MIG-O-MAT Lotstar 141 User manual

MIG·O·MAT Mikrofügetechnik GmbH • Werksstrasse 20 • DE-57299 Burbach • Fon +49 (0) 2736 4154 0 • Fax +49 (0) 2736 4154 99

info@mig-o-mat.com · www.mig-o-mat.com

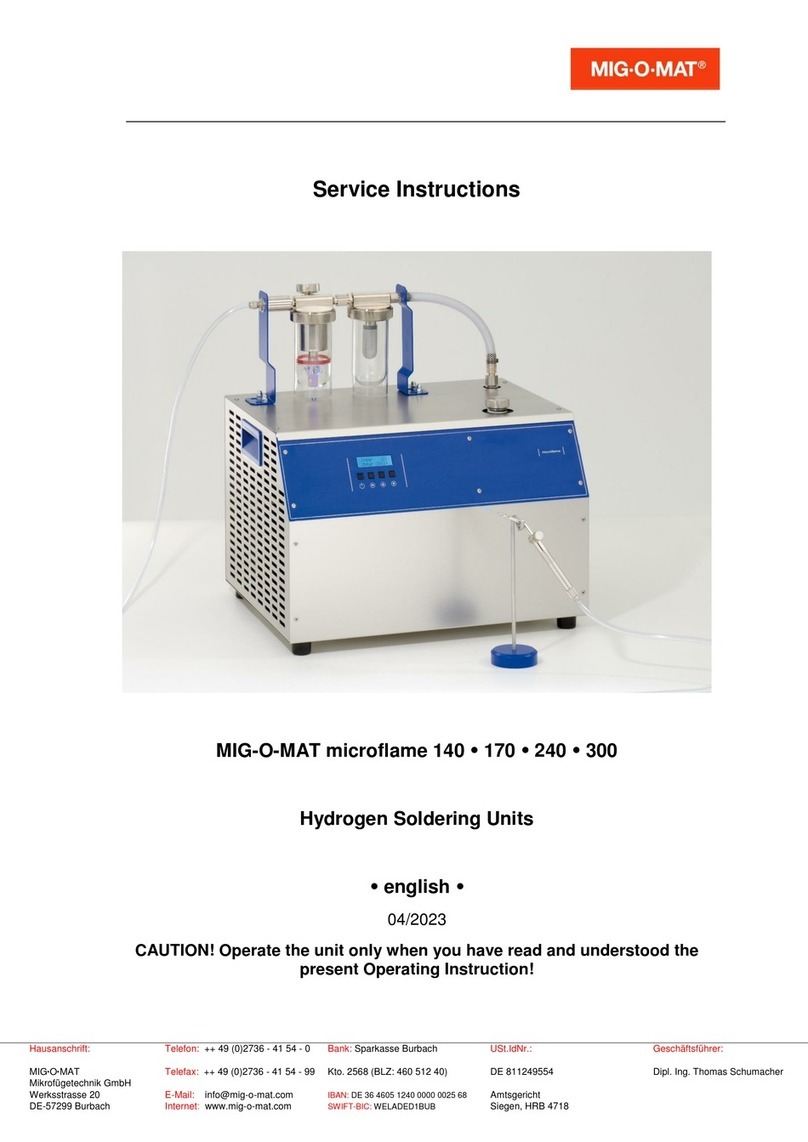

Operating Instructions

MIG-O-MAT Lötstar 141

175

241

301

Hydrogen Soldering Units

English

Contents

2BA_Lötstar_EN_Vers.07.2016

© MIG·O·MAT GmbH

Contents

Contents........................................................................... 2

1 General....................................................................... 4

2 Important safety warnings .......................................... 4

3 Description of operational process ............................. 7

4 Product description..................................................... 8

4.1 Product features MIG-O-MAT Lötstar units .............. 8

4.2 Safety devices ......................................................... 9

4.3 CE conformity .......................................................... 9

4.4 Delivery volume ......................................................10

4.5 Description of unit components...............................11

4.6 Description of unit top part ......................................12

4.7 Description of unit back...........................................13

4.8 Description of operating panel ................................14

5 Preparatory measures for initial operation................ 15

5.1 Unpacking and placement of unit............................15

5.2 Mounting of the unit top part ...................................16

5.3 Filling of the reactor with electrolyte ........................18

5.4 Filling of the vaporizer glass with vaporizer liquid....20

5.5 Connecting the unit to the mains.............................22

5.6 Setting of operating language in the display............23

6 Initial operation ......................................................... 24

6.1 Switch on the unit ...................................................24

6.2 Switch on the operating mode.................................24

6.3 Electrolyte filling level check ...................................24

6.4 Leak check .............................................................25

6.5 Select the burner nozzle .........................................26

6.6 Adjustment of the gas pressure at the operating

panel 27

6.7 Regulation of the burner flame at the burner hand

piece 28

6.8 Operating stops ......................................................28

6.9 After operation ........................................................28

6.10 Extinction of the flame at the burner hand piece .....30

7 Technical details....................................................... 31

8 Maintenance and repair............................................ 32

8.1 Maintenance ...........................................................32

Contents

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 3

8.1.1 Check and refill demineralized water in the reactor

33

8.1.2 Refilling of vaporizer liquid ...................................35

8.1.3 Cleaning of the vaporizer glass............................36

8.1.4 Cleaning of the dryer glass ..................................37

8.1.5 Exchange of the filter cartridge in the dryer glass 37

8.2 Service indications (display)....................................38

8.3 Malfunctions and warnings......................................38

8.4 Trouble shooting .....................................................40

8.5 Repair.....................................................................42

8.6 Transportation of the unit ........................................42

8.7 Removal of electrolyte ............................................43

8.8 Removal of vaporizer liquid.....................................44

8.9 Spare Parts & accessoires......................................45

9 Putting out of operation and waste disposal............. 51

9.1 Waste disposal of Lötstar unit .................................51

9.2 Waste disposal of electrolyte ..................................51

9.3 Waste disposal of vaporizer liquid...........................51

10 Manufacturer’s contact address ............................... 52

4BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

1 General

The present Operating Instructions are part of the delivered

equipment. They must be ready for use at any time and remain

with the unit in case of resale.

We reserve the right to carry out technical modifications on the

unit due to advanced development.

An operating manual cannot take account of every conceivable

use. Contact your dealer or the manufacturer for further

information or in the event of problems which are not covered or

not sufficiently covered in this operating manual

2 Important safety warnings

Carefully read and observe before putting into operation!

The present unit operates with acid, flammable and –

depending on the type of vaporizer liquid – toxic substances.

Therefore, a predetermined operating sequence and strict

observance of the safety and protection measures described

below are prerequisite.

The present operating instructions cannot take each and every

specific regulation into consideration which might apply in

various countries. The operator of the unit must ensure that all

relevant local regulations concerning the prevention of

accidents and the use of hazardous substances are known and

observed.

MIG-O-MAT Lötstar soldering and welding units are

intended for soldering, welding and melting of metals.

Operation is allowed by industrial and commercial

businesses only.

The unit must be operated by specialized, trained staff only.

The operating instructions must be strictly observed. The unit

must not be operated by unauthorized persons or by children.

For reasons of safety, the unit must be connected to a

shockproof socket only. The technical data indicated on the

nameplate must correspond with the available local connection

conditions, particularly with regard to mains voltage and current

consumption values.

For maintenance and service works, in case of liquid inside the

unit and malfunctions, and when you have finished working with

the unit pull the main plug. In case of a malfunctioning please

contact your supplier or the manufacturer.

The unit must be opened by authorized and specialized staff

only!

Instructions for the

operator

Intended use

Operating staff

Mains connection

Risks due to electric

current

Important safety warnings

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 5

Electrolyte solution can cause severe chemical burns!

Always wear alkaline-resistant gloves and goggles when you

work with electrolyte solution! Do not eat or drink while filling

electrolyte solution into the unit!

Wash your hands after filling the reactor!

Avoid contact with eyes and skin! In case of contact with the

eyes rinse the open eye(s) under running water for several

minutes and seek medical advice. In case of contact with the

skin wash immediately with soap and rinse thoroughly.

If you have overfilled the unit, do not remove any excess

electrolyte by sucking it through a hose by mouth. There is a

risk of severe chemical burns! If you have overfilled the unit by

mistake, use a suitable alkaline-resistant suction device which

is not operated by mouth.

Electrolyte containers which are not completely empty must be

kept tightly closed and stored out of reach of unauthorized

persons, in particular of children. Thoroughly rinse empty

electrolyte containers with water. Then the container can be

disposed of into the ordinary waste. We recommend to contact

the local authorities for information on the use and waste

disposal of electrolytes.

Risk of fire and explosion! The vaporizer liquid is a flammable

substance! Keep away from ignition sources while filling

vaporizer liquid into the unit!

Avoid inhaling the vapors! Do not eat, drink or smoke while

handling the vaporizer liquid! Wear goggles and gloves!

MIG-O-MAT vaporizer liquid BLQ 1800 is not toxic. When using

other, methanol-containing vaporizer liquids, take into

consideration that these substances may be highly toxic! Read

and observe the relevant instructions on the labels of the

products used.

Risk of fire and explosion! Do not leave the unit switched on

unsupervised. The gas escaping from the unit is highly

flammable and explosive. The switched-on unit must be

operated with opened valve only until the flame ignites. Any

escaping gas which does not burn in a flame causes a high risk

of fire and explosion! For refilling the reactor keep away from

ignition sources! Even the open pressure-less reactor contains

highly explosive burnable gases.

To prevent the creation of electrostatic sparks immediately

before opening the reactor (e.g. for checking the filling level or

for refilling demineralized water), touch the cap nuts on the top

part of the unit or the metal screws on the housing with both

hands.

Risks caused by

electrolyte

Risks caused by

vaporizer liquid

Risks caused by

burnable gas and gas

flame

6BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

Risk of burns and fire! Hang the torch hand piece with burning

flame onto the soldering stand for short operating stops. Ensure

that there is a sufficient distance between the flame and any

flammable items. Ensure that there is sufficient ventilation for all

soldering and welding operations!

The manufacturer cannot be held liable for damages on

persons, equipment or work pieces caused by improper use.

The operator is responsible for the correct instruction of the

operating staff.

Exclusion of liability

Description of operational process

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 7

3 Description of operational process

Lötstar units produce a hydrogen flame with very high

temperatures of up to approx. 2850°C.

In the integrated reactor, detonating gas is produced through

electrolysis from demineralized water.

The detonating gas is guided from the reactor to a condensate

separator to dry. Then, the gas is enriched with solvent vapours

in a vaporizer tank. The processed detonating gas is then

conducted through the gas hose to the burner hand piece via a

backfire protection device.

If the detonating gas ignites, it reacts releasing heat. The

remainder of the reaction is water (H2O).

Temperature and energy of the burner flame can be adjusted to

the soldering or welding job by the selection of a suitable nozzle

size and the type of vaporizer liquid.

The fine adjustment of the quantity of delivered gas is carried

out by the regulating wheel on the burner hand piece. The

operating pressure can also be set at the operating panel

depending on the required energy of the flame.

As soon as the valve at the burner hand piece is closed the gas

production is automatically interrupted.

Depending on the temperature of the electrolyte reactor the

ventilation device keeps on operating for a certain period of

time until the reactor has cooled down to 45°C. The ventilation

device is fitted with 3 speed ranges which are controlled

electronically.

The extremely low energy consumption and the low cost of

consumption goods (demineralized water, vaporizer liquid)

ensure extraordinarily low operating costs compared to other

procedures.

Operational principle

Adjustment of the

Lötstar

Stand

-

by mode

Economic efficiency

8BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

4 Product description

4.1 Product features MIG-O-MAT Lötstar units

The MIG-O-MAT Lötstar units comprise the latest soldering

and welding technology.

The special top part makes operation, maintenance and

functional checks particularly easy. There is almost no

condensation inside the unit due to the special gas guiding

device. This increases both reliability and service life of the

units.

The MIG-O-MAT Lötstar units are equipped with a quick

analogous pressure control to allow operation of the units on

changing jobs or on more than one workplace. The operating

pressure is variable and is automatically kept precisely at a

constant value even when the ambient conditions change.

Additional advantages:

•Very high safety standard in compliance with DIN 32508

•Hydrogen-oxygen mixture burns without residues

•Easy operation

•Integrated leak detector check

•Microprocessor-controlled regulation of the operating

pressure

•Almost noiseless operation with temperature-controlled

ventilation device („whisper cooling“)

•Single or multi-workplace operation possible

•Low operating costs:

Any losses of liquid due to operational processes are

compensated by refilling demineralized water.

Exchange of the electrolyte is not required before approx.

1000-1500 operating hours.

No mineral wool padding necessary for drying the gas.

Product description

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 9

4.2 Safety devices

Lötstar units are designed and manufactured in compliance with

the latest technology standards. Operation is safe provided that

the safety and operating instructions are observed and provided

that the units are used only for applications for which they are

intended.

Safe operation of the units is ensured by means of the following

safety devices.

•Gas pressure monitoring by means of safety pressure

switch

•Temperature monitoring of the reactor and of the

transformer

•Flame barrier (backfire protection device) integrated in

burner hand piece

•Flame barrier (backfire protection device) and temperature

activated cut off valve at the gas outlet

•Main filters (EMC)

•Mains fuse

A high operating safety is guaranteed because gas is produced

only when it is required (i.e. when the valve at the burner hand

piece is open).

4.3 CE conformity

The present MIG-O-MAT Lötstar hydrogen soldering unit is in

compliance with all relevant CE marking criteria.

The declaration of conformity can be obtained from the

manufacturer.

10 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

4.4 Delivery volume

The delivery volume of the Lötstar units comprises:

•Lötstar soldering and welding unit

•Electrolyte, ready for use

•vaporizer liquid BLQ1800

•5 pieces of burner nozzles depending on type of unit

•gas hose 3.0 m long

•burner hand piece

•Torch stand with holder for nozzles

•filling funnel

•glass floating body for checking the electrolyte filling level

•1 pair of disposable rubber gloves

•goggles

•Operating Instructions

The units are supplied in special packing (reusable, please

store for possible future transportation, e.g. for service or repair

return shipment)

Product description

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 11

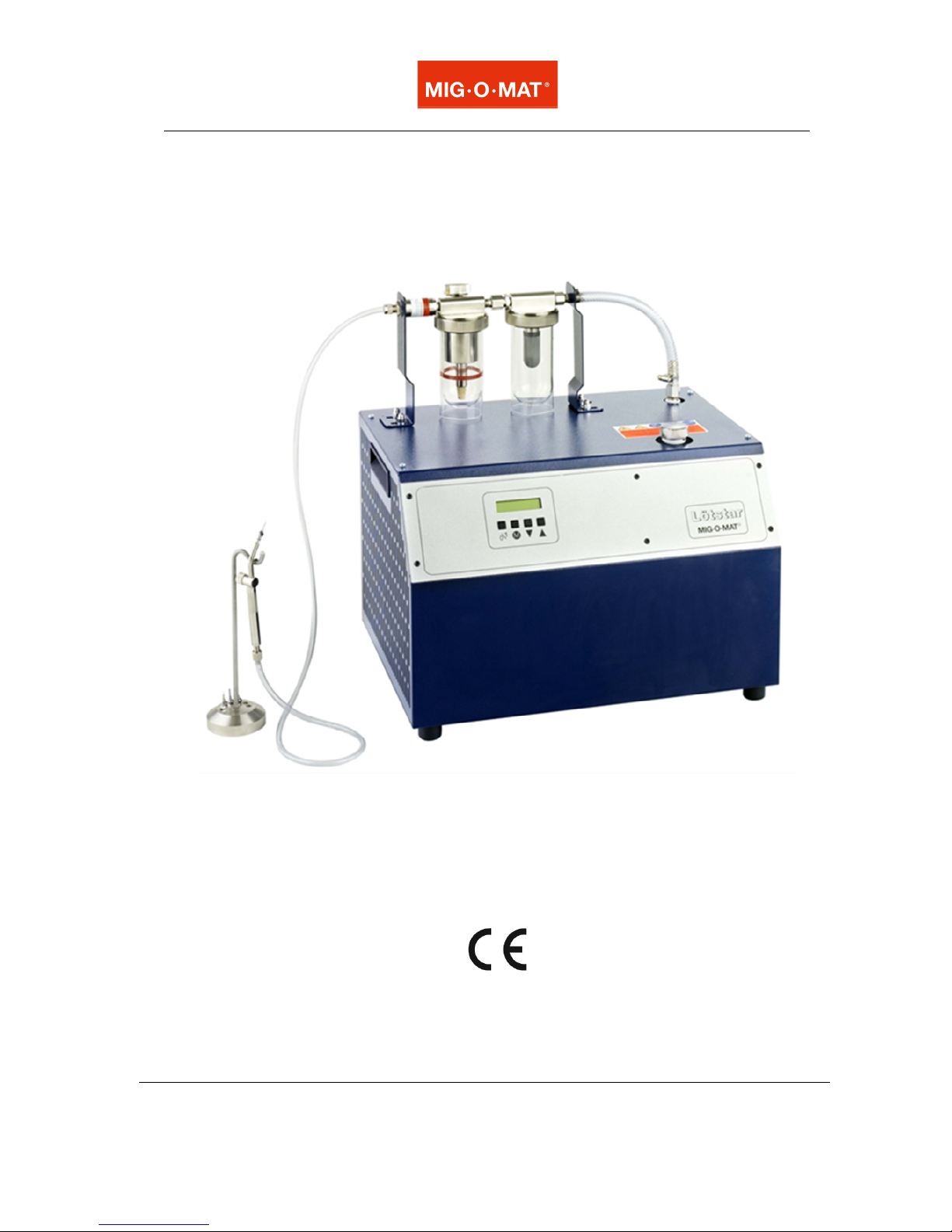

4.5 Description of unit components

Illustration 4.5. Unit front and side view (here Lötstar 300)

Unit top part with glasses for vaporizer liquid and condensate

separator. Moveable for an easy removal of the glasses.

Handles (on both sides)

Operating panel with display and operating keys

Ventilation openings (on both sides)

Burner hand piece

Holder for burner hand piece

A

B

C

D

E

F

A

C

D

E

F

B

12 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

4.6 Description of unit top part

Illustration 4.6. Unit top part of Lötstar

Gas hose (PVC) to burner hand piece with connection to gas

outlet on the unit top part.

Check valve as protection against the flame backfiring into the

unit (flame barrier and temperature-sensitive gas cut-off).

Screw cap on filling duct for vaporizer liquid.

Screw connection for the gas hose at the reactor outlet.

Screw cap of filling duct

for electrolyte (for initial filling) or

for demineralized water (for refilling in case of low reactor filling

level).

Glass container for condensate separator (also termed dryer

glass) with filter piece.

Glass container for vaporizer liquid (also termed vaporizer

glass) with gas distributor (sintered cone).

A

B

C

D

E

F

G

A

B

C

E

D

F

G

Product description

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 13

4.7 Description of unit back

Illustration 4.7. Mains socket with mains switch

Mains switch as main switch for switching off the unit during

longer operating stops, e.g. overnight, over the weekend, etc.

Plug-in mains cable connected with the mains socket.

A

B

A

B

14 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

4.8 Description of operating panel

Illustration 4.8. Operating panel with display and operating keys

Display

Top line – section on the left: indicates the actual value (mbar)

inside the unit.

Top line – section on the right: indicates the actual reactor

power which is required to produce the set gas pressure.

Indication range between 10% and 100% depending on the

actual state of the unit.

Bottom line: indicates the set pressure value (mbar) inside the

unit.

The display also shows service indications, operating hours,

display language, etc.

Key on/off for switching the gas reactor on and off.

Menu selector key to call the following settings and display

indications:

Operating language: The operating language can be selected,

available languages are German, English or French.

Operating hour meter: The operating hour meter shows the

hours during which the unit has produced gas.

Display service mode: The service mode of the display shows

the actual service status of the unit. The optimum on new or

newly serviced units is 100%. At 0% the Lötstar must be

serviced by an authorized service company.

Selector keys for changing and indicating the unit settings.

A

B

C

D / E

B

C

D

E

A

Preparatory measures for initial operation

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 15

5 Preparatory measures for initial operation

5.1 Unpacking and placement of unit

The unit is shipped in a suitable packing. Check the MIG-O-

MAT Lötstar unit for possible transport damages before initial

operation. In case of visible damages do not operate the unit

and contact your supplier and the forwarding agent

immediately.

If possible, keep the original transport packing in store for

possible later shipment for maintenance or repair purposes.

Or dispose of the packing material according to the relevant

local regulations on waste disposal. You can also return the

packing material to the manufacturer for disposal (shipment

charges to be paid by the customer).

The unit must be operated under permanent supervision only.

The workplace must allow free access to the unit. The operator

must be able to supervise the unit at all times. Possible warning

signals of the unit must be audible/visible.

For operation, place the unit on a dry and solid surface. Ensure

that the workplace is sufficiently ventilated! The cooling air must

circulate through the cooling openings on both sides of the unit.

Risk of electrocution due to humidity inside the unit!

Protect the unit from entering humidity!

Keep workplace and housing dry in order to prevent electrical

accidents and damages from the unit.

•Allowed ambient temperature during operation:

+5°C up to +40°C

•Allowed relative humidity of air during operation: max. 80 %

•Indoor operation only (no operation in the open)

•Protect the unit from direct or indirect heat sources (e.g.

heating elements, direct sunlight) to avoid overheating.

Check for transport

damages

Packing

Choice of w

orkplace

Placement

WARNING

Ambient conditions

16 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

5.2 Mounting of the unit top part

The preassembled unit top part is packed separately and must

be mounted onto the Lötstar base unit. The protecting foil

remain around the glass containers (serves as fracture

protection).

Risk of injury splintering glass!

Combustion of gas inside the glasses due to gross disregard of

the safety instructions can cause the glasses to burst.

Do not operate the unit without protective the hood (illustration

5.2.E.) over the glasses.

After replacing either one or both of the glasses, pull the

protective hood(s) over the new glass(es).

•1 fork wrench size 10 mm (or comparable, suitable tool).

•1 fork wrench size 19 mm (or comparable, suitable tool).

Illustration 5.2. Correctly mounted and connected unit top part

1. Use the 4 cap nuts (A) to screw the unit top part to the 4

threaded bolts on the Lötstar unit top (fork wrench 10 mm).

2. Remove the yellow screw cap (transport safety device) on

the reactor outlet (B). Please keep the yellow screw cap for

possible future service purposes.

3. Connect the gas hose to the reactor outlet by means of the

union nut (fork wrench 19 mm). Caution! Do not jam the

connection nut.

Then tighten the connecting nut by means of the fork

wrench. For this, hold the reactor at the filling duct with one

hand. A slight movement of the reactor is possible and

harmless because the reactor connection is elastic. Tighten

WARNING

Required tools

How to proceed

A

A

B

C

D

E

Preparatory measures for initial operation

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 17

the screw connection fast to avoid leaks in the pressure

system.

4. Connect the gas hose of the burner hand piece to the outlet

on the top part (C).

The unit top part is movable to facilitate the removal of the glass

containers.

18 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

5.3 Filling of the reactor with electrolyte

For the production of gas a certain amount of electrolyte

solution is required. When delivered, the unit is not filled with

electrolyte for reasons of safety.

The electrolyte is included in the delivery volume

Electrolyte is a strong caustic solution!

Risk of severe chemical burns on skin, mucous membranes

and eyes!

Risk of chemical burns of the mucous membrane caused by

inhaling of vapours!

Always wear protective gloves and goggles when handling

electrolytes to prevent chemical burns! Do not inhale the

vapours!

Store open containers with electrolyte at a safe place and keep

them out of reach of unauthorized persons, in particular of

children.

Please note! In order to avoid damages on the unit, use suitable

electrolyte and demineralized water only!

If in doubt contact the manufacturer or your supplier for

information.

Lötstar 141 Lötstar 175/241/301

1.8 litre electrolyte

solution

4.0 litre electrolyte

solution

1. Unscrew the closing cap from the filling duct (see illustration

5.2.D.) at the electrolyte reactor.

2. Place the clean funnel (included in the delivery volume) onto

the filling duct.

3. Carefully pour approx. 4/5 of the electrolyte (total quantity

see table in this section) into the filling duct of the reactor.

4. Carefully insert the glass float into the filling duct of the

reactor, with the thin end up. The tip of the float must be

flush with the edge of the duct.

5. If necessary refill liquid. The glass floating body must not

stand out from the edge of the duct by more than 5 mm.

Caution! In case of an overfilling there is a risk of damage

to the unit. If the reactor has been overfilled the excess

electrolyte must be removed from the reactor (for this

carefully read and observe the relevant safety and

procedure instructions in section 8.7.!).

CAUTION!

NOTE

Filling quantities

Electrolyte solution

How to fill electrolyte

solution

Preparatory measures for initial operation

© MIG·O·MAT GmbH BA_Lötstar_EN_Vers. 07.2016 19

The glass float remains in the filling duct for future filling

level checks.

6. Screw the closing cap back onto the filling duct and tighten

it.

7. The filling process is now finished.

Illustration 5.3. Filling duct with glass float at maximum filling level

A

B

20 BA_Lötstar_EN_Vers.07.2016 © MIG·O·MAT GmbH

5.4 Filling of the vaporizer glass with vaporizer liquid

The use of vaporizer liquid is necessary for the soldering of

metals (except platinum). The flowing gas is enriched and

thereby produces a flame which is adjusted to the individual

properties of the metal.

We recommend the use of MIG-O-MAT vaporizer liquid BLQ

1800 (MIG-O-MAT Order No. 50.2501631, 1 litre). Unlike

other methanol-containing liquids MIG-O-MAT BLQ 1800 is

not toxic. Another advantage is that the burner hand piece

cannot be blocked by residues which may be contained in

other media (borax). In these cases the hand piece must be

replaced.

Vaporizer liquids are flammable! Therefore, please observe the

following safety instructions before filling.

Risk of fire and explosion due to ignition sources and

electrostatic charging!

Risk of ignition of the flammable liquids used for filling due to

ignition sources around the workplace!

Keep away from ignition sources when the vaporizer glass is

open or when you handle vaporizer liquid!

Risk of ignition of the flammable vaporizer liquids used for filling

due to electrostatic discharging!

Touch the cap nuts on the holding angle pieces of the top part

with both hands for a short period of time before you handle the

vaporizer liquid. This will branch off any possible electrostatic

charge of the operator without any risk!

Ensure that the workplace is sufficiently ventilated!

Risk of poisoning by toxic solvents when methanol-containing

vaporizer liquids are used!

Do not inhale the vapours!

Avoid contact with eyes and skin!

Wear protective gloves and goggles when handling hazardous

substances! Do not eat, drink or smoke!

Observe the specific safety warnings given on the label of the

vaporizer liquid used. Some types of vaporizer liquids may be

toxic!

Store open containers of vaporizer liquid that are not yet empty

at a safe place and keep out of reach of unauthorized persons,

in particular of children.

CAUTION!

CAUTION!

This manual suits for next models

3

Table of contents

Other MIG-O-MAT Soldering Gun manuals