PL-543 10

GENERAL INSTALLATION STEPS

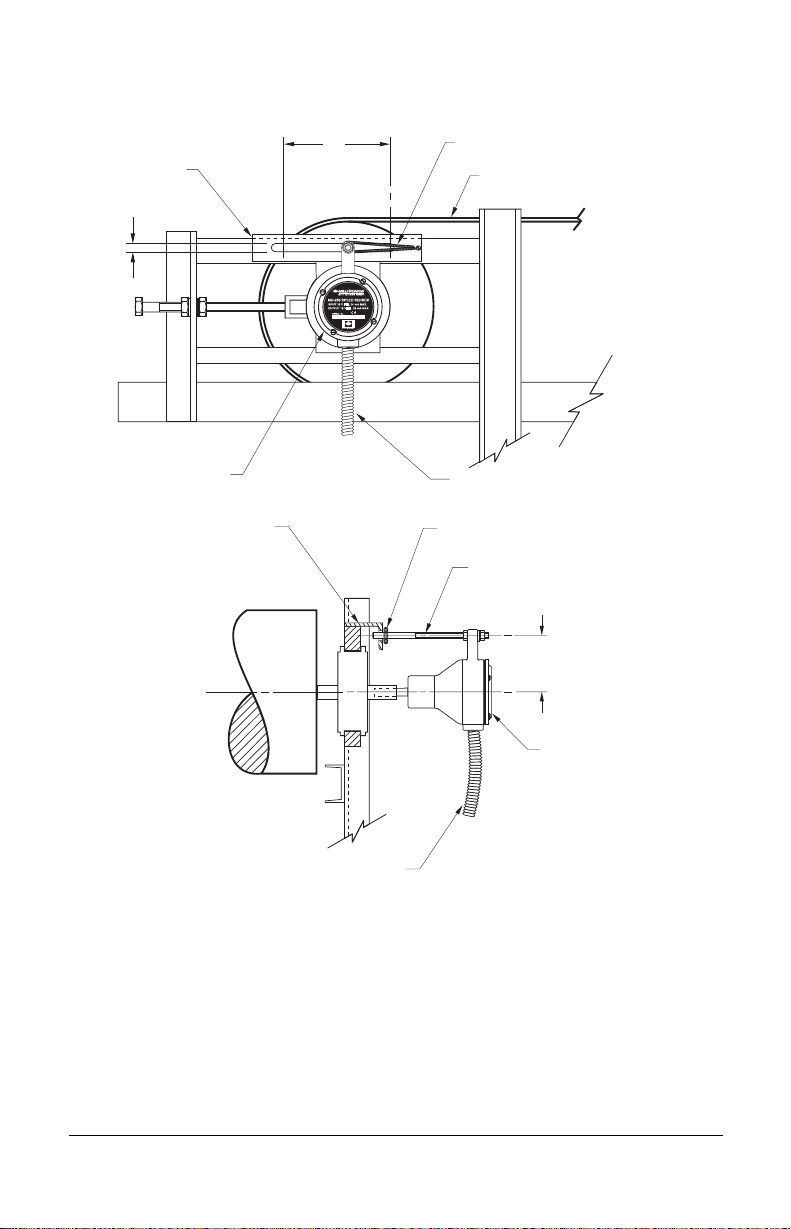

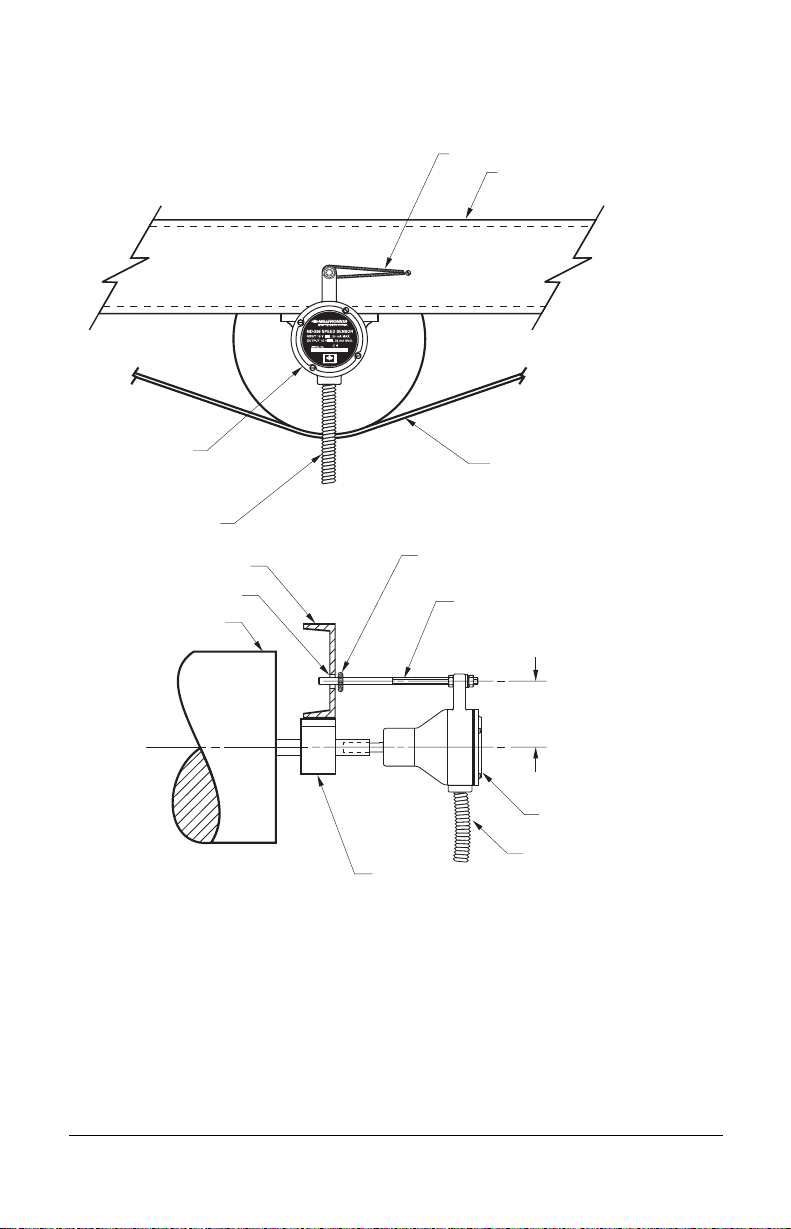

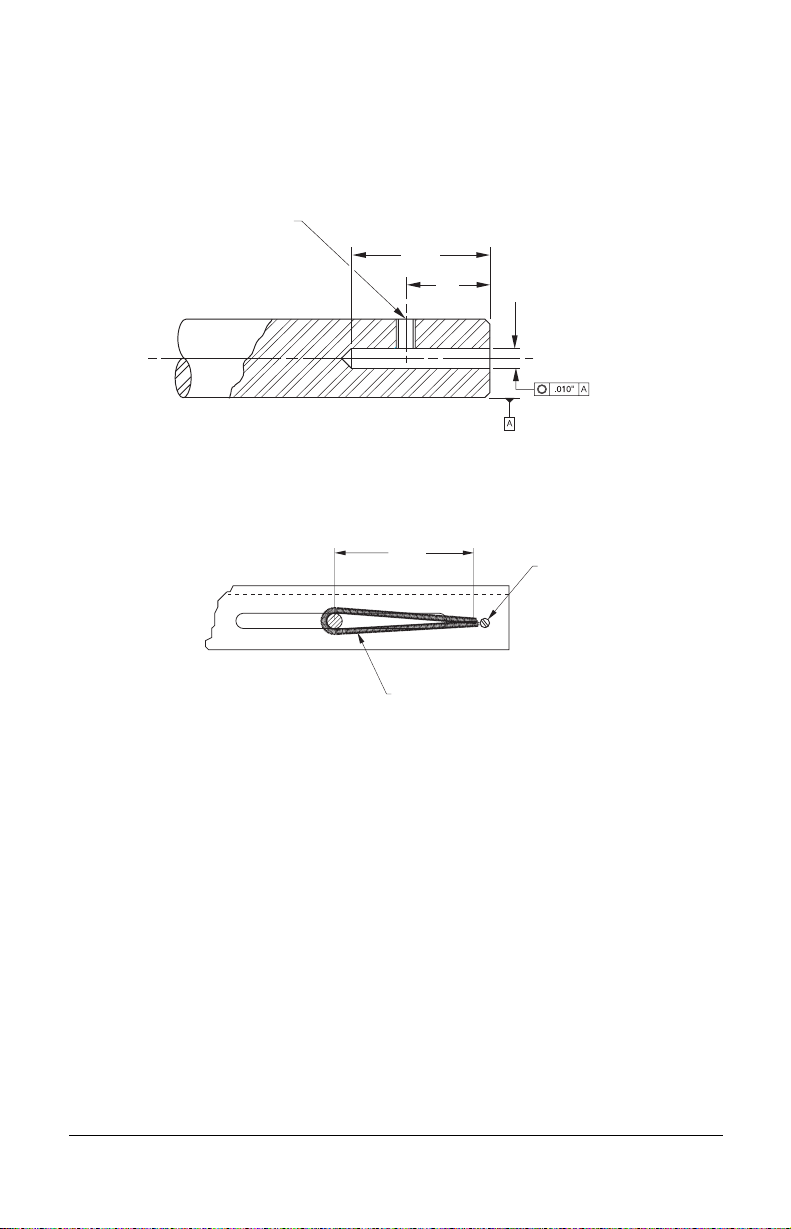

1. Drill out pulley shaft to a depth of 64mm (2.5”) concentric to its centerline. Exercise

caution and remain within specified tolerances.

2. Drill out and thread the set screw hole

3. Attach angle iron bracket to work with the arrestor rod (if mounting on a tail pulley)

4. Cut the arrestor rod to a suitable length

5. Insert the MD-256 shaft into the pulley shaft and lock with set screw on flat of shaft

6. Attach spring to arresting rod and frame

7. Encase wiring in flexible conduit to allow unit to float

8. Wire the MD-256 to the Milltronics’ integrator

See Terminal Connections to Milltronics Integrators on page 12 for terminal post

connections

The arresting rod should only be solidly attached to the MD-256. Fixing the rod at

both ends will apply binding forces and wear the unit’s bearings prematurely.

127mm

(5”)

approx.

Tension spring

Secure with bolt

or post

Angle iron bracket or

conveyor stringer

Example slot for

arrestor rod when

mounted to tail pulley

– use drilled hole for

snub or bend pulley

M8x1.25 (5/16-18 UNC)

set screw (by customer) 64mm

(2.5”)

25mm

(1”) 16.00mm (.630”) DIA.

16.07mm (.633”)