2

WARNING

ŘDo not handle the power cord with wet hands. Wet hand contact with electricity may result in an electric shock.

ŘKeep away from explosive substances and flammable materials.

ŘIf the product overheats or smells of burning, immediately turn off the power and disconnect the main power plug.

Contact your Authorised NSK Dealer.

ŘTO PREVENT ELECTRIC SHOCK, use a main electrical outlet that is protective earthed.

ŘDo not use on the following patients.

-Those with medical complications or allergies

-Those who have pre existing conditions

(Eg Cardiac, Pulmonary, Renal disturbance or High blood pressure)

-Those who are pregnant or lactating

-Patients with cardiac pacemakers and infants

ŘBe careful not to get water or liquid disinfectant on the control unit. This could cause short circuits and lead to fire and/

or electric shock.

ŘRepeatedly turning the Main Power Switch ON and OFF may blow a fuse.

ŘWhen installing the product, provide space of approximately 10cm around the product for easy access to the inlet and

the Power Cord.

ŘThe Irrigation Tubes, included in the product package, are sterile. When using these products, follow the instructions

below.

- The irrigation tube is a single-use item. Do not reuse nor sterillize as product breakage or infection could occur.

- Check before use that the sterile package is NOT open nor damaged. Do not use products with open or damaged

packages as sterility will be negated and infection could occur.

- Observe the use-by date written on the sterile package label. Do not use expired products as sterility may be

negated.

ŘDo not point the handpiece LED light directly to the eyes of the patient, nor the operator, as it may be harmful to eyes.

CAUTION

ŘTo be confident in using this product, please read this Operation Manual before use. We suggest that to fully

understand the product functions and file for future reference.

ŘWhen operating the product always consider the safety of the patient.

ŘThe end user shall be responsible for any judgment that relates to the application of this product to a patient.

ŘThis product does not consider patient’s age (except infants), gender, weight or nationality.

ŘThis product does not consider operator’s age (mature person), height, weight, gender, or nationality.

ŘUsers are responsible for the operational control, maintenance and continual inspection of this product.

ŘThis device is for indoor use only.

ŘKeep the Control Unit on a level surface.

ŘDo not attempt to disassemble the product or tamper with the mechanism except as recommend by NSK in this

Operation Manual.

ŘDo not allow any impact on to the handpiece. Do not drop the handpiece.

ŘOperators and all others in the area must wear eye protection and a mask when operating this handpiece.

ŘShould the product function abnormally, cease operation immediately and contact your Authorized NSK Dealer.

ŘIf the Irrigation Pump gets wet, wipe it dry. If it remains wet, the roller in the pump may slip and the pump may not

operate properly.

ŘDo not bend or fold the Irrigation Tube while the Irrigation Pump is operating as the Tube may be damaged or may

detach.

ŘIf abnormality is detected in irrigation, it may be due to wear of the Irrigation Tube or leaking of saline from the Tube. In

such cases, replace the Irrigation Tube.

ŘDo not use high acid water or sterilizing solutions to wipe, immerse or clean the product.

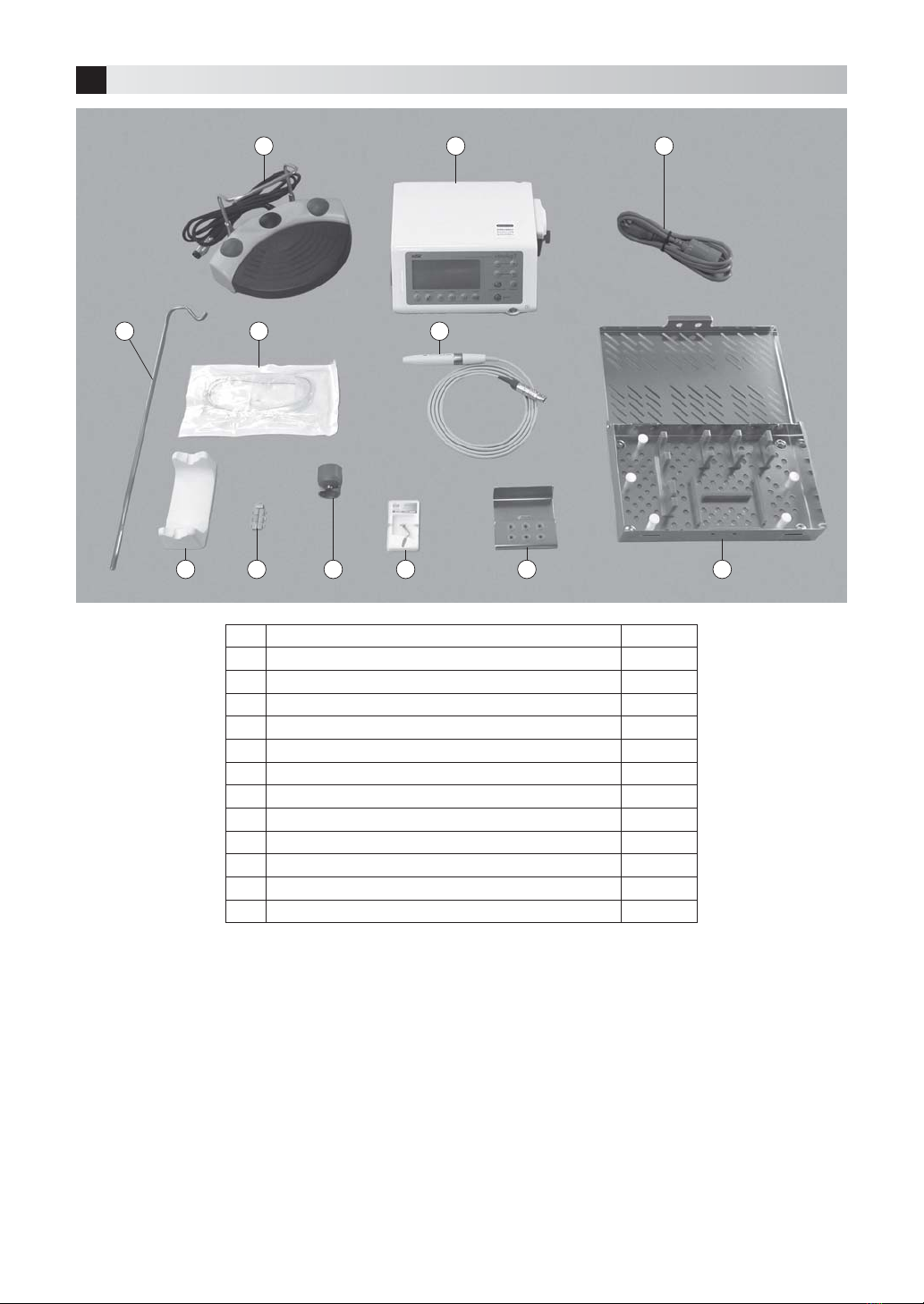

ŘThe following products are delivered in a non-sterile condition and must be autoclaved prior to use. (Handpiece, Tip, Tip

Wrench, Tip Holder, Tube Holder)

ŘPerform regular function and maintenance checks.

ŘIf the product is not used for a long period check it is functioning correctly before using on a patient.

ŘTo avoid clinical downtime it is recommended that a spare be kept on hand in case of a breakdown during surgery.

ŘThis product may be affected by an electric scalpel. Turn OFF the Power Switch when an electric scalpel is used.

9DULR6XUJ(1LQGG