The D12 adapter shaft of the pms

sensor has to stick out at least

6 mm from the screw connection

(see figure 5).

The sealing ring has to fill space

between D12 sensor shaft and cap

nut. Sealing ring should not to be

pressed out excessively from the

shaft gland.

Fig. 3: pms sensor D12-adapter shaft with

sensor screw connection BF-pms/A1,

all surfaces must be inclined at least 3°.

Fig. 4: Mounting of pms sensor with sensor

screw connection BF-pms/A1

Fig. 5: Mounting of pms sensor with sensor

screw connection BF-pms/A1

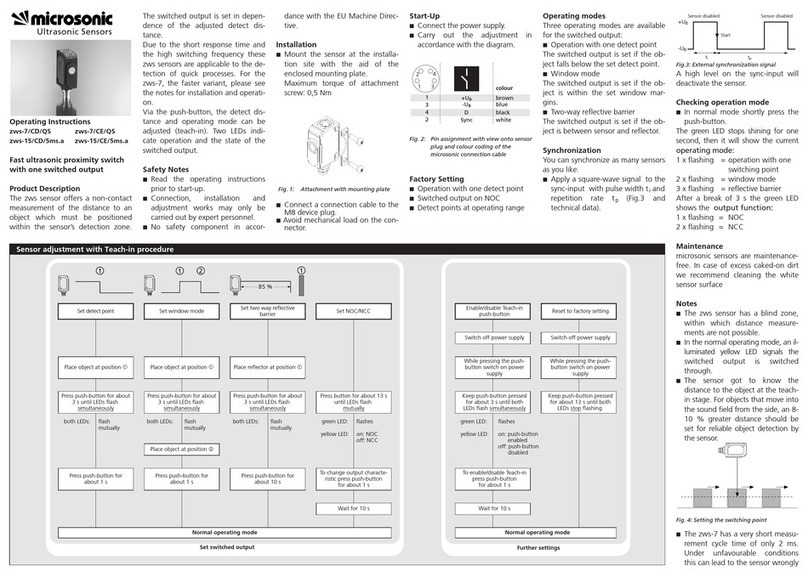

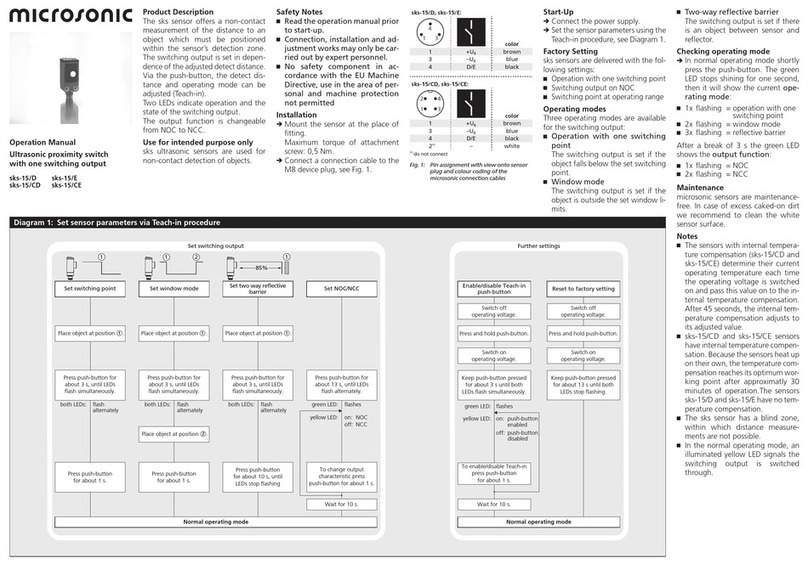

Mounting accessory

D12 sensor screw connection

BF-pms/A1

Accessory for programming

LinkControl adapter LCA-2

Adapter 5G/M12-4G/M12/M8

The pms sensors are IO-Link-capable

in accordance with IO-Link specifica-

tion V1.1.

Note

In IO-Link mode LinkControl and syn-

chronization via pin 2 are not

available.

Smart Sensor Profile

Die pms sensors support the Smart

Sensor Profile. The following profiles

and function classes are integrated:

0x000A - Device Profil:

Digital measuring sensors

0x8000 - Device Identification

0x8001 - Multichannel:

two setpoint switching sensor

0x8003 - Device Diagnosis

0x8004 - Teach Channel

0x800A - Measurement Data Cha-

nel (standard resolution)

Synchronisation in IO-Link Mode

In IO-Link mode each sensor is syn-

chronized on the protocol of the IO-

Link master. In multiple sensor opera-

tion the sensors are synchronous if

the master protocols are synchro-

nous.

System Commands

With 3 system commands the follo-

wing settings may be carried out:

Teach-in SP1

Teach-in SP2

Reset sensor to factory settings

SSC1 Configuration

The pms sensor has 5 modes:

Single point (SP1: switching point)

The switched output is activated

when the distance to an object is

under that of the present single

point SP1.

Window (SP1, SP2: window mode)

The switched output is set when

the object is within the set win-

dow (SP1, SP2).

Two point (SP1, SP2: hystese

mode)

In hysteresis mode, SP1 and SP2

assume the function of the single

point and return single point.

Single point +8 % (SP1 switching

point +8 %)

The switched output is set when

the distance mesaured to an ob-

ject is smaller that the set swit-

ching point SP1 +8%.

Window ±8 % (SP1 two way re-

flective barrier)

The switched output is set when

the object is between sensor and

fixed reflector (with SP1 ±8 %) .

IODD File

The latest IODD file you will find

on

the internet under

www.microsonic.de/en/IODD.

For further informations on IO-Link

see www.io-link.com.

Physical layer SIO mode support

min cycle time

yes

8 ms

baud rate

format of process data

Identification features

content of process data Bit 0: state of switched output, Bit 8-15: scale (Int. 8),

Bit 16-31: measured value (Int. 16) with 0,1 mm resolution

Vendor name microsonic GmbH

Vendor ID

Product name

Product ID

Device ID

35000

SSC1 configuration

Parameter

SP1 (Setpoint 1)

SP2 (Setpoint 2)

60

60

SSC1 configuration

Hysterese 61

Logic

61

Teach-in

Mode

Teach-in channel

61

58

Teach-in status

SP1 single value teach-in

59

2

Filter

SP2 single value teach-in

Type

2

256

Strength

Mode

256

300

Factory settings FactorySettings

DeviceaccessLocks

2

12

1) Distance value, e.g. setpoints, are give with a resolutin of 0,1 mm. The values in the tables are decimal.

format

1

2

INT16

INT16

access range

R/W

R/W

20 - 250 1)

20 - 250 1)

3 INT8

1

format

UINT16

R/W 0,1 - 230 1)

access

R/W

range

0: High active, 1: Low active

2 UINT8

UINT8

UINT8

UINT8

R/W

R/W

1: single point (SP1: switching point), 2: window (SP1, SP2: window mode), 3: two point (SP1, SP2: hysteresis mode), 128: single point +8 % (SP1: switching point +8 %), 129: window ±8 % (SP1: two way reflective barrier)

0: SSC1: Pin 4 (Push-Pull)

RO

WO

Bit 0-3: 0: idle, 1: SP1 success, 2: SP2 success, 7: error; Bit 4: SP1 TP1; Bit 6: SP2 TP1

65: The value 65 must be written to index 2 to trigger the command.

UINT8

UINT8

1

UINT8

UINT8

WO

R/W

66: The value 66 must be written to index 2 to trigger the command.

0-4: F00 (no filter), F01 (standard filter), F02 (averaging filter), F03 (foreground ilter), F04 (background filter)

R/W

R/W

0-9: P00 - P09; For each measurement filter a filter strength between 0, weak filter effect, and 9, strong filter effect, can be chosen.

0: off, 1: on

UINT8

UINT16

WO

R/W

130: The value130 must be written to index 2 to trigger the command.

Bit 0: parameter (write) access lock; Bit 2: local user interface lock

yes

8 ms

yes

Bit 0: state of switched output, Bit 8-15: scale (Int. 8),

Bit 16-31: measured value (Int. 16) with 0,1 mm resolution

35100

Bit 0: state of switched output, Bit 8-15: scale (Int. 8),

Bit 16-31: measured value (Int. 16) with 0,1 mm resolution

35200

index subindex

60

60

1

2

access

UINT16

UINT16

R/W

R/W

61 3 UINT8 R/W

range

60

60

subindex format

1

2

UINT16

UINT16

61 3 UINT8

yes

20 ms

Bit 0: state of switched output, Bit 8-15: scale (Int. 8),

Bit 16-31: measured value (Int. 16) with 0,1 mm resolution

35300

access range

R/W

R/W

index subindex

60

60

1

2

R/W

61 3

format access

UINT16

UINT16

R/W

R/W

range

UINT8 R/W

pms-15...

microsonic

GmbH

/

Phoenixseestraße

7

/

44263

Dortmund

/

Germany

/

T+49

231

975151-0

/

F+49

231

975151-51

/

E[email protected] / Wmicrosonic.de

/

The

content

of

this

document

is

subject

to

technical

changes.

Specifications

in

this

document

are

presented

in

a

descriptive

way

only.

They

do

not

warrant

any

product

features.

MV-DO-187459-589868

2014/30/EU

Ordertel 08-771 00 04 Växel 08-771 02 20

Orderfax 08-771 62 00 Teknisk 08-771 35 80

Länna, S-142 50 SKOGÅS (Stockholm)

www.hemomatik.se