MICRO-TRAK 8000 FA MANUAL VER 2.0

The Micro-Trak 8000 FA is a frequency agile and programmable miniature APRS (Automatic Position

Reporting System) transmitter capable of operating from 144 to 148 MHz. (foreign and gornmental agencies

may contact us to discuss out of band operation, but the Micro-Trak products are not FCC certified for use

outside the ham bands in the United States) The transmitter utilizes a special version of the TinyTrak3

controller and is not compatible with any other version of TinyTrak firmware or config software. The entire

assembly measures only 1 X 4.5 inches, and weighs less than two ounces. The Micro-Trak 8000 FA is a

creation of VHS Products, and is distributed exclusively by Byonics at http://www.byonics.com

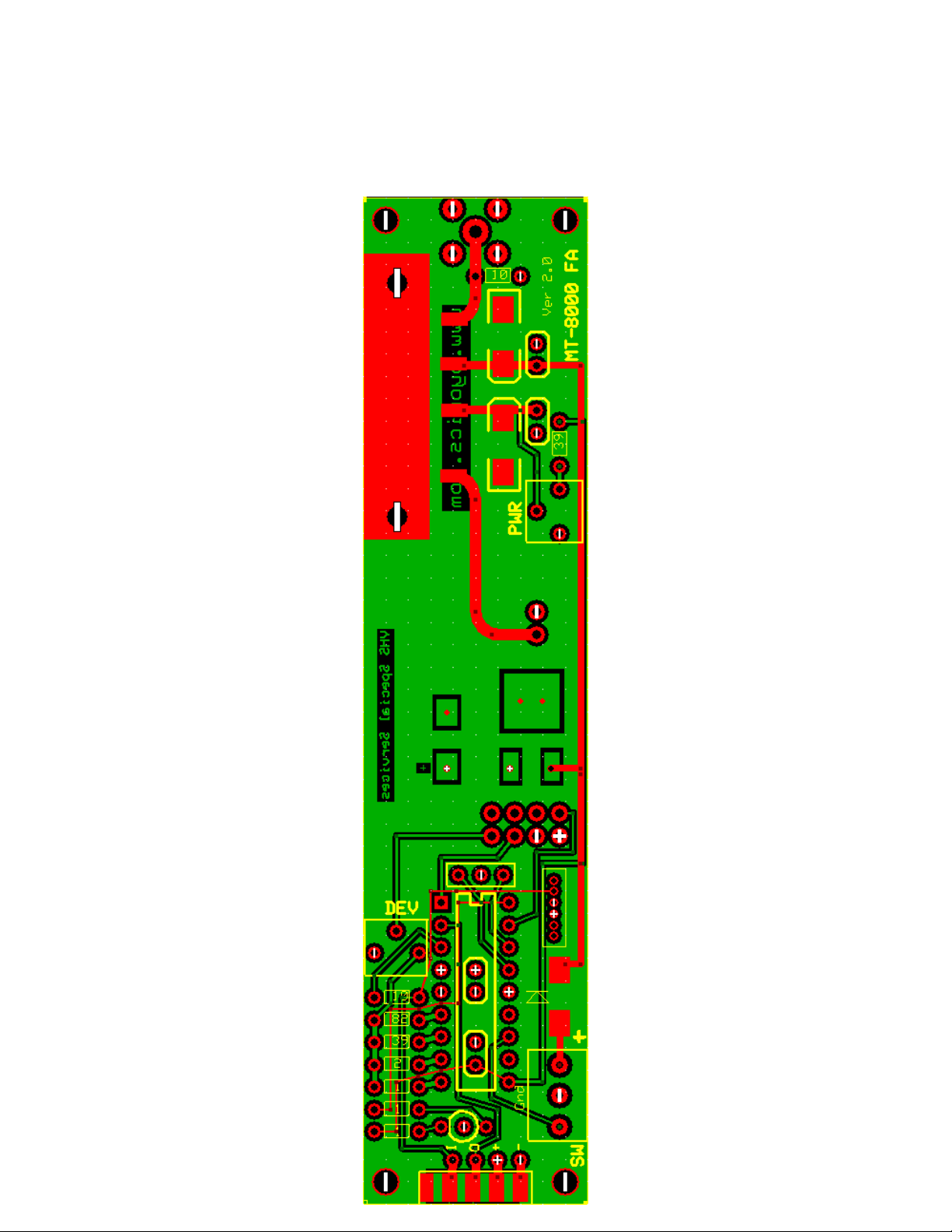

The MT-8000 FA is extremely compact

and light, due in part to the enclosed RF

section. The Micro-Trak 8000 FA is

provided as a fully assembled and

populated printed circuit board assembly.

Completion and operation of the device

will require simple programming, and

providing power, antenna, and a GPS

input. The Micro-Trak 8000 FA is shipped

wired and tested, but should be adjusted

by the user for the desired output power.

The power output may be adjusted with a trimmer potentiometer located on the printed circuit board’s amplifier

section. This version of the Micro-Trak 8000 FA has been provided with an external, user adjustable deviation

control, which should ordinarily be left rotated completely clockwise. Certain areas (Europe, etc.) may have

digipeaters that prefer a slightly more narrow-band deviation level. Using a receiver, you can set your deviation

level to the approximate deviation of users in your area.

Because of its small size and light weight, the MT-8000 FA is ideal for portable and airborne operations. Small

size not withstanding, the Micro-Trak 8000 FA is capable of power output in excess of 8 Watts, and is capable

of operating at extremely long ranges. An on-board 5 volt regulator provides an optional 200 mA, power output

for your GPS receiver. (Many applications, including the use of the device with hand-held GPS units, will not

require the 5 volt output of the Micro-Track.) The entire system runs well on 9-13.2 volts DC, and draws only

about 15 milliamps in standby, and increases to 1.7 amperes during transmissions (which last approximately

1/3 of a second using MIC-E) when set for full power operation. The Micro-Trak 8000 has easily adjustable

power settings for responsible and energy saving operation. The Micro-Trak utilizes a combination green/red

LED: green LED for the green GPS detector light and red LED transmit light.

No case or package is provided with the Micro-Trak 8000 FA, allowing the user to package the device

according to their own unique needs. The design philosophy called for as small, light and basic a package as

possible, with a high enough output for more critical and remote operations. The programming and GPS input

connection is set up to use a DB9 Male connector (The same as a standard TinyTrak 3) by simply sliding the

connector over the tabs, soldering may be required for a good connection. The Micro-Trak can connect to a

standard GPS receiver directly through the DB9 connector, but it is important to remember that computer

programming and communication uses a reversed connection, meaning you will need a female to female null

modem cable, or a null modem adaptor and a gender-changer connector for programming your Micro-Trak.

These cables and/or connectors are available from Byonics. A 6 pin 1 mm style connector is mounted on the