Product Description

The sks sensor offers a non-con-

tactmeasurement of the distance to an

object which must be positioned

within the sensor‘s detection zone.

The switching output is set in depen-

dance of the adjusted detect distance.

Via the push-button, the distance and

operating mode can be adjusted

(Teach-in). Two LEDs indicate the state

of the switching output.

The output function is changeable

from NOC to NCC.

IO-Link

The sks sensor is IO-Link-capable in

accordance with IO-Link specication

V1.1 and supports Smart Sensor Pro-

le like Digital Measuring Sensor.

Safety Notes

Ԏ

Read the operation manual prior

to start-up.

ԎConnection, installation and ad-

justment works may only be car-

ried out by expert personnel.

Ԏ

No safety component in ac-

cordance with the EU Machine

Directive, use in the area of per-

sonal and machine protection

not permitted

Use for intended purpose only

sks ultrasonic sensors are used for

non-contact detection of objects.

Installation

Î

Mount the sensor at the place of

tting.

Maximum torque of attachment

screw: 0,5 Nm.

ÎConnect a connection cable to the

M8 device plug, see Fig.1.

1

2

3

4

colour

1 +UBbrown

3 –UBblue

4 F black

2*)– white

*) do not connect

Fig.1: Pin assignment with view onto sensor

plug and colour coding of the

microsonic connection cables

Start-Up

ÎConnect the power supply.

Î

Set the sensor parameters using the

Teach-in procedure, see Diagram1.

Factory Setting

Ԏ

Operating with one switching point

ԎSwitching output on NOC

Ԏ

Switching points at operating range

ԎFilter F01

ԎFilter strength P00

Operating modes

Three operating modes are available

for the switching output:

Ԏ

Operation with one switching

point

The switching output is set if the

object falls below the set switching

point.

ԎWindow mode

The switching output is set if the

object is inside the set window li-

mits.

ԎTwo-way reective barrier

The switching output is set if there

is an object between sensor and

reector.

Checking operating mode

Î

In normal operating mode shortly

press the push-button. The green

LED stops shining for one second,

then it will show the current ope-

rating mode:

Ԏ1x ashing = operation with one

switching point

Ԏ2x ashing = window mode

Ԏ3x ashing =reective barrier

After a break of 3 s the green LED

shows the output function:

Ԏ1x ashing =NOC

Ԏ2x ashing =NCC

Maintenance

microsonic sensors are maintenance-

free. In case of excess caked-on dirt

we recommend to clean the white

sensor surface.

Notes

Ԏ

Every time the power supply is swit-

ched on, the sensor detects its ac-

tual operating temperature and

transmits it to the internal tempera-

ture compensation. The adjusted

value is taken over after 45 seconds.

Ԏ

If the sensor was switched off for at

least 30 minutes and after power

on the the switching output is not

set for 30 minutes a new adjust-

ment of the internal temperature

compensation to the actual moun-

ting conditions takes place.

Ԏ

The sks sensor has a blind zone

whitin which distance measure-

ments are not possible.

ԎIn the normal operating mode, an

illuminated yellow LED signals the

switching output is switched

through.

Ԏ

In the »Set switching point – me-

thod A« Teach-in procedure the

actual distance to the object is

taught to the sensor as the swit-

ching point. If the object moves

towards the sensor (e.g. with level

control) then the taught distance is

the level at which the sensor has to

switch the output (see Fig.2).

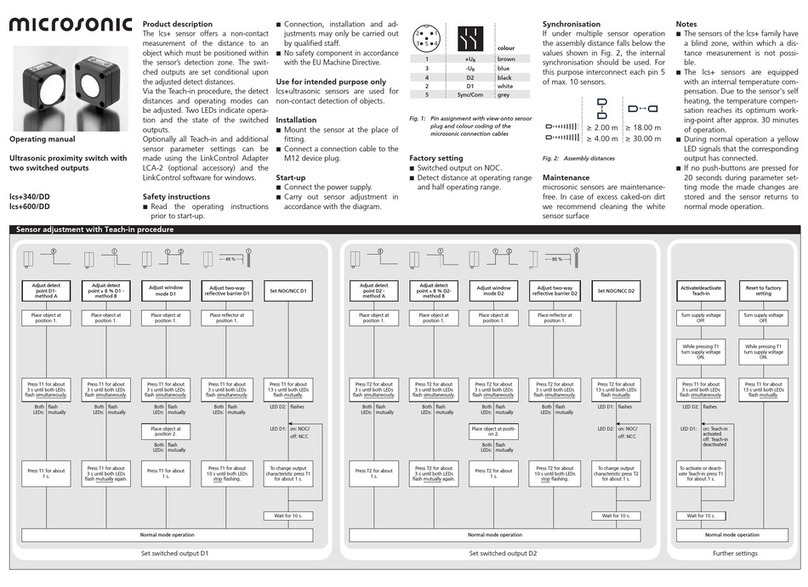

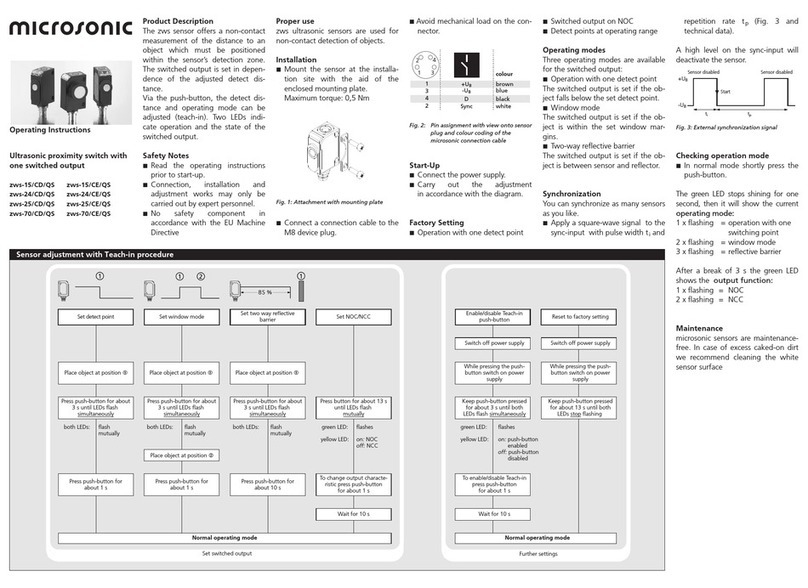

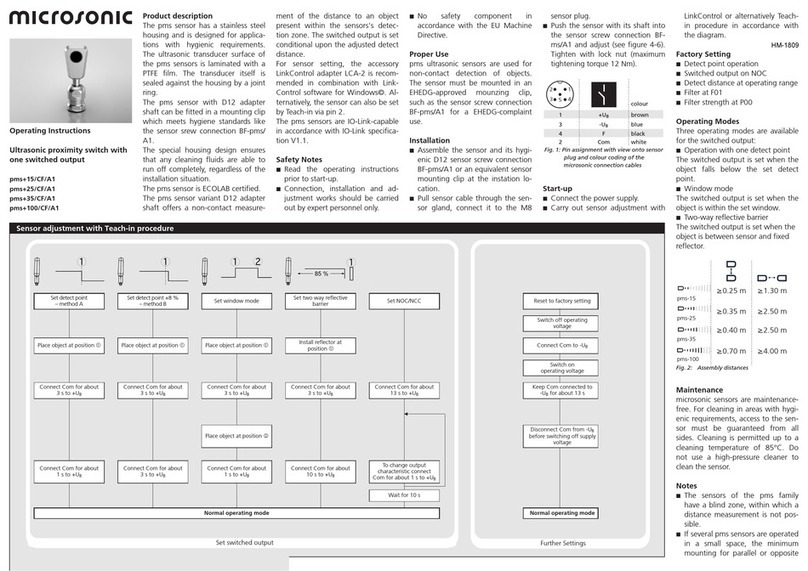

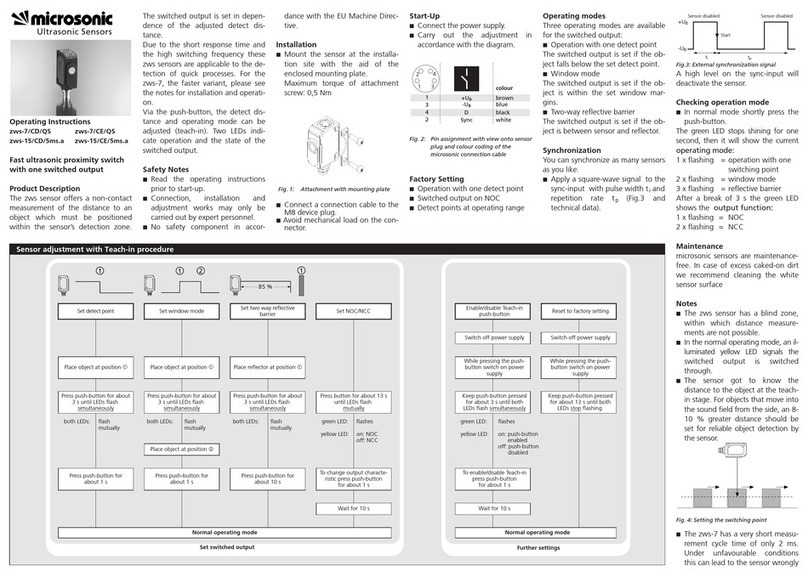

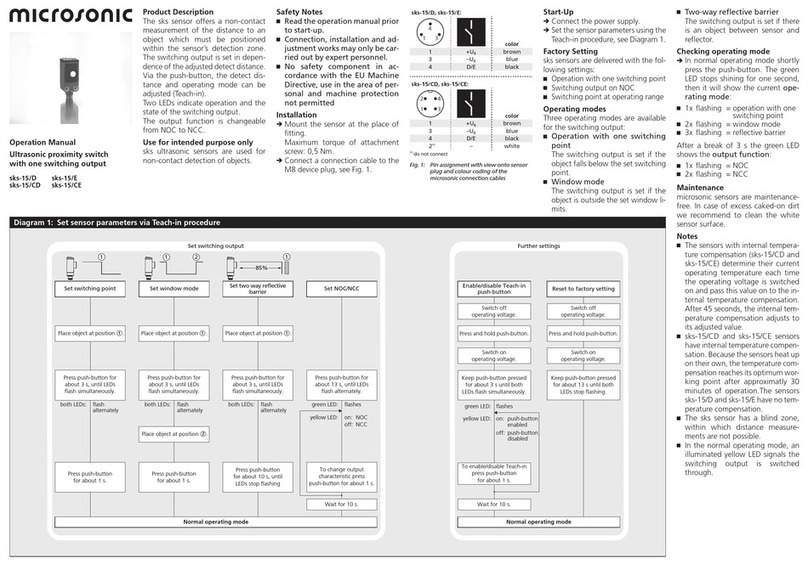

Diagram1: Set sensor parameters via Teach-in procedure

Press push-button for

about 3 s, until LEDs

flash simultaneously.

Press push-button for

about 3 s, until LEDs

flash simultaneously.

Press push-button for

about 3 s, until LEDs

flash simultaneously.

Press push-button for

about 13 s, until LEDs

flash alternately.

Press push-button

for about 1 s.

Press push-button

for about 1 s.

Press push-button for

about 10 s, until both

LEDs stop flashing.

Press push-button for

about 3 s, until both LEDs

flash alternately.

Place object at position .

1Place object at position .

1Place object at position .

1

Place object at position .

2

Wait for 10 s.

To change output

characteristic press

push-button for about 1 s.

Normal operating mode

Set switching outputs

Set window mode Set NOC/NCC

and twin mode 1)

Set switching point

– method A Set switching point +8 %

– method B Set two way reflective

barrier

both LEDs: flash

alternately flash

alternately flash

alternately flash

alternately

Press push-button for

about 3 s, until LEDs

flash simultaneously.

Place object at position .

1

both LEDs: both LEDs: both LEDs: green LED: flashes

yellow LED: on:

off: NCC

NOC

11 2

%92

1

1

Reset to factory setting

Wait for 10 s.

Normal operating mode

Further settings

Switch off

operating voltage.

Switch on

operating voltage.

Switch on

operating voltage.

Switch off

operating voltage.

Enable/disable Teach-in

push-button

To enable/disable Teach-in

press push-button

for about 1 s.

Press and hold push-button. Press and hold push-button.

Keep push-button pressed

for about 3 s until both

LEDs flash simultaneously.

Keep push-button pressed

for about 13 s until only the

yellow LED flashes.

flashesgreen LED:

on:

off:

push-button

enabled

push-button

disabled

yellow LED:

Operation Manual

Ultrasonic proximity switch

with one switching output

sks-15/CF/A