RFT9709 Transmitter Instruction Manual

iii

Table of Contents

continued

Tables

Table 2-1 Sensor-wiring terminal designations. . . . . . . . . 13

Table 2-2 Output-wiring terminal designations . . . . . . . . . 17

Table 2-3 Sensors affected by pressure. . . . . . . . . . . . . . 24

Table 3-1 Parameters that affect event registers . . . . . . . 29

Table 4-1 Conditions indicated by diagnostic LED . . . . . . 32

Table 4-2 Normal resistance for flowmeter circuits. . . . . . 36

Table 4-3 Input and output ratings . . . . . . . . . . . . . . . . . . 36

Table 4-4 Default values after a master reset. . . . . . . . . . 38

Table A Performance specifications. . . . . . . . . . . . . . . . 39

Table B RFT9709 model number matrix . . . . . . . . . . . . 45

Table C-1 Communications configuration . . . . . . . . . . . . . 48

Table C-2 Security modes. . . . . . . . . . . . . . . . . . . . . . . . . 49

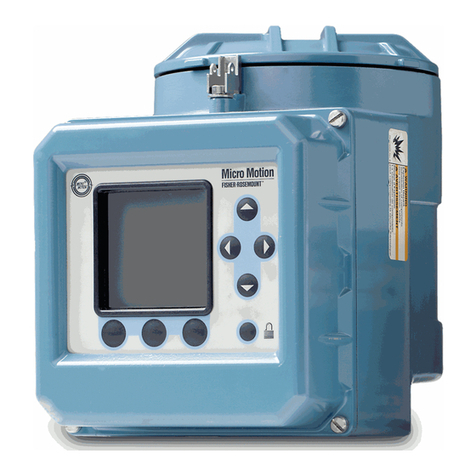

Figures RFT9709 components . . . . . . . . . . . . . . . . . . . 2

Figure 1-1 RFT9709 approvals tag . . . . . . . . . . . . . . . . . . 3

Figure 1-2 RFT9709 dimensions . . . . . . . . . . . . . . . . . . . . 4

Figure 1-3 Factory-supplied NEMA-housing dimensions. . 6

Figure 2-1 RFT9709 wiring terminals. . . . . . . . . . . . . . . . . 7

Figure 2-2 Power-supply wiring and grounding

connections . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2-3 Cable types. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-4 Terminating flowmeter cable. . . . . . . . . . . . . . . 10

Figure 2-5 RFT9709 terminals for sensor wiring . . . . . . . . 13

Figure 2-6 Wiring to ELITE®CMF sensors . . . . . . . . . . . . 14

Figure 2-7 Wiring to BASIS®F, Model D, and

DL sensors. . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 2-8 Wiring to Model DT sensors . . . . . . . . . . . . . . . 16

Figure 2-9 Terminating output-wiring shields and drains. . 17

Figure 2-10 mA output terminals . . . . . . . . . . . . . . . . . . . . . 18

Figure 2-11 Typical HART®network wiring . . . . . . . . . . . . . 19

Figure 2-12 RS-485 wiring. . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-13 Frequency/pulse output terminals. . . . . . . . . . . 21

Figure 2-14 Control output terminals . . . . . . . . . . . . . . . . . . 22

Figure 2-15 Remote-zero switch wiring . . . . . . . . . . . . . . . . 23

Figure 2-16a Pressure transmitter wiring, internally

powered . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 2-16b Pressure transmitter wiring, externally powered

(multidrop network) . . . . . . . . . . . . . . . . . . 25

Figure 3-1 Diagnostic LED and zero button. . . . . . . . . . . . 27

Figure 4-1 Diagnostic LED. . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 4-2 ProLink®PC-Interface connections . . . . . . . . . 34

Figure 4-3 Power-supply wiring and grounding terminals . 35

Figure C-1 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure C-2 Diagnostic LED and zero button. . . . . . . . . . . . 51

Figure D-1 Configuring open collector mode . . . . . . . . . . . 53

09__a.TOC Page iii Monday, March 1, 1999 4:20 PM