3

Introduction

Congratulations, you are actually reading the operations manual!

So many people dismissed user guides these days, but a product

with any degree of complexity and sophistication, one with

robust and exible features such as the one you just bought, is

going to take a little bit of guring out. That’s what this manual

is for.

Register your warranty

Product Overview

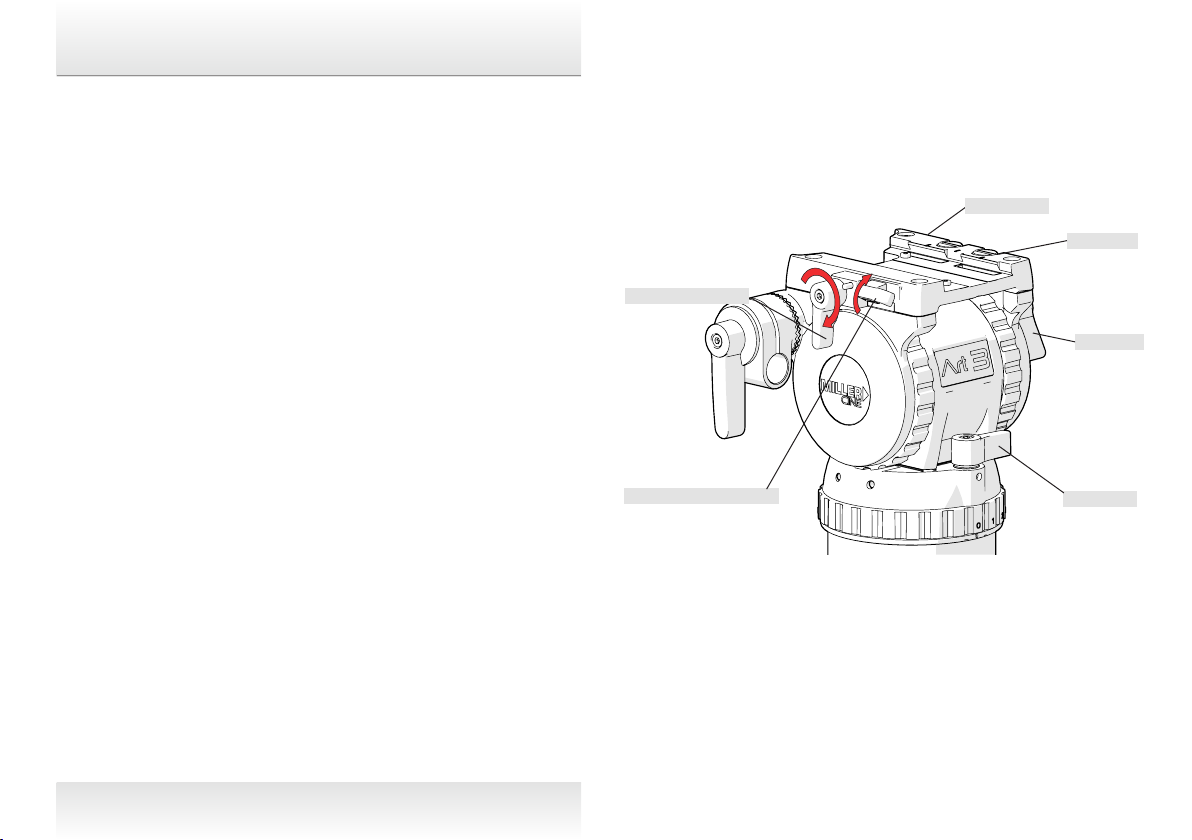

You are now the proud owner of a Miller Fluid Head known as

a “Naked Head” designed for maximum versatility for creative

artists. ArtX is a new concept that provides choices to enable

users to customise a uid head to t their exact purpose.

The key features of ArtX are:

• Customisable uid head

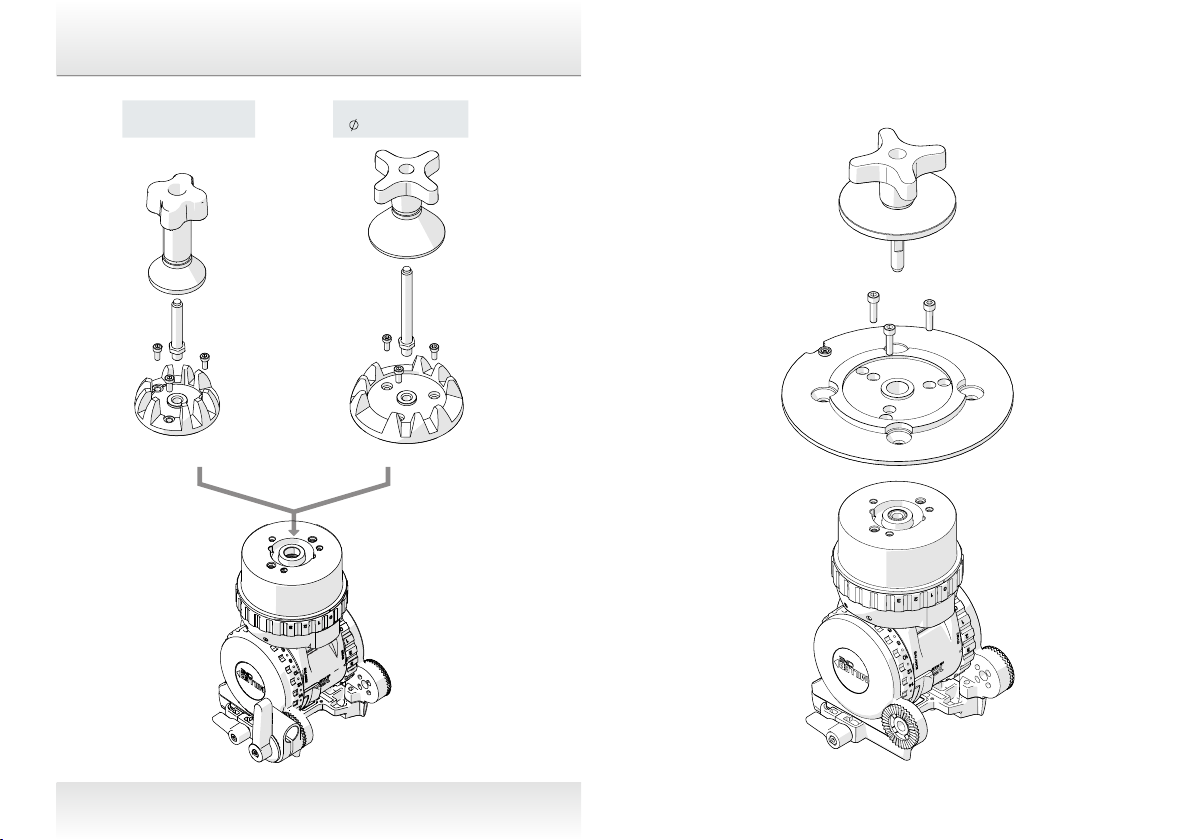

• Flat base (tripod mounting attachments optional)

• The Right Feel, smooth start, soft stop, uid drag

technology.

• Balanced diagonal transitions

• 15+0 CB PlusTM selectable counterbalance positions

• Ergonomically located CB Plus switch

• Positive selection radial drag ring controls

• Illuminated bubble level

• Precise oating pan-tilt calliper locks ensure bounce

free on-off performance

• Robust construction for rugged outdoor shooting

conditions

• Two side mounting points for viewnders and

accessories

• Wear-resistant serrated rosette washer

• Three years full warranty

• Designed and manufactured in Australia

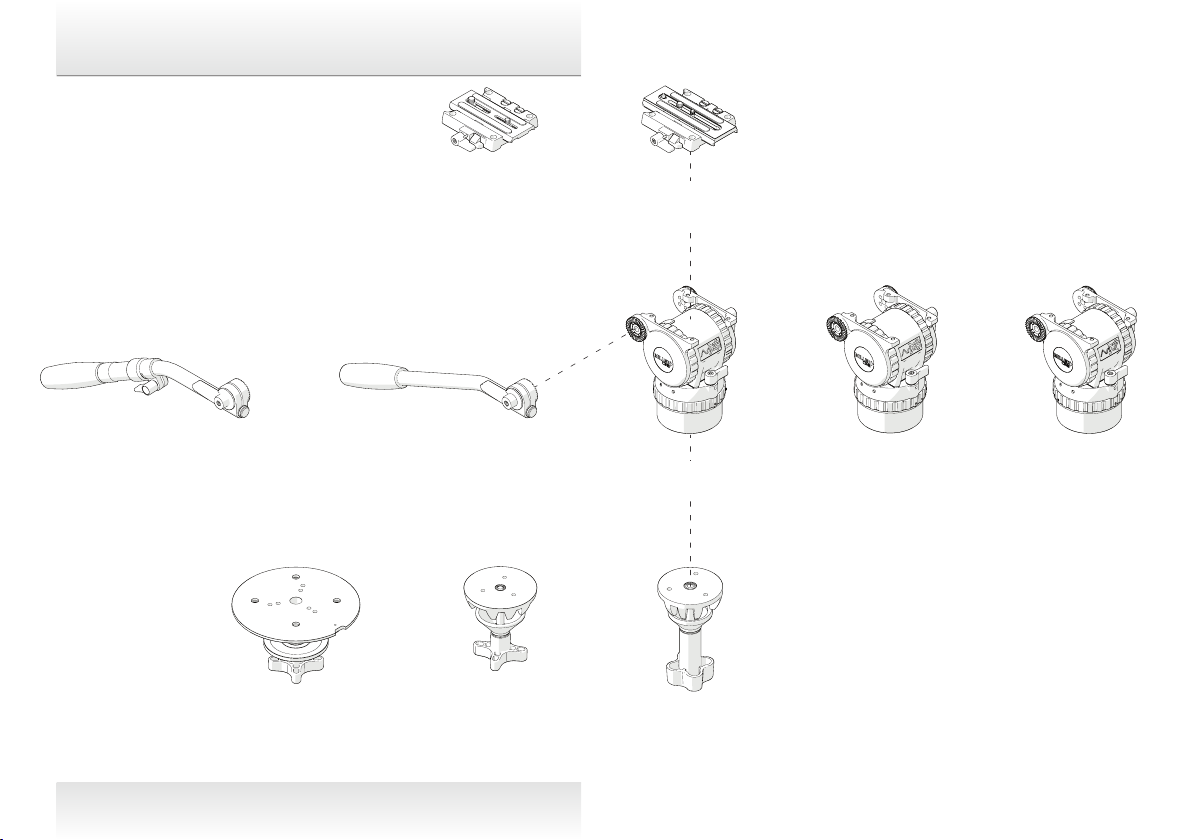

To ready the uid head for use the following are required

a) uid head

b) sliding platform

c) pan handle

d) tripod attachment ( unless used as athead)

Please refer to g 1.

Before we go any further is

very important that you go to

millertripods.com/en/warranty

and register your warranty to

claim your three full factory

warranty. Please read the

warranty information on the same

registration page on the website.

If it is not done now probably it

never will.