Intended Use of the Instrument

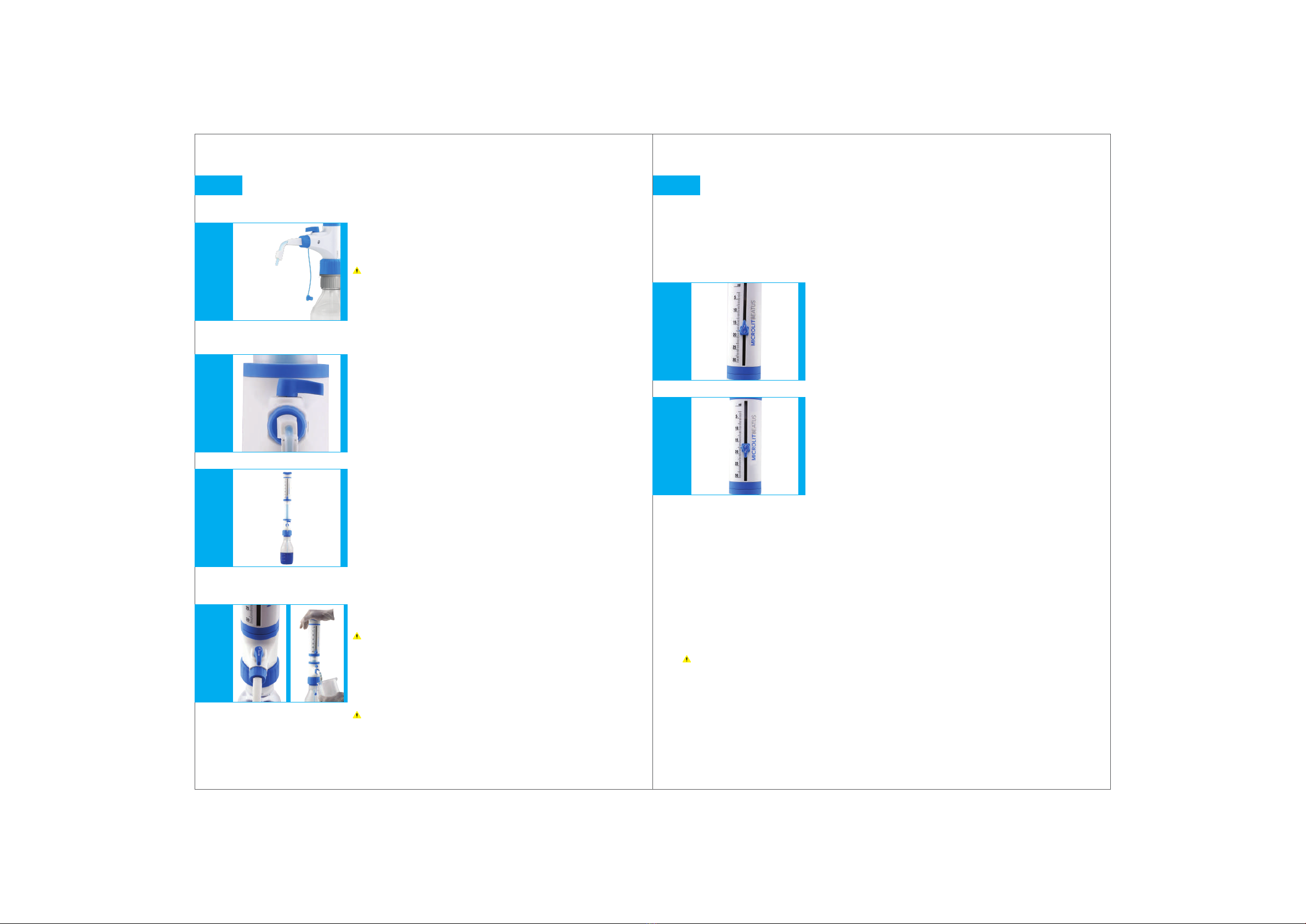

MICROLIT BEATUS is a Bottle Top Dispenser (BTD). It is a high precision

liquid handling instrument intended for use in laboratories for dispensing

reagents and chemicals that are compatible with it. (Refer to section 6)

1.

Safety Instructions

This instrument may sometimes be used for operations involving hazardous

materials and equipment. It is beyond the scope of this manual to address all

of the potential risks associated with its use in such applications.

It is the sole responsibility of the user to consult and establish appropriate safety

and health practices and determine the applicability of regulatory limitations,

prior to the usage of this instrument.

Please read the following instructions carefully.

Read and understand this Operation Manual thoroughly before

using the instrument.

Follow general and safety instructions for hazard prevention.

E.g., always wear protective clothing, protective gear for the eyes and hands.

Carefully observe the specifications provided by reagent manufacturers.

When dispensing inflammable fluids, avoid the built up of static charge.

Make sure that you do not dispense into plastic vessels and do not wipe

the instrument/equipment with a dry cloth.

Use the instrument only for dispensing liquids, with strict regard to the defined

limitations of use and operating constraints. (Refer to section 3 and 4)

Observe operating exclusions. When in doubt, contact the

manufacturer or supplier.

Always use the instrument in such a way that neither the user nor any

other person is in danger. While dispensing, the discharge tube must always

point away from you or any other person. Only dispense into appropriate

vessels and avoid splashes.

Do not press the piston when the discharge tube closure is attached.

Do not remove the discharge tube while the dispensing cylinder is being filled.

Reagents can accumulate in the cap of the discharge tube.

Thus, clean it regularly.

Do not carry the mounted instrument by the cylinder sleeve or the valve block.

Breakage or loosening of the cylinder may lead to personal injury.

Do not use the instrument with force. Apply smooth gentle movements to

operate the piston. Use only original accessories and spare parts.

Do not attempt to make any technical alterations. Do not dismantle the instrument

any further than is described in the Operation Manual.

Always check the instrument for visual damage before use.

If there is any sign of a potential malfunction (e.g. piston difficult to move,

stuck valve or leakage), immediately stop dispensing. Consult the 'Troubleshooting'

section of this Operation Manual and contact the manufacturer if needed.

(Refer to section 16)

2.

•

•

•

•

•

•

•

•

Functions and Limitations of Use

MICROLIT BEATUS is designed to dispense liquids directly from the

reservoir bottle. It is calibrated in accordance with the guidelines of the

DIN EN ISO 8655 – 5.

When the instrument is correctly used, the dispensed liquid comes into contact

with only the following chemically resistant materials:

PTFE, FEP and Borosilicate glass.

Physical limits

MICROLIT BEATUS is designed to be operated under the following physical limits.

Maintain instrument temperature between +15°C and +40°C (from 59°F to 104°F).

Maintain reagent vapour pressure up to 600 mbar (maximum). Aspirate slowly

above 300 mbar in order to prevent the liquid from boiling.

Kinematic viscosity upto 500 mm²/s.

(dynamic viscosity [mPas] = kinematic viscosity [mm² /s] x density [g/cm³])

Use fluids with density upto 2.2 g/cm³.

3.

•

•

•

•

•

•

•

•

•

•

•

21