MIG-O-MAT microflame 140 Operating instructions

Hausanschrift:

Telefon: ++ 49 (0)2736 - 41 54 - 0

Bank: Sparkasse Burbach

USt.IdNr.:

Geschäftsführer:

MIG•O•MAT

Telefax: ++ 49 (0)2736 - 41 54 - 99

Kto. 2568 (BLZ: 460 512 40)

DE 811249554

Dipl. Ing. Thomas Schumacher

Mikrofügetechnik GmbH

Werksstrasse 20

E-Mail: info@mig-o-mat.com

IBAN: DE 36 4605 1240 0000 0025 68

Amtsgericht

DE-57299 Burbach

Internet: www.mig-o-mat.com

SWIFT-BIC: WELADED1BUB

Siegen, HRB 4718

Service Instructions

MIG-O-MAT microflame 140 170 240 300

Hydrogen Soldering Units

english

04/2023

CAUTION! Operate the unit only when you have read and understood the

present Operating Instruction!

MIG-O-MAT Mikrofügetechnik GmbH

Service manual microflame 140-300

1

Contents

2

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

Contents

Contents........................................................................... 2

1General....................................................................... 4

1.1 Structure of the present service instructions............ 4

2Important safety warnings .......................................... 5

Repair and service ........................................................... 7

2.1 Demands on service staff......................................... 7

2.2 Liability..................................................................... 7

2.3 Testing aids, tools and inspection equipment........... 7

2.4 Safety instructions.................................................... 8

3Malfunction and service indications in the display... 10

3.1 Service interval has run down.................................10

3.2 Excess temperature................................................11

3.3 Faulty pressure control ...........................................11

3.4 Excess pressure –safety pressure switch broken...12

4Trouble shooting....................................................... 13

5Preparatory measures.............................................. 16

5.1 Remove the electrolyte from the reactor .................16

5.2 Remove the vaporizer liquid from the vaporizer glass

17

5.3 Open the unit..........................................................18

5.4 Open the operating panel for detail repair on

electronics ...........................................................................18

5.4.1 Description of circuit board ..................................19

5.5 Open the casing top for repair and service purposes

20

5.5.1 Description of internal components......................21

6Troubleshooting........................................................ 22

6.1 Leak check indicates malfunction –unit leaky.........22

6.2 Gas route obstructed, no flame...............................25

6.3 Gas flow reduced, flame too weak..........................26

6.4 Unit overfilled –damage by overfilling.....................28

6.5 Foaming of electrolyte in gas hose..........................31

6.6 Defect of pressure sensor.......................................32

6.7 Exchange the circuit board......................................32

6.8 Exchange the safety pressure switch......................34

Contents

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

3

6.9 Ventilator out of operation / Display indicates excess

temperature.........................................................................36

6.10 Replace the ventilator.............................................37

6.11 Replace the temperature sensor.............................38

7Unit service at service status 0 %............................. 39

7.1 Reset maintenance counter....................................40

7.2 Replace sinter piece and filter candle......................40

7.3 Replace the check valve.........................................42

7.4 Dismount the reactor...............................................44

7.5 Clean reactor and electrodes..................................46

7.6 Replace electrodes inside the reactor.....................51

7.7 Check elbow fitting of the test line...........................51

7.8 Fill unit and put into operation.................................52

8Spare parts............................................................... 53

9Putting out of operation and waste disposal............. 56

9.1 Waste disposal of microflame unit...........................56

9.2 Waste disposal of electrolyte ..................................56

9.3 Waste disposal of vaporizer liquid...........................56

10 Manufacturer’s contact address ............................ 57

4

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

1 General

Carefully read the present Operating and Service Instructions,

in particular the Important safety warnings, before you start

operating the unit or before you carry out any repair or service

works.

It is assumed that any service staff carrying out repair works

possess the required basic electrical knowledge and safety-

related special knowledge. Basic and self-evident safety

instructions are therefore not repeated for the individual

instructions in each section.

We reserve the right to carry out technical modifications on the

units due to advanced development.

1.1 Structure of the present service

instructions

Carefully read before any repair or service work.

Description of simple measures of maintenance and upkeep of

the unit.

Instructions on trouble shooting, repair and service of the unit.

The major spare parts are listed. If a more detailed list of spare

parts is required please contact the manufacturer.

Safety warnings

Maintenance

Repair and service

Spare parts list

Important safety warnings

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

5

2 Important safety warnings

Carefully read and observe before putting into operation!

The present unit operates with acid, flammable and –

depending on the type of vaporizer liquid –toxic substances.

Therefore, a predetermined operating sequence and strict

observance of the safety and protection measures described

below are prerequisite.

The present operating instructions cannot take each and every

specific regulation into consideration which might apply in

various countries. The operator of the unit must ensure that all

relevant local regulations concerning the prevention of

accidents and the use of hazardous substances are known and

observed.

MIG-O-MAT soldering and welding units are intended for

soldering, welding and melting of metals. Operation is allowed

by industrial and commercial businesses only.

The unit must be operated by specialized, trained staff only.

The operating instructions must be strictly observed. The unit

must not be operated by unauthorized persons or by children.

For reasons of safety, the unit must be connected to a

shockproof socket only. The technical data indicated on the

nameplate must correspond with the available local connection

conditions, particularly with regard to mains voltage and current

consumption values.

For maintenance and service works, in case of liquid inside the

unit and malfunctions, and when you have finished working with

the unit pull the main plug. In case of a malfunctioning please

contact your supplier or the manufacturer.

The unit must be opened by authorized and specialized staff

only!

Electrolyte solution can cause severe chemical burns!

Always wear base-resistant gloves and goggles when you work

with electrolyte solution! Do not eat or drink while filling

electrolyte solution into the unit!

Wash your hands after filling the reactor!

Avoid contact with eyes and skin! In case of contact with the

eyes rinse the open eye(s) under running water for several

minutes and seek medical advice. In case of contact with the

skin wash immediately with soap and rinse thoroughly.

If you have overfilled the unit, do not remove any excess

electrolyte by sucking it through a hose by mouth. There is a

risk of severe chemical burns! If you have overfilled the unit by

mistake, use a suitable base-resistant suction device which is

not operated by mouth.

Instructions for the

operator

Intended use

Operating staff

Mains connections

Risks due to electric

current

Risks caused by

electrolyte

Important safety warnings

6

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

Electrolyte containers which are not completely empty must be

kept tightly closed and stored out of reach of unauthorized

persons, in particular of children. Thoroughly rinse empty

electrolyte containers with water. Then the container can be

disposed of into the ordinary waste. We recommend to contact

the local authorities for information on the use and waste

disposal of electrolytes.

Risk of fire and explosion! The vaporizer liquid is a flammable

substance! Keep away from ignition sources while filling

vaporizer liquid into the unit!

Avoid inhaling the vapours! Do not eat, drink or smoke while

handling the vaporizer liquid! Wear goggles and gloves!

The MIG-O-MAT vaporizer liquid BLQ1800 is not toxic. When

using other, methanol-containing vaporizer liquids, take into

consideration that these substances may be highly toxic! Read

and observe the relevant instructions on the labels of the

products used.

Risk of fire and explosion! Do not leave the unit switched on

unsupervised. The gas escaping from the unit is highly

flammable and explosive. The switched-on unit must be

operated with opened valve only until the flame ignites. Any

escaping gas which does not burn in a flame causes a high risk

of fire and explosion! For refilling the reactor keep away from

ignition sources! Even the open pressure-less reactor contains

highly explosive burnable gases.

To prevent the creation of electrostatic sparks immediately

before opening the reactor (e.g. for checking the filling level or

for refilling distilled water), touch the cap nuts on the top part of

the unit or the metal screws on the housing with both hands.

Risk of burning and fire! Hang the burner hand piece with

burning flame onto the soldering stand for short operating

stops. Ensure that there is a sufficient distance between the

flame and any flammable items. Ensure that there is sufficient

ventilation for all soldering and welding operations!

The manufacturer cannot be held liable for damages on

persons, equipment or work pieces caused by improper use.

The operator is responsible for the correct instruction of the

operating staff.

Risks caused by

vaporizer liquid

Risks caused by

burnable gas and gas

flame

Exclusion of laibility

Repair and service

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

7

Repair and service

2.1 Demands on service staff

The present service manual is intended to be used by

instructed specialized service staff. Legitimate users of the

manual are all service staff who do not require to be instructed

on the risks caused by and during works on the electrical

system. It is assumed that any service staff carrying out repair

works possesses the required basic electrical knowledge and

safety-related special knowledge on the work with and on

appliances operated at mains voltage and on the handling of

concentrated bases and solvents.

2.2 Liability

The service staff must be acquainted with the particular safety

instructions given in the present manual and learn to apply the

safety instruction correctly before carrying out any of the

described service works.

The manufacturer cannot be held liable for any service work

carried out by service staff members. The responsibility for the

minute observance of the prescribed safety instructions and for

the safe and proper execution of the service measures taken

lies solely with the executing service staff.

2.3 Testing aids, tools and inspection equipment

In addition to the standard electromechanical equipment the

following testing and inspection aids and tools and protection

gear are required for carrying out the repair and service works

described in the present manual:

Goggles, rubber gloves, smock

Software and adapter cable for diagnosis purposes and for

resetting the service intervals, depends of production year

(available from MIG-O-MAT)

For taking the electrolyte liquid out of the reactor

D.C. current probe / clamp-on ampere meter (measuring range

> DC 170 A) for measuring the electrolysis current

For measuring D.C. and A.C. voltages and for electric continuity

measurings

For leak checks on the reactor tank

Protection gear

Software

Vacuum pump

Current probe

Multimeter

Manometer

Repair and service

8

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

2.4 Safety instructions

Maintenance, service and repair works must be carried out

by instructed specialized staff only.

Observe and follow the safety instructions below when

carrying out any maintenance, service or repair works that

require the handling of electrolyte or vaporizer liquid:

Caution when handling electrolyte! Risk of chemical burn!

Strong acid base!

Risk of chemical burn due to spilling base or splashes of base

from the filling duct during filling!

Always wear protective gloves and goggles when handling

hazardous substances!

Caution with open filling duct of the electrolyte reactor!

Risk of fire and explosion due to ignition sources!

Risk of ignition of the detonating gas in the electrolyte reactor

due to ignition sources!

Keep unit away from any ignition sources! Do not use the

burner flame to shine into the filling duct!

Caution with open filling duct of the electrolyte reactor!

Risk of fire and explosion due to electrostatic

discharging!

Risk of ignition of the detonating gas in the electrolyte reactor

due to electrostatic discharging!

Touch the cap nuts on the holding angle pieces of the top part

with both hands for a short period of time before you open the

glass containers. This will branch off any possible electrostatic

charging of the operator without any risk (mains cable must

be connected to the mains)!

Caution when handling vaporizer liquid! Risk of fire and

explosion due to ignition sources!

Risk of ignition of the flammable liquids contained in the unit,

and of the flammable liquids used for filling, due to ignition

sources in the vicinity of the unit!

Keep the open vaporizer glass container and the vaporizer

liquid away from any ignition sources!

CAUTION!

WARNING!

WARNING!

WARNING!

WARNING!

Repair and service

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

9

Caution when handling vaporizer liquid! Risk of fire and

explosion due to electrostatic discharging!

Risk of ignition of the flammable liquids contained in the unit

top part, and of the flammable liquids used for filling, due to

electrostatic discharging!

Touch the cap nuts on the holding angle pieces of the top part

with both hands for a short period of time before you open the

glass containers. This will branch off any possible electrostatic

charging of the operator without any risk (mains cable must

be connected to the mains)!

WARNING!

Malfunction and service indications in the

display

10

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

3 Malfunction and service indications in the

display

3.1 Service interval has run down

During operation of a soldering unit the anodes and cathodes

wear out. Therefore, the gas drawing hours are measured by

the control of the unit to ensure safe operation.

The service level can be called by changing the display.

Press the key to indicate the gas drawing hours and the

service level:

„100 %“ service level is he standard status of the unit when

delivered or when the unit has been serviced. The reactor

should be serviced every two years or when a service level of

„0 %“ is indicated.

A signal tone and a message in the display indicate when the

unit must be serviced:

Service interval

has run down!

The signal tone can be silenced by pressing any key. Operation

of the unit may continue for a limited period of time.

Carry out the service measures described in section 7 as soon

as possible.

Caution: The manufacturer cannot be held liable for any

damage on persons, or for damage on the equipment caused

by operation of the unit after the service interval has run down!

In case of malfunctions of the unit caused by thermal

overcharging or overpressure, the gas production is

automatically stopped: the unit changes the set value to zero. A

signal tone indicates the malfunction. Close the valve at the

hand piece. The signal tone can be silenced by pressing any

key.

If the main transformer is overloaded, the display shows the

following malfunction message:

Transf. overload!

Let cool down!

Operation can be continued only after the transformer has

cooled down. For this change the set value back to the required

value.

Show service level

Transformer

overload

Malfunction and service indications in the

display

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

11

3.2 Excess temperature

If the allowed reactor temperature of 80°C is exceeded, the

display shows the following malfunction message:

Excess temp.!

Let cool down!

An excess reactor temperature may be caused by the following:

•Filling level of electrolyte too low: check the filling level.

•Ventilator not operating: check if the ventilator operates

during drawing of gas, or at a temperature of approx. 40°C

without drawing of gas. The ventilator speed is controlled

depending on the reactor temperature.

•Adverse ambient conditions:

- the unit is placed at an insufficiently ventilated workplace

- the lateral ventilation openings are blocked

- extremely high ambient temperature

- extreme utilization with at least one of the above adverse

conditions

Operation can be continued after the unit has cooled down. For

this change the set pressure value back to the required value.

In case of malfunctions due to overheating it is important not to

switch off the unit at the mains switch, as the ventilator will then

stop operating, too. If the noise of the operating ventilator is too

loud switch the unit into stand-by operating mode by pressing

the on/off key . In this mode, the ventilator speed is reduced.

Cooling down will take considerably longer!

3.3 Faulty pressure control

If the pressure control device has broken down the unit

automatically switches off and the display shows the following

malfunction message:

Faulty pressure control!

Switch off the unit at the mains switch and restart it (reset the

unit).

If the malfunction continues, the pressure sensor is probably

faulty or damaged (see Section 6.6).

Causes

Cause

Malfunction and service indications in the

display

12

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

3.4 Excess pressure –safety pressure switch broken

If the safety pressure switch is broken the display shows the

following malfunction message

Excess pressure!

Safety pressure switch faulty!

A signal tone indicates the malfunction. The reactor is switched

off automatically and the gas production is stopped.

Replace the safety pressure switch as described in Section 6.8.

Trouble shooting

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

13

4 Trouble shooting

Malfunction / Fault

Possible cause

Remedy

The unit does not build up

any pressure:

The set pressure is e.g.

150 mbar, the actual

pressure does not reach

the set pressure value

(with burner hand piece

closed!)

Unit is leaking.

Carry out the leak check and

check if there is a leak in the gas

route.

If a leak is detected (indicated in

the display) search for the leak

as described in Section 6.1.

Unit builds up pressure

extremely slowly, the set

pressure is not reached or

it takes extremely long

until the set pressure is

reached.

Unit is leaking.

Carry out the leak check and

check if there is a leak in the gas

route.

If a leak is detected (indicated in

the display) search for the leak

as described in Section 6.1.

Electrolyte filling level too low.

Check filling level, refill distilled

water if required.

Reactor output is reduced due to

contaminated or too old

electrolyte.

Check reactor performance as

described in Section 6.3.

Flame is very weak and

„sits“ on the nozzle

(nozzle tip is glowing).

The set pressure, e.g.

150 mbar, is reached.

During operation the

actual pressure goes

down to a value which

does not produce the

same flame as before

with the same nozzle.

Set pressure is too low for the

nozzle size used, unallowable

nozzle size (too large).

Check if the used nozzle is

allowed for the unit. If the nozzle

size is OK increase the set

pressure value.

Very small leak in the unit.

Carry out the leak check and

check if there is a leak in the gas

route.

If a leak is detected (indicated in

the display) search for the leak

as described in Section 6.1.

Electrolyte filling level too low.

Check filling level, refill distilled

water if required.

Gas route is partly obstructed.

Check gas route for obstructions

as described in Section 6.2.

Trouble shooting

14

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

Reactor output is reduced due to

contaminated or too old

electrolyte.

Check reactor performance as

described in Section 6.3.

Malfunction

Possible cause

Remedy

The flame is instable.

The nozzle is obstructed.

Clean or replace the nozzle.

The gas route is partly

obstructed.

Check the gas route for

obstructions as described in

Section 6.2.

The vaporizer liquid has been

consumed.

Remove remaining vaporizer

liquid and fill new vaporizer

liquid, clean the glass.

No gas at the nozzle / no

flame possible.

When the valve at the

hand piece is opened the

actual pressure does not

go down (even with

removed nozzle).

Gas route is obstructed.

Check the gas route for

obstructions as described in

Section 6.2.

Gas production is

automatically switched off

due to excess

temperature.

The display shows the

malfunction message:

Excess temperature

Excess reactor temperature

(max. 80°C).

Let unit cool down.

Foam inside gas hose.

Unit has been overfilled.

Check the filling level, reduce if

necessary (suck off electrolyte)

as described in Section 5.1.

Electrolyte is contaminated.

If the filling level is OK (no

overfilling), exchange the

electrolyte (drain reactor as

described in Section 5.1) and

clean the reactor (see Section

7.5).

The display is dark, unit is

dead.

Faulty fuse(s) on circuit board or

main switch.

Check fuses and replace if

necessary (Section 5.4 / 12.4.1).

Trouble shooting

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

15

(Main switch on the unit

rear is switched on and

the start button in the

display has been

pressed.)

Circuit board faulty.

If the fuses are OK, replace the

circuit board

(Section 6.7).

Malfunction / Fault

Possible cause

Remedy

The display shows the

following malfunction

message: Operating

pressure control faulty

The hose to the pressure sensor

on the circuit board is obstructed

by residues of electrolyte

(electrolyte has been overfilled).

Check the hose to the pressure

sensor, replace if necessary

(Section 6.5).

The pressure sensor on the

circuit board is damaged

(electrolyte has been overfilled).

If the malfunction message

continues to be displayed after

exchange of the obstructed hose:

replace the pressure sensor

(Section 6.7).

The display shows the

following malfunction

message: Excess

pressure!

Faulty safety pressure

switch!

The safety pressure switch is

faulty.

Replace the safety pressure

switch (Section 6.8).

Preparatory measures

16

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

5 Preparatory measures

5.1 Remove the electrolyte from the reactor

For shipment of the microflame unit, and for particular

maintenance works, remove all electrolyte from the unit.

For emptying the electrolyte reactor use a suitable base-

resistant suction device (waterlock), or e.g. a simple suction

device consisting of a PVC hose and a plastic bottle or a

syringe.

Fig. 5.1 Plastic bottle and hose for removal of electrolyte from the

reactor

Caution! Strong acid base!

Risk of severe chemical burn on skin, mucous membranes

and eyes!

Do not suck any electrolyte through a hose by mouth!

To prevent dangerous chemical burn when handling

electrolyte always wear protective gloves and goggles!

1. Switch off the microflame at the mains switch at the back of

the unit.

2. Open the screw cap of the filling duct for electrolyte.

3. Take out the glass floating body. Caution! The glass floating

body is covered with base! Rinse the floating body with

water.

4. Remove all electrolyte from the reactor by means of a

suitable suction device.

WARNING!

How to proceed

A

B

Preparatory measures

MIG-O-MAT Mikrofügetechnik GmbH

Service manual_microflame_EN

17

Example plastic bottle with PVC hose:

1. Insert the hose into the filling duct of the reactor and push

it down as far as it goes.

2. Compress the plastic bottle, then create a vacuum by

releasing the bottle.

3. As soon as electrolyte starts flowing through the hose,

pull off the bottle and hold the hose end into an base-

resistant container. Let all electrolyte drain into the

container.

5. Keep the electrolyte in an base-resistant container and

clearly mark the container. Store the container at a safe

place and keep it away from unauthorized persons, in

particular from children. Or dispose of the electrolyte as

described in Section 9.2.

5.2 Remove the vaporizer liquid from the vaporizer glass

For shipment of the microflame unit, and for particular

maintenance works, remove all vaporizer liquid from the unit.

For the disposal of the vaporizer liquid observe the instructions

given in Section 9.3.

Caution when handling vaporizer liquid! Risk of fire and

explosion due to ignition sources and electrostatic charging!

When handling vaporizer liquid keep away from any ignition

sources!

Avoid electrostatic discharging!

Touch the cap nuts on the holding angle pieces of the top part

with both hands for a short period of time before you open the

vaporizer glass container (the mains cable must be connected

to the mains supply). This will branch off any possible

electrostatic charging of the operator without any risk!

1. Press the on/off key in the operating panel to switch off

the gas production.

2. Unscrew the fastening ring by turning it to the left (see

fig. 7.2.D).

3. Remove the vaporizer glass. Move the complete top part to

the side to facilitate removal of the vaporizer glass.

4. Drain the vaporizer liquid.

5. Fill the vaporizer liquid into a specially marked container

and store out of reach of unauthorized persons, in particular

of children. Or dispose of the electrolyte as described in

Section 9.3.

6. Remount the vaporizer glass by screwing the fastening ring

back to the right (see fig. 7.2.E).

WARNING!

How to proceed

Preparatory measures

18

Service manual_microflame_EN

MIG-O-MAT Mikrofügetechnik GmbH

5.3 Open the unit

Repair and maintenance works that require the unit to be

connected and opened must be carried out by authorized

specialized staff only.

Risk of electric shock due to live parts inside the unit!

Pull the mains plug before you open the unit!

The manufacturer cannot be held liable for any damage

caused by unauthorized repair works on the unit.

5.4 Open the operating panel for detail repair on

electronics

For repair works on the circuit board or the pressure sensor it is

only necessary to open the operating panel:

1. Separate the unit from the mains!

2. Unscrew the screws at the operating panel.

3. Carefully tip the operating panel to the front.

4. Pull the electric contact of the LED connection (fig. 5.4.A) off

the circuit board.

5. Cut the cable clip (fig. 5.4.B) to allow some space to remove

the operating panel from the unit.

Opening of the unit

by authorized,

specialized staff

only

WARNING!

How to proceed

This manual suits for next models

3

Table of contents

Other MIG-O-MAT Soldering Gun manuals

Popular Soldering Gun manuals by other brands

Weller

Weller WSP 150 operating instructions

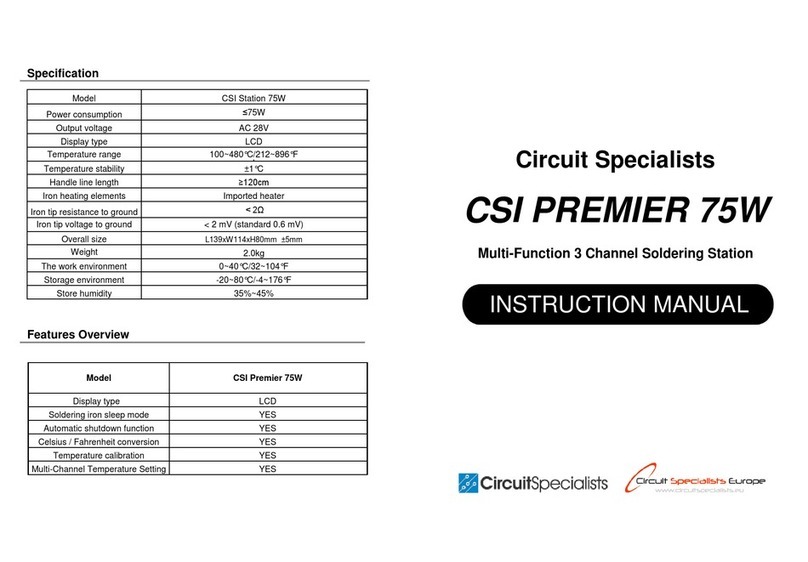

Circuit Specialists

Circuit Specialists CSI PREMIER 75W instruction manual

jbc

jbc B-iRON 115 instruction manual

FTM Technologies

FTM Technologies SI1R user manual

Vishay Precision Group

Vishay Precision Group Micro-Measurements Mark V Operating and maintaining

Weller

Weller FT12 operating instructions