan-

dard function, increase and decrease signals are

controlled solely by pressing the ¸and ¹keys.

POWER FAILURE

After a power failure the controller returns to regula-

tion of the activated set point value.

CALIBRATION OF THE ZERO POINT

NOTE! Loosen pressure tubes to the unit.

Press down the ¸¹ keys simultaneously and keep

these pressed down until the display has gone out,

releasethekeysandthedisplaywillshow“----“

during zero point calibration.

The display shows “ 0000 “ when zero point calibra-

tion is complete.

Calibration of the zero point should be carried out

when the unit has reached its normal ambient tem-

perature and been operational for about 60 min-

utes, and then twice a year.

TECHNICAL DATA

Power voltage: 24 or 230 VAC

±10 % 50/60 Hz

See label on side panel

of case.

Power consumption: 7.5 VA

Connecting set point 2: 24 or 230 VAC

(Same phase as term. 1)

Ambient temperature: 0...55 °C

Measuring range: See label on side panel

of case..

(-300...+300 Pa)

(-3000...+3000 Pa)

(-7500...+7500 Pa)

Measurement error: £±1%FS

Set point range: 0...100% of the

measuring range.

Max pressure load: 25 kPa

Output Relays: 2 pcs.

Max load on relays: 24/230 VAC,

2A cosj=1

Electrical terminals:

- Supply voltage:

- Relays:

- Forced operation:

Max. 2x1,5 mm2wire

Max. 2x1,5 mm2wire

Max. 2x0.75 mm2wire

Cable entries: 2 pcs M16 + 2 pcs M20

Degree of protection: IP 65

Pressure connections: 8/6 HT plastic tube

Dimensions [HxWxD]: 120x200x57 mm

(pressure conn. not ac-

counted for)

Weight: 0,75 kg

3

© AB MICATRONE 2006-02-09 [H:\ Apps \ Typeset \ Mima \ Mi-247gb_060209.vp]

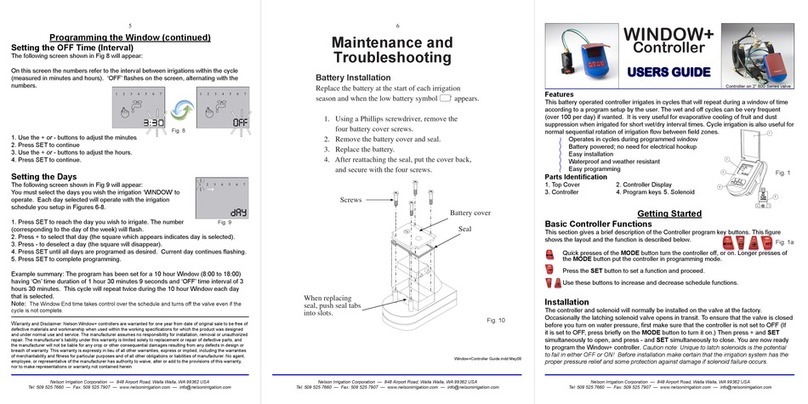

SET POINT

PULSE ZONE

PULSE ZONE

NEUTRAL ZONE

INCREASE

DECREASE

OUTPUT:

PRESSURE

ACTUAL VALUE

Compliancy

-EMC: SS-EN 50081-1

SS-EN 50082-2

-LVD: SS-EN 61010-1

Maintenance

Calibration of the zero-point twice a year is recom-

mended.

Power voltage

MRP-2000 is voltage fed with 24 or 230 VAC ac-

cording to the rating plate on the end of unit. The

Phase is connected to terminal 1 and Neutral to ter-

minal 2.

Control signals

If the control signals are to have the same voltage

supply as MRP-2000, terminals 1 and 5 are

strapped.

If the control signals are to have a different voltage,

remove the strap between 1 and 5 and connect an-

other supply to terminal 5.

The relay contacts behind terminals 4, 5, 6 and 7, 8,

9 are potential-free.

RC-network

The supplied RC network is used to reduce electri-

cal interference (EMI) when the increase and de-

crease pulses are given and should be installed be-

tween terminals 4 and 5. The RC-network also pro-

longs the life of the relay for the control signal.

Unexpected behaviour can be experienced if the

control signal from MRP-2000 is connected to inter-

mediate relays or very small actuators. External re-

lays or actuators can react to the small leakage cur-

rent that passes through the RC-network and give

incorrect increase or decrease signals. This also

applies when the actual value is inside the neutral

zone. Should this behaviour occur disconnect the

RC-network.

4

© AB MICATRONE 2006-02-09 [H:\ Apps \ Typeset \ Mima \ Mi-247gb_060209.vp]

AB Micatrone Telephone: +46 8-470 25 00

Åldermansvägen 3 Fax: +46 8-470 25 99

SE-171 48 SOLNA Internet: www.micatrone.se

Control signals

Neutral

Line

Supply

Decrease output

Closed for

forced operation

Increase output

{

Supply-

voltage

{

A

ctivating signal Set point 2

RC network

ELECTRICAL CONNECTION