4

When you use machine on inclined area, various risk is accompanied. Adhere

rigidly to the following precautions to a minimum, and try for further safety

retention. When you cannot get safety, never use it.

Do not leave machine in the inclined area. There is danger to cause a serious

accident when machine begins to move by any chance.

In the inclined area, grasp a handle well, and never separate a hand from machine.

Machine begins to move in tare weight at the moment when you separated a hand,

and there is danger to cause a serious accident.

Because there is the danger that machine runs uncontrollably when a grip falls out

from the handle, warn you enough.

When you work in inclined area, be located in the upper part of the slope for machine

by all means, and let machine face straight it below for a slope, and work.

When put ring stopper, never go in the front side of the machine. When machine has

begun to move by any chance. There is the danger of serious injury or decease, by

the physical truncation with blade and the conflict of machine.

If hand touches the blade when put ring stopper, there is danger injured seriously. Put

ring stopper from the non blade cover side of the machine by all means.

In case of stop, when water is in the water tank, the center of gravity rises and the

balance worsens . Even if you put ring stopper to the front wheel at the time, it is very

dangerous that the front wheel climbs over ring stopper and begins to move. In this

case pull water out of the water tank by all means.

When a road surface gets wet in inclined area, ring stopper in itself slips depending

on an angle, and effect is gone. Stop on the dry road surface by all means, when you

stop it in inclined area out of necessity.

Do not work on blade installation disassembly in inclined area, because it is

dangerous.

Do not work on to cross the slope. There is danger that tumble of the machine or the

damage of the blade cause a serious accident.

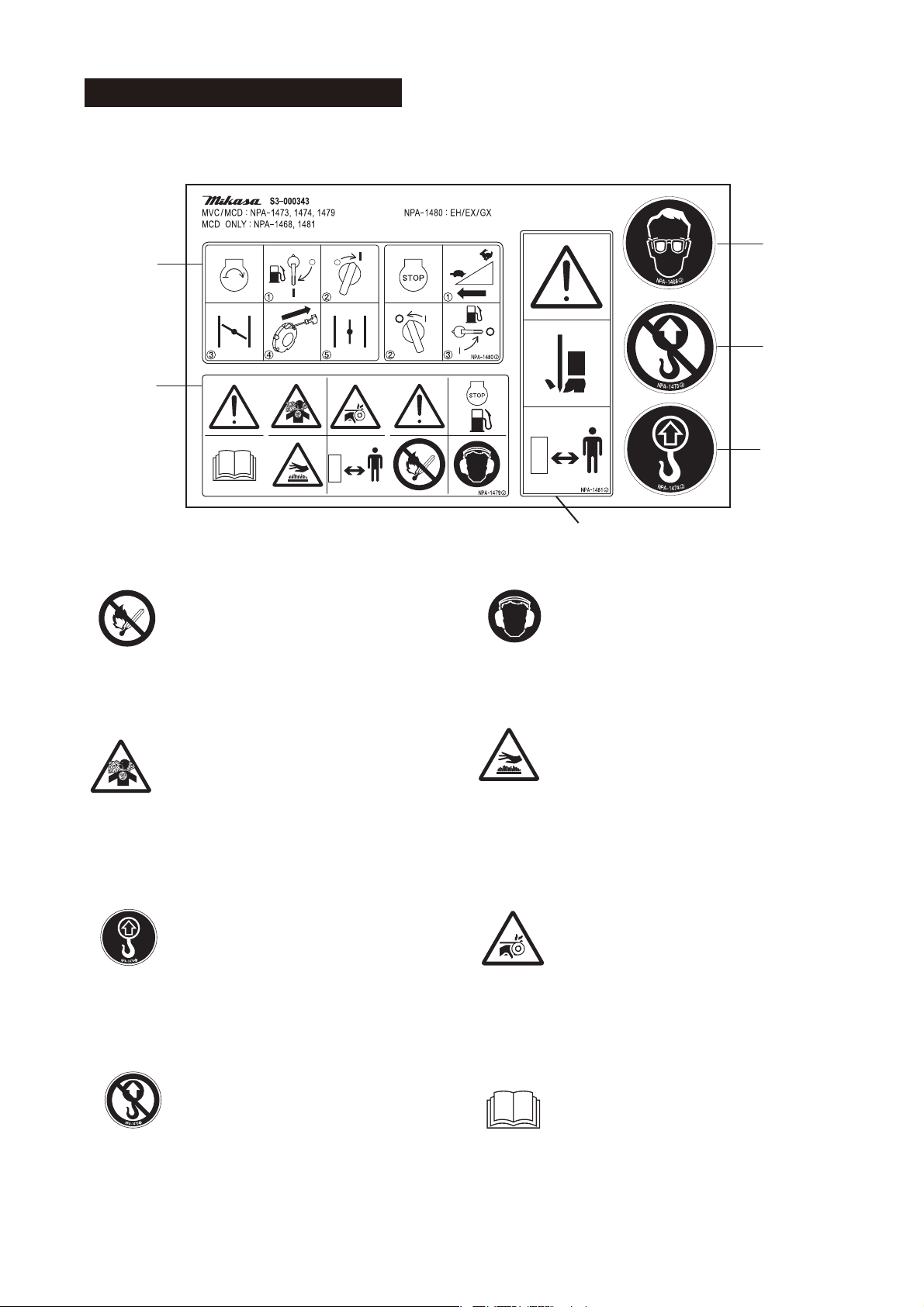

Be sure to work with sling by crane license holder.

Before work of lifting, check any damage of body parts (especially, Lifting hook, etc)

or looseness / omission of screws, and be sure safe.

Stop the engine at the time of the lifting, and close the fuel cock.

Use enough strength of wire rope.

The work of lifting uses only one-point lifting hook, and do not lift in other point

(handles).

Never put any person or animal under the lifted machine.

For safety, do not lift up the machine more than required height.

Stop the machine at flat space. When you stop machine in

inclined area out of necessity, lower straight machine after

having stopped the engine by all means, do ring stopper to the

front wheel for safe retention by all means. When be collided by

an automobile and be shaken in right and left, even if you put on

ring stopper down the front wheel, the machine climbs ring

stopper and begins to move, and be careful this risk is very likely.

Even if you put on ring stopper down the back wheel, there is not

effect. In addition, a parking brake of the rear wheel is not a thing

to guarantee certain fixation of the machine. Use ring stopper for

a front wheel on the occasion of a stop by all means.

4.5 Precautions During Work

4.6 Lifting Precautions

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

䖃

DANGER

䟿

DANGER

䟿

Precautions in inclined area