1. Safety Recommendations

Please read the instruction manual carefully before using the dispenser. Although we have

tried to cover all safety requirements, it is impossible for this manual to prevent all possible

safety hazards. It is the responsibility of the user to establish their own safety requirements and

to determine the necessary precautions prior to using the dispenser.

Please read and follow the following safety recommendations:

•Fully read and adhere to all recommendations and instructions in this manual

•Use protective clothing, eye protection and gloves when working with hazardous liquids.

•Do not dispense inflammable reagents into plastic vessels that can potentially generate a

static charge.

•This device is not suitable for use with the following:

Concentrated {hydrochloric acid, fluorinated hydrocarbons, saline solutions, nitric

acid), highly concentrated alkaline solutions and crystallizing solutions.

Incompatible liquids that attack FEP, PFA, PTFE, borosilicate glass, AbO3, organic

solvents, trifluoroacetic acid, explosive liquids, fuming acids, tetrahydrofuran, suspension {e.g.

charcoal) as solid particles.

•Handle the dispenser carefully to avoid any accidents or spills during usage.

•The nozzle should always point away from the user while dispensing. Avoid splashes.

•Always use suitable vessels for dispensing liquids.

•Never push down on the piston while the nozzle cap is on.

•Clean the discharge tube regularly.

•Do not use excess pressure on the piston while aspirating or dispensing or the glass tube

may break inside. Follow the troubleshooting guide if you experience any difficulty moving

the piston up and down.

•Only use Globe Scientific accessories.

2. Operating Conditions

•+ 15

°

C to +40

°

C {59

°

F to 104

°

F) for bottle top dispenser and reagent

•Vapor pressure upto 500 mbar.

•Densityupto2.2g/cm

3

•Kinematic viscosity upto 500 mm

2

/second

{dynamic viscosity [mPas]=Kinematic Viscosity [mm

2

/s] x density [g/cm

3] )

3. Package Contents

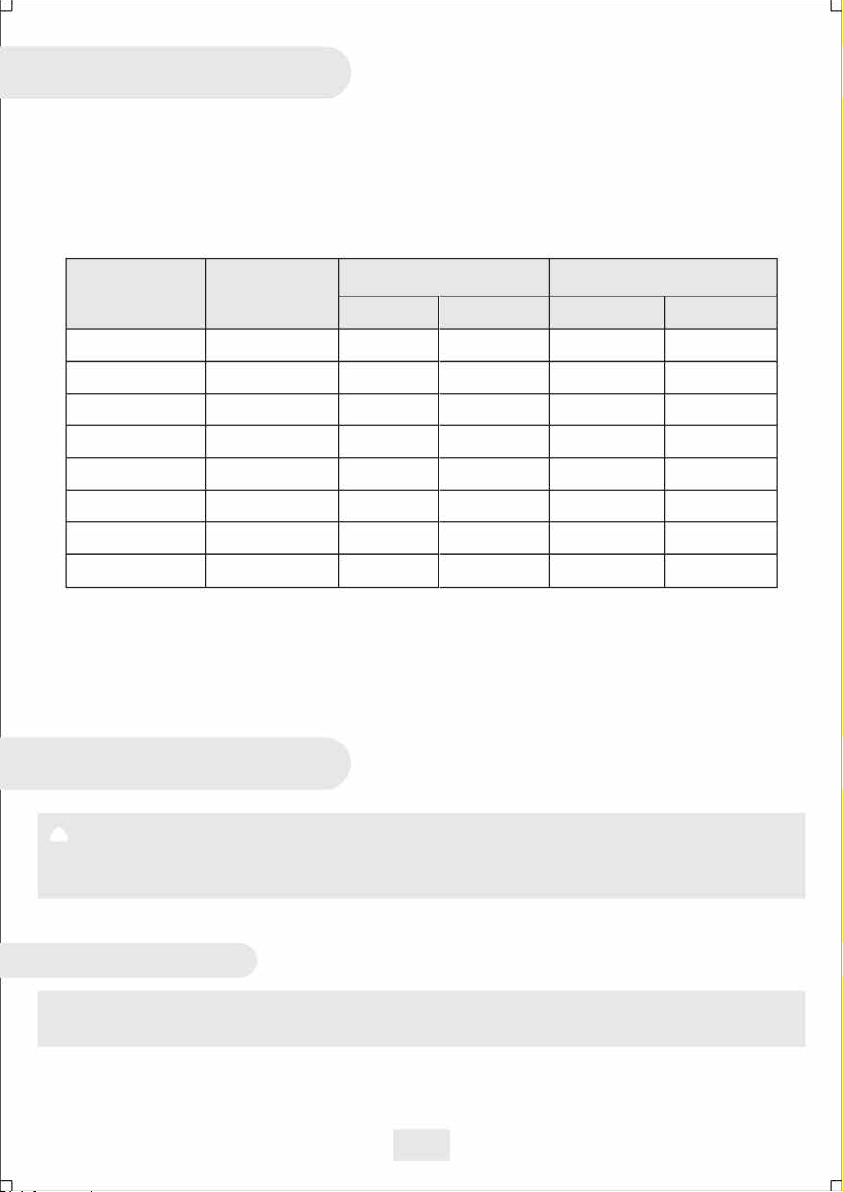

Description

-Dispenser

-Telescopic filling tube

-Recirculation tube*

- Bottle adapters** {Adapter thread sizes : 28, 38, 40 & 45mm)

-Calibration Tool

-Service tool

-Connector {only for 100 ml) {Thread size: 40 / 32 mm)

-User manual

-Certificate of Conformity including calibration certificate

-Warranty card

*This accessory is included in recirculating models only

** 32mm thread size is the standard thread built into each dispenser. No adapter is required for this

thread type

1