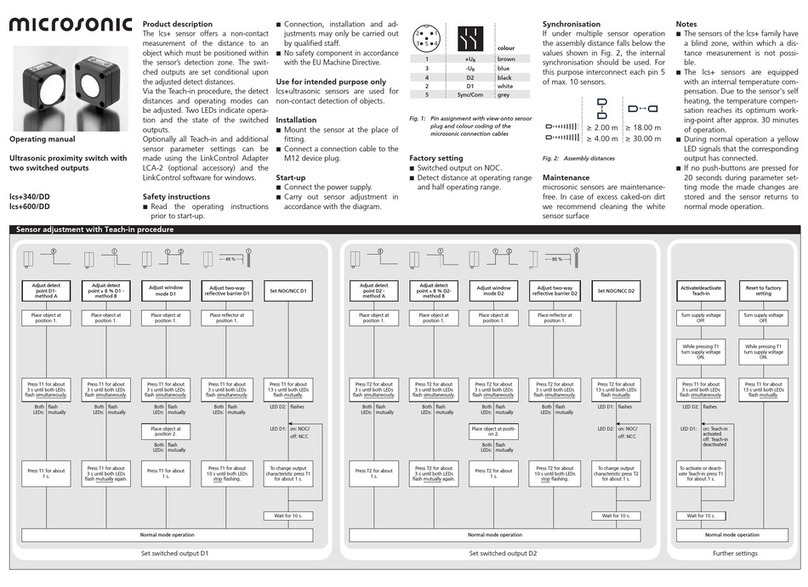

resolution, sampling rate

detection zones

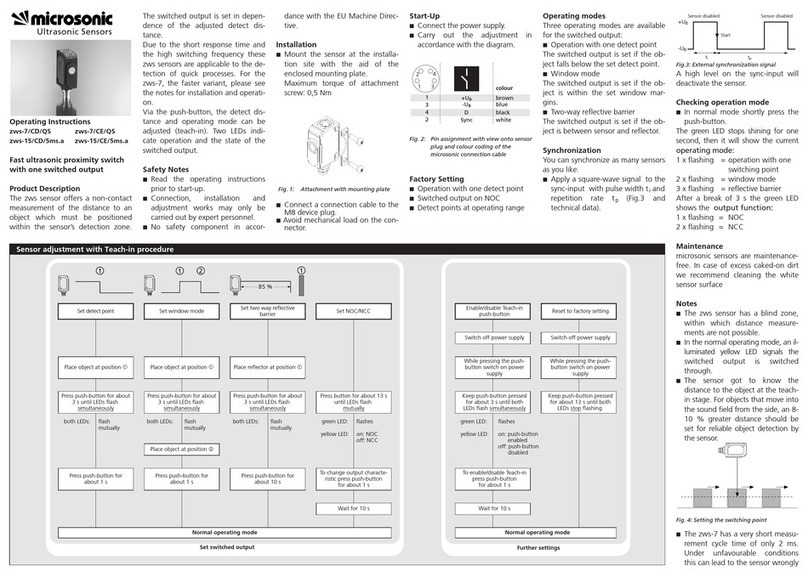

for different objects:

The dark grey areas are determined

with a thin round bar (10 mm dia.)

and indicate the typical operating range

of a sensor. In order to obtain the light grey

areas, a plate (100 x 100 mm) is introduced

into the beam spread from the side.

In doing so, the optimum angle between

plate and sensor is always employed.

This therefore indicates the maximum

detection zone of the sensor.

It is not possible to evaluate ultrasonic

reflections outside this area.

no-load current consumption

temperature drift 0.17 %/K

20 - 30 V DC, reverse polarity protection

temperature drift 0.17 %/K

20 - 30 V DC, reverse polarity protection

class of protection to EN 60 529

ultrasonic transducer: polyurethane foam,

ultrasonic transducer: polyurethane foam,

epoxy resin with glass content

epoxy resin with glass content

LED yellow (state of output)

LED yellow (state of output)

pulse width synchronization signal ti

repetition rate synchronization signal tp

time delay before availability

pnp, UB-2 V, Imax = 200 mA

pnp, UB-2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

switchable NOC/NCC, short-circuit-proof

npn, -UB+2 V, Imax = 200 mA

npn, -UB+2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof switchable NOC/NCC, short-circuit-proof

temperature drift 0.17 %/K

20 - 30 V DC, reverse polarity protection

temperature drift 0.17 %/K

20 - 30 V DC, reverse polarity protection

ultrasonic transducer: polyurethane foam,

ultrasonic transducer: polyurethane foam,

epoxy resin with glass content

epoxy resin with glass content

LED yellow (state of output)

LED yellow (state of output)

pnp, UB-2 V, Imax = 200 mA

pnp, UB-2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof

switchable NOC/NCC, short-circuit-proof

npn, -UB+2 V, Imax = 200 mA

npn, -UB+2 V, Imax = 200 mA

switchable NOC/NCC, short-circuit-proof switchable NOC/NCC, short-circuit-proof

1

2

4

3

+UB

-UB

Sync

U

1

2

4

3

+UB

-UB

Sync

U

1 pnp switched output

1 npn switched output

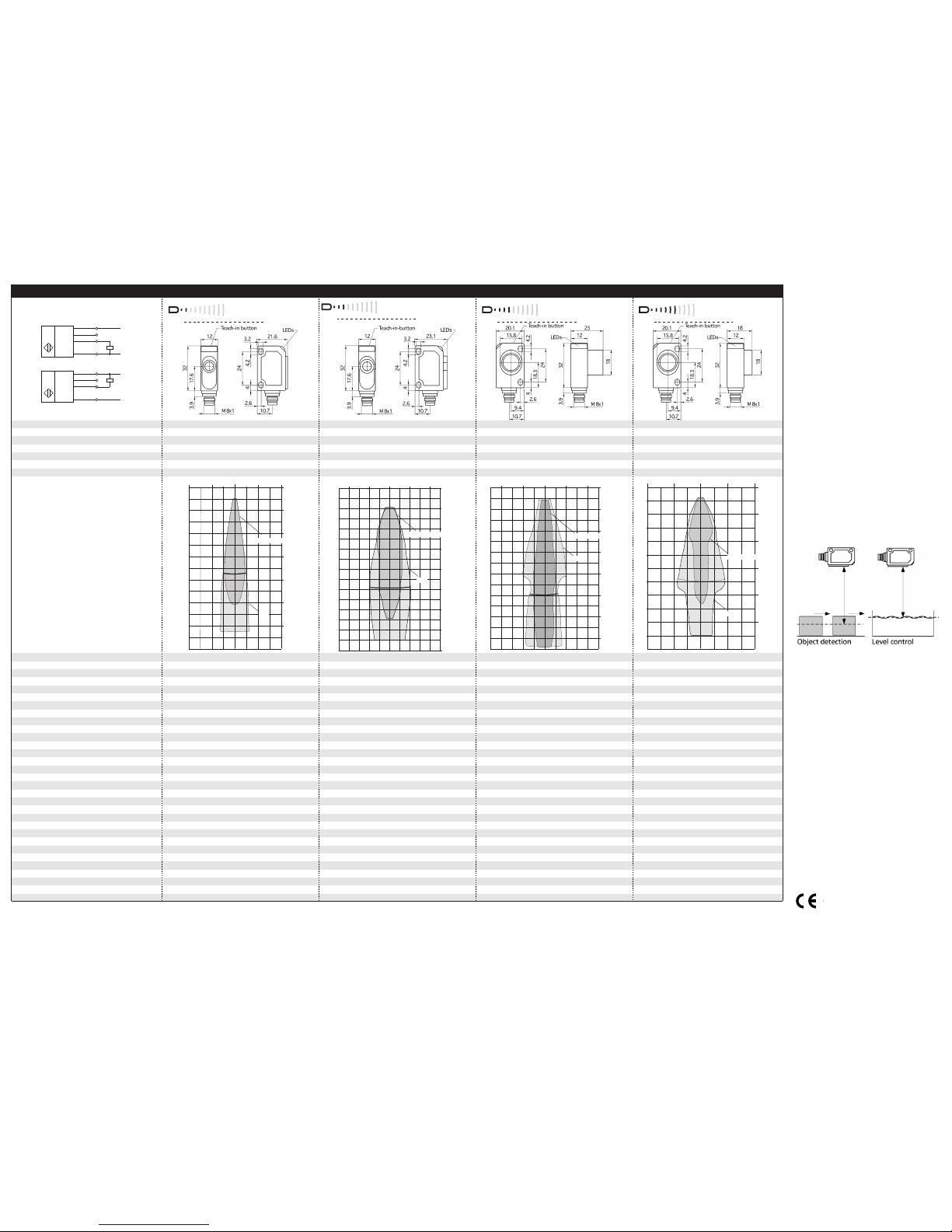

8 cm 4 cm 0 cm 4 cm 8 cm

0 cm

4 cm

8 cm

12 cm

16 cm

20 cm

24 cm

Round bar ø 10 mm

Plate

10 cm 5 cm 0 cm 5 cm 10 cm

0 cm

5 cm

10 cm

15 cm

20 cm

25 cm

30 cm

35 cm

Plate

Round bar ø 10 mm

10 cm 5 cm 0 cm 5 cm 10 cm

0 cm

5 cm

10 cm

15 cm

20 cm

25 cm

30 cm

35 cm

Round bar ø 10 mm

Plate

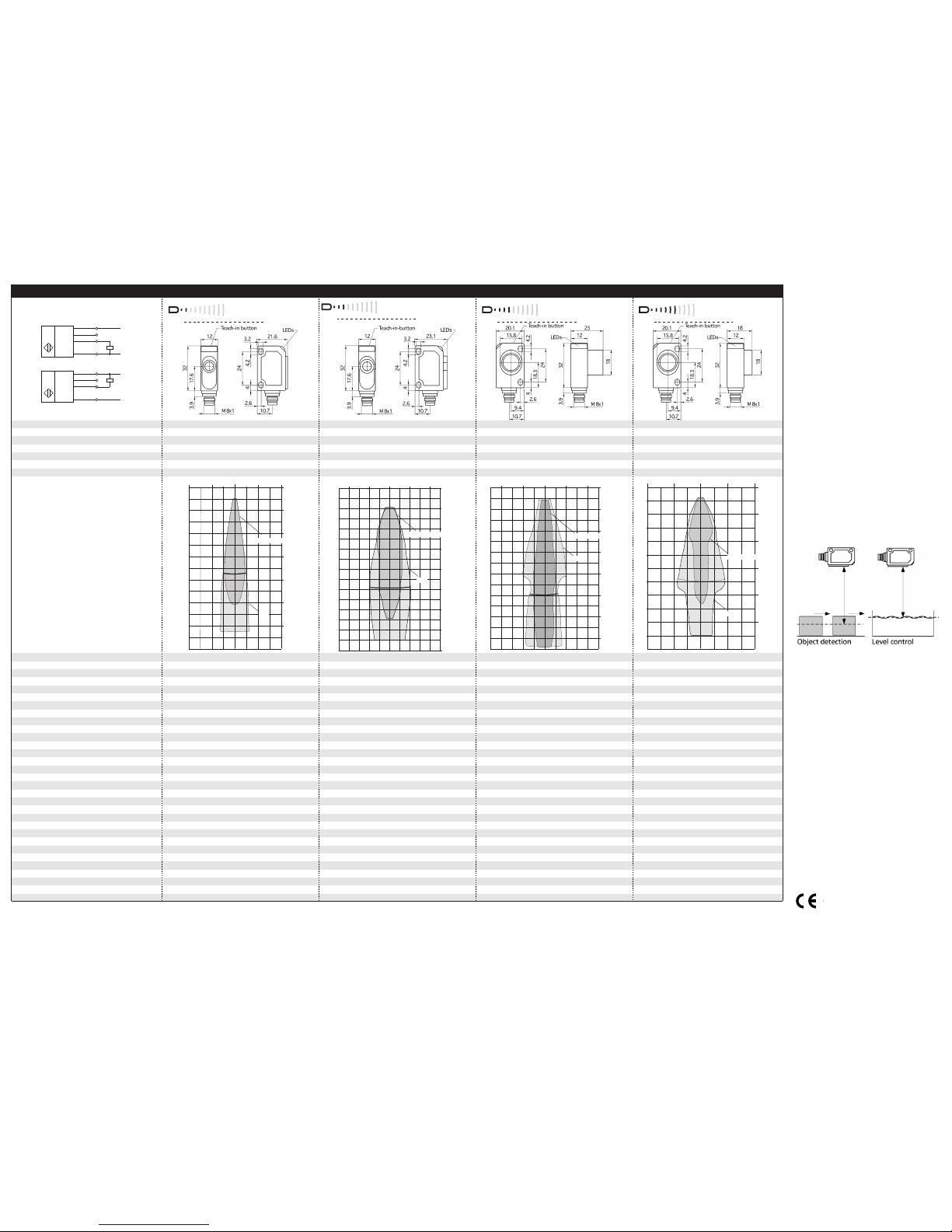

40 cm 20 cm 0 cm 20 cm 40 cm

0 cm

20 cm

40 cm

60 cm

80 cm

100 cm

Round bar ø 10 mm

Plate

microsonic

GmbH

/

Phoenixseestraße

7

/

44263

Dortmund

/

Germany

/

T+49 231 975151-0 / F+49 231 975151-51 / E[email protected] / Wmicrosonic.de The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not warrant any product features.

MV-DO-052889-437422

Notes

The zws sensor has a blind zone,

within which distance measure-

ments are not possible.

In the normal operating mode, an il-

luminated yellow LED signals the

switched output is switched

through.

The standard sensor has no tempe-

rature compensation.

If the object to be sensed moves

into the detection area from the

side, the switching distance should

be set 8-10 % further than the de-

sired switch point to obtain a reli-

able object detection.

If the object moves towards the

sensor (e.g. level control) the detect

point can be taught to the actual

distance at which the sensor has to

switch the output.

Fig. 4: Set the detect point for different

directions of movement of the object

In the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0-85 % of

the set distance.

If the push-button is not pressed

for 10 minutes during the teach-in

setting, the settings made hitherto

are deleted.

The sensor can be reset to its fac-

tory setting.

2014/30/EU