Installation & Commissioning Handbook, ,

P-ASENSE75/IE 980302, 7483 Trondheim

Page 1

Table of Contents

1. Introduction......................................................................3

1.1 About this manual............................................................................... 3

1.2 The product......................................................................................... 3

1.3 Application ......................................................................................... 3

1.4 The reader........................................................................................... 3

1.5 Other reference documents................................................................. 4

2. Installation .......................................................................5

2.1 Recommended height for mounting................................................... 5

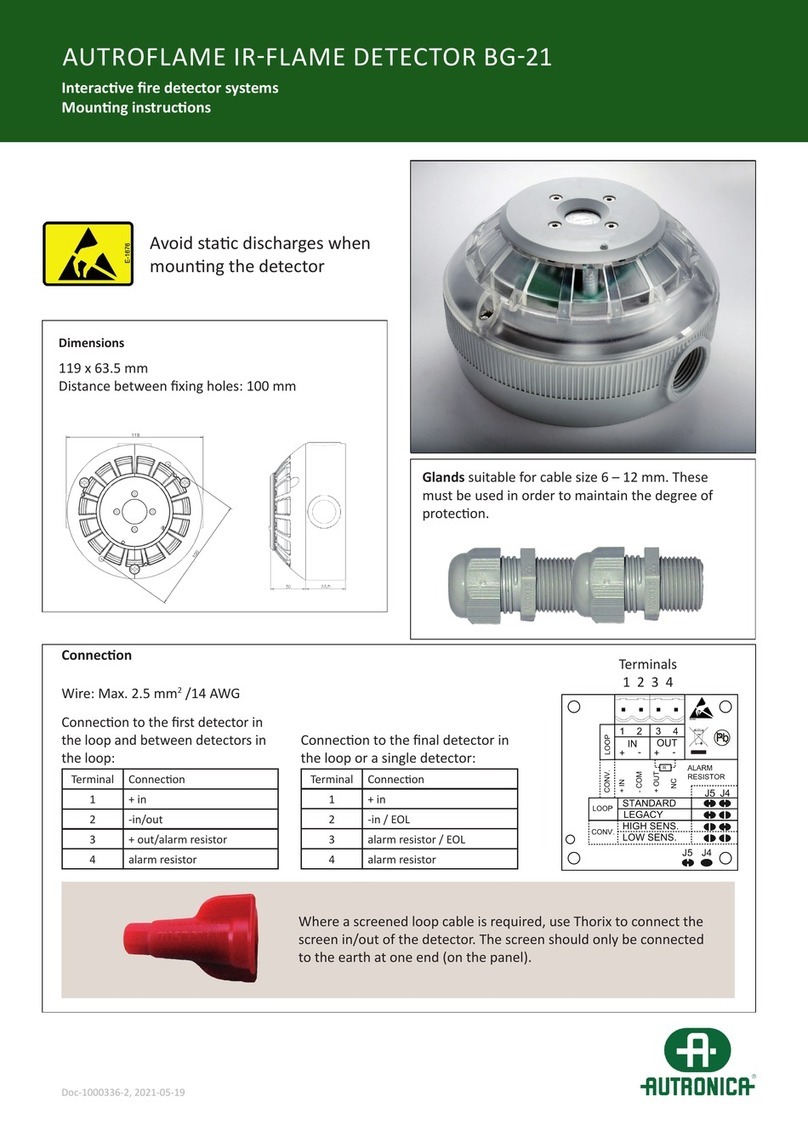

2.2 Dimensions......................................................................................... 5

2.3 Positioning of the detector.................................................................. 6

2.4 Mounting the detector......................................................................... 6

2.5 Cable entry.......................................................................................... 7

2.6 Cable connections............................................................................... 8

2.6.1 Introduction........................................................................... 8

2.6.2Overview................................................................................ 8

2.6.3 Terminal strips 1 and 2.......................................................... 8

2.6.4 External connection of 2 detector loops - conventional

version............................................................................................ 9

2.6.5 External connection of 1 detector loop - conventional

version............................................................................................ 9

2.6.6 External connection of detector loop - analogue

addressable system......................................................................... 10

2.6.7 Power supply......................................................................... 10

3. Installing the pipe system...............................................11

3.1 General guidelines.............................................................................. 11

3.2 Guidelines for agricultural installations ............................................. 12

3.3 Installing the pipe system in the roof/ceiling ..................................... 13

3.4 Pipe joints........................................................................................... 13

3.5 Cleaning out the pipe system following installation .......................... 13

3.6 Concealed pipes.................................................................................. 14

3.7 Connecting to the AutroSense 75 detector unit.................................. 14

3.8 Installing a “moisture trap”................................................................. 14