0 to 350 mm

3,400 mm

0 to 600 mm

6,000 mm

5,000 mm

see »detection zones«

8,000 mm

see »detection zones«

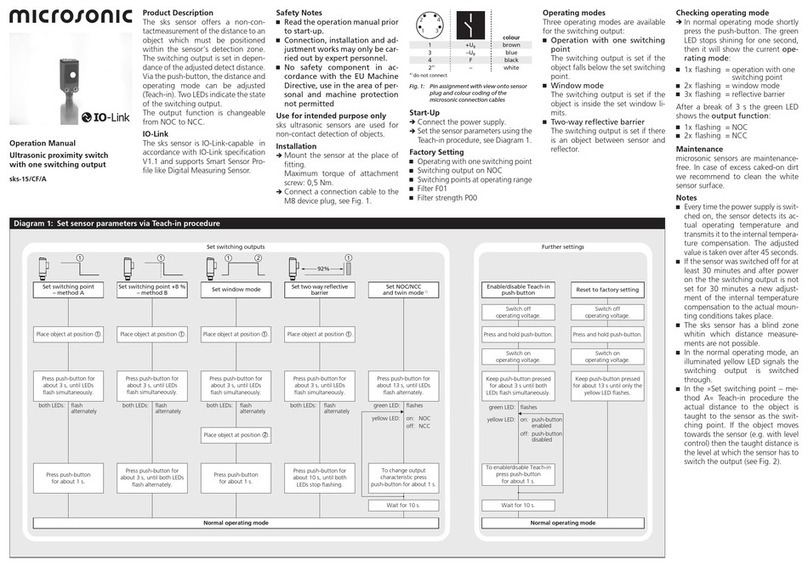

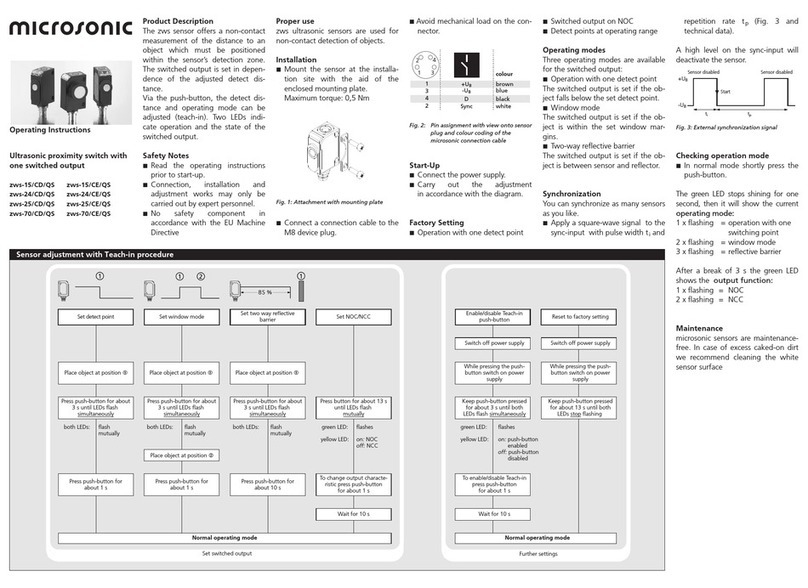

detection zones

for different objects:

The dark grey areas represent the zone

where it is easy to recognise the normal

reflector (round bar). This indicates the typical

operating range of the sensors. The light

grey areas represent the zone where a

good reflector – for instance a

plate – can still be regognised. The

requirement here is for an optimum

alignment to the sensor. It is not

possible to evaluate ultrasonic

reflections outside this area.

ca. 120 kHz

0.18 mm

ca. 80 kHz

0.18 mm

±1 % (temperature drift internally compensated; may

be deactivated, 0.17 %/K without compensation)

±1 % (temperature drift internally compensated; may

be deactivated, 0.17 %/K without compensation)

9 V to 30 V DC, Class 2

reverse polarity protection

9 V to 30 V DC, Class 2

reverse polarity protection

no-load current consumption

PBT, Polyester; ultrasonic transducer:

polyurethane foam, epoxy resin with glass content

PBT, Polyester; ultrasonic transducer:

polyurethane foam, epoxy resin with glass content

class of protection per EN 60 529

IP 67

5-pin M12 circular plug, PBT

IP 67

5-pin M12 circular plug,. PBT

2 push-buttons

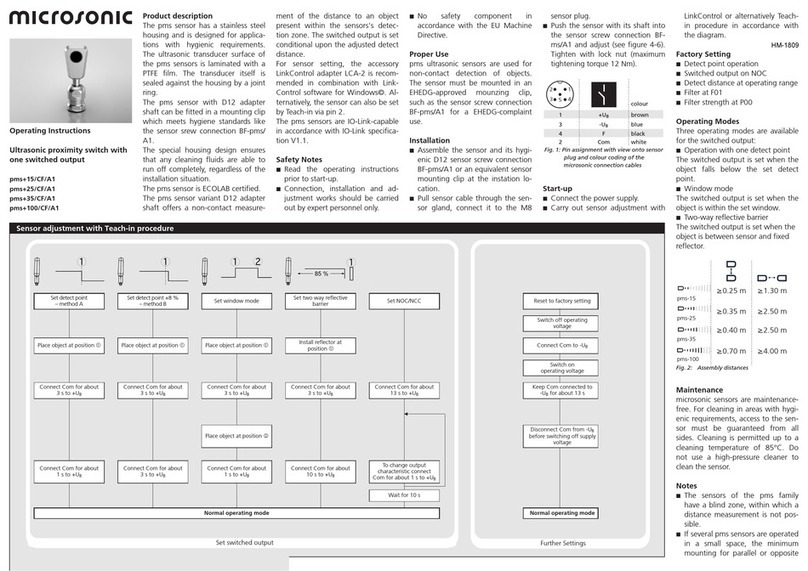

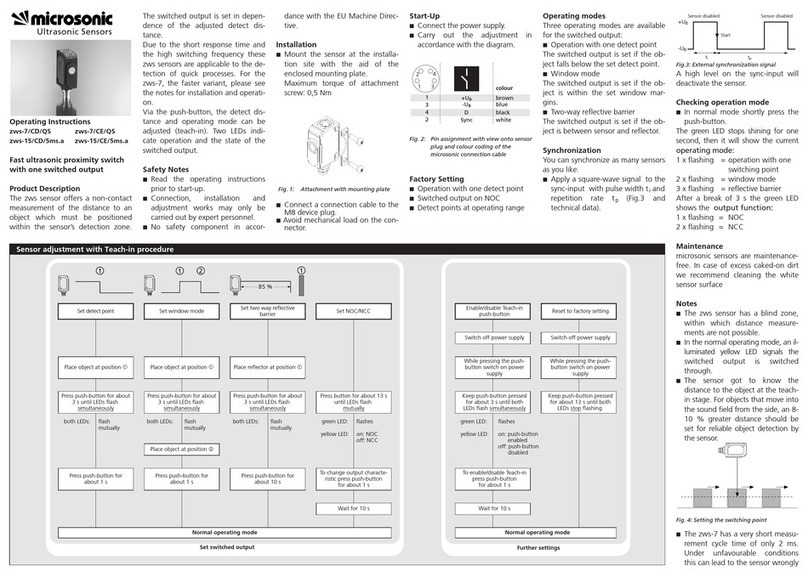

• Teach-in via push-buttons

2 push-buttons

• Teach-in via push-buttons

• LCA-2 with LinkControl

2 LEDs yellow/green (switched output set/not set)

• LCA-2 with LinkControl

2 LEDs yellow/green (switched output set/not set)

internal synchronisation up to 10 sensors

-25°C to +70°C

internal synchronisation up to 10 sensors

-25°C to +70°C

-40°C to +85°C

180 g

-40°C to +85°C

240 g

50 mm

4 Hz

100 mm

3 Hz

time delay before availability 1)

172 ms

< 380 ms

240 ms

< 450 ms

EN 60947-5-2 EN 60947-5-2

1) Can be programmed with LinkControl

2 x pnp, UB-2 V, Imax = 2 x 200 mA

2 x pnp, UB-2 V, Imax = 2 x 200 mA

NOC/NCC adjustable, short-circuit-proof NOC/NCC adjustable, short-circuit-proof

+UB

-UB

D1

D2

Sync/Com

1

2

4

5

3

2 pnp switched outputs

U

0 m

0.8 m

1.6 m

2.4 m

3.2 m

4 m

4.8 m

5.6 m

3.4 m

Plate

Round bar ø 27 mm

1.6 m

0.8 m

0 m

0.8 m

1.6 m

0 m

1.2 m

2.4 m

3.6 m

4.8 m

6 m

7.2 m

8.4 m

Plate

Round bar ø 27 mm

2.4 m

1.2 m

0 m

1.2 m

2.4 m

MV-DO-121024-464442

microsonic

GmbH

/

Phoenixseestraße

7

/

44263

Dortmund

/

Germany

/

T+49 231 975151-0 / F+49 231 975151-51 / E[email protected] / Wmicrosonic.de The content of this document is subject to technical changes. Specifications in this document are presented in a descriptive way only. They do not confirm any product features.

Enclosure Type 1

For use only in industrial

machinery NFPA 79 applications.

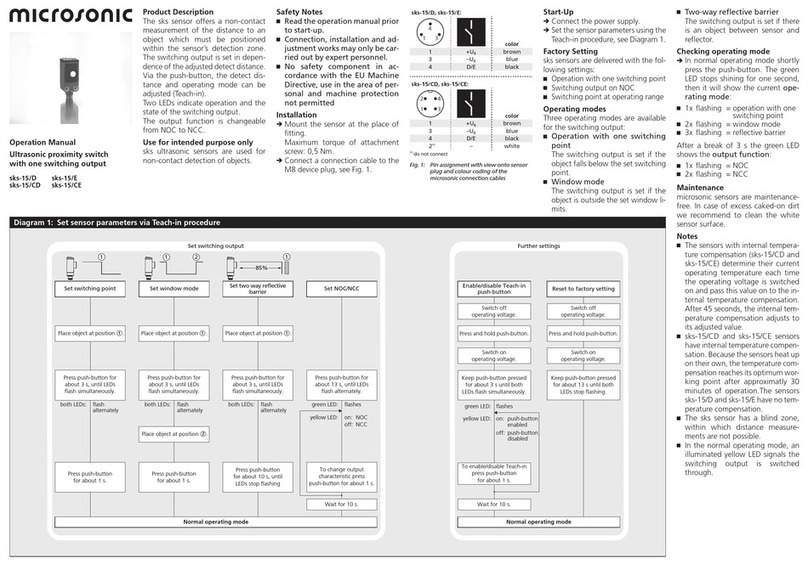

In the »Two-way reflective barrier«

operating mode, the object has to

be within the range of 0-85 % of

the set distance.

In the Teach-in procedure »Set de-

tect point – method A« the actual

distance to the object is taught to

the sensor as the detect point. If

the object moves towards the

sensor (e.g. with level control) then

the taught distance is the level at

which the sensor has to switch the

output.

If the object to be scanned moves

into the detection area from the

side, the Teach-in procedure »Set

detect point +8 % – method B«

should be used. In this way the

switching distance is set 8 % fur-

ther than the actual measured dis-

tance to the object. This ensures a

reliable switching distance even if

the height of the objects varies

slightly.

Fig. 3: Setting the detect point for different

directions of movement of the object

The sensor can be reset to its fac-

tory setting (see »Sensor adjust-

ment with Teach-in procedure«).

Optionally all Teach-in and addi-

tional sensor parameter settings

can be made using the LinkCon-

trol adapter (optional accessory)

and the LinkControl software for

windows.

Enclosure Type 1

For use only in industrial

machinery NFPA 79 applications.