7

Please observe the operating instructions when handling the ligh!

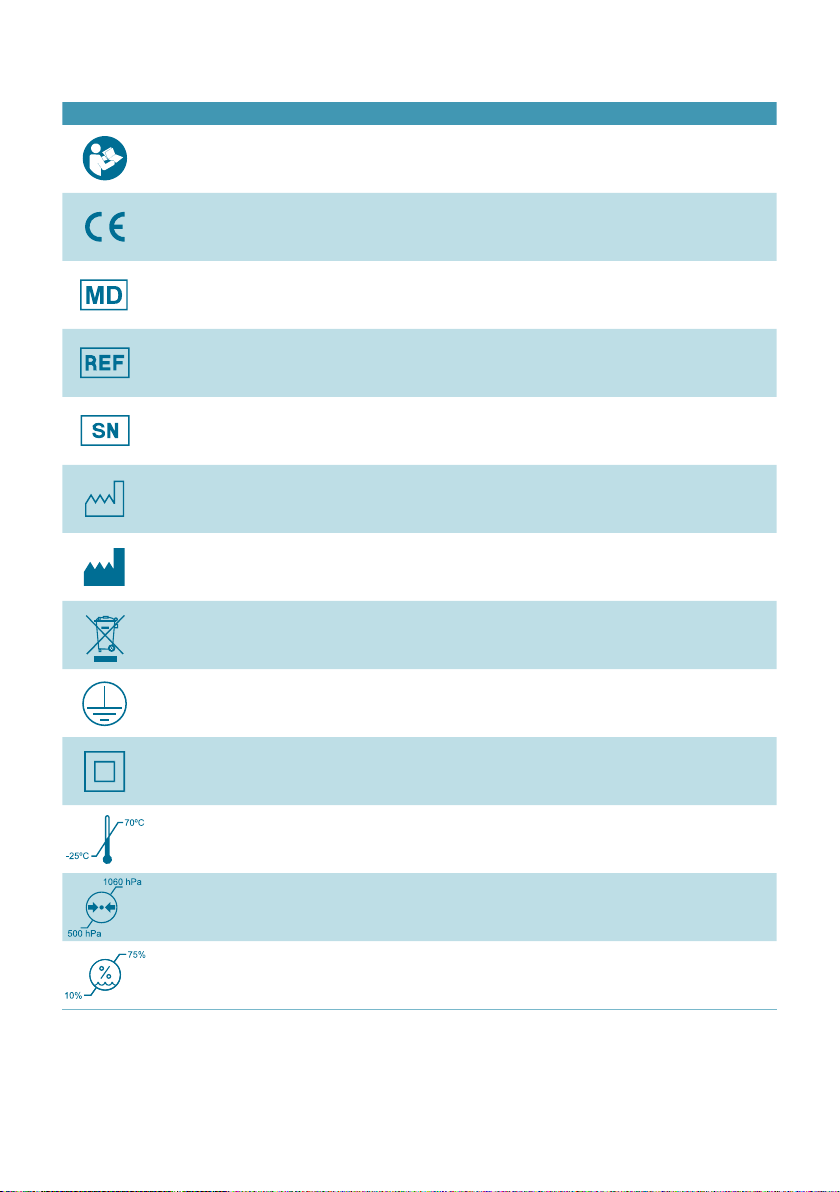

The light is a class I medical device according to EU 2017/745.

Surroundings

1. This device is not intended for operation in potentially explosive areas!

2. Do not use in oxygen-enriched areas!

3. Do not use near flammable anesthetic gases!

4. Do not place near strong magnetic fields such as MRI systems!

5. Do not cover the top of the lamp head! Risk of overheating!

6. In operating rooms with displacement ventilation: Do not block the ventilation with the

light!

7. In the operating room with displacement ventilation: Position the light at an angle to the

flow!

8. Store the light in the packaging for at least 24 hours before mounting in the room to avoid

droplet formation due to condensation!

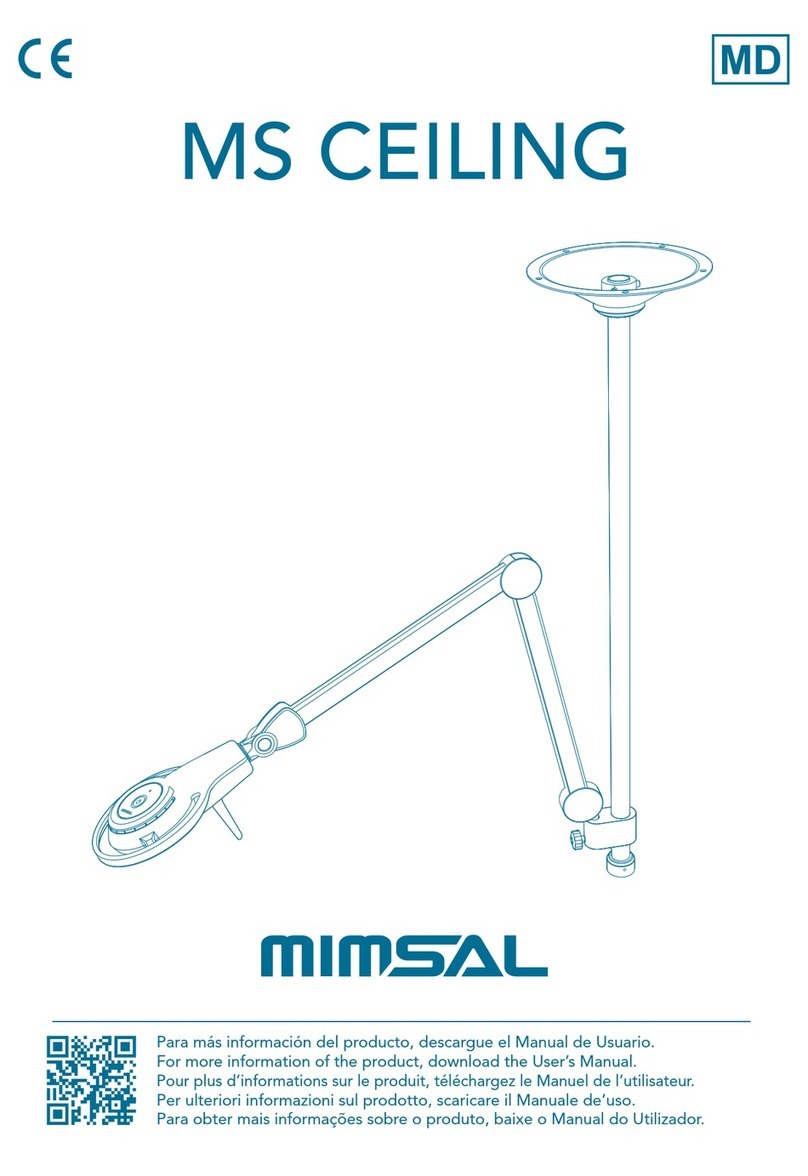

Support arm system

1. Only use the supplied support arm system for lamp suspension!

2. The entire system must be completely disconnected from the mains supply before

mounting!

3. Please observe the enclosed operating instructions!

4. The support arm system is intended exclusively for the suspension of the MIMLED. Do not

attach or stack other units!

Electronic and optical safety

1. When using several lights, the total irradiance must be <1000 W/m2!

2. Only connect the unit to the mains supply with the protective ground conductor connected!

3. Only use the integrated or enclosed power supply unit on the support arm system!

4. The light does not include a fail-safe power supply or an emergency battery!

5. In the event of a power failure, the light will be switched off completely!

6. Keep a backup unit ready in the operating rooms to ensure fail-safe operation!

7. Short interruptions in lighting are possible in the event of external EMC interference!

8. Only connect the device to a fused power supply (max. 20 A)!

9. To switch off the lamp completely, the mains plug must be removed from the socket or the

live socket must be deactivated by a separate switch!

Maintenance and liability

1. Electrical, installation or maintenance work must be carried out by qualified personnel

!

2. The manufacturer is not liable for damage caused by improper use!

3. The manufacturer is responsible for the safety of the lamp only if repairs and modifications

are carried out by the manufacturer itself or by a company that guarantees compliance with

the safety regulations, using original spare parts!

Before each use, make sure the lamp is in good condition.

1. SAFETY INSTRUCTIONS