Microcyber NCS-MH105 User manual

NCS-MH105 Converter

User Manual

V1.5

Microcyber Inc.

I

Content

1Overview...................................................................................................................................1

2Performance Parameter.............................................................................................................2

3Structure and Working Principle...............................................................................................3

4Installation and Usage...............................................................................................................3

4.1 MODBUS Parameter Setting....................................................................................4

4.1.1 Brief Operation Steps for SDC625 Parameter Setting......................................5

4.1.2 NCS-MH105 Converter Parameters..................................................................5

4.2 Menu Tree.................................................................................................................8

4.3 Parameter Setting......................................................................................................9

4.3.1 Process Variables..............................................................................................9

4.3.2 Diag/Service......................................................................................................9

4.3.2.1 Test Device................................................................................................9

4.3.2.1.1 Status.........................................................................................9

4.3.2.1.2 Selftest.....................................................................................10

4.3.2.1.3 Device Reset............................................................................12

4.3.2.2 Calibration...............................................................................................14

4.3.2.2.1 Re-range..................................................................................14

4.3.2.2.1.1 Range Values...................................................................14

4.3.2.2.1.2 Apply Values...................................................................16

4.3.2.2.2 Analog Output.........................................................................18

4.3.2.2.2.1 Loop Current Mode.........................................................18

4.3.2.2.2.2 Loop Test.........................................................................20

4.3.2.2.2.3 D/A Trim.........................................................................22

4.3.2.2.3 Sensor Trim.............................................................................26

4.3.2.2.4 Coils Trim ...............................................................................28

4.3.2.2.5 Register Trim...........................................................................32

4.3.2.2.6 Recall Factory Trim ................................................................36

4.3.2.2.6.1 Restore to Default Factory ..............................................36

4.3.2.2.6.2 Save as Factory................................................................38

4.3.2.2.6.3 Restore to Factory ...........................................................39

4.3.3 Basic Setup......................................................................................................41

4.3.3.1 Tag ..........................................................................................................41

4.3.3.2 Long tag ..................................................................................................42

4.3.3.3 PV Unit....................................................................................................43

4.3.3.4 PV Damp.................................................................................................44

4.3.3.5 Range Values ..........................................................................................45

4.3.3.6 Device Information .................................................................................48

II

4.3.4 Detailed Setup.................................................................................................49

4.3.4.1 Device Variable Assignments.................................................................49

4.3.4.1.1 PV Is........................................................................................49

4.3.4.1.2 SV Is........................................................................................51

4.3.4.1.3 TV Is........................................................................................51

4.3.4.1.4 QV is .......................................................................................51

4.3.4.2 Sensors....................................................................................................51

4.3.4.2.1 Device Variable 0....................................................................52

4.3.4.2.1.1 Class................................................................................52

4.3.4.2.1.2 Unit..................................................................................53

4.3.4.2.1.3 USL.................................................................................54

4.3.4.2.1.4 LSL..................................................................................55

4.3.4.2.1.5 Min Span.........................................................................56

4.3.4.2.1.6 URV ................................................................................57

4.3.4.2.1.7 LRV.................................................................................58

4.3.4.2.2 Device Variable 1....................................................................60

4.3.4.2.3 Device Variable 2....................................................................60

4.3.4.2.4 Device Variable 3....................................................................60

4.3.4.2.5 Device Variable 4....................................................................60

4.3.4.2.6 Device Variable 5....................................................................60

4.3.4.3 Modbus....................................................................................................60

4.3.4.3.1 Modbus Variables ...................................................................60

4.3.4.3.1.1 Address............................................................................60

4.3.4.3.1.2 Baud Rate........................................................................61

4.3.4.3.1.3 Data Bits..........................................................................61

4.3.4.3.1.4 Parity ...............................................................................62

4.3.4.3.1.5 Stop Bits..........................................................................62

4.3.4.3.1.6 CRC Order.......................................................................63

4.3.4.3.1.7 Frame Idle Time..............................................................63

4.3.4.3.2 Device Status...........................................................................64

4.3.4.3.2.1 Device Status Register Address.......................................64

4.3.4.3.2.2 Device Status Bit Pattern.................................................65

4.3.4.3.3 PV RANGE.............................................................................65

4.3.4.3.3.1 PV Range Source.............................................................66

4.3.4.3.3.2 PV Range Option.............................................................66

4.3.4.3.3.3 Register Data Type..........................................................67

4.3.4.3.4 Device Variable 0....................................................................67

4.3.4.3.4.1 Default Unit.....................................................................68

III

4.3.4.3.4.2 MODBUS Function Code...............................................69

4.3.4.3.4.3 Register Address..............................................................69

4.3.4.3.4.4 Register Data Type..........................................................69

4.3.4.3.4.5 Scaling Factor..................................................................70

4.3.4.3.4.6 Upper Regsiter Address...................................................71

4.3.4.3.4.7 Lower Register Address..................................................72

4.3.4.3.5 Device Variable 1....................................................................72

4.3.4.3.6 Device Variable 2....................................................................72

4.3.4.3.7 Device Variable 3....................................................................72

4.3.4.3.8 Device Variable 4....................................................................72

4.3.4.3.9 Device Variable 5....................................................................72

4.3.4.4 Signal Condition......................................................................................73

4.3.4.4.1 PV LRV...................................................................................73

4.3.4.4.2 PV URV ..................................................................................74

4.3.4.4.3 PV Damp.................................................................................75

4.3.4.5 Output Condition.....................................................................................76

4.3.4.5.1 Analog Output.........................................................................76

4.3.4.5.1.1 Loop Current Mode.........................................................76

4.3.4.5.1.2 Loop Test.........................................................................77

4.3.4.5.1.3 D/A Trim.........................................................................79

4.3.4.5.2 HART Output..........................................................................83

4.3.4.5.2.1 Poll Address ....................................................................83

4.3.4.6 Operation Mode ......................................................................................85

4.3.4.7 Device Information .................................................................................85

4.3.5 Review ............................................................................................................86

5Fast Setting..............................................................................................................................91

6Device Diagnose and Maintenance.........................................................................................92

7Index 1 NCS-MH105 Converter Model Selection..................................................................93

1

1Overview

NCS-MH105 Converter is a new R&D converter between MODBUS-RTU protocol and HART

protocol. As MODBUS host, NCS-MH105 converter communicates with the device with

MODBUS-RTU communication function via RS485 interface, and it is able to convert the data in

the device to HART device variable output, supporting 4~20mA current output. NCS-MH105

converter is shown as Figure 1:

Figure 1 NCS-MH105 Converter

As a HART device, NCS-MH105 converter and PC can make up HART system via HART

modem. It is able to configure NCS-MH105 converter parameters via HART configuration

software, shown as Figure 2.

Figure 2 NCS-MH105 Converter System Connection

2

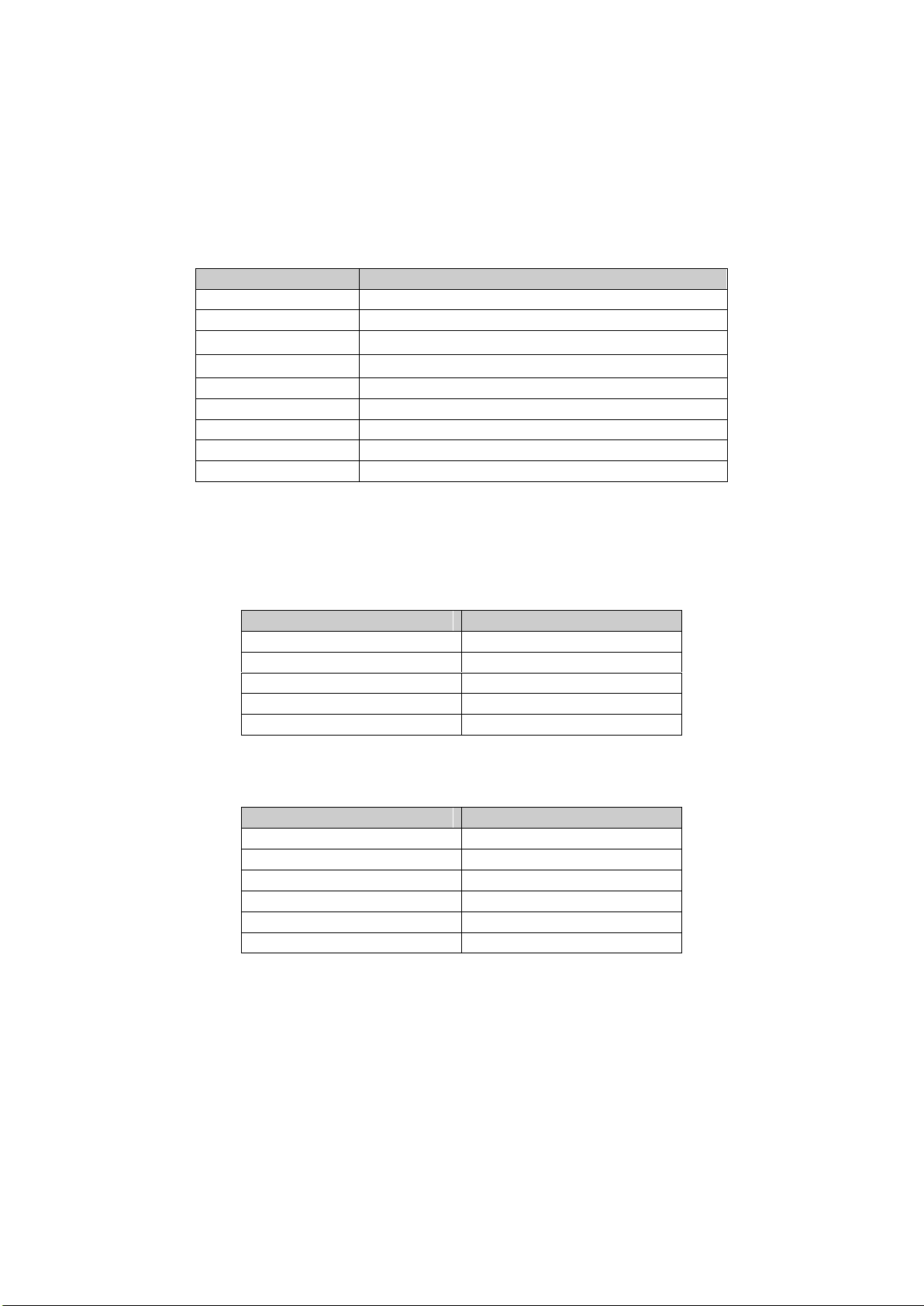

2Performance Parameter

NCS-MH105 Converter has powerful processing capacity, and the hardware parameters are shown

as following:

Parameter

Description

Bus Signal

4~20mA output with HART protocol digital communication

Bus Power

9~40V

Working Temperature

-40 ~85℃

Humidity Range

5% ~95%,non-dew

Mechanism Size

96mm ×56mm (can be customized)

CPU

M430F149

FLASH

60K

RAM

2K

EEPROM

2K

NCS-MH105 Converter and MODBUS device communicate via standard MODBUS-RTU

protocol. NCS-MH105 converter is used as master, and MODBUS device is used as slave. The

default communication parameters are shown as following:

Parameter

Default Value

Address

1

Baud Rate

9600

Data Bit

8

Stop Bit

1

CRC Calibration

low byte ahead

The MODBUS function codes supported by NCS-MH105 converter shown as following:

Function Code

Function

1

read loop status

2

read discrete input status

3

read keeping register value

4

read input register value

6

write loop

16

write multiple register values

3

3Structure and Working Principle

NCS-MH105 Converter supports 4 dynamic variables, 6 device variables. Via MODBUS register,

the data selected by MODBUS device is configured to NCS-MH105 Converter device variables,

and then it enters the mapping from device variable to dynamic variable, as the device output,

supporting 4~20mA analog signal output. NCS-MH105 Converter principle is shown as following

Figure 3:

MODBUS

REGISTER

MODBUS

Device

Configure Input Channel

Data Type

Register Addr

Unit

0

1

2

3

4

5

Device Variable

NCS-MH105 Converter

PV

SV

TV

QV

Dynamic Variable

Mapping from Device Variable to

Dynamic Variable

Control System

Process Varable

Analog

Channel

Process

Connection

Figure 3 NCS-MH105 Converter Principle

4Installation and Usage

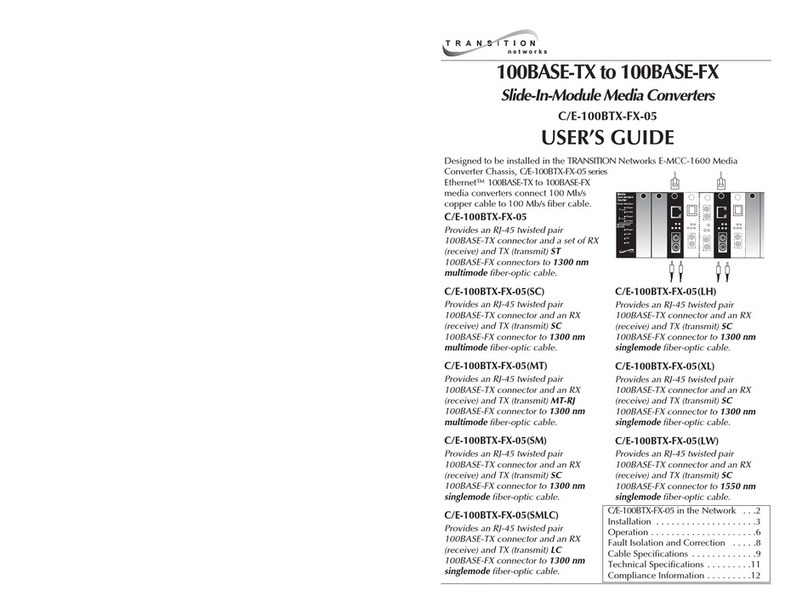

The mechanism size of NCS-MH105 converter is 96 mm*56 mm, which not only matches

standard Adam module housing, also can be installed to device through positioning hole, shown as

Figure 4.

4

Figure 4 NCS-MH105 Converter Wiring Connection Terminal

The wiring connection of NCS-MH105 converter is shown as following:

Terminal

Signal Name

J1-4

HART+

J1-5

HART-

J2-4

GND

J2-5

B-

J2-6

A+

J2-7

5V

J2-8

GND

HART Bus gives power supply to NCS-MH105 converter. RS485 electrical interface requires an

external 5V power supply. It is recommended to use twisted-pair with shield, which improves

device anti-electromagnetic capacity. According to the wiring method above, the system is

powered on, firstly, the system will be self-testing, which will carry out system initialization,

protocol initialization, etc., and then starts to work.

4.1 MODBUS Parameter Setting

MODBUS communication parameter of NCS-MH105 converter is carried out via SDC625

configuration software, shown as Figure 5:

5

Figure 5 NCS-MH105 Converter Parameter Displayed in Configuration Software

4.1.1 Brief Operation Steps for SDC625 Parameter Setting

1) Click the parameters to set twice, and get the configure image.

2) Input the parameter value to set.

3) Click Set, the parameters will be yellow.

4) Click Send in the Tool bar to configure.

4.1.2 NCS-MH105 Converter Parameters

Name

Description

Operation Mode

Operation Method

0x00, "Configuration Mode"

0x01, "Normal Operation Mode"

Address

MODBUS Address

1~255

Baud Rate

Baud Rate

0x00, "1200"

0x01, "2400"

0x02, "4800"

0x03, "9600"

0x04, "19200"

6

0x05, "35700"

0x06, "38400"

0x07, "57600"

Data Bits

Data Bits

0x00, "7 Data Bits"

0x01, "8 Data Bits"

Parity

Parity

0x00, "NONE"

0x01, "ODD"

0x02, "EVEN"

Physical Standard

Physical Standard

0x00, "RS232"

0x01, "RS485"

0x02, "RS422"

Stop Bits

Stop Bits

0x00, "1 Stop Bits"

0x01, "2 Stop Bits"

CRC Order

CRC Order

0x00, "Low-High order"

0x01, "High-Low order"

Frame Idle Time

Frame Idle Time

0x00, "4 Character Times"

0x01, "5 Character Times"

0x02, "6 Character Times"

0x03, "7 Character Times"

0x04, "8 Character Times"

0x05, "9 Character Times"

0x06, "10 Character Times"

Device Status Register Address

Device Status Register

0~65535

Device Status Bit Pattern

Device Status Register Usage

0x0000, " NONE "

0x0001, "1 Bit"

0x0003, "2 Bit"

0x0007, "3 Bit"

0x000F, "4 Bit"

0x001F, "5 Bit"

0x003F, "6 Bit"

0x007F, "7 Bit"

0x00FF, "8 Bit"

0x01FF, "9 Bit"

0x03FF, "10 Bit"

0x07FF, "11 Bit"

0x0FFF, "12 Bit"

0x1FFF, "13 Bit"

0x3FFF, "14 Bit"

0x7FFF, "15 Bit"

0xFFFF, "16 Bit"

PV Range Source

PV Range Source

0x00, "Local"

0x01, "Remote"

PV Range Option

PV Range Option

0x00, "Read and Write"

0x01, "Read Only"

Default Unit

Device Variable Default Unit

MODBUS Function Code

MODBUS Function Code used by Device Variable

0x03, "READ HOLDING REGISTERS"

0x04, "READ INPUT REGISTERS"

7

Register Data Type

MODBUS Register Data Type

0x00, "Undefine"

0x01, "Char 0"

0x02, "Char 1"

0x03, "Unsigned Char 0"

0x04, "Unsigned Char 1"

0x05, "Short 0 1"

0x06, "Short 1 0"

0x07, "Unsigned Short 0 1"

0x08, "Unsigned Short 1 0"

0x09, "Long 0 1 2 3"

0x0A, "Long 1 0 3 2"

0x0B, "Long 3 2 1 0"

0x0C, "Long 2 3 0 1"

0x0D, "Unsigned Long 0 1 2 3"

0x0E, "Unsigned Long 1 0 3 2"

0x0F, "Unsigned Long 3 2 1 0"

0x10, "Unsigned Long 2 3 0 1"

0x11, "Float 0 1 2 3"

0x12, "Float 1 0 3 2"

0x13, "Float 3 2 1 0"

0x14, "Float 2 3 0 1"

Upper Register Address

Upper Register Address of Device Variable

0~65535

Lower Register Address

Lower Register Address of Device Variable

0~65535

Register Address

Register Address of Device Variable

0~65535

Scaling Factor

Scaling Factor of Device Variable

Floating number

8

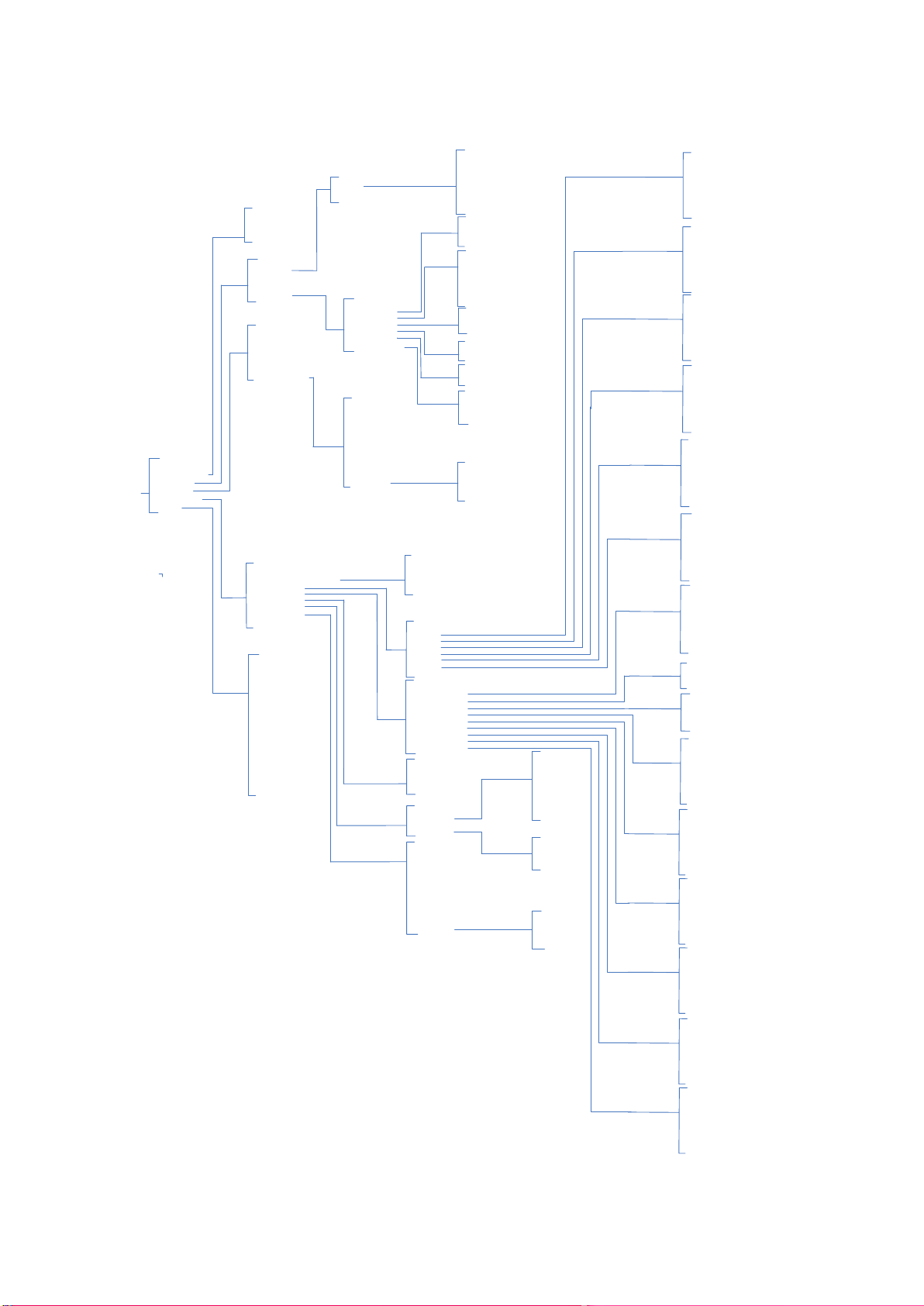

4.2 Menu Tree

1 Process Variables

2 Diag/Service

3 Basic Setup

4 Detailed Setup

5 Review

On line

1

Process Variables

1 PV

2 PV % rnge

3 PV LoopCurrent

4 Pv Range

1 Status

2 Test self

1 Test Device

2 Calibration

Diag/Service

2

Test Device

2-1 2-1-1

Calibration

1 Re-range

2 Anolog output

3 Sensor trim Sensor trim

2-4

2-4-1

Registers trim

2-4-4

1 Tag

2 Long Tag

3 Pv Unit

Basic Setup

3

Device information

5 Tag

6 Long Tag

7 Date

9 Descriptor

4 Cfg chng count

8 Write project

3-7

1 Device Variable Assignments

2 Sensors

3 MODBUS

4 Signal condition

Detailed Setup

Sensors

1 Device 0

4

4-1

1 MODBUS Variables

2 Device status

3 PV Range

Modbus

4-2

Signal Condition

2 PV URV

3 PV % rnge

4 PV Damp

1 PV LRV

4-3

1 Model

2 Manufaturer

3 Write project

4 Device id

Review

5

3 Device Test

1 Status group 0

2 Status group 1

3 Status group 2

4 Status group 3

5 Status group 4

6 Status group 5

7 Ext dev status

8 Operate mode 1

4 Coils trim

5 Registers trim

6 Recall factory trim

Re-range

1 Range Values

2 Apply Values

2-4-2 Anolog output

1 PV Loop current

2 PV Alrm typ

3 PV Channel flags

4 PV Xfer fnctn

5 Loop current mode

6 Loop test

7 D/A trim

2-4-3 1 Zero trim

1 Coils trim

Coils trim

2-4-5 1 Registers trim

2-4-6 Recall factory trim

2 Save as factory

1 Restore to default factory

3 Restore to factory

4 PV xfer fncnt

5 PV Damp

6 Range values

7 Device information

1 Manufacturer

2 Model

3 Dev id

10 Message

11 Final asmbly num

12 Revision #’s

Revision #’s

1 Universal rev

2 Fld dev rev

3 Software rev

3-7-12

5 Output condition

6 Device information

Device Variable Assignments

1 PV is

2 SV is

3 TV is

4 QV is

2 Device 1

3 Device 2

4 Device 3

5 Device 4

6 Device 5

7 Max dev vars

4 Device variable 0

5 Device variable 1

6 Device variable 2

7 Device variable 3

8 Device variable 4

9 Device variable 5

4-4

4-5 Output condition

1 Analog output

2 HART output

5 Tag

6 Long Tag

7 Date

9 Descriptor

4 Cfg chng count

8 Write project

1 Manufacturer

2 Model

3 Dev id

10 Message

11 Final asmbly num

12 Revision #’s

Revision #’s

1 Universal rev

2 Fld dev rev

3 Software rev

4-6

5 Cfg chng count

6 Max dev vars

7 Tag

8 Long tag

9 Descriptor

10 Message

11 Date

12 Final asmbly num

13 Universal rev

14 Fld dev rev

15 Software rev

16 Poll addr

17 Loop current mode

18 Num req preams

19 Num resp preams

Device 0

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

Device 1

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

Device 2

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

Device 3

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

Device 4

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

Device 5

1 Classe

2 Unit

3 USL

4 LSL

5 Min span

6 URV

7 LRV

MODBUS Variables

1 Address

2 Baud Rate

3 Data Bits

4 Parity

5 Stop Bits

6 CRC Order

7 Frame Idle Time

Device Status

1 Device Status register address

2 Device Status Bit parttren

PV Range

1 PV Range Source

2 PV Range Option

3 Register Data Type

Device variable 0

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

Device variable 1

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

Device variable 2

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

Device variable 3

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

Device variable 4

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

Device variable 5

1 Default Unit

2 Modbus function Code

3 Register address

4 Register Date Type

5 Scaling Factor

6 Uper Register Address

7 Lower Register Address

1 PV Loop current

3 PV Channel flags

4 PV Xfer fnctn

Analog output

2 PV alrm typ

5 Loop current mode

6 Loop test

7 D/A trim

2 Num req preams

Hart output

1 Poll addr

3 Num resp preams

Status

Device information

4-2-1

4-2-2

4-2-3

4-2-4

4-2-5

4-2-6

4-3-1

4-3-2

4-3-3

4-3-4

4-3-5

4-3-6

4-3-7

4-3-8

4-3-9

4-5-1

4-5-2

4-6-12

7 Configuration Mode

Figure 6 Menu Tree

9

4.3 Parameter Setting

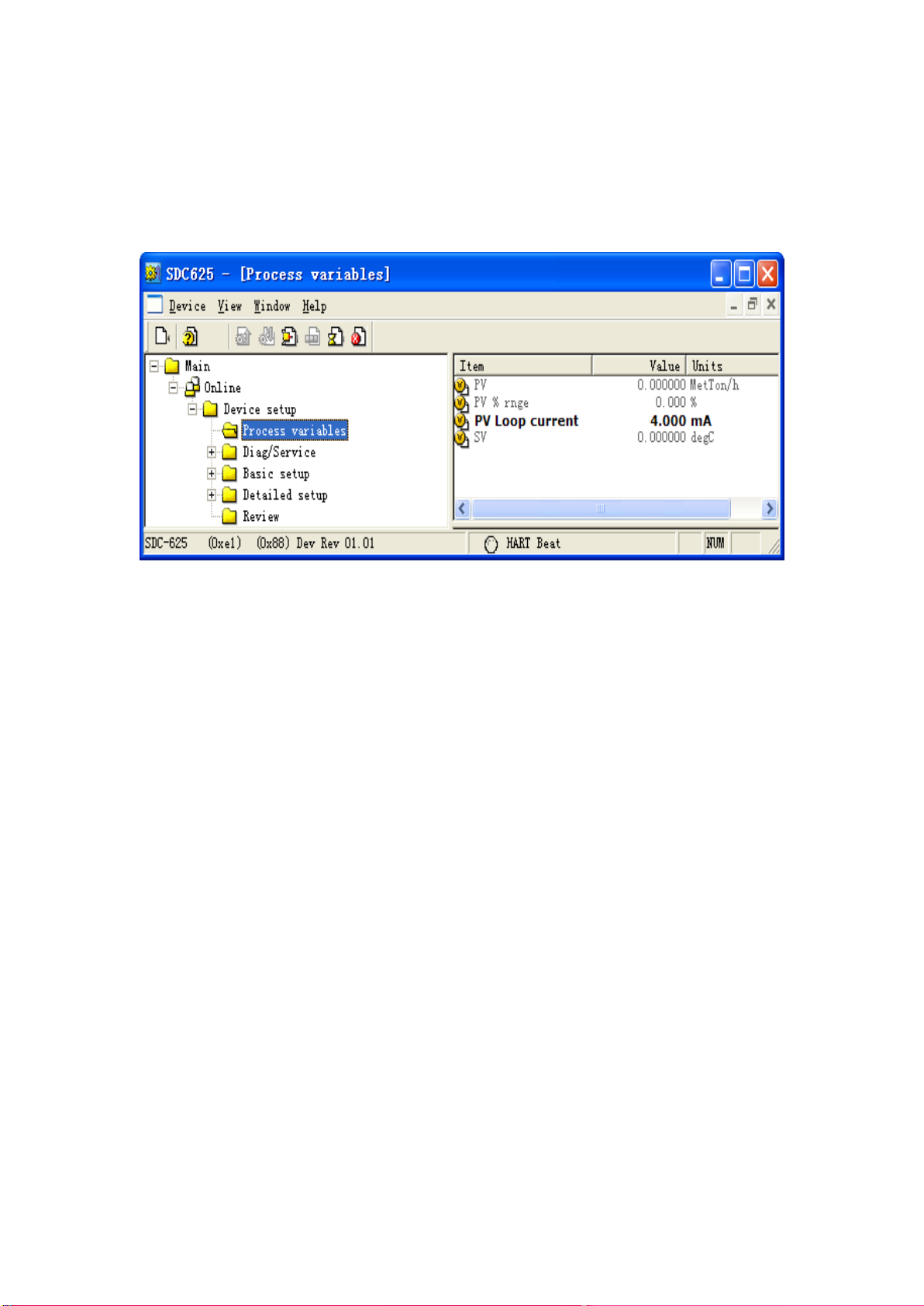

4.3.1 Process Variables

Process variable, is used to check PV and SV processing values.

Figure 7 Process Variables

4.3.2 Diag/Service

Diag/Service, provides device diagnose, service, etc.

4.3.2.1 Test Device

Test Device, can report device electric failure and other failures effected performance.

4.3.2.1.1 Status

Device additional status, and each bit represents each device status. It is needed to configure if the

user needs to use device status function, please refer to 4.3.4.3.2.

10

Figure 8 Device Diagnose Statue

4.3.2.1.2 Selftest

Device Selftest.

1) Click Selftest, to get Selftest interface, and click OK.

Figure 9 Selftest

2) Click ok, to test.

11

Figure 10 Confirm Selftest

3) Selftest is performing.

Figure 11 Performing Selftest

4) If there is no mistake, it will display “Self test OK”.

Figure 12 Selftest OK

5) Click OK, it will display return interface, and click OK to return.

12

Figure 13 Return Interface for Selftest OK

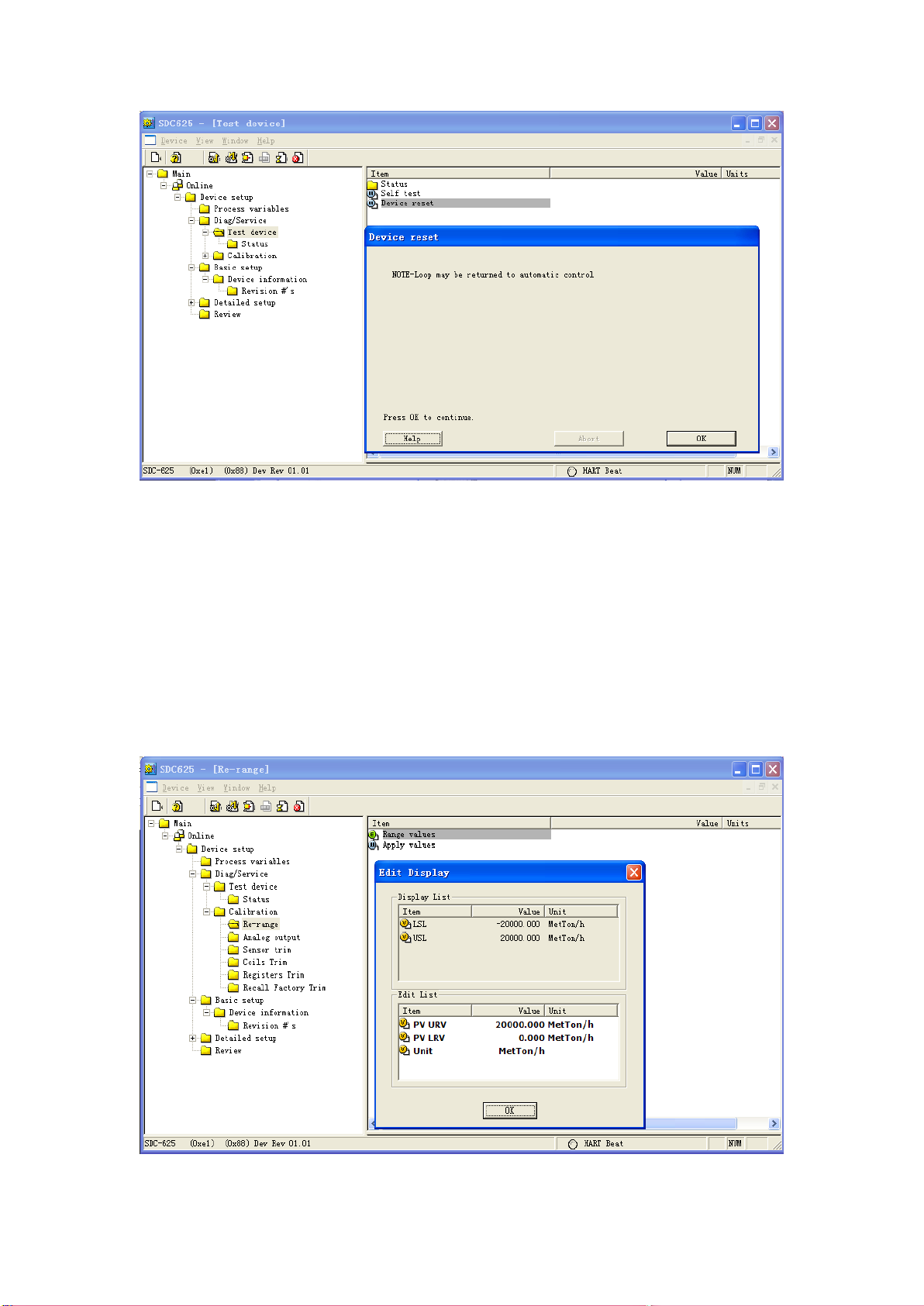

4.3.2.1.3 Device Reset

The steps for device reset as following:

1) Click Device reset twice and click OK.

Figure 14 Device Reset

2) To carry our device reset, click OK.

13

Figure 15 Confirm Device Reset

3) Device reset is performing, please wait.

Figure 16 Device Reset Performing

4) When device reset is successful, it will return and click OK.

Figure 17 Device Reset OK

5) Return and click OK.

14

Figure 18 Device Reset Return

4.3.2.2 Calibration

4.3.2.2.1 Re-range

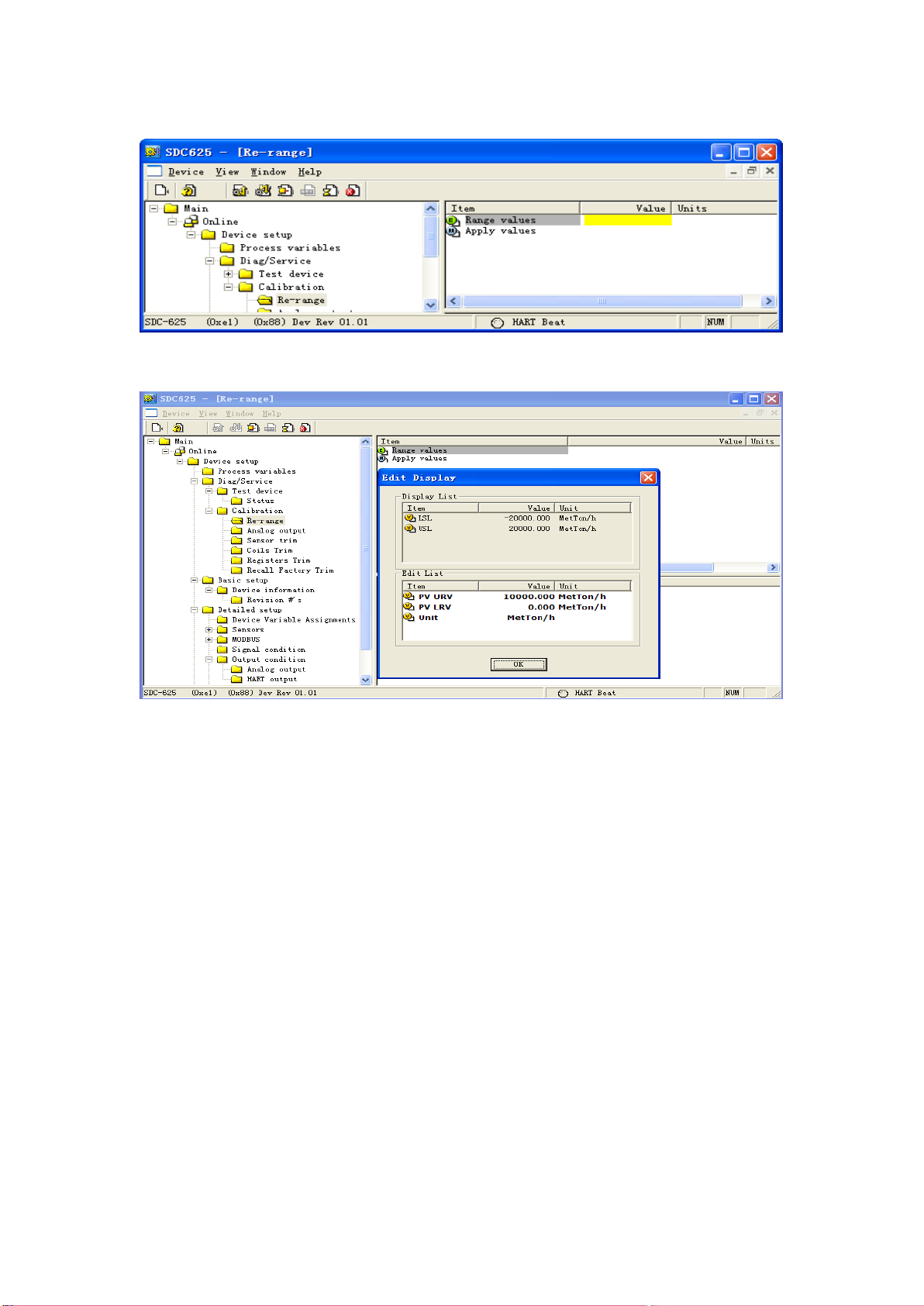

4.3.2.2.1.1 Range Values

PV range upper and lower value setting.

Example: Set PV URV from 20000 MetTon/h to 10000 MetTon/h.

1) Click Range values twice.

Figure 19 Range Value Setting

15

2) Click PV URV twice.

Figure 20 PV Range Setting

3) Click PV URV twice, input setting value 10000, and click OK.

Figure 21 Input PV Range Upper Limit Value

4) Click OK.

Figure 22 Confirm PV Range Upper Limit Setting

16

5) Click Send.

Figure 23 Send PV Range Upper Limit Value to Device

6) Click Range values twice, sending setting is successful.

Figure 24 PV Range Upper Limit Setting Successful

4.3.2.2.1.2 Apply Values

The method is used to set sensor present value to range upper and lower limit.

Example: To set present value as range lower limit.

1) Click Apply values twice and click OK.

Table of contents

Other Microcyber Media Converter manuals

Popular Media Converter manuals by other brands

Hengstler

Hengstler RI 36-H installation instructions

Soekris

Soekris dac1321 user manual

SEI

SEI ADVISOR AE100 Programming and installation guide

Baumer

Baumer HUBNER BERLIN AMG 11 FSL Mounting and operating instructions

Moxa Technologies

Moxa Technologies IMC-P101 Series Quick installation guide

IFM

IFM RM 3 Series operating instructions