©2019 Mid West Products, Inc. -4- Form No. M1-1726

OPERATION

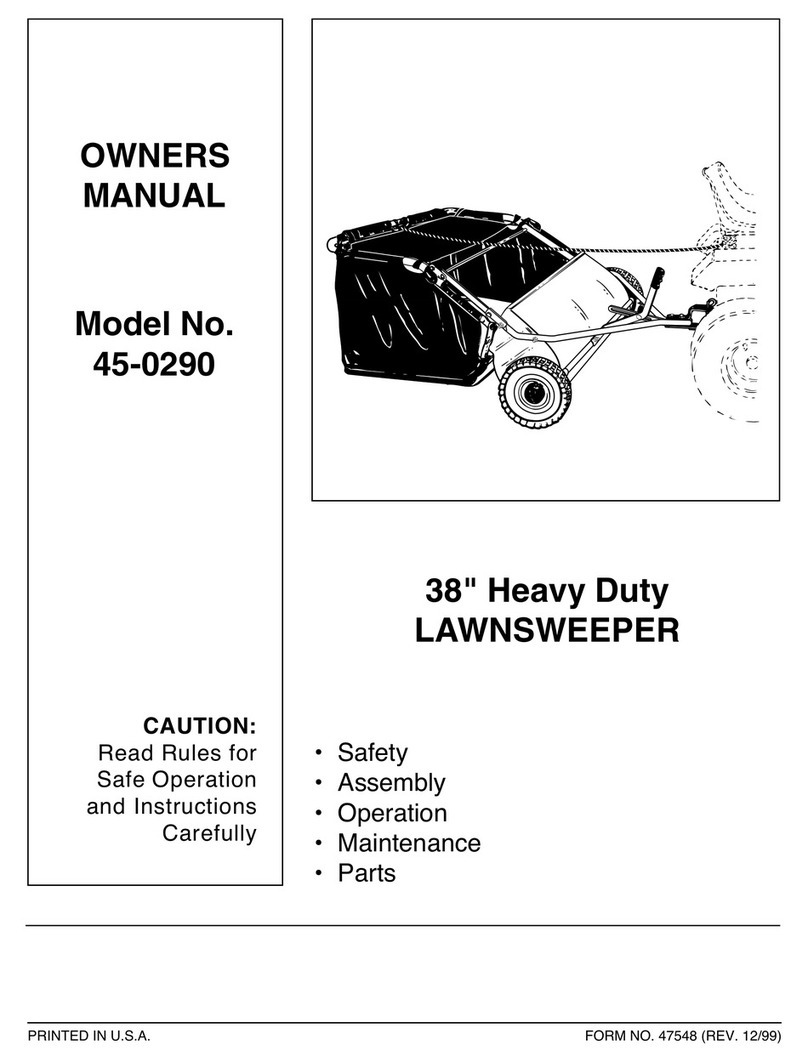

1. BRUSH ADJUSTMENT: Your new Trailing

Sweeper is equipped with a handy, “from the

Rider/Tractor seat,” Brush Adjustment. To

raise, push Tube (7) back and down until

desired sweeping height is attained. To lower,

push Tube (7) back and pull up to desired

sweeping height. See Fig. 4. For best results,

Brush should merely flick tops of grass

blades. Brushes should be raised when

transporting to and from sweeping area.

2. SWEEPING SPEED: For best results,

Rider/Tractor should travel at a 3 to 5 M.P.H.

range.

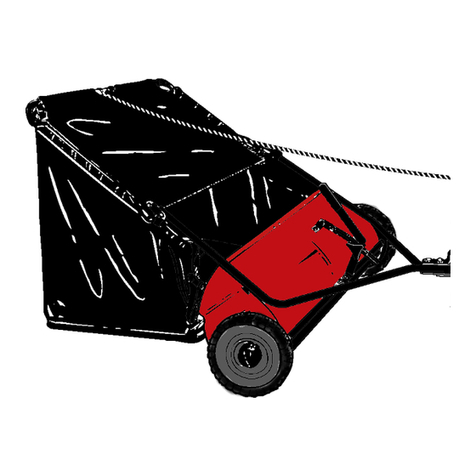

3. DUMPING: Exclusive rear dump action with

Lift-Out Hamper feature. To dump, merely

pull on Nylon Rope until Hamper turns over

dumping debris. Return Hamper slowly to its

original position by keeping pressure on

Rope.

MAINTENANCE

LUBRICATION:

1. Remove Wheel by removing Snap Ring.

Apply RETINAX LC grease (Available from

Mid West Products –937-337-3641) to Wheel

Gear and Pinion Gear. NOTE: Apply grease

to the center of Pinion Gear. Lubricate at

beginning of each season and every 20 hours

of use, or more often as conditions dictate.

See Fig. 6.

2. Remove Pinion Gear grease Pawl with

RETINAX LC.

3. When installing Pinion and Pawl refer to Fig.

8 for correct position.

4. Grease Wheel Axle at beginning of season

and before each use thereafter.

5. Apply SAE #20 oil or equivalent to Brush Axle

Bearings twice a season.

6. Oil Hamper Pivot Pins occasionally to prevent

rust and insure easy dumping.

BRUSH REPLACEMENT: Place Brush Strips in

slots of Brush Disc so shorter supporting bristles

are away from Brush sweeping rotation. Secure

at each Disc with three Holder Springs. Feed

Spring thru hole of Disc. Place upper point into

bristles with point next to Disc. With Pliers, grasp

Springs, turn and raise upward so lower point is

secured on backing of second Brush. Tap each

end of Spring with Pliers to make certain that the

points are completely down into bristles. See Fig.

9.