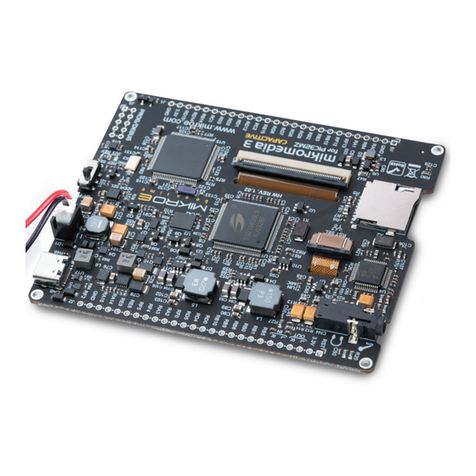

mikromedia 4 for PIC CAPACITIVE FPI is a compact development

board designed as a complete solution for the rapid development

of multimedia and GUI-centric applications. By featuring a 4.3”

capacitive touch screen driven by the powerful graphics controller

that can display the 24-bit color palette (16.7 million colors), along

with a DSP-powered embedded sound CODEC IC, represents a

perfect solution for any type of multimedia application.

At its core, there is a powerful 8-bit PIC18F97J94 microcontroller

(referred to as “host MCU” in the following text), produced by

Microchip, which provides sufficient processing power for the most

demanding tasks, ensuring fluid graphical performance and glitch-

free audio reproduction.

However, this development board is not limited to multimedia-based

applications only: mikromedia 4 for PIC CAPACITIVE FPI (“mikromedia

4 FPI” in the following text) features USB, RF connectivity options,

digital motion sensor, piezo-buzzer, battery charging functionality,

SD-Card reader, RTC, and much more, expanding its use beyond

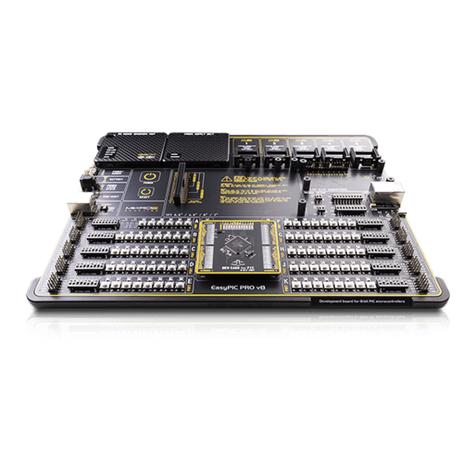

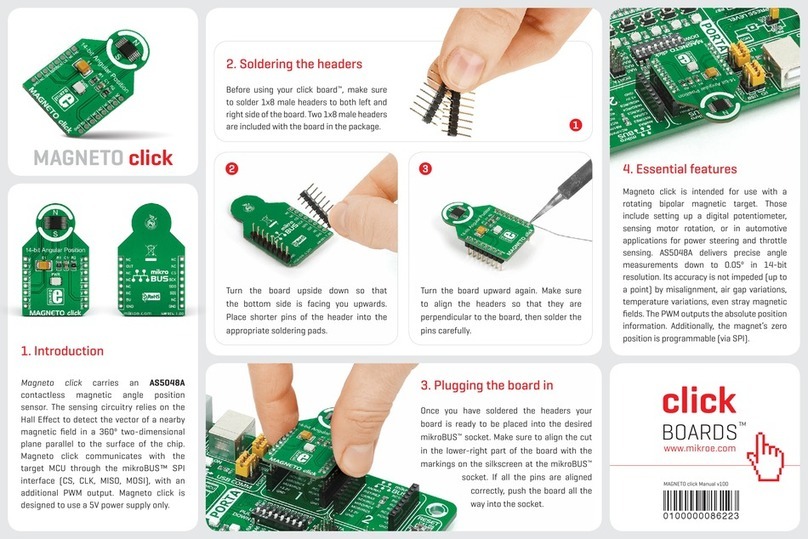

the multimedia. Two compact-sized mikroBUS Shuttle connectors

represent the most distinctive connectivity feature, allowing access

to a huge base of Click boards™, growing on a daily basis.

The usability of mikromedia 4 FPI does not end with its ability to

accelerate the prototyping and application development stages: it

is designed as the complete solution which can be implemented

directly into any project, with no additional hardware modifications

required. We offer two types of mikromedia 4 for PIC CAPACITIVE

FPI boards. The first one has a TFT display with a bezel around it

and is ideal for handheld devices. The other mikromedia 4 for PIC

CAPACITIVE FPI board has a TFT display with a metal frame, and four

corner mounting holes that enable simple installation in various kinds

of industrial appliances. Each option can be used in smart home

solutions, as well as wall panel, security and automotive systems,

factory automation, process control, measurement, diagnostics and

many more. With both types, a nice casing is all that you need to turn

the mikromedia 4 for PIC CAPACITIVE FPI board into a fully functional

design.

Pick your own look

Identical in the back, choices up front.

mikromedia 4 for PIC Capacitive FPI with bezel

mikromedia 4 for PIC Capacitive FPI with frame

N O T EThis manual, in its entirety, showcases just one option of mikromedia

4 for PIC CAPACITIVE FPI for illustration purposes. The manual applies

to both options.