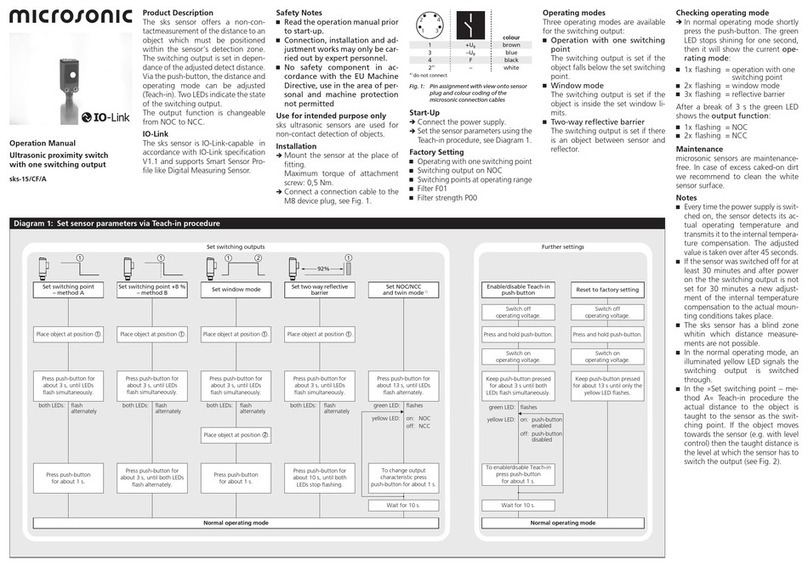

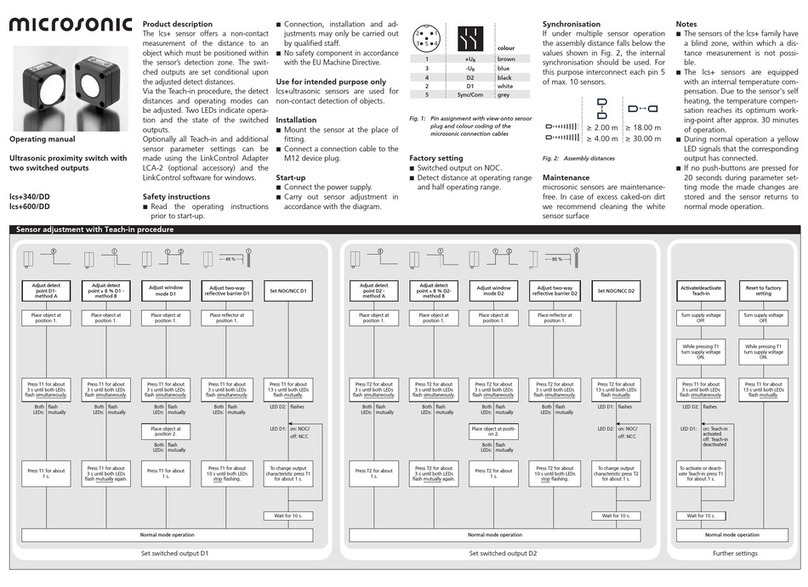

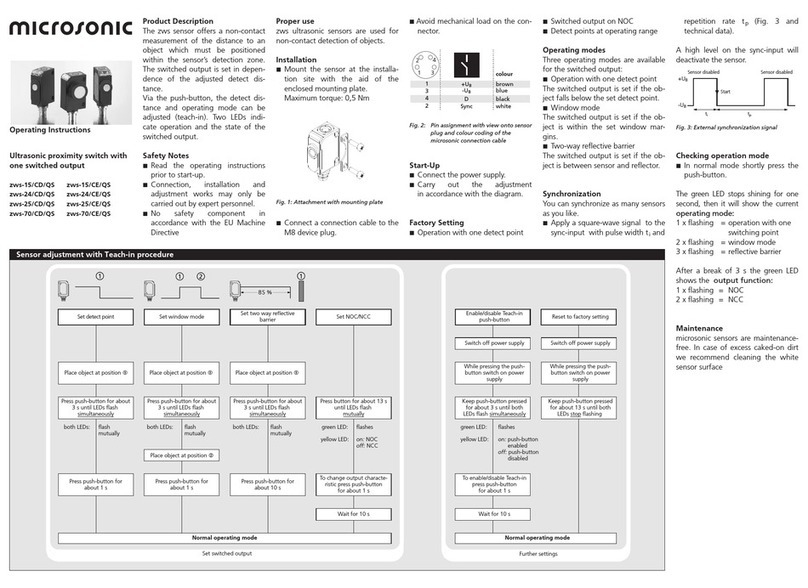

Operating manual

sks-15/CF/A

Ultrasonic proximity switch

with one switching output and

IO-Link interface

Product description

The sks sensor offers a non-contact-

measurement of the distance to an

object which must be positioned

within the sensor's detection zone.

The switched output is set in depen-

dance of the adjusted detect distan-

ce.

Via the push-button, the distance

and operating mode can be adjusted

(Teach-in). Two LEDs indicate operati-

on and the state of the switched

output. The output function is chan-

geable from NOC to NCC.

IO-Link

The sks sensor is IO-Link-capable in

accordance with IO-Link specification

V1.1 and supports Smart Sensor Pro-

file like Digital Measuring Sensor.

Safety notes

■Read operating instructions pior to

start-up.

■Connection, installation and ad-

justment works may only be

carried out by expert personnel

■No safety component according to

EU Machinery Directive

Proper use

sks ultrasonic sensors are used for

non-contact detection of objects.

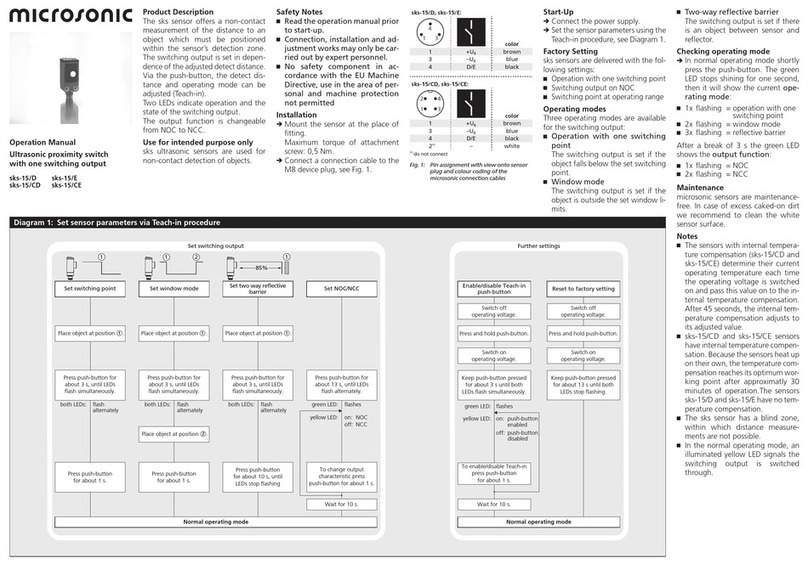

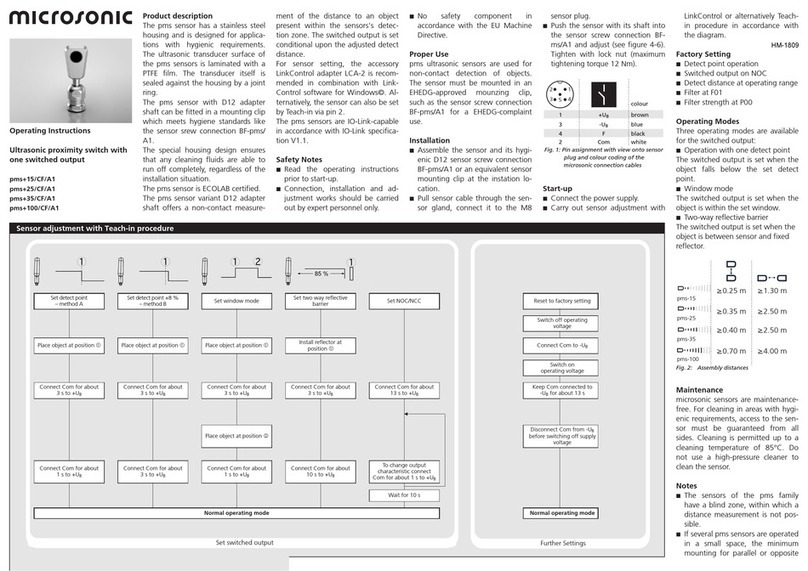

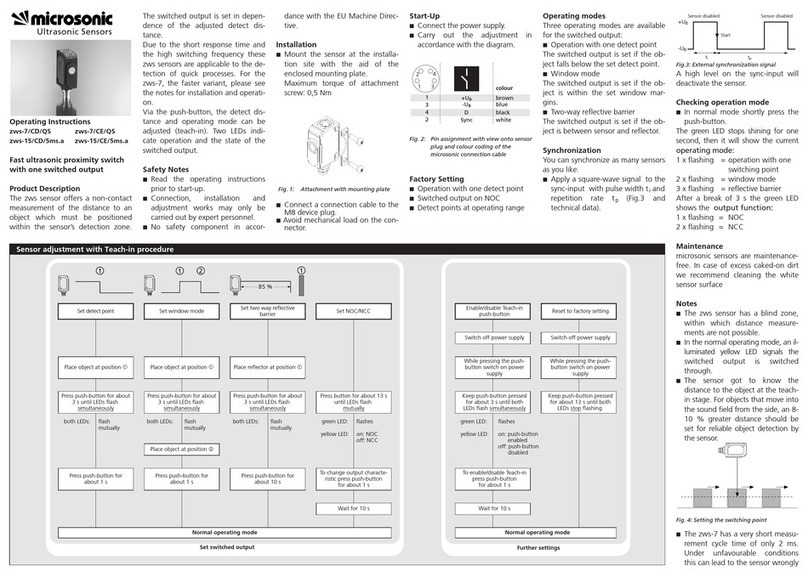

Mounting

■ Mount the sensor at installation

site, Maximum torque: 0.5 Nm

■Connect a connection cable to the

M8 device plug

Start-Up

■Connect the power supply

■Carry out the adjustment in accor-

ding with the diagram

Factory setting

■Operating with one detect point

■Switched output on NOC

■Detect points at operating range

■Filter F01

■Filter strength P00

Fig. 1: Pin assignment with view of the sensor

plug and color coding of the microsonic

connection cables

* Do not connect

Operating modes

Three operating modes are available

for the switches output:

■Operation with one switching point

The switched output is set if the ob-

ject falls below the set detect point.

■Window mode

The switched output is set if the object

is outside the set window margins.

■Two-way reflective barrier

The switched output is set if the ob-

ject is located between the sensor

and reflector.

Checking operation mode

■In normal mode shortly press the

push-button.

The green LED stops shining for one

second, then it will show the current

operating mode:

1 x flashing = operation with one

switching point

2 x flashing = window mode

3 x flashing = reflective barrier

After a break of three seconds, the

green LED shows the output func-

tion:

1 x flashing = NOC

2 x flashing = NCC

Maintenance

microsonic sensors are maintenance-

free. In case of excess caked-on dirt

we recommend cleaning the white

sensor surface.

Notes

■Every time the power supply is swit-

ched on, the sensor detects its actu-

al operating temperature and trans-

mits it to the internal temperature

compensation. The adjusted value is

taken over after 45 seconds.

■If the sensor was switched off for

at least 30 minutes and after po-

wer on the the switched output is

not set for 30 minutes a new ad-

justment of the internal tempera-

ture compensation to the actual

mounting conditions takes place.

■The sks sensor has a blind zone

whithin which distance measure-

ments are not possible.

■In the normal operating mode, an

illuminated yellow LED signals the

switched output is switched

through.

■In the »Set detect point – method A«

Teach-in procedure the actual dis-

tance to the object is taught to the

sensor as the detect point. If the ob-

ject moves towards the sensor (e.g.

with level control) then the taught

distance is the level at which the sen-

sor has to switch the output.

■If the object to be scanned moves

into the detection area from the

side, the »Set detect point +8 % –

method B« Teach-in procedure

should be used. In this way the

switching distance is set 8 %

further than the actual measured

distance to the object. This ensu-

res a reliable switching distance

even if the height of the objects

varies slightly, see fig. 2.

■In the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0-85 % of

the set distance.