Midwest SHORESTATION User manual

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 1 of 23 shorestation.com 12-3-19

Owner’s Manual

SHORESTATION®HYDRAULIC BOAT LIFT

U.S. Patent Nos. 8,777,513

Models:

LTBH408HS, LTBH608HS, LTBH8010HS, LTPL15010HS, LTPL20010HS, LTPL808HS,

LTPM408HS, LTPM608HS, LTPM8010HS, LTPM10010HS, LTPM10016HS, LTPM15010HS,

LTPM15016HS, LTPM20010HS, LTPM20016HS

(LTPM808HS shown)

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 2 of 23 shorestation.com 12-3-19 asd 2021-12-16

Midwest Industries, Inc

122 E State Hwy 175

Ida Grove, IA 51445

Phone: (800) 859-3028

Fax: (712) 364-3361

www.ShoreStation.com

Congratulations on the purchase of your ShoreStation Hydraulic

boat lift! ShoreStation has been dedicated to providing innovative,

high quality, and reliable boat lifts since 1959. Our founder Byron

Godbersen built the brand with the philosophy “We build it

best…or we don’t build it”. That tradition continues today and

ensures that your boating experience will be enhanced by the

performance of your ShoreStation boat lift.

Thank you for choosing ShoreStation. Please study this manual

carefully BEFORE operating your lift and keep it in a safe place for

future reference. If you have questions or concerns about the

operation and/or service of your lift, please contact us at (800)

859-3028 or email shorestation@midwestindustries.com.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 3 of 23 shorestation.com 12-3-19 asd 2021-12-16

Contents

Safety Definitions......................................................................................4

Safety Instructions ....................................................................................5

Overview and Terminology.......................................................................7

Lift Operation..........................................................................................10

Wired Dock Switch Operation.............................................................10

Wireless Operation .............................................................................11

Loading Your Boat into the Lift ...............................................................13

Unloading Your Boat from the Lift..........................................................16

Leveling the Boat Lift ..............................................................................18

Lift Maintenance.....................................................................................19

Before and after every operation ...................................................19

Every Season ...................................................................................19

Every 5 Years...................................................................................20

Winter Storage Procedures.............................................................21

Other Storage Considerations.........................................................22

Warranty.................................................................................................22

Technical Specifications..........................................................................23

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 4 of 23 shorestation.com 12-3-19

Safety Definitions

Safety messages are presented throughout this document and labels

affixed to the product. The messages alert you to potential hazards to

you and/or property. The signal words DANGER, WARNING, and

CAUTION are preceded by an alert symbol and communicate the

severity of potential hazard. The severity of each type of message is

defined as follows:

DANGER indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury.

WARNING

DO NOT INSTALL OR OPERATE A LIFT WITHOUT

STUDYING THIS MANUAL AND INFORMATION ON LABELS

INCLUDED WITH THE LIFT. FAILURE TO DO SO CAN LEAD

TO IMPROPER OPERATION RESULTING INSERIOUS

PERSONAL INJURY AND/OR PRODUCT DAMAGE. IF YOU

HAVE FURTHER QUESTIONS AFTER REVIEWING THIS

INFORMATION, CONTACT A SHORESTATION

REPRESENTATIVE AT (800) 859-3028.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 5 of 23 shorestation.com 12-3-19

Safety Instructions

Every installation presents unique conditions that the customer should evaluate

before operating the equipment. The following instructions must be followed,

but may not encompass all potential hazards:

WARNING

This lift must be installed and setup by a qualified contractor. Do not operate

the lift unless the setup and inspection of the lift has been completed by a

qualified installer.

Review all operating instructions before operating the lift.

Never use this equipment to lift people. People must exit the boat prior to

lifting it out of the water.

Never use this equipment to lift overhead. Install the lift so the load remains at

or below the dock level.

This equipment is designed to lift boats. Never use it to lift other items.

Never exceed the stated capacity of the lift.

Do not allow children to operate or play on the equipment.

Do not install or use the lift if there are any signs of damage.

The wireless control system should only be operated if the operator has clear

vision of the lift equipment and its surrounding location.

Never install or work on the equipment without first verifying that the A/C

power supply (if present) is protected by a functioning Ground Fault Circuit

Interrupt (GFCI) in accordance with National Electric Code section 210.8 and any

additional local code requirements.

Do not modify the equipment unless you have received direct written approval

from the manufacturer (ShoreStation).

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 6 of 23 shorestation.com 12-3-19

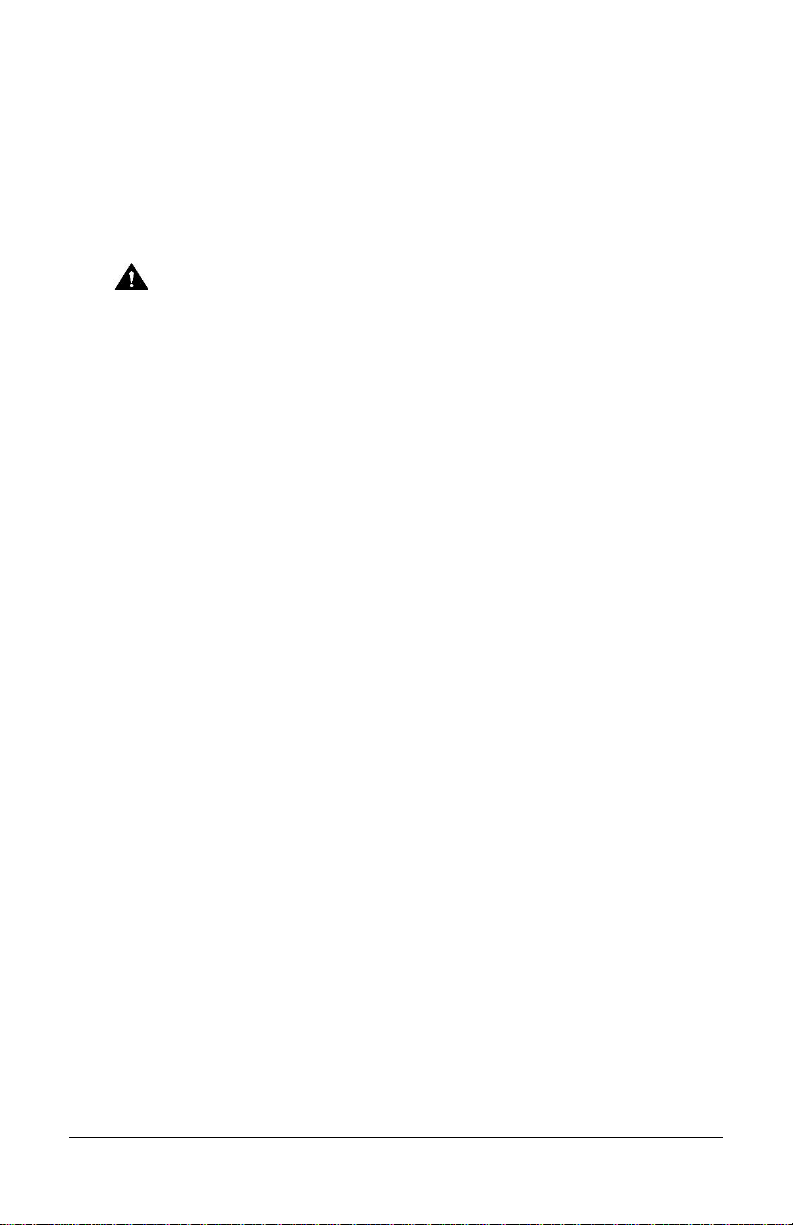

DO NOT GO NEAR

LEAKS!

•

High pressure oil

easily punctures skin

causing serious injury,

gangrene or death.

•

If injured, seek

emergency medical

help. Immediate

surgery is required to

remove oil.

•

Do not use finger or

skin to check for leaks.

•

Lower load or relieve

hydraulic pressure

before loosening

fittings.

DANGER

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 7 of 23 shorestation.com 12-3-19 asd 2021-12-16

Overview and Terminology

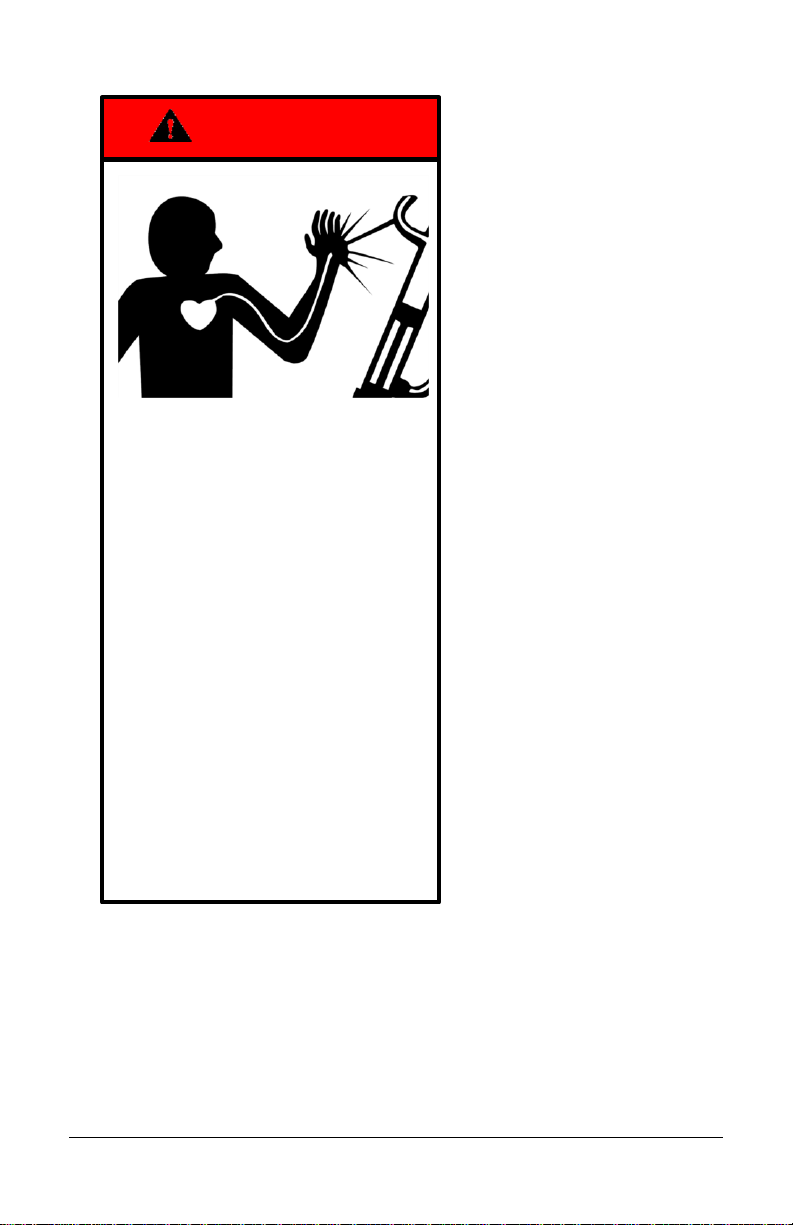

ShoreStation piling-mounted and roof-mounted systems have 4 main

components: the Hydraulic Power Unit, Lift tubes, Platform, and Bunks.

The components are illustrated in Figure 1 and Figure 2 below.

Lift Tube

Lift Tube

Lift Platform

Support

Bunks

Figure 1 –ShoreStation Boat Lift Components

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 8 of 23 shorestation.com 12-3-19 asd 2021-12-16

The Hydraulic Power Unit (HPU) is a 24 VDC powered

hydraulic system (Figure 2). This system converts the electric

power stored within the batteries into hydraulic pressure. The

pressure is delivered to the lift tube through hoses and causes

the lift cylinders inside the lift tubes to retract.

The retract motion pulls the lift cables and generates the lifting

motion of the boat lift platform. The internal structure of the lift

tubes is show in Figure 3.

The system charge is maintained by either a solar panel or an A/C

powered Battery Tender®. The charge source should be constantly

connected to the lift batteries. The lift can operate without the

charging source present, but permanent battery damage could result

if the batteries are run too low.

Figure 2 - Hydraulic Power Unit (HPU300 shown)

Batteries

Power Unit

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 9 of 23 shorestation.com 12-3-19 asd 2021-12-16

The ShoreStation boat lifts come standard with two operating

controls: Wireless and Dock Box. The Wireless system allows you to

operate the lift remotely but should only be used when you have

clear vision of the entire lift and surroundings. The Dock Box provides

a hard-wired control of the lift. The operation of both is described in

the Controls section of this document.

Figure 3 - Lift Tube Internal Structure

Lift Cylinder

Lift Cable

Pulley

block

Lift Cable

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 10 of 23 shorestation.com 12-3-19

Lift Operation

There are two methods of operating the lift: wired dock switch (Figure

4) and wireless remote (Figure 5).

Wired Dock Switch Operation

1 –Unlockthelift

The lockout switch disables the lift control system (wired and wireless).

To unlock it, insert the key and turn clockwise 90 degrees (horizontal).

2 –Run theliftUP orDOWN usingtheToggleSwitch

Follow all warnings and instruction printed on the Dock Switch Box.

Press the rocker switch up to run the lift up. Press the toggle switch

down to run the lift down.

3 –Lockthelift

When finished using the lift, disable it by turning the lockout key

counter clockwise 90 degrees (vertical) and remove the key.

Figure 4 - Wired Dock Switch

Level

Switch

Lockout Key

Switch

UP/Down

Toggle Switch

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 11 of 23 shorestation.com 12-3-

19 asd 2021-12-16

Wireless Operation

Figure 5 –Wireless Remote Control

NEVER LIFT YOUR BOAT

WITH PEOPLE IN IT. DOING

SO COULD RESULT DEATH

OR SERIOUS INJURY!

WARNING

OPERATE THE LIFT ONLY

WHEN YOU HAVE CLEAR

VIEW OF THE LIFT AND

SURROUNDING AREA.

WARNING

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 12 of 23 shorestation.com 12-3-

19 asd 2021-12-16

1 –Unlockthekeyfob

Lock mode is indicated by all 5 Mode Indicator lights

flashing when a button is pressed on the key fob. The key

fobs will automatically go into ‘lock mode’ after 3 minutes.

In ‘lock mode’ the transmitter will not react until it is

unlocked. To unlock the key fob, hold both the Up and

Down buttons at the same time for 3 seconds. The mode

indicator light will flash indicating that the key fob is

unlocked and will operate the lift. If no button is pressed for

3 minutes, the key fob will automatically go into lock mode.

2 –Upanddownfunctions

Press and hold the Up button to

run the lift up. Press and hold the

Down button to run the lift down.

3 –Locking thekey fob

The key fob will automatically go

into lock mode after 3 minutes or

you can lock the key fob by

holding both the Up and Down buttons at the same time for 3 seconds. The

flashing mode indicator light will turn off indicating the key fob is in lock mode.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 13 of 23 shorestation.com 12-3-19

Loading Your Boat into the Lift

1 –Lowerthelift

Before loading your boat into

the lift, be sure the platform has

been lowered into the water

deep enough to ensure the boat

will float over the top of the

cradle and support bunks. It is a

good idea to use tape to mark

the lift cables. This mark should

be placed to refer to the water

line when the platform is at

sufficient depth. This reference

mark is helpful if your lift is in

an area where the tide

changes the water level.

If you are approaching

the lift in the boat, lower

the lift using the wireless

remote to your reference

mark.

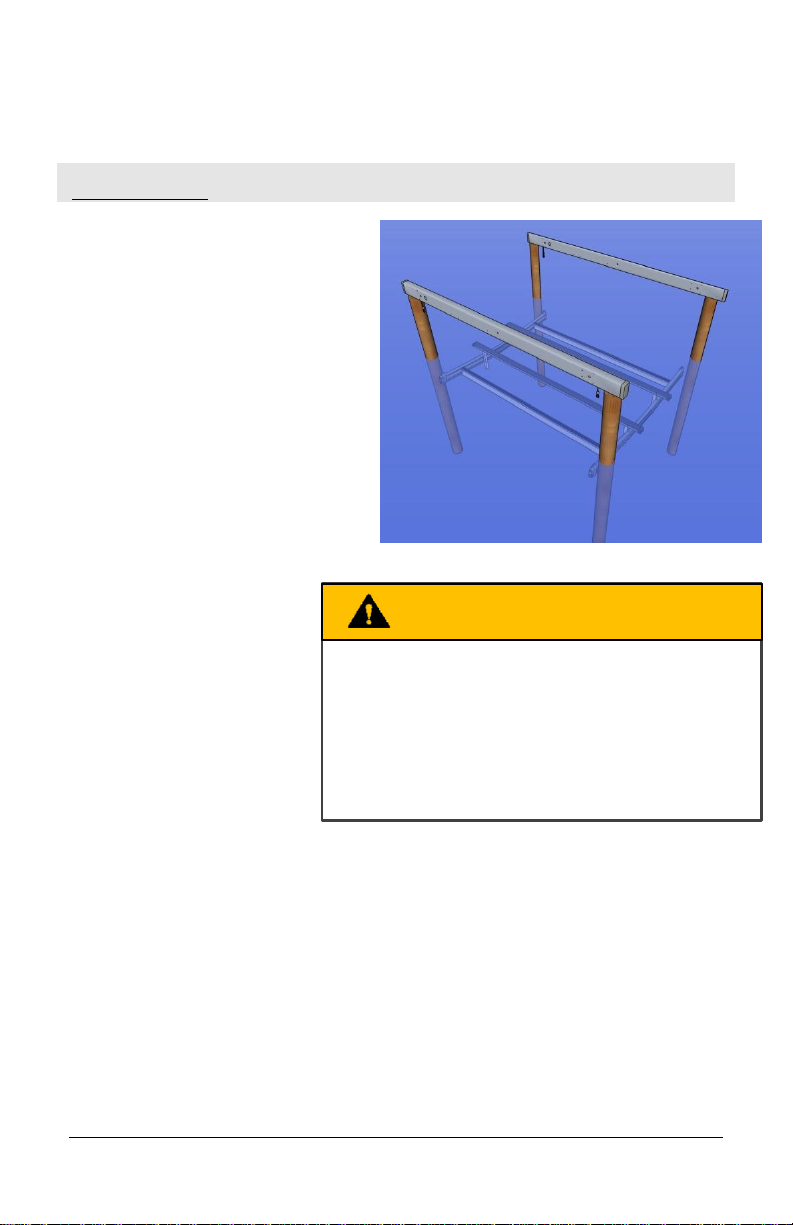

DO NOT ATTEMPT TO LOAD OR

UNLOAD YOUR BOAT WHEN LARGE

WAVES, WAKES, OR HIGH WINDS ARE

PRESENT. DOING SO COULD CAUSE

DAMAGE TO YOUR LIFT AND/OR

BOAT.

WARNING

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 14 of 23 shorestation.com 12-3-

19 asd 2021-12-16

2 –Preparetodriveintothelift

The first time your boat is put on the lift, the proper

position of the boat should be marked or referenced

so that the driver can easily identify the correct

position of the boat on the lift. This avoids

accidentally driving too far into the lift and causing

damage to the lift or boat.

When approaching the lift, unlock the remote control by pressing the

UP and DOWN buttons at the same time for more than 3 seconds until

the mode 1 light starts to flash.

Ensure that your lift platform is low enough by looking at the reference

mark the lift. If needed, use the remote control to run the lift down or

up to properly position the lift platform.

3–Driveintothelift

With the remotes unlocked and the boat lift platform lowered, slowly

drive into the lift at idle speed and stop the boat when positioned at the

reference mark.

Use mode 1 (first light

flashing) of the remote

control to run the lift up

until the boat is secured

by the lift platform and

all passengers can safely

disembark from the

boat. Do not raise the

boat totally out of the

water with passengers

in the boat.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 15 of 23 shorestation.com 12-3-

19 asd 2021-12-16

4–Fullylift theboat

Hold the up button on the remote control or on the dock switch to raise

the boat. Continue running

the lift until the limit

switches turn the lift off. If

limit switches are not

installed, run the lift until

both sides (port and

starboard) stop moving.

This ensures that both lift

cylinders are fully retracted

and the lift platform is

level. Avoid running the lift for more than a few seconds when both

sides are not moving.

5 –Lockouttheliftandremotes

Turn the lockout switch to the off position

(vertical) and remove the key.

The remote controls will automatically lock if

not used for more than 3 minutes. You can

lock the remotes before the 3 minute period

by holding both the UP and DOWN buttons on

the remote until the light stops flashing.

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 16 of 23 shorestation.com 12-3-19

Unloading Your Boat from

the Lift

1 –Unlockthelift

Unlock your boat lift by inserting the lockout

switch key and turning to the on position (90

degrees clockwise).

2 –Lowerthe boat

Lower the boat using the

dock switch until the boat

is in the water enough to

safely start the motor

while still being secured

by the lift platform.

DO NOT ATTEMPT TO LOAD OR

UNLOAD YOUR BOAT WHEN LARGE

WAVES, WAKES, OR HIGH WINDS ARE

PRESENT. DOING SO COULD CAUSE

DAMAGE TO YOUR LIFT AND/OR

BOAT.

WARNING

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 17 of 23 shorestation.com 12-3-

19 asd 2021-12-16

3 –Preparetodrive outofthelift

Unlock the remote control by holding the UP and DOWN buttons until

the mode 1 light

flashes.

Ensure that the

waterway

surrounding the lift is

clear of people and

other objects. Start

the boat and put into

idle reverse. Do not

attempt to ‘power

off’ the lift.

With the boat in idle

reverse, lower the lift using

the remote control until the

boat is free to move.

Carefully navigate the boat

out of the lift.

If your location experiences heavy currents due to tide or other actions,

or if you plan to leave the lift unattended for more than a day, raise the

lift platform out of the water using the remote control to avoid damage

and debris accumulation on the lift.

Never leave the boat

running while unattended in

the lift.

WARNING

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 18 of 23 shorestation.com 12-3-

19 asd 2021-12-16

Leveling the Boat Lift

1 –Unlockthelift

Unlock your boat lift by inserting the lockout switch key and turning to

the on position (90 degrees clockwise).

2–RuntheliftDOWN

Hold the toggle switch DOWN to

start running the lift down.

3 –AdjusttheliftwithLevel Switch

While running down, press the

level switch forward or backward

to adjust the level of the

platform.

Level

Switch

Lockout Key

Switch

UP/Down

Toggle Switch

The level switch levels the

lift manually. You must be

able to see the entire lift

and boat to ensure the lift

is adjusting correctly.

Incorrectly adjusting the

lift could cause the lift to

become more out of level

and damage the lift and/or

boat.

WARNING

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 19 of 23 shorestation.com 12-3-19

Lift Maintenance

ShoreStation Hydraulic lifts are low maintenance systems; however, all

mechanical systems require frequent inspection and proper

maintenance procedures to ensure proper, safe performance. The

following procedures must be performed:

Before and after every operation

•Check the lift at every operation for hydraulic leaks and damage

to the hydraulic hoses and fittings. Have any worn or damaged

components replaced by your ShoreStation dealer before

operating the lift.

•Check all lift cables and extension chains for signs of wear or

fraying. Have any worn or damaged components replaced by

your ShoreStation dealer before operating the lift.

•If an A/C Battery Tender is used to charge the lift batteries,

check the system to make sure it is powered and charging

correctly after operating the lift. If an error condition exists

(alternating lights), unplug the Battery Tender for a few seconds

and plug back in to ensure the system recharges while

unattended.

•If a solar panel is used to charge the lift batteries, check the

panel to make sure it is clean and clear of debris.

Every Season

•Remove the storage pins from the lift tubes by running the lift

UP to make sure it is fully UP. This will free any load against the

pins making them easier to remove.

•Visually check all hydraulic fittings and hoses for signs of leaks

or damage.

•Check the hydraulic fluid level with the lift fully raised to make

sure the reservoir is at least ¾ full. The reservoir level is highest

when the lift is fully UP. If additional fluid is required, contact

Midwest Industries, Inc. Ida Grove, IA 51445 800-859-3028 0004549

Page 20 of 23 shorestation.com 12-3-

19 asd 2021-12-16

your ShoreStation dealer to get the correct type of fluid for your

system.

•Check the color of the hydraulic fluid. If the fluid appears to be

‘milky’, it could be contaminated. The oil should be changed by

your ShoreStation dealer.

•Clean the solar panel (if used) using window cleaner.

•Make sure the Battery Tender (if used) is functioning. Refer to

the instruction manual provided with the Battery Tender

system.

•Use a battery tester to test the lift batteries to make sure they

are able to charge.

•Check all battery connections to make sure they are tight and

not corroded. Connections should be carefully cleaned to

ensure reliable lift performance. Contact your dealer to clean

the connections if you are not familiar with the process.

•Check any structural connections between the lift and wood

dock, beam and piling components. Have any components that

show signs of deterioration replaced by your installer.

Every 5 Years

•A full lift inspection should be performed by a ShoreStation

dealer every 5 years to ensure the dock and lift structure is

sound.

•The hydraulic fluid should be changed every 5 years (depending

on use and condition). The fluid change should only be

performed by a qualified ShoreStation dealer.

Table of contents

Popular Lifting System manuals by other brands

Palfinger

Palfinger ILU 40 INSTALLATION MANUAL & CHECK-OFF SHEET

RGC

RGC HL7000 instructions

Lifton

Lifton DUO user manual

Nussbaum

Nussbaum UNI-LIFT 2500 Operating Instruction and Documentation

Hy-Brid Lifts

Hy-Brid Lifts HB-1230CE MAINTENANCE & TROUBLESHOOTING MANUAL

ThyssenKrupp

ThyssenKrupp HOMEGLIDE STAIRLIFT user manual