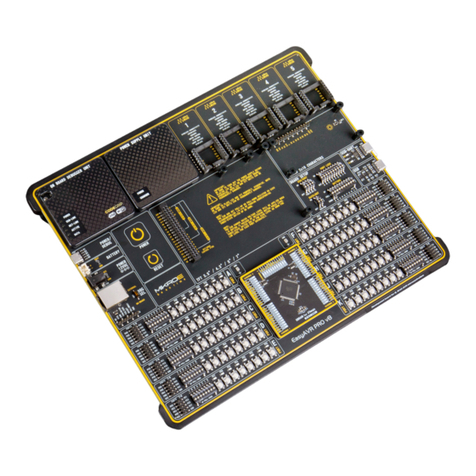

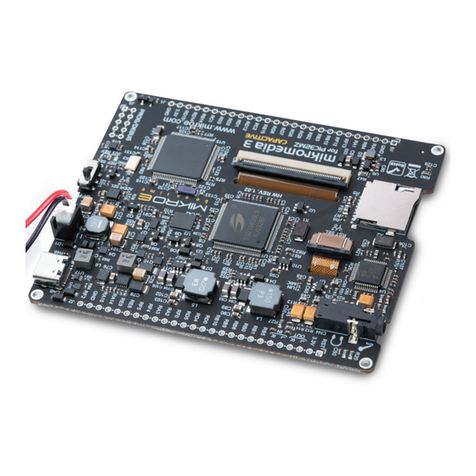

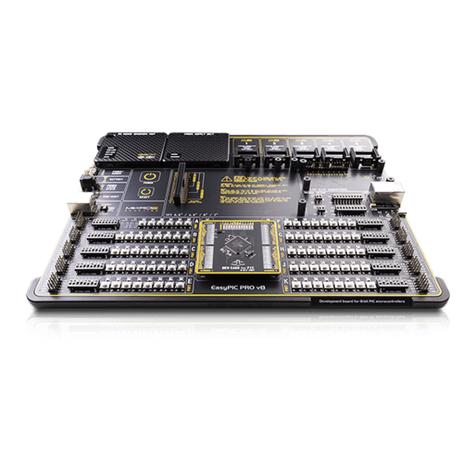

Clicker 4 for STM32 is a compact development board

designed as a complete solution, you can use it to quickly

build your own gadgets with unique functionalities.

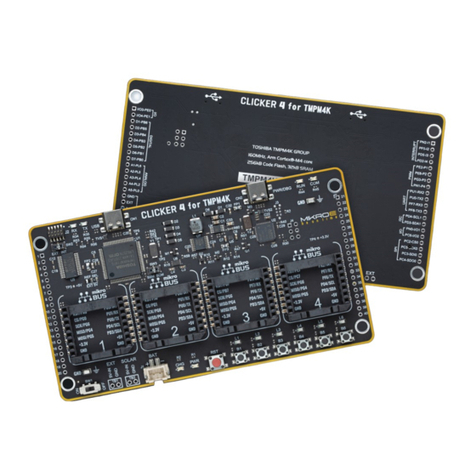

Featuring a STM32F767BI MCU, four mikroBUS™sockets for

Click boards™connectivity, power managment, and more, it

represents a perfect solution for the rapid development of

many different types of applications.

At its core, there is a STM32F767BI MCU, a powerful

microcontroller by STMicroelectronics, based on the high-

performance Arm® Cortex®-M7 32-bit RISC core operating

at up to 216 MHz frequency.

It provides sufficient processing power for the most

demanding tasks, allowing Clicker 4 to adapt to any specific

application requirements.

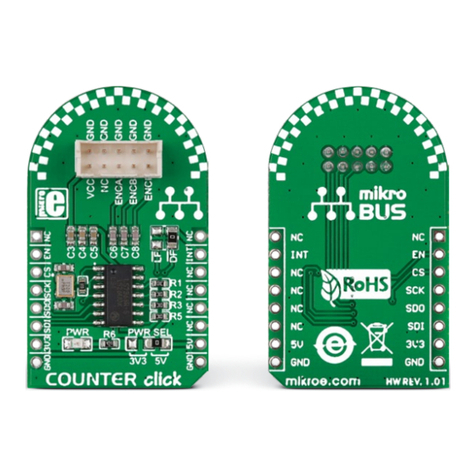

Besides two 1x23 pin headers, four improved mikroBUS™

sockets represent the most distinctive connectivity feature,

allowing access to a huge base of Click boards™, growing on

a daily basis.

Each section of Clicker 4 is clearly marked, offering an

intuitive and clean interface. This makes working with the

development board much simpler and thus, faster.

The usability of Clicker 4 doesn’t end with its ability to

accelerate the prototyping and application development

stages: it is designed as a complete solution which can be

implemented directly into any project, with no additional

hardware modifications required. Four mounting holes

[3.2mm/0.126”] at all four corners allow simple installation

by using mounting screws. For most applications, a nice

stylish casing is all that is needed to turn the Clicker 4

development board into a fully functional, custom design.