MIHM-VOGT MV-R 100/120 User manual

Translated from

Original German Operating Manual

MV-R 100/120

Version 1.0de - 09/2019

Friedrich-List-Straße 8

76297 Stutensee-Blankenloch, Germany

Tel.: +49 (0) 7244 70871-0

www.mihm-vogt.de

EN

Page 2 MV-R 100/120 Version1.0de-09/2019

Table of Contents

General information ..................................................................3

Limitation of liability .....................................................................3

Responsibilities of the operator .......................................................................3

Documentation ............................................................................4

Content and structure......................................................................................4

Labelling scheme for integrated text boxes and references............................4

Formatting and symbols ..............................................................5

Service address...........................................................................5

Safety..........................................................................................6

Requirements for personnel ........................................................6

Technical description................................................................10

Function.......................................................................................10

Conformity ...................................................................................11

Intended use................................................................................12

Potential misuse ..........................................................................12

Technical data............................................................................13

Installation..................................................................................14

Setup ...........................................................................................14

Setup conditions..............................................................................................14

Electrical connection....................................................................15

Local installation..............................................................................................15

Rating plate .................................................................................16

Product description...................................................................17

Main product components ...........................................................17

Base unit......................................................................................17

Rear of the base unit ...................................................................18

Initial commissioning ...................................................................19

Using the door insulation.............................................................20

Main screen after starting up the unit ..........................................20

Explanation of symbols................................................................21

Units symbols ..................................................................................................22

Sintering aids...............................................................................23

Transport, packaging and storage...........................................24

Transport .....................................................................................24

Packaging....................................................................................25

Storage........................................................................................25

Care and maintenance ..............................................................26

Service programs ........................................................................26

Faults and error messages.......................................................27

Safety ..........................................................................................27

Overview of error codes ..............................................................28

Decommissioning......................................................................29

Disposal......................................................................................29

Safety ..........................................................................................29

Disposal.......................................................................................29

General information

Version1.0de-09/2019 MV-R 100/120 Page 3

General information

Limitation of liability

The contents of this operating manual were created taking the applicable

laws and standards into account.

The unit was developed using state-of-the-art technology.

Notice

The manufacturer assumes no liability for damage resulting from:

hDisregard/non-observance of the operating manual

hIntentional misuse

hUse other than as intended

hOperation by untrained personnel

hOperation by non-professionals (carrying out maintenance work, etc.)

hTechnical modications to the unit that were not agreed with the

manufacturer

hUse of replacement parts that were not approved by the manufacturer

Responsibilities of the operator

The unit is used for commercial purposes. The operator of the unit is

therefore subject to the statutory obligations relating to occupational safety.

In addition to the safety instructions in this operating manual, the regulations

on safety, accident prevention and environmental protection that apply to

the unit's area of application must be complied with.

In particular, the following apply:

yThe operator must be familiar with the applicable regulations on

occupational safety.

yThe operator must ensure that all employees who use the unit have

read and understood this operating manual.

yThe operator must also train personnel at regular intervals and inform

them of the dangers that can arise when using the unit.

yThe operator must provide personnel with the necessary protective

equipment.

yThe operator must have all safety devices checked regularly for

operability and completeness.

Page 4 MV-R 100/120 Version1.0de-09/2019

General information

Documentation

Content and structure

This operating manual is an essential part of this unit. It contains instructions

and information on how to use the unit safely and must be available to all

users throughout the unit's service life. This operating manual is intended for

use by trained operating personnel.

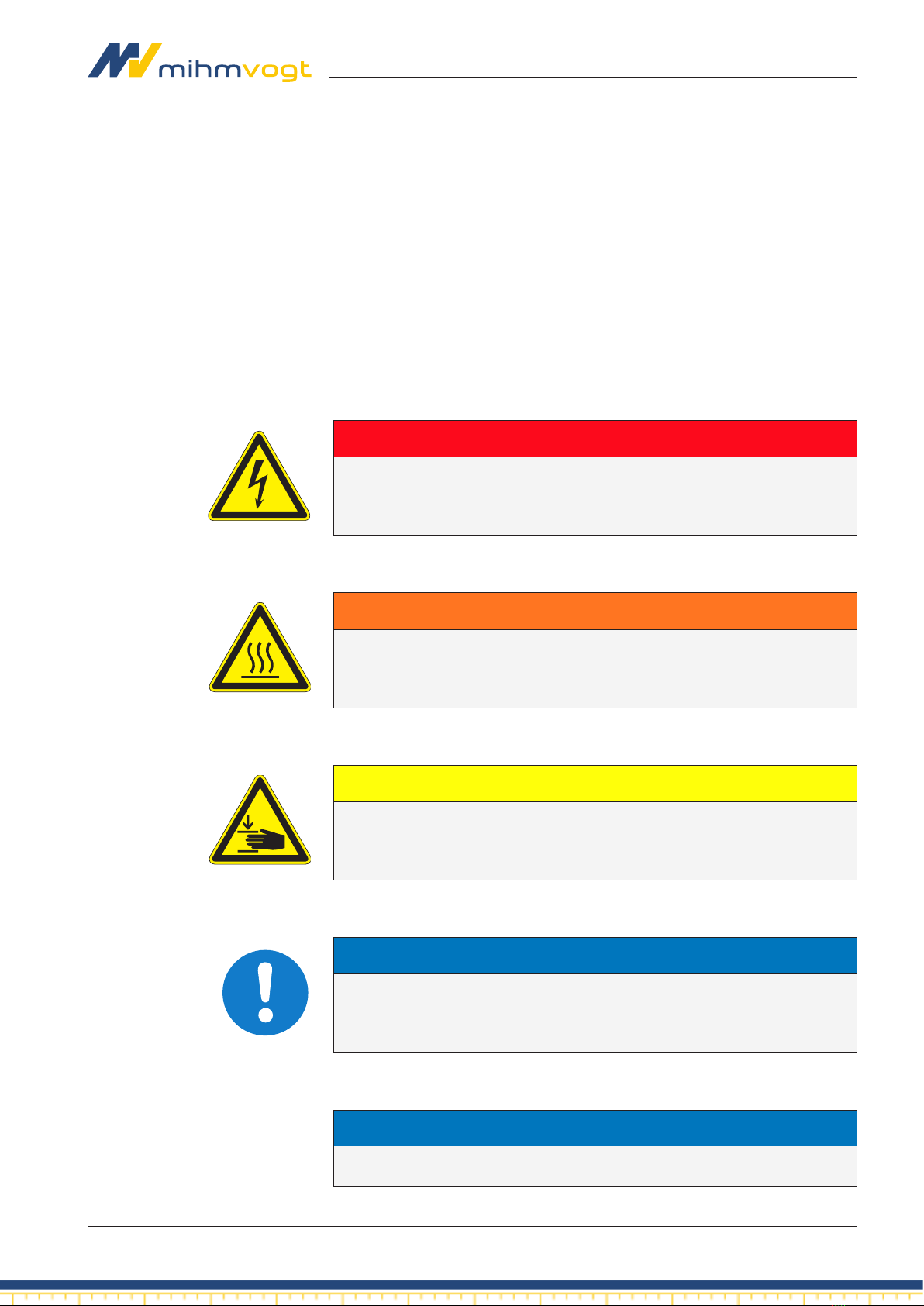

Labelling scheme for integrated text boxes and references

The following safety notices are used in this manual:

Danger

Indicates an imminent danger that may cause serious physical

injury or death.

Warning

Indicates a potentially dangerous situation that may cause serious

physical injury or death.

Caution

Indicates a potentially dangerous situation that may cause minor

physical injury.

Notice

Indicates a potentially harmful situation in which the product or an

object in its vicinity may be damaged.

Notice

Information or tips for easier operation.

General information

Version1.0de-09/2019 MV-R 100/120 Page 5

Formatting and symbols

$indicates a general safety instruction

;indicates that a requirement must be met

1. indicates a step to be carried out

Âindicates the outcome of carrying out a step

yindicates a list

S1

indicates a button

Service address

Friedrich-List-Straße 8

76297 Stutensee-Blankenloch, Germany

Tel.: +49 (0) 7244 70871-0

www.mihm-vogt.de

Table of contents

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual