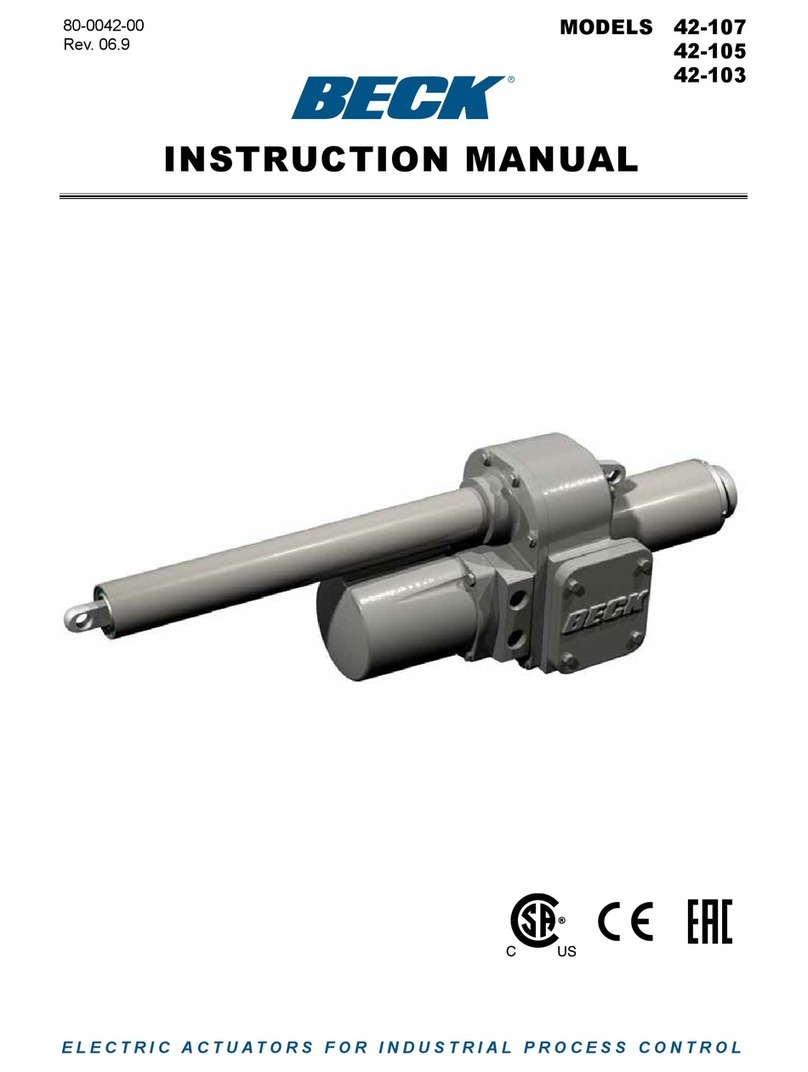

Beck 22 Series User manual

ELECTRIC ACTUATORS FOR INDUSTRIAL PROCESS CONTROL

22-309

22-409

22-809

MODELS

Group 22 - Quick Reference

PAGES 2-7 -- WIRING CONNECTIONS

PAGES 8-11 -- ELECTRONICS

PAGES 12-13 - MAINTENANCE KITS

PAGES 14-17 -- TROUBLESHOOTING

AND TESTPOINTS

PAGES 18-19 -- HART MENU

This reference supports

Group 22 actuators

using DCM-2 part numbers:

12-8224-41

12-8224-45

12-8224-51

12-8224-55

Group 22

Quick Reference

INSTALLATION - ELECTRICAL

2

POWER QUALITY

Power quality disturbances such as power

outages, transient voltages, harmonic distortions,

and electrical noise should be accounted for

during installation of your drive. Protecting your

drive from these conditions can reduce downtime

and promote a longer lifetime for the equipment.

Following the recommendations below will

maximize the protection.

aSelect wiring materials according to the correct

ampacity ratings dictated by national and local

regulations.

aShielded, twisted pair cables can be used for

signal connections to avoid being affected by

electrical noise. These signal wires, based

on Noise Susceptibility Level (NSL) per

IEEE-518, fall into the level 1 classification.

A braided shield will be more effective than

a wrapped foil shield. Signal wire shields

should be connected to the drive casting

grounding screw. If grounding at the signal

source is required, then the shield should not

be grounded at the drive.

aRaceways such as conduits and trays have

to be grounded at both ends to properly meet

immunity requirements.

aAn AC power ground connection should be

made between the power source and the

Beck drive. Grounding connections including

wire and metal conduit are permitted, except

the drive-grounding conductor may not be

connected to a structured metal frame of a

building.

aSurge suppression equipment that meets

Underwriters Laboratory (UL) Standard 1449

may be used to protect against transient

voltage conditions.

aPower Conditioners may be used to regulate

the supply voltage and maintain a constant

voltage level. They are helpful in protection

against voltage sags and swells, as well as

some measure of electrical noise protection.

aHarmonic lters may be used to minimize the

effects of supply voltage waveform distor-

tions and are used in applications that incur

a large amount of high-frequency electronic

noise.

ELECTRICAL INSTALLATION

Three 1” N.P.T. conduit connections are

provided for power and signal wiring to the

drive. One conduit is provided for signal wiring

connections, and the other conduits are provided

for power and auxiliary switch connections. Use of

a sealant on the threaded conduit connections is

recommended to keep moisture out. Routing the

conduits from below the drives will help to prevent

water and other contaminants from entering the

drive.

Power and signal wires should be routed

to the drive separately. Shielded cables are

recommended, otherwise the wires should be

installed in conductive conduit and/or cable trays.

Large, clearly labeled terminal blocks are

enclosed in a gasketed compartment. Terminals

will accommodate up to 12 AWG (3.31 mm2)

wires.

Refer to the wiring diagram furnished with your

Beck drive (fastened to the inside of the terminal

block cover) for proper AC power and signal

connections. It is advisable to provide normal

short circuit protection on the AC power line.

For maximum safety, the Beck drive body

should be grounded. Separate ground terminals

are provided in the wiring compartment for power

and signal wiring. Wire size 12 AWG (3.31 mm2)

is recommended for this purpose.

TERMINAL CONNECTIONS

The Group 22 terminal block assemblies have

screw-down clamp terminals with separation

barriers and nylon paper electrical shields (shields

not shown on terminal connection diagrams). The

terminals can accept a variety of lug types or a

bare wire. The maximum wire size capacity is #12

AWG (3.31 mm2).

TERMINAL SCREW TORQUES

Regardless of wire termination type, each

terminal screw should be torqued to the proper

specification upon landing your wire.

All input power terminal screws (terminals 1

to 3) on the model 22-309 and 22-409 should be

tightened to 10 lb-in. The input power terminal

screws on the model 22-809 and the optional

transformer enclosure for 22-309 and 22-409

drives should be tightened to 20 lb-in. All signal

wiring terminal screws (terminals 4 to 21) on all

Group 22 models should be tightened to 9 lb-in.

Both the power and signal ground screws should

be tightened to 20 lb-in.

Group 22

Quick Reference

3

SUPPLY POWER

TERMINALS 1, 2, AND 3

Standard supply power for the model 22-309 is

single-phase 120 VAC (refer to the drive nameplate

for specific rating). Input power connects line to

terminal 1, neutral to terminal 2, and ground to

the enclosure power ground screw. Terminal 3 is

unused for 120 VAC operation.

Standard supply power for the model 22-409

is three-phase 208 VAC. Standard supply power

for the model 22-809 is three-phase 480 VAC.

Lines 1, 2, and 3 connect to terminals 1, 2, and 3

respectively on each of these drives. The ground

wire should be connected to the enclosure power

ground screw.

Alternate voltage options include single-phase

240 VAC for the model 22-309 and three-phase

208, 240, 380, 416, 480, & 575 VAC for all Group

22 models. The model 22-309 and 22-409 require

an optional transformer enclosure to accommodate

any non-standard voltage configuration.

Group 22 drives are equipped with a transient

protector assembly installed across each, or a

combination of terminals 1, 2, and 3 (dependent

upon your drive model and configuration). Note:

The transient protector assembly should not be

removed.

AUXILIARY LIMIT SWITCHES

TERMINALS 4 THROUGH 9

Group 22 drives include two single pole double

throw (SPDT) auxiliary limit switches rated for 1

Amp at 250 VAC. These switches may be useful

for discrete position indication. The limit switches

are actuated by adjustable cams on the control

shaft (located with the position sensing device).

Details on standard factory switch settings can be

found in the configuration section of this manual.

AUTO MODE INDICATION

TERMINALS 10 AND 11

A dry contact is available at terminals 10 and

11 to indicate when the handswitch is in the AUTO

position. The switch contact is Form A; when

the handswitch is not in the AUTO position, the

contact is open and when the handswitch is in the

AUTO position, the contact is closed. The contact

is rated for 1 Amp at 250 VAC.

CAUTION

Always close covers immediately after

installation or service to prevent moisture or

other foreign matter from entering the drive.

SYSTEM ALARM

TERMINALS 12 AND 13

Indication of the system alarm is available as

a dry contact at terminals 12 and 13. The factory

standard is a form B contact configuration (open on

alarm). It is configurable to a form A configuration

(closed on alarm). Reference the configuration

section of the manual for additional details on how

to change this functionality. The contact is rated

for a maximum of 80 milliamps at 120 VAC/VDC.

DEMAND SIGNAL

TERMINALS 14 AND 15

The DCM monitors an analog 4-20 milliamp

input signal at terminals 14 (–) and 15 (+), and

positions the output shaft position to match in

response. The standard response is to follow the

demand signal linearly.

FEEDBACK SIGNAL

TERMINALS 16 AND 17

When feedback sourcing is enabled, the DCM-2

transmits a 4-20 milliamp position feedback signal

on terminals 16 (–) and 17 (+) that is proportional

to the drive output shaft position.

CONTROL OVERRIDE INPUTS

TERMINALS 18 THROUGH 21

Analog signal operation may be overridden by

using discrete input signals on the control override

input terminals. CW (19), CCW (20), and STOP

(21) terminals require connection to a common

(COM) terminal (18) to perform the override as

shown in the table below.

Terminal

Connections

Output Shaft

Action

19 to 18 Clockwise Rotation

20 to 18 Counter-Clockwise Rotation

21 to 18 Stop in Current Position

The connection to terminal 18 is designed to

be made through relay contacts or through a solid

state switch capable of sinking at least 5 milliamps

DC. When the circuit is open, terminals 19, 20,

and 21 should measure +12 VDC with respect to

terminal 18.

CAUTION

Do not connect an external voltage source to

override terminals 18–21; an external voltage

source may damage the DCM circuitry.

80-4280-02

Rev. 05.3

INSTALLATION - WIRING

4

4

3

2

1

5

6

7

8

9

10

11

12

13

14

18

17

21

16

20

15

19

Auxiliary

Switch 2

Auxiliary

Switch 1

Power

Handswitch

Auto Indication

Power

Ground

Signal

Ground

System Alarm

Demand Signal

Feedback Signal

Control Override

Inputs

Surge

Suppressor

Assembly

(22-309)

3

2

1

Power

Ground

Transient

Protector

Assembly

(22-309)

Transient

Protector

Assembly

(22-409)

1

2

3

Power

OPTIONAL

TRANSFORMER

ENCLOSURE POWER

CONNECTIONS

FOR MODELS 22-309 / 22-409

MODEL 22-309 & 22-409

TERMINAL CONNECTIONS

OPTIONAL ENCLOSURE

(Refer to page 41 for replacement

fuse part numbers)

80-4280-02

Rev. 05.3

5

See terminal

connction

table below

PSA-1 YEL

PSA-2

PSA-3

PSA-4

PSA-5

PSA-6 WHT

GRN

BLU

VIO

GRY

BRN

RED

ORG

YEL

RED

BRN

ORG

YEL

GRN

BLU

PSL-1

J1-2

PSL-4

PSL-3

PSL-2

J1-1

J1-3

J1-4

J1-5

J1-6

BRN

YEL

GRN

WHT

GRY

BLK

BRN

RED

ORG

RED

ORG

J3-1

J3-4

J3-2

J3-3

J5-1

J5-4

J5-3

J5-2

J5-5

J5-6

J4-4

J4-5

J4-8

J4-9

J4-1

J4-10

PP-2

PP-1

PP-3

PP-5

DCM FUSES

F1,F2,F3†

(8A 250V)

CW

RED

ORG

YEL

GRN

AUTO CCW STOP

BRN

WHT

BLK

RED

BRN

AUTO

5 4 3 12 109 11

12

J3-6

J2-5

J2-6

J2-4

J2-3

J2-1

J2-2

J3-9

J3-8

J3-7

J3-5

PP-9

PP-10

J4-2

J4-3

J4-6

J4-7

BLU

VIO

PP-16

PP-15

ORG

RED

PM-1

PM-2

PM-4

PM-3

YEL

ORG

RED

BRN

PP-11

PP-14

PP-13

PP-12

S1

S2

CW

TRAVEL LIMITS

CCW CONTACTLESS

POSITION

SENSOR SWITCHES

AUXILIARY

CUSTOMER TERMINAL BLOCK

250VAC, 1 AMP

INPUT / FEEDBACK SIGNALS:

ISA TYPE 4, CLASS U, POWER ISOLATED

STOP

CONTROL

SIGNAL

DEMAND

OVERRIDE

INPUTS

CCW

CW

COM

EXTERNAL

HART

COMMUNICATION

TERMINALS

DIGITAL

CONTROL

MODULE

HANDSWITCH

TORQUE

SENSING

MOTOR

80mA MAX.

OPENS ON ALARM

SYSTEM ALARM

120 VAC/VDC

HANDSWITCH AUTO

INDICATION

250VAC, 1 AMP

FEEDBACK TO CUSTOMER

CONTROL DRIVE

OUTPUT SHAFT POSITION

(DCM-2)

MODEL 22-309 & 22-409 TYPICAL WIRING SCHEMATIC

(a wiring schematic specic to each drive is located under the wiring terminal cover)

USE FUSE KIT

P/N 12-8061-53

TERMINAL CONNECTION TABLE

*Other operating voltages are available with an optional transformer.

†Fuse F3 is only applicable to the model 22-409.

22-309 22-409

Operating Voltage Phases Single-Phase Three-Phase

Operating Voltage Refer to drive nameplate for

voltage rating (120 or 240 VAC)*

208 VAC*

Terminal 1 Line Line 1

Terminal 2 Neutral Line 2

Terminal 3 Unused Line 3

80-4280-02

Rev. 05.3

INSTALLATION - WIRING

6

21

2015 16 17 18 19

14

4 7 8 9 10 11 12 136

5

Demand Signal

Feedback Signal

Control Override Inputs

Signal Ground

Power Ground

Auxiliary Switch 1

Handswitch Auto Indication

Auxiliary Switch 2

System Alarm

Power

Switch Ground

Transient

Protector

Assembly

MODEL 22-809 TERMINAL CONNECTIONS

80-4280-02

Rev. 05.3

7

G

CW

RED

J3-6

BRN J3-1

RED

ORG

YEL

RED

BRN

J3-4

J3-2

J3-3

J5-1

ORG

YEL

GRN

BLU

J5-4

J5-3

J5-2

J5-5

J5-6

STOP

CCW

CW

COM

ORG

YEL

J2-5

BRN

YEL

GRN

WHT

GRY

BLK

J4-4

J4-5

J4-8

J4-9

J4-1

J4-10

PP-2

PP-1

J2-6

J2-4

J2-3

J2-1

J2-2

J3-9

J3-8

J3-7

GRN

AUTO CCW

J4-6

J4-7

BLU

VIO

PP-16

PP-15

J3-5

PP-9

PP-10

ORG

RED

STOP

BRN

WHT

BLK

RED

BRN

AUTO

PSL-1

J1-2

PSL-4

PSL-3

PSL-2

J1-1

J1-3

J1-4

J1-5

J1-6

PSA-1 YEL

PSA-2

PSA-3

PSA-4

PSA-5

PSA-6 WHT

GRN

BLU

VIO

GRY

5 4 3 12 109 1112

PP-3

PP-5

RED

ORG

J4-2

J4-3

PP-14

PP-13

YEL

ORG PM-3

PM-4

PP-11

PP-12 RED

BRN

PM-2

PM-1

PM-5GRN

PP-15

PM-6BLU

PP-16

BLK

BLK

BLK

GRN

HANDSWITCH

CONTROL

SIGNAL

DEMAND

OVERRIDE

INPUTS DIGITAL

CONTROL

MODULE

TORQUE

SENSING

80mA MAX.

OPENS ON ALARM

SYSTEM ALARM

120 VAC/VDC

HANDSWITCH AUTO

INDICATION

CW

TRAVEL LIMITS

CCW CONTACTLESS

POSITION

SENSOR

S1

S2

SWITCHES

AUXILIARY

CUSTOMER TERMINAL BLOCK

#

250VAC, 1 AMP

250VAC, 1 AMP

MOTOR

DCM FUSES

F1,F2,F3

(8A 250V)

FEEDBACK TO CUSTOMER

CONTROL DRIVE

OUTPUT SHAFT POSITION

EXTERNAL

HART

COMMUNICATION

TERMINALS

INPUT / FEEDBACK SIGNALS:

ISA TYPE 4, CLASS U, POWER ISOLATED

ORG

RED

BRN

LINE 2

LINE 3

LINE 1

G

3-PHASE POWER

REFER TO DRIVE

NAMEPLATE FOR

VOLTAGE RATING

(DCM-2)

MODEL 22-809 TYPICAL WIRING SCHEMATIC

(a wiring schematic specic to each drive is located under the wiring terminal cover)

* Kits also include (3) 8 Amp, 250 Volt DCM fuses.

Three-Phase

Voltage Rating Fuse Rating

Fuse Kit

Part Number*

208 10 Amps, 600 Volts 12-8061-51

240 10 Amps, 600 Volts 12-8061-51

380 4 Amps, 600 Volts 12-8061-52

416 4 Amps, 600 Volts 12-8061-52

480 4 Amps, 600 Volts 12-8061-52

575 4 Amps, 600 Volts 12-8061-52

Group 22

Quick Reference

ELECTRONICS

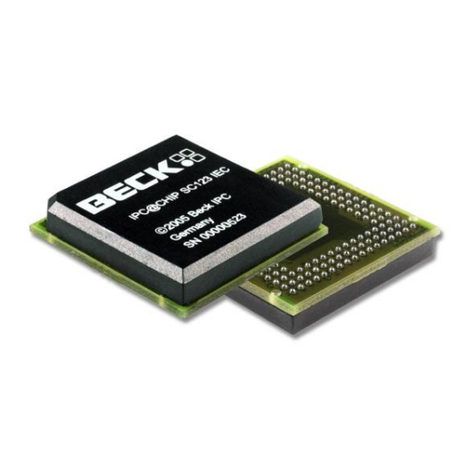

DIGITAL CONTROL MODULE (DCM-2)

8

DCM

COMPARTMENT

CONTROL END

COMPARTMENT

The DCM-2 is a micro-processor based circuit

board assembly that serves as the actuator’s

control center. The DCM-2 chassis assembly

is comprised of a Control circuit board, a Driver

circuit board (inverter circuit), additional circuit

components like capacitors and transformers,

and an aluminum chassis to which both the

boards and the components are fastened. The

whole assembly is mounted in the actuator’s DCM

compartment (see photo).

The main function of the DCM-2 chassis

assembly is to be the actuator’s positioner. The

control board compares the Demand input signal

to the actuator shaft position feedback signal from

the Contactless Position Sensor (CPS-4) located

in the control end compartment (see photo).

See the troubleshooting section of this manual

for details regarding the fuse locations, the test

point locations, and expected test point voltage

levels.

INTERFACES

The DCM-2 has three configuration interfaces:

a local pushbutton interface, a HART interface,

and a serial port interface.

PUSHBUTTONS

The local pushbutton interface is integral to

the DCM-2 assembly. It requires no additional

equipment to perform calibration procedures,

but is limited in functionality. This interface

also has LEDs for diagnostic information.

HART

The HART interface may be accessed by a

HART handheld communicator* or a HART

equipped control system. All electronic

calibration, configuration, and diagnostics

can be accomplished through HART

communications.

SERIAL PORT

The serial port interface is accessible by

connecting a computer to the DCM-2 using a

Beck serial cable**. All electronic calibration

and configuration can be accomplished

through the serial port interface.

The DCM-2 chassis assembly is mounted in a

dedicated compartment (see photo) and normally

does not need to be removed.

Accessing the DCM-2 assembly may be

required for configuration or diagnostic purposes

using either the pushbutton or serial port

interfaces.

If the DCM-2 needs to be repaired for any

reason, the whole chassis should be removed and

replaced as an assembly. See the Maintenance

section of this manual for complete details on

chassis removal and installation.

* See the HART appendix for details on connecting via HART

communicators.

** See the serial port appendix for details on connecting via

the serial port.

Group 22

Quick Reference

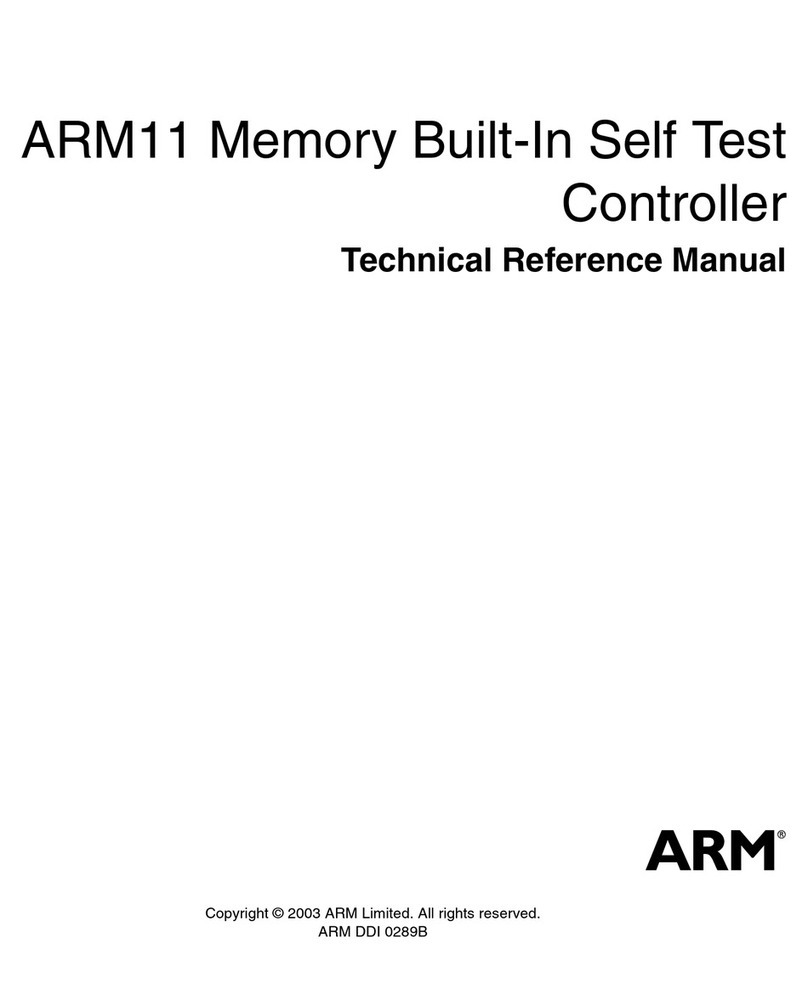

9

R

1

10

1

1

11

FWD

STAT

REV

PWR

TP4

SERIAL

PORT

TP1

INPUT

RESISTOR

R11

TP3

TP2

MOUNTING

SCREWS

SERIAL PORT

DCM

FUSES

LOCAL

PUSHBUTTON

INTERFACE

STATUS INDICATION

LEDs

OVERVIEW

LEDs

MOUNTING

SCREWS

CALIBRATE

SET POS

100%

SET POS

0%

SET DEM

100%

SET DEM

0%

DEMAND

POSITION

TORQUE

STALL

TEMP °F

FB OPEN

UVOLT

ACKNOWLEDGE

J5 J2

J4 J3A J3B

F1

F2

J5

TB1 TB2 TB3 TB4 TB5

TB6

12-8224-41

MODEL 22-309 DIGITAL CONTROL MODULE (P/N 12-8224-41)

FUSES

8 AMP

12-8224-51

1

SERIAL

PORT

J4 J3A J3B

TP4

TP1

J5

FWD

STAT

REV

PWR

CALIBRATE

SET POS

100%

SET POS

0%

SET DEM

100%

SET DEM

0%

DEMAND

POSITION

TORQUE

STALL

TEMP °F

FB OPEN

UVOLT

ACKNOWLEDGE

F1

F2

F3

INPUT

RESISTOR

R11

TP3

TP2

DCM

FUSES

LOCAL

PUSHBUTTON

INTERFACE

MOUNTING

SCREWS

MOUNTING

SCREWS

STATUS INDICATION

LEDs

OVERVIEW

LEDs

SERIAL PORT

MODEL 22-409 & 22-809 DIGITAL CONTROL MODULE (P/N 12-8224-51)

Group 22

Quick Reference

ELECTRONICS

10

FWD

STAT

REV

PWR

CALIBRATE

SET POS

100%

SET POS

0%

SET DEM

100%

SET DEM

0%

DEMAND

POSITION

TORQUE

STALL

TEMP °F

FB OPEN

UVOLT

ACKNOWLEDGE

LOCAL PUSHBUTTON

INTERFACE / LEDs

OVERVIEW LEDs

There are four LEDs in the upper right corner

of the DCM-2 circuit board. These provide an

overview of DCM-2 status.

PWR

This LED is lit when power is applied to the

drive. After initial power up, this LED pulses

from bright to dim indicating the micro-

processor is operating.

STAT

This LED is lit when a system alarm occurs.

When the STAT LED is lit, typically a status

indication LED will be illuminate to further

explain the status.

REV

This LED is lit when the drive is instructed to

move in the reverse direction. The instructions

may come from a demand signal, a control

override input, the handswitch, HART, or serial

commands.

FWD

This LED is lit when the drive is instructed to

move in the forward direction. The instructions

may come from a demand signal, a control

override input, the handswitch, HART, or serial

commands.

STATUS INDICATION LEDs

The status indication LEDs are located on the

left side of the local pushbutton interface.

The applicable status indication LED(s) will

illuminate when the “STAT” LED is lit, to reveal

the condition(s) as described below. When more

than one status LED is required at one time, the

illuminated LEDs will cycle rather than illuminate

all at once.

Refer to the troubleshooting section of this

manual for corrective actions that will eliminate

system alarms, status indication LEDs from being

lit, and the STAT LED from being lit.

DEMAND

The demand signal is outside of the acceptable

range of values.

(Standard current range is 3.2 - 21.0 mA DC)

POSITION

The internal position signal from the CPS-4

is outside of the acceptable range of values.

(Standard voltage is 1.3 - 3.7 volts DC)

TORQUE

The torque sensed at the output shaft of the

actuator exceeds the torque alarm threshold.

(Standard torque alarm threshold is 105%)

STALL

The drive is in a stall condition and stall

protection has been activated.

TEMP °F.

The temperature sensed at the DCM-2 is

outside of the acceptable range.

(Acceptable range is -40°F to 185°F (-40°C

to 85°C)

FB OPEN

The feedback current loop is disconnected,

open, or does not sense a load.

UVOLT

The operating voltage is below the rated

voltage tolerance (under voltage condition).

This LED could also be lit if an individual phase

of a three-phase operating voltage is lost.

ACKNOWLEDGE

Temporarily lit when a pushbutton configuration

operation is performed to confirm that the

pushbutton configuration operation has been

completed.

When a status LED is lit the system alarm

contact will change state. Indication of the system

alarm is available as a dry contact at terminals 12

and 13. The standard factory setting is for the

contact to be closed in the normal state and open

in an alarm state.

Group 22

Quick Reference

11

COUPLING

THUMB NUT

SWITCH CAMS

COUNTER-CLOCKWISE SWITCH

CLOCKWISE SWITCH

PIN CONNECTORS

AUXILIARY

SWITCH S2

AUXILIARY

SWITCH S1

THUMB NUT

LOCKING SCREW

(Do Not Adjust Set Screws (4))

CONTACTLESS POSITION SENSOR

(CPS-4)

CONTROL END / CONTACTLESS POSITION SENSOR

CONTROL END

The control end assembly is comprised of

the contactless position sensor (CPS-4), limit

switches, and limit switch cams. The control end

assembly is located in the actuator’s control end

compartment under the cylinder shaped cover.

The assembly is installed on the control shaft

which is geared into the main output shaft of

the actuator. As the output shaft turns it moves

the control shaft , the limit switch cams, and the

contactless position sensor ferrite core.

The control end includes two SPDT auxiliary

limit switches (labeled S1 and S2) for customer

connection and two over-travel limit switches

(labeled CW and CCW). The cams can be adjusted

to actuate the auxiliary switches anywhere in the

actuator’s range of travel.

CONTACTLESS POSITION SENSOR

(CPS-4)

The contactless position sensor (CPS-4) is a

circuit board and sensor assembly that is part of

the control end assembly. The CPS-4 provides

the DCM-2 with a continuous position signal

proportional to the position of the actuator’s output

shaft. The CPS-4 is located in the actuator’s

control end compartment under the cylinder

shaped cover.

The position sensing function of the CPS-4 is

provided by a ferrite magnetic sensing element.

An electronic circuit translates the voltage from

the ferrite magnetic sensor into a position signal.

The position signal is used by the DCM-2 to

determine the actuator’s output shaft position for

control and to generate an analog 4-20 milliamp

position feedback signal for external use.

LOCAL PUSHBUTTON INTERFACE

The five pushbuttons located on the local

pushbutton interface are used for simple calibration

features. To utilize the pushbuttons, the user must

press and hold the calibrate button, then press and

hold the button for the desired function. Pressure

should be maintained until the “ACKNOWLEDGE”

LED lights; this confirms receipt of the pushbutton

command.

See the calibration section of this manual for

further explanation of the calibration procedures.

CAUTION

Pressing the following buttons may

change calibration and cause the drive to

reposition.

CALIBRATE

As a safety feature, this button must be

pressed and held simultaneously with another

pushbutton to perform a calibration.

SET POS 100%

Calibrates the DCM-2 to recognize the current

output shaft position as the 100% position.

SET POS 0%

Calibrates the DCM-2 to recognize the current

output shaft position as the 0% position.

SET DEM 100%

Calibrates the DCM-2 to recognize the

currently applied demand signal as the 100%

demand signal.

SET DEM 0%

Calibrates the DCM-2 to recognize the

currently applied demand signal as the 0%

demand signal.

Group 22

Quick Reference

MAINTENANCE

12

COMPONENT REPLACEMENT

The Group 22 was designed modularly for

ease of maintenance and parts replacement. The

individual components of the actuator are available

in replacement parts kits as detailed in the

replacement parts kits tables in this section. Each

replacement parts kit includes the component(s),

necessary hardware, and detailed instructions for

installation of the parts.

HOW TO ORDER SPARE PARTS

Any customer replacement kit may be

purchased for spare parts, however several kits

have been selected by the factory as recommended

spares. Contact your Beck Sales Engineer for

questions regarding recommended replacement

parts particular to your application. Parts may be

ordered by mail, telephone, fax or e-mail, with the

confirming order sent to the factory.

ROUTINE MAINTENANCE

Beck drives require only a minimum of routine

maintenance. At regular plant maintenance

intervals, a visual inspection is recommended to

verify that the connection to the final control element

is intact and operating normally. If vibration is

present, check the electrical terminal connections

and other hardware for tightness. Check the

conduit seals for any moisture penetration and

reseal if necessary.

LUBRICATION

The Group 22 control drive has a grease

filled gear housing, so periodic lubrication is not

required. However, to extend the life of the linkage,

rod ends should be lubricated periodically.

GASKETS

During routine service, inspect the cover

gaskets for wear or damage. In order to protect

internal components, worn or damaged gaskets

and O-rings should be replaced.

To remove, scrape all of the old adhesive and

gasket material from the body housing and cover.

Cement the new gasket to the drive body using

a gasket cement such as 3M #847 Rubber and

Gasket Adhesive, or equivalent.

MOTOR

The motor assembly is not field-repairable and

is intended to last for the lifetime of the actuator.

Disassembly of the motor will result in a loss of

torque that can only be restored by returning the

motor to the factory for re-magnetizing.

If you suspect a motor problem, contact the

factory for assistance.

CAUTION

Before removing the control motor, block

the control drive crank arm to prevent the

crank arm and the gear train from moving

when the motor is removed. Failure to do

so can cause damage to equipment and

serious injury or death.

RECOMMENDED REPLACEMENT PARTS KITS

Applicable Model

Replacement Kit 22-309 22-409 22-809 KIT P/N

Control End Assembly X X X 12-8061-05

DCM Replacement (1-phase) X 12-8061-75

(DCM-2 p/n 12-8224-41)

DCM Replacement (1-phase) CE rating X 12-8061-78

(DCM-2 p/n 12-8224-45)

DCM Replacement (3-phase) X X 12-8061-85

(DCM-2 p/n 12-8224-51)

DCM Replacement (3-phase) CE rating X X 12-8061-88

(DCM-2 p/n 12-8224-55)

Gasket Set X X 12-8061-09

Gasket Set X 12-8061-29

Fuse Kit - 8 Amps

22-309 (120 VAC 1-phase ) & 22-409 (208 VAC 3-phase) X X 12-8061-53

*Fuse Kit - 8 Amps DCM & 4 Amps - input

380, 416, 480, 575 VAC ( 3-phase ) X12-8061-52

*Fuse Kit - 8 Amps DCM & 10 Amps - input

208, 240 VAC ( 3-phase ) X12-8061-51

* Select the proper Fuse Kit based on your actuator operating voltage.

Group 22

Quick Reference

13

3

2

1

Power

Ground

Transient

Protector

Assembly

(22-409)

3

2

1

Power

Ground

Transient

Protector

Assembly

(22-309)

Transient

Protector

Assembly

(22-809)

Power

Ground

GROUP 22 TRANSIENT PROTECTION

OTHER AVAILABLE REPLACEMENT PARTS KITS

Applicable Model

Replacement Kit 22-309 22-409 22-809 KIT P/N

CPS-4 Switch Assembly X X X 12-8061-06

CPS-4 P.C. Board X X X 12-8061-07

CPS-4 Coupling X X X 12-8061-08

Mounting Shim Set X X X 12-8061-11

Handswitch Assembly X X X 12-8061-12

Capacitor X 12-8061-14

Motor X X 12-8061-01

Handwheel / Dampener X X 12-8061-02

Self Locking Mechanism Rebuild X X 12-8061-69

Motor w/ Hand crank Assembly Replacement X 12-8061-20

Handwheel / Dampener X 12-8061-22

Self Locking Mechanism Rebuild X 12-8061-23

Hand crank Assembly X 12-8061-27

Service Screw Set X X 12-8061-10

Service Screw Set X 12-8061-30

*Fuse Kit - 8 Amps-DCM, & 4 Amps - input

240 VAC ( 1-phase ) X 12-8061-50

Optional Transformer fuse (9 A - 208 VAC) (3 required) X X 11-1372-10

Optional Transformer fuse (8 A - 240 VAC) (3 required) X X 11-1372-09

Optional Transformer fuse (4 A - 380 VAC) (3 required) X X 11-1372-06

Optional Transformer fuse (4 A - 416 VAC) (3 required) X X 11-1372-06

Optional Transformer fuse (4 A - 480 VAC) (3 required) X X 11-1372-06

Optional Transformer fuse (3.5 A - 575 VAC) (3 required) X X 11-1372-08

**Transient Protector (120 VAC, 1-phase) X 12-8061-44

**Transient Protector (240 VAC, 1-phase) X 12-8061-42

**Transient Protector (208 VAC, 3-phase) X 12-8061-43

**Transient Protector (208 VAC, 3-phase) X 12-8061-45

**Transient Protector (240 VAC, 3-phase) X 12-8061-46

**Transient Protector (380 VAC, 3-phase) X 12-8061-54

**Transient Protector (416 VAC, 3-phase) X 12-8061-55

**Transient Protector (480 VAC, 3-phase) X 12-8061-47

**Transient Protector (575 VAC, 3-phase) X 12-8061-48

** Select the proper Transient Protector Kit based on your actuator operating voltage.

Group 22

Quick Reference

TROUBLESHOOTING

14

CPS-4 TESTPOINTS

R

10

1

1

FWD

STAT

REV

PWR

SERIAL

PORT

TP1

CALIBRATE

SET POS

100%

SET POS

0%

SET DEM

100%

SET DEM

0%

DEMAND

POSITION

TORQUE

STALL

TEMP °F

FB OPEN

UVOLT

ACKNOWLEDGE

J3 J3A J3B

J5

INPUT

RESISTOR

R11

TP3

TP2

TP4

STATUS

INDICATION

LEDs

OVERVIEW

LEDs

DCM-2 TESTPOINTS

WHERE DO I START?

The Group 22 actuator was designed so the

user can quickly diagnose any actuator status

conditions causing an interruption in operation.

By removing the DCM compartment cover to

access the DCM-2, you can view the overview

and status indication LEDs. These LEDs provide

an efficient means of determining the actuator

problem, in many cases without the need for

metering equipment.

The following matrix lists some of the potential

conditions that a user may experience when

troubleshooting.

DCM-2

The DCM-2 board is the control center of the

drive. Drive configuration and calibration are

accessed and set through the DCM-2 board. The

DCM-2 has the overview and status indication

LEDs that indicate status and alarm conditions.

More advanced troubleshooting features may

be accessed via HART or serial connection (see

respective appendixes in this manual). Reference

Menu 8, Diagnostics menu, for troubleshooting

with HART and for serial port troubleshooting use

the diagnostic commands featured in the serial

port appendix.

The DCM-2 performs an error based positioning

function. It accepts a demand signal, compares it

to an internal position feedback voltage provided

by the CPS-4, and controls the motor to correct for

a difference. The DCM-2 includes four test points

for measuring the demand and internal position

signal voltages at the DCM-2. The demand

signal should measure 1-5 volts DC across test

points TP3 (-) and TP2 (+), proportional to the

4-20 mA demand input signal. The raw position

signal should measure approximately 1.3 to 3.7

volts DC across test points TP4 (+) and TP1 (-),

proportional to the output shaft’s 0-100 degree

position (shaft position can be determined by

viewing the mechanical index).

CPS-4

The output voltage of the CPS-4 ranges from

1.3 to 3.7 volts DC for 100° drive shaft rotation.

This can be measured across CPS-4 test points

TP3(+) and TP1(-). If the position signal is outside

the anticipated range, the “STAT” and “POSITION”

LEDs will light, and contacts at terminals 12 &

13 will open if the PositionLOS alarm mask bit

is ON (default state). When the Position signal

is corrected, the drive will automatically resume

normal operation. The 5 volts DC CPS-4 power

supply can be measured across test points TP2(+)

and TP1(-).

Group 22

Quick Reference

15

CONDITIONS POSSIBLE CAUSES CORRECTIONS

1. No DCM-2 LEDs are

illuminated.

a. No power is applied to the

actuator.

b. Incorrect power is applied to the

actuator.

c. Main power fuse/breaker is

blown.

d. DCM-2 malfunction.

a. Apply operating voltage to the

operating voltage terminals.

b. Verify correct voltage on actuator

nameplate and ensure that it is

applied at the operating voltage

terminals.

c. Verify fuse/breaker integrity. Replace/

reset if blown. Find cause of the

short circuit.

d. Replace DCM-2.

2. STAT LED is illuminated. a. A status alarm is active. a. Check the status indication LEDs on

the local pushbutton interface of the

DCM-2. Continue troubleshooting

based on the LEDs that are

illuminated.

3. DEMAND LED is

illuminated.

a. No demand signal.

b. Applied demand signal is outside

of configured range.

c. Polarity of applied signal wires is

reversed.

a. Apply a demand signal to terminals 14

(-) & 15 (+).

b. Confirm demand signal value via

HART or by measuring DC voltage

across DCM-2 test points TP3(+) &

TP2(-). Should see 1-5 volts for 4-20

mA applied signal.

c. Correct the polarity of the applied

control signal wires on terminals 14

(-) & 15 (+).

4. POSITION LED is

illuminated.

a. Position signal voltage generated

by CPS-4 read by the DCM-2 is

outside of the configured range.

b. CPS-4 malfunction.

c. DCM-2 malfunction.

a. Using HART communicator check the

Position Sensor Setup menu to verify

the Present CPS voltage falls within

the configured CPS Zero% and Span

(typical range 1.3 to 3.7 volts). OR

measure DC volts between DCM-2

test points TP4 (+) and TP1 (-) to

verify present CPS voltage. If the

voltage is outside of the configured

range, replace control end.

b. Replace control end.

c. Replace DCM-2.

5. TORQUE LED is

illuminated.

a. Torque exceeding configured

limit (typically over 105% of

rated torque) is being applied to

the output shaft.

b. Torque Null and Torque Constant

values are not set correctly.

c. Torque cable is not connected to

DCM-2.

a. Eliminate cause of excessive torque

(i.e. binding damper, improper

linkage, etc.)

b. Locate torque null and constant values

inside DCM compartment and set via

HART or serial port.

c. Reconnect torque cable to DCM-2.

6. STALL LED is illuminated. a. Actuator has been energizing

either the FWD or REV motor

winding longer than the

configured stall timer due to a

physical obstruction.

b. The configured stall time is less

than the configured Max Travel

Time.

a. Eliminate the obstruction and reset the

stall by reversing direction on your

demand signal, cycling the power, or

issuing the stall reset from HART or

serial command.

b. Configure the stall time to exceed the

Max Travel Time via HART or serial

command.

7. TEMP F LED is illuminated. a. The measured temperature at

the DCM-2 is outside of the

normal operating range of -40°

to 185° Fahrenheit.

a. Protect the actuator from the extreme

temperatures below or above the

operating range to eliminate the

alarm.

80-4280-02

Rev. 05.3

TROUBLESHOOTING

16

CONDITIONS POSSIBLE CAUSES CORRECTIONS

8. FB OPEN LED is illuminated. a. The position feedback circuit

current loop is not complete.

b. The position feedback is

enabled, but not in use.

a. Ensure the device measuring the

4-20 mA feedback is properly

terminated on terminals 16 (-)

and 17 (+) and is applying a 0 -

800 ohm load resistance.

b. Disable feedback via HART or

serial command. OR terminate

the feedback loop by applying

a 0 - 800 ohm load resistance

across terminals 16 and 17.

9. UVOLT LED is illuminated. a. The applied operating voltage is

outside of the tolerance (+10%/-

15%) of the nameplate operating

voltage.

b. A DCM-2 fuse is open. (or

primary transformer fuse on 22-

809 is open)

c. A component failure has

occurred on the DCM-2.

a. Apply the correct operating

voltage to the actuator per

the voltage stamped on the

nameplate.

b. Replace the open fuse with

the appropriate fuse kit; check

page 17 or 19 to identify the

appropriate kit for your drive.

c. Replace the DCM-2.

10. All LEDs are illuminated or

flashing.

a. A component failure has

occurred on the DCM-2.

a. Replace the DCM-2.

11. The actuator will only move at

a very slow speed when using

the handswitch or override

terminals.

a. The DCM-2 does not detect a

valid position signal from the

CPS-4.

b. The drive max travel time is

set to a high value (maximum

allowable time is 300 seconds).

a. Verify CPS-4 cable connections,

check CPS-4 raw position

voltage test points TP3 and TP1

for 1.3 - 3.7 volts DC, check

CPS-4 power supply test points

TP2 and TP1 for 5 volts DC, and

replace control end if necessary.

b. Adjust max travel time via HART

or serial closer to the minimum

(30 seconds for 22-309 and 15

seconds for 22-409/22-809).

12. FWD or REV LED illuminated,

drive is not moving, and there

are no other status alarms.

a. Handswitch is in the STOP

position.

b. CW or CCW limit switch is open.

a. Place the handswitch in the

AUTO position.

b. Verify if the limit switch is set

outside of the electrically

calibrated limits, readjust if

necessary or replace.

13. Drive runs uncontrolled to one

end of travel.

a. The CPS-4 is malfunctioning.

b. The DCM-2 is malfunctioning.

a. Verify CPS-4 cable connections,

check CPS-4 raw position

voltage test points TP3 and TP1

for 1.3 - 3.7 volts DC, check

CPS-4 power supply test points

TP2 and TP1 for 5 volts DC, and

replace control end if necessary.

b. Verify the raw position signal

seen by the DCM-2 at test points

TP4 and TP1 for 1.3 - 3.7 volts

DC. If valid signal is measured,

replace DCM-2.

14. Drive will not hold position with

handswitch in STOP.

a. Self Locking Mechanism (SLM)

is damaged.

a. Rebuild the SLM assembly.

80-4280-02

Rev. 05.3

17

CONDITIONS POSSIBLE CAUSES CORRECTIONS

15. Actuator has a flashing PWR

LED on, but does not respond to

demand signal, handswitch, or

override terminals.

a. The emergency override STOP

terminal (21) is connected to the

common terminal (18).

b. The safety shutoff circuit is

damaged

c. The handswitch is damaged.

a. Remove the connection from

terminal 21 to terminal 18.

b. Contact the factory.

c. Replace the handswitch.

16. HART communications cannot

be established with the DCM-2.

a. The device description (DD) file

is not installed.

b. The HART communicator is

not compatible with Beck

equipment.

c. The HART communications

circuit on the DCM-2 is

damaged.

a. Install the Beck MK-2 DD on your

HART device.

b. Utilize a compatible HART

communicator or configure the

actuator through the serial port.

c. Replace the DCM-2.

17. Present CPS voltage appears to

be within the configured range,

but the position feedback signal

at terminals 16 and 17 remains

constant or is erratic.

a. The position feedback circuit on

the DCM-2 is damaged.

a. Replace the DCM-2.

18. Power LED is pulsing bright to

dim.

a. This is a normal condition

indicating that the processor is

functioning.

a. No action required.

19. Actuator output shaft rotates

opposite of the desired direction

when applying a 4-20 mA

demand signal.

a. The rotation direction is

incorrectly configured.

a. Configure the rotation direction

using pushbutton, HART, or

serial method. (page 30)

Group 22

Quick Reference

APPENDIX - HART

HART DEVICE DESCRIPTION (DD) MENU STRUCTURE

18

1 Functions LINK TO MENU 2

2 Position 0.0%–100.0%

3 Demand 0.0%–100.0%

4 Loop(Dem) 4.00–20.00 mA

5 Trq/Thrust Percentage

6 Temp °F. or °C.

7 Feedback 4.00–20.00 mA

FROM MENU 1

1 Setup Checklist LINK TO MENU 3

2 Device Information LINK TO MENU 4

3 Configuration LINK TO MENU 5

4 Statistics LINK TO MENU 6

5 Manual Operation LINK TO MENU 7

6 Diagnostics LINK TO MENU 8

7 Calibration Trim LINK TO MENU 9

FROM MENU 2

FROM MENU 2

1 Tag* Alphanumeric

2 Descriptor* Alphanumeric

3 Message* Alphanumeric

4 Model# Actuator model no.

5 Drive S/N* Number

6 Instld* Date–DD/MM/YYYY

7 Setup* Date–DD/MM/YYYY

8 Calibrtd* Date–DD/MM/YYYY

9 Review LINK TO MENU 15

10 Poll Addr* Integer

FROM MENU 4

FROM MENU 2

1 Starts Integer

2 Reversals Integer

3 Stalls Integer

4 OverTorques Integer

5 Pk Torque Percentage

6 TotRunTm Seconds

7 High Temp Degrees

8 Low Temp Degrees

FROM MENU 2

1 Op Mode* Follow, Hold, Stay, Stop

2 Demand* Percentage

3 Reset Stall» Action

FROM MENU 2

1 PresCPS V* Voltage

2 Loop(Dem)* 4.00 mA, 20.00 mA

3 Feedback* mA

4 Trq/Thrust* Percentage

MENU 2 - FUNCTIONS

MENU 3 - SETUP CHECKLIST

MENU 4 - DEVICE INFORMATION

MENU 6 - STATISTICS

The review menu allows the user to view many

parameters in a read-only format.

MENU 15 - REVIEW

MENU 7 - MANUAL OPERATION

The setup checklist gathers some of the more commonly accessed

parameters and settings in one location for ease of access. All items

in this menu are accessible through the categorized menus that follow.

MENU 1 - ONLINE

MENU 9 - CALIBRATION TRIM

FROM MENU 2

1 General Setup LINK TO MENU 5A

2 PositionSensrSetup LINK TO MENU 5B

3 Demand Setup LINK TO MENU 5C

4 Feedback Setup LINK TO MENU 5D

5 Torque Setup LINK TO MENU 5E

6 Restore to Factory» Action

7 Use Default Setup» Action

FROM MENU 5

1 Drive Dir* CW Incr or CCW Incr

2 Max Travel* Degrees

3 Travel* Degrees

4 StepSize* 0.100%–2.500%

5 Stall Time* 30–300 (seconds)

6 StallProt* Enabled or Disabled

7 LimitSwitch* Accept or Alert

8 PositionUnit* Degrees

9 Temperature Unit* degF or degC

10 Max Freq* Hertz

11 MaxTravelTm* Seconds

12 Power* 1-phase / 3-phase

FROM MENU 5

1 Set Pos 0%» Action

2 Set Pos 100%» Action

3 PresCPS V Voltage

4 CPS Zero%* 1.000–5.000 v

5 CPS Span Voltage

6 CPS RngLwr Voltage

7 CPS RngUpr Voltage

8 Pos S/N* Number

9 Snsr Dir CW Incr or CCW Incr

FROM MENU 5

1 DemRngLwr* 4.00–16.00 mA

2 DemRngUpr* 8.00–20.00 mA

3 Dem Curve* Linear, Square, Square Root,

Special

4 Dem Curve Spcl LINK TO MENU 14

5 LOS Mode* Stay or Go-to-Pos

6 LOS Pos* -5.00%–105.00%

7 DemLimLwr* 0.00–12.00 mA

8 DemLimUpr* mA

FROM MENU 5C

1 DemNode1X* Percentage

2 DemNode1Y* Percentage

3 DemNode 2X* Percentage

4 DemNode 2Y* Percentage

. . .

41 DemNode21X* Percentage

42 DemNode21Y* Percentage

FROM MENU 5

1 FB RngLwr* 3.00–16.00 mA

2 FB RngUpr* 7.00–21.00 mA

3 Feedback* Enabled or Disabled

4 FB Curve* Linear or InvDem

FROM MENU 5

1 Trq/Thrust* Enabled or Disabled

2 Ovt Prot* Enabled or Disabled

3 AlarmLevel* Percentage

4 ShutDwnTrq* Percentage

5 Trq Null* Integer

6 Trq Const* Integer

MENU 5 - CONFIGURATION

MENU 14 - DEM CURVE SPECIAL

MENU 5D - FEEDBACK SETUP

MENU 5E - TORQUE SETUP

MENU 5A - GENERAL SETUP

MENU 5B - POSITION SENSOR SETUP

MENU 5C - DEMAND SETUP

Group 22

Quick Reference

19

DIAGNOSTICS

FROM MENU 2

1 Status LINK TO MENU 8A

2 Tests LINK TO MENU 10

3 CW Torque LINK TO MENU 11

4 CCW Torque LINK TO MENU 11

5 Alarm Setup LINK TO MENU 12

6 RealTimeClock LINK TO MENU 13

FROM MENU 8

1 LED Status LINK TO MENU 8B

2 Operating Status LINK TO MENU 8C

3 Switch Status LINK TO MENU 8D

4 Local Cntrl Status LINK TO MENU 8E

5 Line Freq Hertz

6 CW Inhibitors (1) LINK TO MENU 8F

7 CCW Inhibitors (1) LINK TO MENU 8F

8 CW Inhibitors (2) LINK TO MENU 8G

9 CCW Inhibitors (2) LINK TO MENU 8G

10 DC Volts Bus Voltage

11 PresFreq Motor Frequency

FROM MENU 8A

1 Status ON or OFF

2 Reverse ON or OFF

3 Forward ON or OFF

4 Demand ON or OFF

5 Position ON or OFF

6 Trq/Thrust ON or OFF

7 Stall ON or OFF

8 Temperature ON or OFF

9 FB Open ON or OFF

10 Uvolt ON or OFF

11 Acknowledge ON or OFF

FROM MENU 8A

1 Dem <> Limits ON or OFF

2 Pos <> Limits ON or OFF

3 Temp <> Limits ON or OFF

4 Torq <> Limits ON or OFF

5 Over-Torq Stop ON or OFF

6 Stalled ON or OFF

7 Feedback Open ON or OFF

8 Low Volts AC ON or OFF

FROM MENU 8A

1 Limit CCW ON or OFF

2 Limit CW ON or OFF

3 OvrRd CCW ON or OFF

4 OvrRd CW ON or OFF

5 OvrRd STOP ON or OFF

6 HndSw CCW ON or OFF

7 HndSw CW ON or OFF

8 HndSw AUTO ON or OFF

FROM MENU 8A

1 Calibrate ON or OFF

2 Set Pos 100% ON or OFF

3 Set Pos 0% ON or OFF

4 Set Dem 100% ON or OFF

5 Set Dem 0% ON or OFF

FROM MENU 8A

1 Balance ON or OFF

2 Supervisory ON or OFF

3 Stall ON or OFF

4 OverTrq/Thr ON or OFF

5 Switch Block ON or OFF

6 Bad Pos Sig ON or OFF

7 Bad Dem Sig ON or OFF

8 Local Cal ON or OFF

FROM MENU 8A

1 Inh 1 ON or OFF

2 Ovrd ON or OFF

3 LimSw ON or OFF

4 HndSw ON or OFF

MENU 8 - DIAGNOSTICS

MENU 8F - CW & CCW INHIBITOR (1)

MENU 8G - CW & CCW INHIBITOR (2)

MENU 8A - STATUS

MENU 8B - LED STATUS

MENU 8C - OPERATING STATUS

MENU 8D - SWITCH STATUS

MENU 8E - LOCAL CONTROL STATUS

FROM MENU 8

1 FB Out Test» Action

2 Board Self-Test» Action

3 Identify Device» Action

4 Board Reset» Action

FROM MENU 8

1 Segment 1 Percentage

2 Segment 2 Percentage

. . .

10 Segment 10 Percentage

FROM MENU 8

1 AlarmPol* Drops Out or Pulls In

2 Alarm Mask LINK TO MENU 12A

FROM MENU 12

1 DemandLOS* ON or OFF

2 Trq/Thrust High* ON or OFF

3 Stall* ON or OFF

4 Trq/Thrust Stop* ON or OFF

5 Stop/Limit* ON or OFF

6 FeedbackLOS* ON or OFF

7 Temperature* ON or OFF

8 PositionLOS* ON or OFF

9 RTC Fail* ON or OFF

10 Torq/Thrust/MeasFail* ON or OFF

11 PositionA/D Error* ON or OFF

12 Demand/MeasFail* ON or OFF

13 Reserved 1* ON or OFF

14 PositionLOS* ON or OFF

15 TemperatureMeasFail* ON or OFF

16 MemoryFail* ON or OFF

17 InvalButtonPress* ON or OFF

18 DemandTooHigh* ON or OFF

19 DemUnderHART/FF Ctl* ON or OFF

20 DemUnderPAT Ctl* ON or OFF

FROM MENU 8

1 RTC Day* Integer

2 RTC Month* Integer

3 RTC Year* Integer

4 Hour (24)* Integer

5 Minute* Integer

Previous Menu

1 Parameter Range / Units / Info.

* Parameter names marked with an asterisk indicate that the value may be edited.

... Indicates that the menu is longer than shown

S

AMPLE MENU BL

OC

K F

O

RMAT

MENU # - MENU DESCRIPTION

» Parameter names marked with a double arrow indicate that the menu item

performs a function.

MENU 10 - TESTS

MENU 11 - CW TORQUE / CCW TORQUE

MENU 12 - ALARM SETUP

MENU 12A - ALARM MASK

MENU 13 - REAL TIME CLOCK

This manual suits for next models

3

Other Beck Controllers manuals