This document is strictly private and confidential, reproduction without Micropack approval is prohibited. © Micropack Engineering Ltd, 2018

Detector Positioning

Detectors should be positioned to provide the best unobstructed view of the area to be

protected.

The following factors should also be taken into consideration:

•Identify all high-risk fire ignition sources. Ensure that enough detectors are used to

adequately cover the hazardous area.

•Locate and position the detector so that the fire hazard(s) are within both the field of

view and detection range of the device.

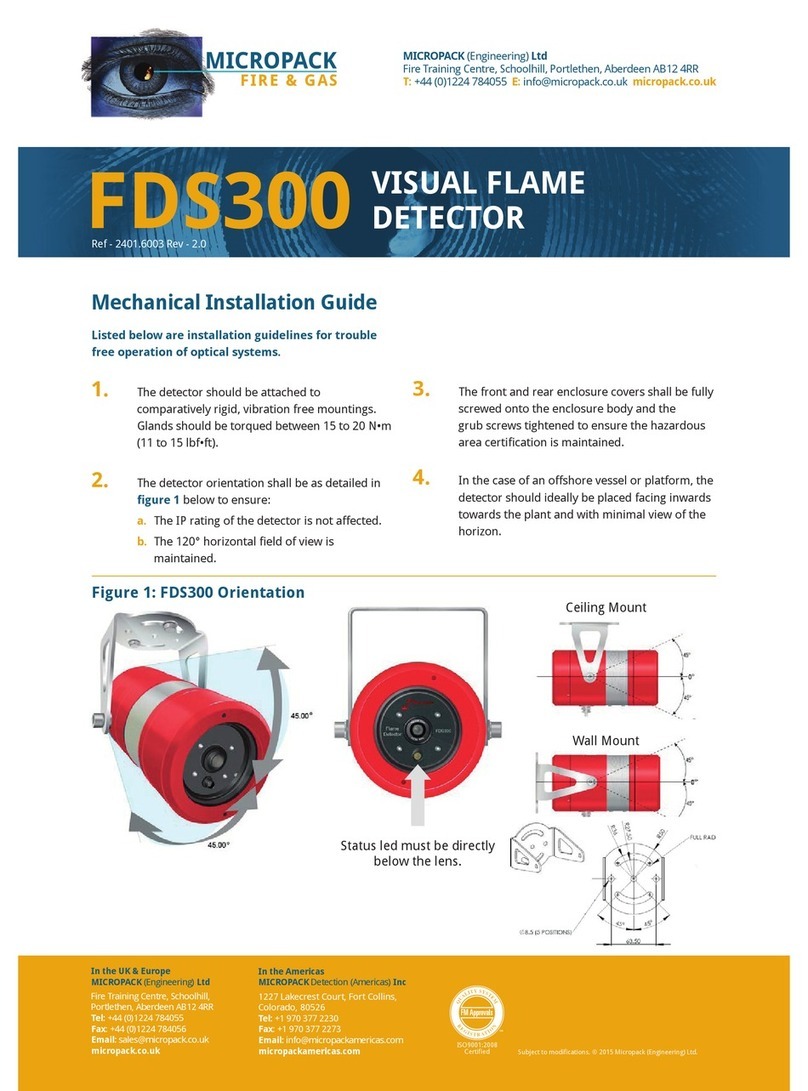

•For best performance, the detector should be mounted on a rigid surface in a low

vibration area.

•Extremely dense fog or blizzard conditions could eventually block the vision of the

detector.

•For indoor applications, if dense smoke is expected to accumulate at the onset of a

fire, mount the detector on a side wall (approximately 1 to 2 metres) below the ceiling.

•The FDS303 has three sensitivity settings, which may be changed via a Micropack

application.

•The Detector carries out continuous internal hardware diagnostic testing to ensure

correct operation is relayed to the control system.

•The FDS303 is not designed to annunciate diagnostic failure of signal returns via

external wiring. Control systems and fire panels generally have fault monitoring for

such an eventuality.

2.4 EN 54-part 10 Limitation of use

The FDS303 is not approved for use in Oxygen-enriched atmospheres.

As the FDS303 responds to flame. It cannot be used in locations where flare stacks are within its

field of view or a reflected view is present without triggering alarms.

As the FDS303 responds to CO2Emissions of a flame the FDS303 cannot detect non-Hydrocarbon

fires, such as those using pure hydrogen, Silane and Sulphur as fuel.

The sensitivity of the FDS303 is reduced by obscurants such as smoke, fog and other

airborne particulates. The FDS303 may be blinded by extremely dense obscurants.

Arc welding should not take place within 10m of the FDS303 when using the highest

sensitivity setting.